Professional Documents

Culture Documents

IJEETC 5ccd682d1af25

IJEETC 5ccd682d1af25

Uploaded by

ritesh agarwalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IJEETC 5ccd682d1af25

IJEETC 5ccd682d1af25

Uploaded by

ritesh agarwalCopyright:

Available Formats

Int. J. Engg. Res. & Sci. & Tech. 2014 Arunesh Kumar et al.

, 2014

ISSN 2319-5991 www.ijerst.com

Vol. 3, No. 4, November 2014

© 2014 IJERST. All Rights Reserved

Research Paper

VARIATION OF BOILER EFFICIENCY WITH

RESPECT TO BOILER LOADS BY INCREASING

OF EXCESS AIR

Arunesh Kumar1*, Abhishek Arya2 and Rahul Kumar Singh3

*Corresponding Author: Arunesh Kumar arunesh.mechanical@gmail.com

The main motive of this study is to identify maximum energy loss areas in any thermal power

stations and generate a plan to reduce them using energy and exergy analysis as the tools. The

energy sources are decreasing down day by day around the world due to the growing demand

and sometimes due to ageing of machinery. Most of the power plants are designed by the

energetic performance criteria based not only on the first law of thermodynamics, but the real

useful energy loss cannot be justified by the fist law of thermodynamics, because it does not

differentiate between the quality and quantity of energy. The main objective of this paper is to

survey the technical options for waste heat capture and consider in greater depth of Waste heat

capture method through the use of real life examples. Present study deals with the comparison

of energy and exergy analysis of thermal power plants stimulated by coal. Our national electricity

requirement is about 2100 MW against 1615 MW supply; this is evident of about 21% deficit in

terms of power requirements. In view of this situation, greater need of efficiency improvement of

a thermal power plants

Keywords: Energy, Exergy, Heat balance sheet, Thermal Power Station, Fuel

INTRODUCTION generation. The role of efficiency monitoring lies

Power plant is assembly of systems or in maximizing generation from power plants. It

subsystems to generate electricity. Power plant enhances energy efficiency of the power plant. In

generates the electricity result of combustion of order to keep maximum output from a given input,

fuel into mechanical work and is thermal energy. the units must run at the maximum possible

The availability of electricity and its per capita efficiency. Power sector is one of the key sectors

consumption shows index of national standard contributing significantly to the growth of country’s

of living in the present day and flourishing power economy. Power sector needs a more useful role

1

M.Tech Scholar (Thermal Engineering), Department of Mechanical Engineering, SCOPE Engineering College, Bhopal, India.

2

Assistant Professor, Scholar, Department of Mechanical Engineering, SCOPE Engineering College, Bhopal, India.

3

M.Tech Scholar, Department of Mechanical Engineering, SCOPE Engineering College, Bhopal, India.

This article can be downloaded from http://www.ijerst.com/currentissue.php

307

Int. J. Engg. Res. & Sci. & Tech. 2014 Arunesh Kumar et al., 2014

to be played in defining, formulating and to be come f rom renewable sources by

implementing the research projects with close governmental as well as various private

involvement of all utilities like solar energy and participation.

other various non conventional sources. The

Process of Thermal Power Plants

increase in energy consumption, particularly in

The whole process comprises of generating heat

the past several decades, has raised fears of

energy in the boiler and then converting heat

exhausting the globes reserves of coal, petroleum

energy generated in the boiler into mechanical

and other resources in the future. The huge

energy in the turbine and further converting this

consumption of fossil fuels has caused visible

mechanical energy generated in the turbine into

damage to the environment in various forms.

electrical energy in the alternator. Coal will be

Every year human activity dumps roughly 8 billion

used as fuel in the boiler. The combustion of the

metric tons of carbon into the atmosphere, 6.5

fuel generates the heat energy in the boiler. The

billion tons from fossil fuels and 1.5 billion from

heat energy transfer to heat transfer area provided

deforestation At present India is sixth largest

in the different area like (bed coils, water wall,

country in the world in electricity generation,

steam drawn /mud drum economizer super

having aggregate capacity of 177 GWs out of

heater, air pre heater. This will be transferred to

which 65% is from thermal, 21% from hydro, 3%

the water which will pass through and steam is

from nuclear and the rest about 11% is from

generated and this steam will be further

renewable energy sources. Although over the

superheated in the super heater so that dry

years, Indian power sector has experienced a five-

superheated steam will be generated. This steam

time increased in its installed capacity—a jump

will be fed into the turbine and this steam expands

from 30,000 MW in 1981 to over 176,990.40 MW

in the turbine and generates mechanical energy

by 30 June 2014 but still there is a huge gap in

will be converted in to electrical energy. The whole

generation and demand in India hence need to

process is comprises in Figure 1.

be establish more generation plants preferably

Figure 1: General Layout of Thermal Power

This article can be downloaded from http://www.ijerst.com/currentissue.php

308

Int. J. Engg. Res. & Sci. & Tech. 2014 Arunesh Kumar et al., 2014

Aim of the it’s thermal energy is converted into

The main analysis of the study is to find out those mechanical energy which is further used for

areas where energy losses are occurring generation electric power. The steam coming out

maximum and modified them for efficient and of the steam turbine is condensed in the

effective improvement in thermal power station. condenser and condensate is supplied back to

the boiler with the help of the feed pump and cycle

Objectives is repeated.

The object to satisfy this are The function of the boiler is to generate the

• To conduct energy calculation of the overall steam .The function of condenser is to condense

plant and determine the efficiencies and energy the steam coming out of steam turbine at low

losses of all the major components on the pressure. The function of the steam turbine is to

power station. convert part of heat energy of steam into

mechanical energy. The function of feed pump is

• Select and modified the areas where energy

to raise the pressure of the condensate from the

losses are being experienced.

condenser pressure (0.015 bar ) to boiler

• Determine the costs and payback periods for pressure (200 bar). The other components like

the new technologies suggested for efficiency economizer, super heater and steam feed

improvements. heaters are used in the primary circuit to increase

Types of Fuel Used in Boiler the overall efficiency of the thermal power plant.

There are many type of fuel used in boiler to Figure 2: working of Thermal Power Plant

generate necessary heat (Table 1).

Table 1: Various Types of Fuels Used in Boiler

Fuel GCV(Kcal/kg)

Coal

a) Bituminous 4,500 to 6,500

b) Anthracite 6,500 to 7,700

c) Lignite 3,500 to 4500

Furnace oil 10,500 to 11,700

Natural Gas 8,200 to 8,600 KCal/Nm3 HISTORICAL PROSPECTIVE

Agro fuels 3,100 to 4,500 The scenario of energy in thermal power plant

Kerosene 11,100 11,100 are discussed that fossil fuels contribute 80%,

LPG 11,600 to 11,700 KCal/Kg

renewable Energy resources contribute 14% and

nuclear 6% of world annual energy use. These

Working of Thermal Power Plant numbers will soon change as the world’s

Steam is generated in the boiler of the thermal population grows, energy demand rises,

power plant using the heat of the fuel burned in inexpensive oil and gas deplete, global warming.

the combustion chamber. The steam generated Effects continue to rise and urban pollution

is passed through steam turbine where the part worsens the living conditions. The development

This article can be downloaded from http://www.ijerst.com/currentissue.php

309

Int. J. Engg. Res. & Sci. & Tech. 2014 Arunesh Kumar et al., 2014

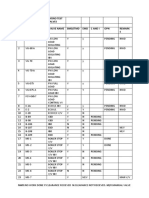

Table 2: Heat Balance Sheet

Steam G ross

Theoretical Excess Total air oxygen

S.No. Bioler Generation Calorific Boiler Fuel air air req.@0% @0%

Load TPH Value Efficiency Consumption Requirement req.@ ex ce ss ex ce ss

Kcal/kg. kg /s kg 0% air air

kg

1 60 81 3300 80.6 19.44 4.58 0 4.58 0

2 65 87.75 3300 81.7 20.77 4.58 0 4.58 0

3 70 94.5 3300 82.3 22.21 4.58 0 4.58 0

Table 3: Standard Values Table 4: Efficiency Of Boiler With Different

Boiler Loads And 0% Excess Air

Grass calorific value of coal 3300 kcal/kg

Feed water temperature 180oc

% of oxygen in flue gases 5.5

% of co2 in flue gases 11

Flue gas temperature 1400C

% Hydrogen in fuel 1.2

Ambient air temperature 350C

Humidity of air 0.018 kg/kg of dry air

Theoretical air required for boiler 4.58 kg/kg of coal

Actual mass of air supplied 5.95 kg/kg of coal

Specific heat of superheated steam 0.45k cal/kg,k

Boiler pressure 96 bar

Steam temperature 3800c

Enthalpy of steam 3060 kj/kg

Enthalpy of feed water temperature 763.22kj/kg

Table 5: Efficiency of Boiler With Different Boiler Loads and 20% Excess Air

Steam G ross

Theoretical Excess Total air oxygen

S.No. Bioler Generation Calorific Boiler Fuel air air req.@0% @0%

Load TPH Value Efficiency Consumption Requirement req.@ ex ce ss ex ce ss

Kcal/kg. kg /s kg 0% air air

kg

1 60 81 3300 80.12 19.44 4.58 0.91 5.49 0.209

2 65 87.75 3300 81.2 20.77 4.58 0.91 5.49 0.209

3 70 94.5 3300 81.82 22.21 4.58 0.91 5.49 0.209

This article can be downloaded from http://www.ijerst.com/currentissue.php

310

Int. J. Engg. Res. & Sci. & Tech. 2014 Arunesh Kumar et al., 2014

Table 6: Efficiency of Boiler With Different Boiler Loads and 30% Excess Air

Steam G ross

Theoretical Excess Total air oxygen

S.No. Bioler Generation Calorific Boiler Fuel air air req.@0% @0%

Load TPH Value Efficiency Consumption Requirement req.@ ex ce ss ex ce ss

Kcal/kg. kg /s kg 0% air air

kg

1 60 81 3300 79.82 19.44 4.58 1.37 5.95 0.31

2 65 87.75 3300 81.02 20.77 4.58 1.37 5.95 0.31

3 70 94.5 3300 81.62 22.21 4.58 1.37 5.95 0.31

Table 7: Efficiency of Boiler With Different Boiler Loads and 40% Excess Air

Steam G ross

Theoretical Excess Total air oxygen

S.No. Bioler Generation Calorific Boiler Fuel air air req.@0% @0%

Load TPH Value Efficiency Consumption Requirement req.@ ex ce ss ex ce ss

Kcal/kg. kg /s kg 0% air air

kg

1 60 81 3300 79.52 19.44 4.58 1.83 6.41 0.42

2 65 87.75 3300 80.72 20.77 4.58 1.83 6.41 0.42

3 70 94.5 3300 81.32 22.21 4.58 1.83 6.41 0.42

of alternative energy sources and devices will hour is called the evaporation rate. It is expressed

emerge more rapidly to address the world’s

as kg of steam/h, or kg of steam/h/m2 of heating

energy and Environmental situation. Thus, the

surface, or kg of steam/h/m3 of furnace volume,

establishment of a sustainable energy Is one of

the most pressing tasks of humanity? With the or kg of steam/kg of fuel fired.

exhaustion of Fossil resources, the energy Equivalent Evaporation

economy will change to a chemical and an

It is the equivalent of the evaporation of 1 kg of

Electrical base. Mahindra Lalwani and Mool Singh

water at 100oC to steam at 100 oC, it requires

revealed that, India consumes 7% of coal of the

2256.9 kJ = 2260 kJ.

world where as China, US, Japan and Rest of

the world consumes 43%, 9%, 4% and 20%, Factor of Evaporation

respectively. 68% of World’s consumption of coal The ratio of actual heat absorption above feed

for the generation of electricity. Coal-fired

water temperature for transformation to steam

Generation increases by an annual average of

(wet, dry, or superheated), to the latent heat of

2.3%, making coal the second fastest-growing

steam at atmospheric pressure (1.01325 bar) is

source for electricity generation.

known as factor of evaporation.

METHODOLOGY AND Then equivalent evaporation = Actual

FORMULAE USED evaporation × Factor of evaporation

Performance of Steam Generator where

Evaporation Rate

me = [ (h1 – hf ) / hfg ]× ms = F × ms

The quantity of water evaporated into steam per

This article can be downloaded from http://www.ijerst.com/currentissue.php

311

Int. J. Engg. Res. & Sci. & Tech. 2014 Arunesh Kumar et al., 2014

Heat Losses in a Boiler Plant C = fraction of carbon in 1 kg of fuel

1. Heat used to generate steam, Q= ms (h1– hf ) Heat lost due to incomplete combustion of

2. Heat lost to flue gases. carbon per kg of fuel,

The flue gases contain dry products of CO C

combustion and the steam generated due to the Q3 35, 000 10, 200

CO CO2

combustion of hydrogen in the fuel.

CO C

Heat lost to dry flue gases, Q3 24,800 ki / kg of fuel

CO CO2

Q1= mg cpg(Tg – Ta )

mg = Mass of gases formed per kg of fuel 5. Heat lost due to unburnt fuel

cpg = Specific heat of gases Q4 = mf1× C.V

Tg = Temperature of gases, oC mf1= Mass of unburnt fuel per kg of fuel burnt

T a = Temperature of air entering the 6. Heat unaccounted

combustion chamber of the boiler, oC

Q6= Q– (Q1+Q2+Q3+Q4+Q5)

3. Heat carried by steam in flue gases-

Q = mf ×C.V

Q2= ms1(hs1– hf1)

= Heat released per kg of fuel

ms1 = Mass of steam formed per kg of fuel

due to combustion of H2 in fuel Boiler Trial and Heat Balance Sheet

h f1 = Enthalpy of water at boiler house There are three purposes of conducting the boiler

temperature trial.

hs1= Enthalpy of steam at the gas temperature 1. To determine and check the specified

and at the partial pressure of the vapor in the flue generating capacity. Of the boiler when

gas working at full load conditions.

4. Heat loss due to incomplete combustion 2. To determine the thermal efficiency of the

plant.

If carbon burns to CO instead of CO2 then it is

known as incomplete combustion. 3. To draw up the heat balance sheet so that

suitable corrective measures may be taken

1 kg of C releases 10,200 kJ/kg of heat if it

to improve the efficiency.

burns to CO whereas it releases 35,000 kJ/kg if

it burns to CO2. if the percentages of CO and The following measurements should be

CO2 in flue gases by volume are known, then observed during the boiler trial.

1. The fuel supplied and its analysis.

CO C

Mass of C burnt to CO 2. Steam generated and its quality or superheat.

CO CO2

3. Flue gases formed from exhaust analysis.

CO, CO2 = % by volume of CO and CO2 in 4. Air inlet temperature and gases exhaust

flue gases temperature.

This article can be downloaded from http://www.ijerst.com/currentissue.php

312

Int. J. Engg. Res. & Sci. & Tech. 2014 Arunesh Kumar et al., 2014

5. Volumetric analysis of exhaust gases. Figure 4: Efficiency Vesus Excess Air

6. Mass of fuel left unburnt in ash.

7. Feed water temperature.

The Heat balance sheet is a symmetric

representation of heat released from burning of

fuel and heat distribution on minute, hour or per

kg of fuel basis.

RESULTS AND DISCUSSION

Vardhman Group is a leading textile conglomerate

in India having a turnover of $1009 mn. Spanning

over 25 manufacturing facilities in five states Figure 5: Efficiency Vesus Excess Air

across India, the Group business portfolio

includes Yarn, Greige and Processed Fabric,

Sewing Thread, Acrylic Fiber and Alloy Steel.

Vardhman has evolved through history from a

small beginning in 1965 into a modern textile major

under the dynamic leadership of its chairman, S

P Oswal. His vision and insight has given

Vardhman an enviable position in the textile

industry. Under his leadership, Vardhman is

efficiently using resources to innovate, diversify,

integrate and build its diverse operations into a

dynamic modern enterprise.

Figure 6: Efficiency Vesus Excess Air

Figure 3: Efficiency Versus Excess Air

This article can be downloaded from http://www.ijerst.com/currentissue.php

313

Int. J. Engg. Res. & Sci. & Tech. 2014 Arunesh Kumar et al., 2014

Figure 7: Efficiency Vesus Excess Air steam generation also varies at different boiler

loads.

4. In this study show the variation of excess air

with fuel consumption and basically 40%

excess air use to reduce the loses and improve

boiler efficiency

5. In this study the calculation of efficiency based

on 20%, 30%, 40% excess air which gives the

excellent variation in boiler efficiency.

6. In this study we see that at minimum boiler

load the efficiency of boiler is minimum in range

which is show in graph and with the variation

CONCLUSION of boiler load efficiency of boiler range also vary

which is clearly show in graph.

The following conclusions have been drawn from

the experimental results: 7. Boiler load and excess air variation help to

show the variation in the boiler efficiency. In

This paper show the enervative ideas to

graph 1.1 we are see that at 0% excess air

reduce losses of boiler and improve boiler the boiler efficiency range is maximum and at

efficiency by using the variation of boiler load and 40% excess air the boiler efficiency range is

also percentage of excess air minimum

We conclude the following point which points

REFERENCES

show in paper and by using of heat balance sheet

clearly indicate unnecessary loss of heat. Give 1. Bejan (2002), “Fundamentals of Exergy

Analysis, Entropy Generation Minimization,

some ideas to reduce unnecessary loses and

and the Generation of Flow Architecture”,

improve boiler efficiency.

International Journal of Energy Research,

1. This study shows the working process of Vol. 26, No. 7, pp. 545-565.

thermal power plants and indicates the

2. Jin H, Ishida M, Kobayashi M and Nunokawa

performance of boiler which can be improving

M (1997), “Exergy Evaluation of Two Current

by using load variation.

Advanced Power Plants: Supercritical

2. This study show the performance of Vardhman Steam Turbine and Combined Cycle”,

Yarns, Satlapur, Mandideep in which steam Trans. of ASME, Vol. 119, pp 250-256.

generation has been done at a boiler pressure

3. Naterer G F, Regulagadda P and Dincer I

of 96 bars and temperature approximately 380

(2010), “Exergy analysis of a thermal power

degree Celsius. plant with measured boiler and turbine

3. In this study show the variation of fuel Losses”, Applied Thermal Engineering, Vol.

consumption for various boiler loads and also 30, pp. 970-976.

This article can be downloaded from http://www.ijerst.com/currentissue.php

314

Int. J. Engg. Res. & Sci. & Tech. 2014 Arunesh Kumar et al., 2014

4. Tekin T and Bayramoglu M (1998), “Exergy 5. W iser W endell H (2000), “Energy

Analysis of the Sugar Production Process Resources: Occurrence, Production,

from Sugar Beets”, Int. J. of Energy Conversion, Use”, ISBM 0-387-98744-

Research, Vol. 22, pp. 591-601. 4(Alk.Paper).

This article can be downloaded from http://www.ijerst.com/currentissue.php

315

International Journal of Engineering Research and Science Technology

1120 S Walton Blvd, Suite 138, Bentonville, Arkansas - 72712-0077, USA.

www.ijerst.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Franchisee Model in Electricity DistributionDocument17 pagesThe Franchisee Model in Electricity Distributionritesh agarwal100% (1)

- Internship Report: Rayalaseema Thermal Power ProjectDocument34 pagesInternship Report: Rayalaseema Thermal Power ProjectGoutham Reddy100% (2)

- Instuments Calibration ListDocument4 pagesInstuments Calibration Listritesh agarwalNo ratings yet

- Mock Drill Test of Emergency U-4Document1 pageMock Drill Test of Emergency U-4ritesh agarwalNo ratings yet

- Aph LKG FormulaDocument2 pagesAph LKG Formularitesh agarwalNo ratings yet

- Hydro Test Valves S.N Valve Valve Name BMD/TMD Emd C and I OPN Remark SDocument4 pagesHydro Test Valves S.N Valve Valve Name BMD/TMD Emd C and I OPN Remark Sritesh agarwalNo ratings yet

- Basic Kalina MarutiimpDocument10 pagesBasic Kalina Marutiimpritesh agarwalNo ratings yet

- New Doc 2019-05-26 12.35.49Document13 pagesNew Doc 2019-05-26 12.35.49ritesh agarwalNo ratings yet

- Draft MomDocument3 pagesDraft Momritesh agarwalNo ratings yet

- St-I Apc Vs Loading Factor (%) St-Ii Apc Vs Loading Factor (%)Document10 pagesSt-I Apc Vs Loading Factor (%) St-Ii Apc Vs Loading Factor (%)ritesh agarwalNo ratings yet

- Design Criteria For Petcoke CalcinersDocument6 pagesDesign Criteria For Petcoke CalcinersAnonymous 1XHScfCINo ratings yet

- Heat Exchanger Types and Classifications: September 2017Document39 pagesHeat Exchanger Types and Classifications: September 2017qamar abbasNo ratings yet

- Chapter 9 GAS Power CycleDocument87 pagesChapter 9 GAS Power CyclezabidullahNo ratings yet

- Thermodynamic Analysis of Rankine Cycle in Ocean Thermal Energy ConversionDocument4 pagesThermodynamic Analysis of Rankine Cycle in Ocean Thermal Energy ConversionKumar KumarNo ratings yet

- The Second Law of Thermodynamics MPDocument51 pagesThe Second Law of Thermodynamics MPKyle DonagheyNo ratings yet

- Pipe-Alcorcon 1Document86 pagesPipe-Alcorcon 1Antonette DatoonNo ratings yet

- 3.internal Combustion Engine-1-10Document10 pages3.internal Combustion Engine-1-10Aqsa KanwalNo ratings yet

- Jntuk 2 1 T&HPM Nov 2017 Q.PDocument8 pagesJntuk 2 1 T&HPM Nov 2017 Q.Panon_920598081No ratings yet

- Lecture Notes On Mar 862-PpDocument349 pagesLecture Notes On Mar 862-PpViolet PellyNo ratings yet

- Experimental Study On The Effects of Injection Timing Using Reuse of Waste Energy As A Fuel On A Diesel EngineDocument9 pagesExperimental Study On The Effects of Injection Timing Using Reuse of Waste Energy As A Fuel On A Diesel EngineIJRES teamNo ratings yet

- Power Plant Engineering Unit:Iv Gas Turbine PlantDocument30 pagesPower Plant Engineering Unit:Iv Gas Turbine PlantshivaNo ratings yet

- PIPE PPT 01Document171 pagesPIPE PPT 01Joms De CastroNo ratings yet

- Chapter 05Document184 pagesChapter 05kphays_98104692875% (4)

- Combined Cycle PowerplantDocument34 pagesCombined Cycle PowerplantDarrel Camacho100% (1)

- Soal EtkDocument2 pagesSoal EtkNiswatun ChasanahNo ratings yet

- Lectut MIN 106 PDF MI 106 Tutorial VIII - BcPSc3PDocument2 pagesLectut MIN 106 PDF MI 106 Tutorial VIII - BcPSc3PPritam PaulNo ratings yet

- Thermo HWDocument6 pagesThermo HWMuhammad Fawwad ObaidaNo ratings yet

- 5A. Gas TurbinesDocument4 pages5A. Gas TurbinesKathlyn Kyle MoralesNo ratings yet

- Srr210304 ThermodynamicsDocument8 pagesSrr210304 ThermodynamicsandhracollegesNo ratings yet

- Revision SolutionDocument19 pagesRevision SolutionHassan Abo NagaNo ratings yet

- Chapter 6: The Second Law of Thermodynamics: η net wor k output total heat output W Q Q QDocument4 pagesChapter 6: The Second Law of Thermodynamics: η net wor k output total heat output W Q Q QMariana CaballeroNo ratings yet

- Energy Analyses To A Ci-Engine Using Diesel and Bio-Gas Dual Fuel-A Review StudyDocument6 pagesEnergy Analyses To A Ci-Engine Using Diesel and Bio-Gas Dual Fuel-A Review Studysirajudeen INo ratings yet

- Blue Book With Solution VIPDocument266 pagesBlue Book With Solution VIPMarvin MarianoNo ratings yet

- 05-1-Collection of Problems PDFDocument15 pages05-1-Collection of Problems PDFFistia MaulinaNo ratings yet

- Types of BoilersDocument9 pagesTypes of BoilersAhmad CheemaNo ratings yet

- Me6016 TeDocument44 pagesMe6016 TeKALIMUTHU KNo ratings yet

- Cryocar ReportDocument10 pagesCryocar ReportTharun Kaushik VP100% (1)

- RH 60% Iso, 15 C For GTDocument6 pagesRH 60% Iso, 15 C For GTYamin AliNo ratings yet

- CalculationDocument12 pagesCalculationIsmail IbrahimNo ratings yet