Professional Documents

Culture Documents

3.2t X 6m Span Elv PDF

3.2t X 6m Span Elv PDF

Uploaded by

pawanCopyright:

Available Formats

You might also like

- 203 656 44 Accesorios ElectricosDocument32 pages203 656 44 Accesorios ElectricosJESUSCALVILLONo ratings yet

- Extracted Pages From 3601709 - Fabrication Drawings1Document1 pageExtracted Pages From 3601709 - Fabrication Drawings1ahmed aboyosefNo ratings yet

- Bus Bar Selection 20338744 - 0606073419Document40 pagesBus Bar Selection 20338744 - 0606073419yac128No ratings yet

- ABUS Overhead CranesDocument36 pagesABUS Overhead CranesAya AlgalladNo ratings yet

- Port Douglas 3 304Document1 pagePort Douglas 3 304Ngaire TaylorNo ratings yet

- AbusDocument22 pagesAbusJose De Jesus MejiaNo ratings yet

- Abus 1Document6 pagesAbus 1Slobodan NesovicNo ratings yet

- Making Intelligent: Moving On UpDocument2 pagesMaking Intelligent: Moving On UpMiklo Balazs-ErzsebetNo ratings yet

- Abus Single PDFDocument1 pageAbus Single PDFkeerthivasan_mrvNo ratings yet

- Demag DMR (Brochure)Document20 pagesDemag DMR (Brochure)MadhaneNo ratings yet

- Abus Electric Wire Rope HoistsDocument14 pagesAbus Electric Wire Rope Hoistsprihharmanto antokNo ratings yet

- ManualDocument11 pagesManualfpersiancatNo ratings yet

- 4ductor Engl PDFDocument8 pages4ductor Engl PDFNilesh MahajanNo ratings yet

- 130724Document20 pages130724Caracal MohNo ratings yet

- GalviDocument41 pagesGalvidhanishlNo ratings yet

- Operation Instructions: ABUS - Load Indicator SystemDocument12 pagesOperation Instructions: ABUS - Load Indicator SystemShane PNo ratings yet

- 31 SeriesDocument4 pages31 SeriesJESUSCALVILLONo ratings yet

- D 0498Document28 pagesD 0498Bang OchimNo ratings yet

- Electrical Drawings For 15T OH CraneDocument36 pagesElectrical Drawings For 15T OH CraneArmnn RasmoNo ratings yet

- Demag DC-PRO4 PDFDocument176 pagesDemag DC-PRO4 PDFRudianto SohandjajaNo ratings yet

- SC10876B - Hoist DrawingDocument1 pageSC10876B - Hoist DrawingMotlatjo RakgothoNo ratings yet

- AbusDocument27 pagesAbusMargelatu AndreyNo ratings yet

- 130718Document176 pages130718Th NattapongNo ratings yet

- Demag Cranes BruchureDocument24 pagesDemag Cranes BruchureAnand TornekarNo ratings yet

- Economical. Durable. Easy To Operate.: DBR Rope HoistDocument12 pagesEconomical. Durable. Easy To Operate.: DBR Rope HoistsarochimNo ratings yet

- Demag DMR (Brochure)Document20 pagesDemag DMR (Brochure)Hendra HalimNo ratings yet

- GM - 6000 20000 - L-242 41 15000 3 D - 200 24 2500 GBDocument1 pageGM - 6000 20000 - L-242 41 15000 3 D - 200 24 2500 GBEduardo Garcia SaraviaNo ratings yet

- Brugg Catalog enDocument28 pagesBrugg Catalog enSinoj V AntonyNo ratings yet

- SWF RopeHoists CraneKits 09 2012 enDocument21 pagesSWF RopeHoists CraneKits 09 2012 enGogyNo ratings yet

- Demag DR Rope Hoist: Without Electrical ControlDocument32 pagesDemag DR Rope Hoist: Without Electrical ControlDante WilliamsNo ratings yet

- Component Parts: DZW Position Measuring SystemDocument12 pagesComponent Parts: DZW Position Measuring SystemBang OchimNo ratings yet

- DemagDocument20 pagesDemagPajserchinaNo ratings yet

- Casar Steel Wire RopesDocument32 pagesCasar Steel Wire Ropessgupta_615796No ratings yet

- Demag Drives PDFDocument24 pagesDemag Drives PDFRafael Linarez100% (1)

- Liebherr RMG Technical DescriptionDocument4 pagesLiebherr RMG Technical DescriptionHua Hidari YangNo ratings yet

- Operating/maintenance Instructions: I-Beam Pillar and Wall-Mounted Jib CranesDocument44 pagesOperating/maintenance Instructions: I-Beam Pillar and Wall-Mounted Jib Cranesrochim_putech_126885No ratings yet

- Technical Information: 1. Hoist RopesDocument17 pagesTechnical Information: 1. Hoist RopesvikasgahlyanNo ratings yet

- 8 X 26 Cabos Compactados EspeciaisDocument60 pages8 X 26 Cabos Compactados EspeciaisEvandro BeserraNo ratings yet

- End Carriage DFW S E AssmeblyDocument52 pagesEnd Carriage DFW S E AssmeblycutenganNo ratings yet

- Alignment of CouplingDocument24 pagesAlignment of Couplinger_sanjaypatelNo ratings yet

- AS 7 Wire Rope Hoist - : Now The Standard Version Is Even More PowerfulDocument4 pagesAS 7 Wire Rope Hoist - : Now The Standard Version Is Even More PowerfuljavierNo ratings yet

- Abus-Double Girder CraneDocument3 pagesAbus-Double Girder CraneAlwin Victor WilliamsNo ratings yet

- 2 Tonne Spark Resistant 220model Post Swing Jib Crane - 1Document1 page2 Tonne Spark Resistant 220model Post Swing Jib Crane - 1AnishNo ratings yet

- Abus Electric Chain HoistDocument32 pagesAbus Electric Chain HoistراموندولدولاوNo ratings yet

- TGN 08 Crane Rail Selection 2Document3 pagesTGN 08 Crane Rail Selection 2Prasad PatilNo ratings yet

- Abus CranesDocument12 pagesAbus Cranesmahhor82_635643838No ratings yet

- EN DEMAG PogledajDocument158 pagesEN DEMAG PogledajNenad TabandzelicNo ratings yet

- Technical Data Accessories DEMAG DC-COM Chain Hoist PDFDocument40 pagesTechnical Data Accessories DEMAG DC-COM Chain Hoist PDFMarco SilvaNo ratings yet

- Verlinde Electric Wire Rope HoistDocument12 pagesVerlinde Electric Wire Rope HoistMahmoud AllamNo ratings yet

- Abus Electric Chain Hoists AbucompactDocument32 pagesAbus Electric Chain Hoists Abucompactnicoka50No ratings yet

- Rope Guide: Service PartsDocument2 pagesRope Guide: Service PartsDumebiNo ratings yet

- ABUS 120.0t EOT Layout - 22.0m SpanDocument1 pageABUS 120.0t EOT Layout - 22.0m Spanfud3n100% (1)

- Product SWF End CarriagesDocument63 pagesProduct SWF End CarriagesGogyNo ratings yet

- Non-Driven Wheel DIN15090 Series 223 enDocument1 pageNon-Driven Wheel DIN15090 Series 223 enayavuzbvsNo ratings yet

- Abus Cranes CatalogDocument28 pagesAbus Cranes CatalogGeorge JabbourNo ratings yet

- Scx1000a-3 Stage3a PRDocument8 pagesScx1000a-3 Stage3a PRДмитрий БакайNo ratings yet

- SBFL Rnav-Punod-3a-Rwy14 Sid 20210520Document1 pageSBFL Rnav-Punod-3a-Rwy14 Sid 20210520jose netoNo ratings yet

- Self Potential (SP) and Direct Current (DC) Electrical Methods For Leak DetectionDocument1 pageSelf Potential (SP) and Direct Current (DC) Electrical Methods For Leak DetectionbataraNo ratings yet

- 1000 SFC RCR27 Rcr2: Ils Rwy27Document1 page1000 SFC RCR27 Rcr2: Ils Rwy27tommyNo ratings yet

- Santa Marta, Colombia SKSM/SMR VOR Rwy 01: 13-1 119.1 118.7 VOR Cat A, B & C Simon Bolivar Intl 125.0 127.7Document1 pageSanta Marta, Colombia SKSM/SMR VOR Rwy 01: 13-1 119.1 118.7 VOR Cat A, B & C Simon Bolivar Intl 125.0 127.7Guillermo Serrano KelcyNo ratings yet

- Pipe Line No As Per P & Id: Base Skid & Piping Routing PlanDocument1 pagePipe Line No As Per P & Id: Base Skid & Piping Routing PlanpawanNo ratings yet

- L001-04050-CX-4018-100239-1200 - SHT 359 of 400Document1 pageL001-04050-CX-4018-100239-1200 - SHT 359 of 400pawanNo ratings yet

- Cummins Arabia: General NotesDocument3 pagesCummins Arabia: General NotespawanNo ratings yet

- Section 1.1. General: 1.1.1. ApplicationDocument1 pageSection 1.1. General: 1.1.1. ApplicationpawanNo ratings yet

- L001-04050-CX-4018-100239-1200 - SHT 354 of 400Document1 pageL001-04050-CX-4018-100239-1200 - SHT 354 of 400pawanNo ratings yet

- Tp5-Manual Fuel Supply-Plan: TP-5 Pipe Cut List Tag No Size QTY LENGTH (MM)Document1 pageTp5-Manual Fuel Supply-Plan: TP-5 Pipe Cut List Tag No Size QTY LENGTH (MM)pawanNo ratings yet

- AC EGR Roup P: Minu Utes of Me EetingDocument3 pagesAC EGR Roup P: Minu Utes of Me EetingpawanNo ratings yet

- Ga Drawing For C1400D5 in 40FTDocument1 pageGa Drawing For C1400D5 in 40FTpawanNo ratings yet

- MOM - General (9-10-14)Document1 pageMOM - General (9-10-14)pawanNo ratings yet

- Q922 C722-01 - C700D5 20 FT ContainerDocument3 pagesQ922 C722-01 - C700D5 20 FT ContainerpawanNo ratings yet

- Fire Alarm SystemDocument10 pagesFire Alarm SystempawanNo ratings yet

- Zimbabwe School Examinations Council Physics 6032/1: Electronic Calculator And/or Mathematical TablesDocument16 pagesZimbabwe School Examinations Council Physics 6032/1: Electronic Calculator And/or Mathematical TablesKuzivakwasheNo ratings yet

- Composite Structures: Jawdat Tashan, Riadh Al-MahaidiDocument7 pagesComposite Structures: Jawdat Tashan, Riadh Al-Mahaidino_milk_todayNo ratings yet

- DL 0 DegreeDocument2,120 pagesDL 0 DegreePraveen CyssanNo ratings yet

- Huawei Data Center Facility Handbook 20230425-1Document67 pagesHuawei Data Center Facility Handbook 20230425-1SatriaWahyuEkaSaputraNo ratings yet

- Artificial Neural Network Maximum Power Point Tracker For Solar Electric VehicleDocument5 pagesArtificial Neural Network Maximum Power Point Tracker For Solar Electric Vehiclepavan gangwarNo ratings yet

- RCD-Lecture 5-T BeamsDocument23 pagesRCD-Lecture 5-T BeamsHassan AhmedNo ratings yet

- Test On Cyclic Creep Behavior of Mucky Clay in Shanghai Under Step Cyclic LoadingDocument8 pagesTest On Cyclic Creep Behavior of Mucky Clay in Shanghai Under Step Cyclic LoadingJoselle RuizNo ratings yet

- Unesco - Eolss Sample Chapters: Earthquake Ground MotionDocument9 pagesUnesco - Eolss Sample Chapters: Earthquake Ground MotionEba GetachewNo ratings yet

- EN2090 Engineering Mathematics 2 Fourier Analysis: Prof. Adrian Porch DR Yue ZhouDocument18 pagesEN2090 Engineering Mathematics 2 Fourier Analysis: Prof. Adrian Porch DR Yue ZhouGhulam MujtabaNo ratings yet

- D 903 - 98 - Rdkwmy05oa - PDFDocument3 pagesD 903 - 98 - Rdkwmy05oa - PDFPatricioArrienNo ratings yet

- Viva-Voce 1 BDocument5 pagesViva-Voce 1 Bchanjaneyulu9100% (1)

- Heat Capacity: Prof. Dr. Aytunç ATEŞDocument38 pagesHeat Capacity: Prof. Dr. Aytunç ATEŞKatrina Ranee RamosNo ratings yet

- Tecanat™ Tecanat™ Gf20 (Polycarbonate and Glass Filled Polycarbonate)Document1 pageTecanat™ Tecanat™ Gf20 (Polycarbonate and Glass Filled Polycarbonate)David Matthew Kurniawan BEngNo ratings yet

- LectureDocument128 pagesLectureDiego FernandezNo ratings yet

- Newtons Law of Universal GravitationDocument10 pagesNewtons Law of Universal Gravitationdheerajr97No ratings yet

- Perforating Oil and Gas WellsDocument6 pagesPerforating Oil and Gas WellsRizwan FaridNo ratings yet

- Traveling & Cabtyre CablesDocument44 pagesTraveling & Cabtyre Cables이종욱No ratings yet

- Modification and Evaluation of A Reciprocating Machine For Shelling PeanutDocument16 pagesModification and Evaluation of A Reciprocating Machine For Shelling PeanutFiraol GudisaNo ratings yet

- Załacznik NR 2 Spec - techn.MASONEILANDocument7 pagesZałacznik NR 2 Spec - techn.MASONEILANEric CastilloNo ratings yet

- From ChatAIDocument3 pagesFrom ChatAIMunaliza IbrahimNo ratings yet

- Compass Course Corrections 20.10.20Document51 pagesCompass Course Corrections 20.10.20freyanerisebrownNo ratings yet

- API 510. Daily Exam-3 (Closed Book)Document5 pagesAPI 510. Daily Exam-3 (Closed Book)Maher ShehabNo ratings yet

- Science 8-Q3 M-EDocument2 pagesScience 8-Q3 M-Enelson dante jr.No ratings yet

- HOMEWORK Algebra 3 Feb 212023Document6 pagesHOMEWORK Algebra 3 Feb 212023Sharmaine FajutaganaNo ratings yet

- Ginzburg-Landau Theory For Superconducting MaterialsDocument9 pagesGinzburg-Landau Theory For Superconducting MaterialsAnkan Das RoyNo ratings yet

- Astm 400Document9 pagesAstm 400JOSEPH REFUERZONo ratings yet

- 7.6 Spin Density: SDW MottDocument1 page7.6 Spin Density: SDW MottKetanNo ratings yet

- Kumera Helical and Bevel Gear Units PDFDocument136 pagesKumera Helical and Bevel Gear Units PDFanto starlinNo ratings yet

- On Job Training Proposal PPSDM Migas CepuDocument20 pagesOn Job Training Proposal PPSDM Migas Cepujerry farhanNo ratings yet

- Soal Toku Goldgen TbiDocument4 pagesSoal Toku Goldgen TbiStepanus18No ratings yet

3.2t X 6m Span Elv PDF

3.2t X 6m Span Elv PDF

Uploaded by

pawanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3.2t X 6m Span Elv PDF

3.2t X 6m Span Elv PDF

Uploaded by

pawanCopyright:

Available Formats

>= 130 6000 >= 130

>= 100

HL

installations

>= 390

<=1150

290

3,2 t 3,2 t

>= 300 270

-10

390

lower

safety distance

810 610

>= 6420

6030

1)

34

6000

5640

<= 5450

-360

50

≈1000

load hook: E 1.0 - V

crane runway beam

1 2

mains power line

crane control

center line

1-EFF

R1 trolley power supply R3

1165

RAL 1007

1900

1165

center line mobile control

2-EFF R2 R4

kumarath0657_20200304_08501751_TM0_TE1

80

derailment protection

crane ELV 3,2 t x 6000 mm

Ø 80

design basis DIN 15018, H2/B3

hoist + trolley GM 800.3200 H-162.41.6000.4.E 100.20

FEM group 2m / M5

operation location indoor operation

ambient conditions -5° C up to +40° C, without special requirements

185

crane travel 5 / 20 m/min

Ø 130

trolley travelling 5 / 20 m/min

Ø 156

100

hoisting 0.7 / 4 m/min

14

20

total weight 1070 kg (thereof hoist + trolley 247 kg)

30

mains voltage; admissible voltage swing 3/PE ~50 Hz 400 V (TN-S); -6.5% / +5%

(10)

total power consumption 3.1 kW (starting current * cos phi: 28 A) +SKR-F1 = 20 A gG

wheel loads (kN) crane axis 1 (min/max) 3.8 17.1

50 (without vibration coefficient) crane axis 2 (min/max) 3.8 17.3

© ABUS Kransysteme GmbH

62 lateral loads (kN) mass forces crane travel (min/max) 0.3 1.0

load data

skewing force on guide side (coefficient of frictional contact <= 0,3) 5.6 -

= = horizontal loads from skewing front crane axis in driving direction 1.0 4.6

151 (guide side/opposite side) back crane axis in driving direction 0.0 0.0

longitudinal loads (kN) mass forces crane travel (max.) 0.6

(per crane runway beam) collision forces (max.) 5.4

(motion limiter taken into account)

1)

maximum hook path of hoist 6 m, actual use according to conditions on site

Ace Crane Systems LLC

P.O. Box: 231314 crane ELV

211806 - 008

Dubai

phone person in charge: Kumar,A.

fax 065700-0012854-20200304-02 / 1 Date: 04/03/2020

ABUKonfis Version 5.12w1060 www.acecranes.com athith@acecranes.com

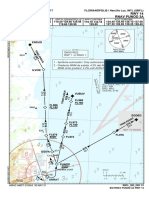

Load data according to DIN EN 1991-3

Classification

S3 (for the verification of the runway beam)

of crane

Dynamic coefficients φi:

φ1 1.10 Acceleration (resulting from lifting and gravitation) acting on the mass of the crane

φ2 1.10 inertia and gravitation when lifting an unrestricted load from off the floor

φ3 1.00 inertia and gravitation when suddenly releasing a part of the lifted load

φ4 1.00 Loads resulting from travelling across uneven surfaces

φ5,Kr 1.80 Loads resulting from acceleration of crane travel drives

φ6,dyn 1.05 Dynamic test load

φ6,stat 1.00 static test load

φ7,Kr 1.25 Loads resulting from buffer forces

Load effects and relevant force components:

Wheel loads Force component from the mass of the crane Qc,min,1 2.2 Qc,max,1 2.9 [kN]

(vertical) and the hoist(s) per crane axis Qc,min,2 2.2 Qc,max,2 3.1 [kN]

Force component from Qh,min,1 1.6 Qh,max,1 14.2 [kN]

mass of hoist load per crane axis Qh,min,2 1.6 Qh,max,2 14.2 [kN]

Lateral loads Force from the acceleration of the

HT,min 0.1 HT,max 0.7 [kN]

(horizontal) crane with hoist load (mass force)

skewing force (coefficient of frictional contact <= 0,3) S 5.6 [kN]

HS,min,1 0.0 HS,max,1 0.0 [kN]

Horizontal force from skewing per crane axis

HS,min,2 1.0 HS,max,2 4.6 [kN]

Longitudinal loads Force from the acceleration of the

HL 0.4 [kN]

(horizontal) crane with hoist load (mass force)

(per runway beam)

Force from impact on buffer (collision force)

HB1 4.3 [kN]

(motion limiter taken into account)

HL HL

Qc,min,1 Qc,max,1

crane axis Qh,min,1 min. Qh,max,1

HS,min,1 HT,min HT,max HS,max1

1-IFF

kumarath0657_20200304_08502271

S HS,min,2 HT,min HT,max HS,max2

2-IFF

Qc,min,2 Qc,max,2

Qh,min,2 Qh,max,2

HB1 crane travel direction HB1

© ABUS Kransysteme GmbH

The drawing shows the crane travel situation for the purpose of generating minimum and maximum loads.

The decisive crane travel situation may vary depending on the crane version (travel direction, trolley position and / or means of guidance).

All load effects constitute characteristic static force components and have to have the corresponding dynamic coefficient φ applied to them.

Crane track tolerances DIN EN 1090-2, tolerance class 2

tolerance of the track centre dimension of the crane rails +/- 5 mm

Ace Crane Systems LLC

P.O. Box: 231314 crane ELV

20328742 - 000

Dubai

phone person in charge: Kumar,A.

fax 065700-0012854-20200304-02 / 1 Date: 04/03/2020

ABUKonfis Version 5.12w1060 www.acecranes.com athith@acecranes.com

You might also like

- 203 656 44 Accesorios ElectricosDocument32 pages203 656 44 Accesorios ElectricosJESUSCALVILLONo ratings yet

- Extracted Pages From 3601709 - Fabrication Drawings1Document1 pageExtracted Pages From 3601709 - Fabrication Drawings1ahmed aboyosefNo ratings yet

- Bus Bar Selection 20338744 - 0606073419Document40 pagesBus Bar Selection 20338744 - 0606073419yac128No ratings yet

- ABUS Overhead CranesDocument36 pagesABUS Overhead CranesAya AlgalladNo ratings yet

- Port Douglas 3 304Document1 pagePort Douglas 3 304Ngaire TaylorNo ratings yet

- AbusDocument22 pagesAbusJose De Jesus MejiaNo ratings yet

- Abus 1Document6 pagesAbus 1Slobodan NesovicNo ratings yet

- Making Intelligent: Moving On UpDocument2 pagesMaking Intelligent: Moving On UpMiklo Balazs-ErzsebetNo ratings yet

- Abus Single PDFDocument1 pageAbus Single PDFkeerthivasan_mrvNo ratings yet

- Demag DMR (Brochure)Document20 pagesDemag DMR (Brochure)MadhaneNo ratings yet

- Abus Electric Wire Rope HoistsDocument14 pagesAbus Electric Wire Rope Hoistsprihharmanto antokNo ratings yet

- ManualDocument11 pagesManualfpersiancatNo ratings yet

- 4ductor Engl PDFDocument8 pages4ductor Engl PDFNilesh MahajanNo ratings yet

- 130724Document20 pages130724Caracal MohNo ratings yet

- GalviDocument41 pagesGalvidhanishlNo ratings yet

- Operation Instructions: ABUS - Load Indicator SystemDocument12 pagesOperation Instructions: ABUS - Load Indicator SystemShane PNo ratings yet

- 31 SeriesDocument4 pages31 SeriesJESUSCALVILLONo ratings yet

- D 0498Document28 pagesD 0498Bang OchimNo ratings yet

- Electrical Drawings For 15T OH CraneDocument36 pagesElectrical Drawings For 15T OH CraneArmnn RasmoNo ratings yet

- Demag DC-PRO4 PDFDocument176 pagesDemag DC-PRO4 PDFRudianto SohandjajaNo ratings yet

- SC10876B - Hoist DrawingDocument1 pageSC10876B - Hoist DrawingMotlatjo RakgothoNo ratings yet

- AbusDocument27 pagesAbusMargelatu AndreyNo ratings yet

- 130718Document176 pages130718Th NattapongNo ratings yet

- Demag Cranes BruchureDocument24 pagesDemag Cranes BruchureAnand TornekarNo ratings yet

- Economical. Durable. Easy To Operate.: DBR Rope HoistDocument12 pagesEconomical. Durable. Easy To Operate.: DBR Rope HoistsarochimNo ratings yet

- Demag DMR (Brochure)Document20 pagesDemag DMR (Brochure)Hendra HalimNo ratings yet

- GM - 6000 20000 - L-242 41 15000 3 D - 200 24 2500 GBDocument1 pageGM - 6000 20000 - L-242 41 15000 3 D - 200 24 2500 GBEduardo Garcia SaraviaNo ratings yet

- Brugg Catalog enDocument28 pagesBrugg Catalog enSinoj V AntonyNo ratings yet

- SWF RopeHoists CraneKits 09 2012 enDocument21 pagesSWF RopeHoists CraneKits 09 2012 enGogyNo ratings yet

- Demag DR Rope Hoist: Without Electrical ControlDocument32 pagesDemag DR Rope Hoist: Without Electrical ControlDante WilliamsNo ratings yet

- Component Parts: DZW Position Measuring SystemDocument12 pagesComponent Parts: DZW Position Measuring SystemBang OchimNo ratings yet

- DemagDocument20 pagesDemagPajserchinaNo ratings yet

- Casar Steel Wire RopesDocument32 pagesCasar Steel Wire Ropessgupta_615796No ratings yet

- Demag Drives PDFDocument24 pagesDemag Drives PDFRafael Linarez100% (1)

- Liebherr RMG Technical DescriptionDocument4 pagesLiebherr RMG Technical DescriptionHua Hidari YangNo ratings yet

- Operating/maintenance Instructions: I-Beam Pillar and Wall-Mounted Jib CranesDocument44 pagesOperating/maintenance Instructions: I-Beam Pillar and Wall-Mounted Jib Cranesrochim_putech_126885No ratings yet

- Technical Information: 1. Hoist RopesDocument17 pagesTechnical Information: 1. Hoist RopesvikasgahlyanNo ratings yet

- 8 X 26 Cabos Compactados EspeciaisDocument60 pages8 X 26 Cabos Compactados EspeciaisEvandro BeserraNo ratings yet

- End Carriage DFW S E AssmeblyDocument52 pagesEnd Carriage DFW S E AssmeblycutenganNo ratings yet

- Alignment of CouplingDocument24 pagesAlignment of Couplinger_sanjaypatelNo ratings yet

- AS 7 Wire Rope Hoist - : Now The Standard Version Is Even More PowerfulDocument4 pagesAS 7 Wire Rope Hoist - : Now The Standard Version Is Even More PowerfuljavierNo ratings yet

- Abus-Double Girder CraneDocument3 pagesAbus-Double Girder CraneAlwin Victor WilliamsNo ratings yet

- 2 Tonne Spark Resistant 220model Post Swing Jib Crane - 1Document1 page2 Tonne Spark Resistant 220model Post Swing Jib Crane - 1AnishNo ratings yet

- Abus Electric Chain HoistDocument32 pagesAbus Electric Chain HoistراموندولدولاوNo ratings yet

- TGN 08 Crane Rail Selection 2Document3 pagesTGN 08 Crane Rail Selection 2Prasad PatilNo ratings yet

- Abus CranesDocument12 pagesAbus Cranesmahhor82_635643838No ratings yet

- EN DEMAG PogledajDocument158 pagesEN DEMAG PogledajNenad TabandzelicNo ratings yet

- Technical Data Accessories DEMAG DC-COM Chain Hoist PDFDocument40 pagesTechnical Data Accessories DEMAG DC-COM Chain Hoist PDFMarco SilvaNo ratings yet

- Verlinde Electric Wire Rope HoistDocument12 pagesVerlinde Electric Wire Rope HoistMahmoud AllamNo ratings yet

- Abus Electric Chain Hoists AbucompactDocument32 pagesAbus Electric Chain Hoists Abucompactnicoka50No ratings yet

- Rope Guide: Service PartsDocument2 pagesRope Guide: Service PartsDumebiNo ratings yet

- ABUS 120.0t EOT Layout - 22.0m SpanDocument1 pageABUS 120.0t EOT Layout - 22.0m Spanfud3n100% (1)

- Product SWF End CarriagesDocument63 pagesProduct SWF End CarriagesGogyNo ratings yet

- Non-Driven Wheel DIN15090 Series 223 enDocument1 pageNon-Driven Wheel DIN15090 Series 223 enayavuzbvsNo ratings yet

- Abus Cranes CatalogDocument28 pagesAbus Cranes CatalogGeorge JabbourNo ratings yet

- Scx1000a-3 Stage3a PRDocument8 pagesScx1000a-3 Stage3a PRДмитрий БакайNo ratings yet

- SBFL Rnav-Punod-3a-Rwy14 Sid 20210520Document1 pageSBFL Rnav-Punod-3a-Rwy14 Sid 20210520jose netoNo ratings yet

- Self Potential (SP) and Direct Current (DC) Electrical Methods For Leak DetectionDocument1 pageSelf Potential (SP) and Direct Current (DC) Electrical Methods For Leak DetectionbataraNo ratings yet

- 1000 SFC RCR27 Rcr2: Ils Rwy27Document1 page1000 SFC RCR27 Rcr2: Ils Rwy27tommyNo ratings yet

- Santa Marta, Colombia SKSM/SMR VOR Rwy 01: 13-1 119.1 118.7 VOR Cat A, B & C Simon Bolivar Intl 125.0 127.7Document1 pageSanta Marta, Colombia SKSM/SMR VOR Rwy 01: 13-1 119.1 118.7 VOR Cat A, B & C Simon Bolivar Intl 125.0 127.7Guillermo Serrano KelcyNo ratings yet

- Pipe Line No As Per P & Id: Base Skid & Piping Routing PlanDocument1 pagePipe Line No As Per P & Id: Base Skid & Piping Routing PlanpawanNo ratings yet

- L001-04050-CX-4018-100239-1200 - SHT 359 of 400Document1 pageL001-04050-CX-4018-100239-1200 - SHT 359 of 400pawanNo ratings yet

- Cummins Arabia: General NotesDocument3 pagesCummins Arabia: General NotespawanNo ratings yet

- Section 1.1. General: 1.1.1. ApplicationDocument1 pageSection 1.1. General: 1.1.1. ApplicationpawanNo ratings yet

- L001-04050-CX-4018-100239-1200 - SHT 354 of 400Document1 pageL001-04050-CX-4018-100239-1200 - SHT 354 of 400pawanNo ratings yet

- Tp5-Manual Fuel Supply-Plan: TP-5 Pipe Cut List Tag No Size QTY LENGTH (MM)Document1 pageTp5-Manual Fuel Supply-Plan: TP-5 Pipe Cut List Tag No Size QTY LENGTH (MM)pawanNo ratings yet

- AC EGR Roup P: Minu Utes of Me EetingDocument3 pagesAC EGR Roup P: Minu Utes of Me EetingpawanNo ratings yet

- Ga Drawing For C1400D5 in 40FTDocument1 pageGa Drawing For C1400D5 in 40FTpawanNo ratings yet

- MOM - General (9-10-14)Document1 pageMOM - General (9-10-14)pawanNo ratings yet

- Q922 C722-01 - C700D5 20 FT ContainerDocument3 pagesQ922 C722-01 - C700D5 20 FT ContainerpawanNo ratings yet

- Fire Alarm SystemDocument10 pagesFire Alarm SystempawanNo ratings yet

- Zimbabwe School Examinations Council Physics 6032/1: Electronic Calculator And/or Mathematical TablesDocument16 pagesZimbabwe School Examinations Council Physics 6032/1: Electronic Calculator And/or Mathematical TablesKuzivakwasheNo ratings yet

- Composite Structures: Jawdat Tashan, Riadh Al-MahaidiDocument7 pagesComposite Structures: Jawdat Tashan, Riadh Al-Mahaidino_milk_todayNo ratings yet

- DL 0 DegreeDocument2,120 pagesDL 0 DegreePraveen CyssanNo ratings yet

- Huawei Data Center Facility Handbook 20230425-1Document67 pagesHuawei Data Center Facility Handbook 20230425-1SatriaWahyuEkaSaputraNo ratings yet

- Artificial Neural Network Maximum Power Point Tracker For Solar Electric VehicleDocument5 pagesArtificial Neural Network Maximum Power Point Tracker For Solar Electric Vehiclepavan gangwarNo ratings yet

- RCD-Lecture 5-T BeamsDocument23 pagesRCD-Lecture 5-T BeamsHassan AhmedNo ratings yet

- Test On Cyclic Creep Behavior of Mucky Clay in Shanghai Under Step Cyclic LoadingDocument8 pagesTest On Cyclic Creep Behavior of Mucky Clay in Shanghai Under Step Cyclic LoadingJoselle RuizNo ratings yet

- Unesco - Eolss Sample Chapters: Earthquake Ground MotionDocument9 pagesUnesco - Eolss Sample Chapters: Earthquake Ground MotionEba GetachewNo ratings yet

- EN2090 Engineering Mathematics 2 Fourier Analysis: Prof. Adrian Porch DR Yue ZhouDocument18 pagesEN2090 Engineering Mathematics 2 Fourier Analysis: Prof. Adrian Porch DR Yue ZhouGhulam MujtabaNo ratings yet

- D 903 - 98 - Rdkwmy05oa - PDFDocument3 pagesD 903 - 98 - Rdkwmy05oa - PDFPatricioArrienNo ratings yet

- Viva-Voce 1 BDocument5 pagesViva-Voce 1 Bchanjaneyulu9100% (1)

- Heat Capacity: Prof. Dr. Aytunç ATEŞDocument38 pagesHeat Capacity: Prof. Dr. Aytunç ATEŞKatrina Ranee RamosNo ratings yet

- Tecanat™ Tecanat™ Gf20 (Polycarbonate and Glass Filled Polycarbonate)Document1 pageTecanat™ Tecanat™ Gf20 (Polycarbonate and Glass Filled Polycarbonate)David Matthew Kurniawan BEngNo ratings yet

- LectureDocument128 pagesLectureDiego FernandezNo ratings yet

- Newtons Law of Universal GravitationDocument10 pagesNewtons Law of Universal Gravitationdheerajr97No ratings yet

- Perforating Oil and Gas WellsDocument6 pagesPerforating Oil and Gas WellsRizwan FaridNo ratings yet

- Traveling & Cabtyre CablesDocument44 pagesTraveling & Cabtyre Cables이종욱No ratings yet

- Modification and Evaluation of A Reciprocating Machine For Shelling PeanutDocument16 pagesModification and Evaluation of A Reciprocating Machine For Shelling PeanutFiraol GudisaNo ratings yet

- Załacznik NR 2 Spec - techn.MASONEILANDocument7 pagesZałacznik NR 2 Spec - techn.MASONEILANEric CastilloNo ratings yet

- From ChatAIDocument3 pagesFrom ChatAIMunaliza IbrahimNo ratings yet

- Compass Course Corrections 20.10.20Document51 pagesCompass Course Corrections 20.10.20freyanerisebrownNo ratings yet

- API 510. Daily Exam-3 (Closed Book)Document5 pagesAPI 510. Daily Exam-3 (Closed Book)Maher ShehabNo ratings yet

- Science 8-Q3 M-EDocument2 pagesScience 8-Q3 M-Enelson dante jr.No ratings yet

- HOMEWORK Algebra 3 Feb 212023Document6 pagesHOMEWORK Algebra 3 Feb 212023Sharmaine FajutaganaNo ratings yet

- Ginzburg-Landau Theory For Superconducting MaterialsDocument9 pagesGinzburg-Landau Theory For Superconducting MaterialsAnkan Das RoyNo ratings yet

- Astm 400Document9 pagesAstm 400JOSEPH REFUERZONo ratings yet

- 7.6 Spin Density: SDW MottDocument1 page7.6 Spin Density: SDW MottKetanNo ratings yet

- Kumera Helical and Bevel Gear Units PDFDocument136 pagesKumera Helical and Bevel Gear Units PDFanto starlinNo ratings yet

- On Job Training Proposal PPSDM Migas CepuDocument20 pagesOn Job Training Proposal PPSDM Migas Cepujerry farhanNo ratings yet

- Soal Toku Goldgen TbiDocument4 pagesSoal Toku Goldgen TbiStepanus18No ratings yet