Professional Documents

Culture Documents

100%(3)100% found this document useful (3 votes)

981 views17) Calcium Propionate Manufacturing Process

17) Calcium Propionate Manufacturing Process

Uploaded by

Shankar kumar royThe document summarizes the manufacturing process for calcium propionate. Calcium hydroxide and propionic acid are mixed in a vessel with process water. The mixture is heated for 3 hours to allow the chemical reaction to occur, forming calcium propionate and water. The calcium propionate solution is then cooled, filtered, centrifuged, dried, and pulverized. The mother liquor is reused in the next batch. The process uses 398 kg of calcium hydroxide, 795.5 kg of propionic acid, and 1000 kg of fresh water to produce 1000 kg of calcium propionate.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- 60 KLPD Grain-Based Distillery - A SnapshotDocument9 pages60 KLPD Grain-Based Distillery - A SnapshotAmrit Agarwal100% (2)

- Monoglycerides and Free Glycerol: ObjectiveDocument5 pagesMonoglycerides and Free Glycerol: ObjectiveJuan OlivaNo ratings yet

- Shimadzu LC 2010Document20 pagesShimadzu LC 2010Cooordinación Metrologia Nutermía sas100% (1)

- Product Information: Belsperse 164 - High Performance Dispersant For Industrial Water SystemsDocument2 pagesProduct Information: Belsperse 164 - High Performance Dispersant For Industrial Water SystemsEti SureniNo ratings yet

- Sion CalculationDocument387 pagesSion CalculationHena AgrawalNo ratings yet

- Standard Test Methods of Sampling and Chemical Analysis of Chlorine-Containing Bleaches (ASTM) (VERRRRR)Document3 pagesStandard Test Methods of Sampling and Chemical Analysis of Chlorine-Containing Bleaches (ASTM) (VERRRRR)DiplomadoEnTecnicasCromatograficasNo ratings yet

- Practical Handbook OnDocument47 pagesPractical Handbook OnSleepyHead ˋωˊ100% (1)

- Operation and Cleaning of Glass Lined ReactorDocument2 pagesOperation and Cleaning of Glass Lined ReactorDrVishwanatha HN100% (1)

- Design of A PipeRing Type of Sparger For A Bubble Column Reactor PDFDocument8 pagesDesign of A PipeRing Type of Sparger For A Bubble Column Reactor PDFAshkanHosseini100% (1)

- Exp - S10A - Forced Draft Tray DryerDocument6 pagesExp - S10A - Forced Draft Tray DryerSenthilNathanNo ratings yet

- .. PDF SugarDocument34 pages.. PDF SugarSnehal Badwaik100% (1)

- 18.) Calcium Stearate: (A) Manufacturing ProcessDocument2 pages18.) Calcium Stearate: (A) Manufacturing ProcessShankar kumar royNo ratings yet

- 20.) Calcium Gluconate: - (A) Manufacturing ProcessDocument2 pages20.) Calcium Gluconate: - (A) Manufacturing ProcessShankar kumar royNo ratings yet

- 21.) Potassium Oxalate: (A) Manufacturing ProcessDocument2 pages21.) Potassium Oxalate: (A) Manufacturing ProcessShankar kumar roy100% (1)

- Boiler KPI Webinar SlidesDocument45 pagesBoiler KPI Webinar SlidesEscobar ValderramaNo ratings yet

- Clear Shaveng Gel VsDocument1 pageClear Shaveng Gel Vsahmed lasdNo ratings yet

- Sodium and Methods of Test: Potassium SilicatesDocument12 pagesSodium and Methods of Test: Potassium SilicatesAnuradhaPatraNo ratings yet

- Raw Salt: 1-Determination of Ca & MGDocument8 pagesRaw Salt: 1-Determination of Ca & MGmohamed azzamNo ratings yet

- Antiscalant Technical SheetDocument4 pagesAntiscalant Technical SheetBenjamin MillerNo ratings yet

- Calcium Propionate IS MethodDocument13 pagesCalcium Propionate IS MethodkapilNo ratings yet

- Experiment A1: Continuous Stirred Tank Reactor: Department of Chemical EngineeringDocument4 pagesExperiment A1: Continuous Stirred Tank Reactor: Department of Chemical EngineeringChuchayLucasNo ratings yet

- Glycerine Vaccum Distillation PDFDocument6 pagesGlycerine Vaccum Distillation PDFPravin Agalave100% (1)

- III Sem ICTDocument56 pagesIII Sem ICToctoviancletusNo ratings yet

- Production of Erythromycine With Reference PDFDocument117 pagesProduction of Erythromycine With Reference PDFClaChristina100% (1)

- EIA Manual - Distilleries (MoEF 2010) PDFDocument230 pagesEIA Manual - Distilleries (MoEF 2010) PDFomung lalchandaniNo ratings yet

- Acrylic Acid MSDS: Section 1: Chemical Product and Company IdentificationDocument6 pagesAcrylic Acid MSDS: Section 1: Chemical Product and Company Identificationzaaba100% (1)

- Calcium PropionateDocument8 pagesCalcium PropionateGaganpreet KaurNo ratings yet

- Ethyl AcrylateDocument4 pagesEthyl AcrylateFirdaus ImamNo ratings yet

- Purity of AmmoniaDocument2 pagesPurity of AmmoniaAjay Patel100% (1)

- Certificate of Analysis Gelatin Powder: Test SpecificationDocument1 pageCertificate of Analysis Gelatin Powder: Test SpecificationSerly AlizahNo ratings yet

- India Standard For STPPDocument32 pagesIndia Standard For STPPNurhafizah Abd JabarNo ratings yet

- Standard Operating Procedure For The Parr 1261 Bomb CalorimeterDocument2 pagesStandard Operating Procedure For The Parr 1261 Bomb CalorimeterShurlandJamesJr.100% (1)

- Addrill Ea (HS) : The Advanced Drilling FluidDocument1 pageAddrill Ea (HS) : The Advanced Drilling FluidamistalokNo ratings yet

- EPA-Method-3771 Potassium Iodite-Iodate STD SolutionDocument3 pagesEPA-Method-3771 Potassium Iodite-Iodate STD SolutionZiauddeen NoorNo ratings yet

- Aoac 975.08 FluorurosDocument1 pageAoac 975.08 FluorurosNeidys Sanchez100% (1)

- Iodine Value Determination Porim Test MethodDocument2 pagesIodine Value Determination Porim Test MethodAdawiyah Ali100% (1)

- Sodium Silicate 30mtperdayDocument5 pagesSodium Silicate 30mtperdaySubrata BanerjeeNo ratings yet

- Chapter 5 Molecular Diffusion in Biological Solutions & GelsDocument14 pagesChapter 5 Molecular Diffusion in Biological Solutions & Gelsrushdi100% (2)

- Practical Project: Production of Mango Powder From MangoDocument12 pagesPractical Project: Production of Mango Powder From MangoTakreem SindhuNo ratings yet

- Sop For MeeDocument1 pageSop For MeeChirag Dobariya100% (1)

- Glycerine DeterminationDocument3 pagesGlycerine DeterminationorganodieselNo ratings yet

- Analytical Test ProcedureDocument48 pagesAnalytical Test Procedureamirul Islam100% (1)

- The Use of Polymers To Improve Control of Calcium Phosphonate and Calcium Carbonate in High StressedDocument23 pagesThe Use of Polymers To Improve Control of Calcium Phosphonate and Calcium Carbonate in High Stressedwilmar100% (1)

- Sodium Tripolyphosphate D ChinaDocument11 pagesSodium Tripolyphosphate D ChinaKarem Jeanette Saenz BernalNo ratings yet

- Calcium Chloride DihydrateDocument2 pagesCalcium Chloride DihydrateMulayam Singh YadavNo ratings yet

- Short Path DistillationDocument12 pagesShort Path Distillationup4all33% (3)

- Enteric Coated Aspirin Tablets FinalDocument72 pagesEnteric Coated Aspirin Tablets Finalronak_panchal_21No ratings yet

- Material Standard FOR Inhibitor For Hydrochloric Acid AS: IPS-M-TP-673Document7 pagesMaterial Standard FOR Inhibitor For Hydrochloric Acid AS: IPS-M-TP-673RezaNo ratings yet

- Rice Training Module - SalesDocument25 pagesRice Training Module - SalesRamesh NairNo ratings yet

- Multi Pressure DistillationDocument19 pagesMulti Pressure DistillationHardik ChauhanNo ratings yet

- AOCS DB 2-48Document1 pageAOCS DB 2-48Asadulhaq Ali HamidiNo ratings yet

- Food Chemistry: Bénédicte Van Steertegem, Bram Pareyt, Kristof Brijs, Jan A. DelcourDocument7 pagesFood Chemistry: Bénédicte Van Steertegem, Bram Pareyt, Kristof Brijs, Jan A. DelcourDiego PinaresNo ratings yet

- COA and MSDS DM WaterDocument4 pagesCOA and MSDS DM WaterPRadeep Jain100% (1)

- Magnesium Acetate: - (A) Manufacturing ProcessDocument2 pagesMagnesium Acetate: - (A) Manufacturing ProcessShankar kumar royNo ratings yet

- 19.) Copper Gluconate: - (A) Manufacturing ProcessDocument2 pages19.) Copper Gluconate: - (A) Manufacturing ProcessShankar kumar royNo ratings yet

- Flowdiagram of Disperse Blue 79Document4 pagesFlowdiagram of Disperse Blue 79kanji63No ratings yet

- 0 0 1211812181211ManufacturingProcessDocument17 pages0 0 1211812181211ManufacturingProcessLUISNo ratings yet

- Isolation of Potassium Carbonate From Banana Plant (Musa Balbisiana)Document17 pagesIsolation of Potassium Carbonate From Banana Plant (Musa Balbisiana)zawNo ratings yet

- Presentation On DM PlantDocument16 pagesPresentation On DM PlantVenkat Dora100% (4)

- Acid Purification and RecoveryDocument4 pagesAcid Purification and RecoverythiagoNo ratings yet

- 4,7-Dichloroquinoline: Molecular Formula: Molecular Weight: Cas NumberDocument5 pages4,7-Dichloroquinoline: Molecular Formula: Molecular Weight: Cas NumberShankar kumar royNo ratings yet

- Magnesium Acetate: - (A) Manufacturing ProcessDocument2 pagesMagnesium Acetate: - (A) Manufacturing ProcessShankar kumar royNo ratings yet

- 18.) Calcium Stearate: (A) Manufacturing ProcessDocument2 pages18.) Calcium Stearate: (A) Manufacturing ProcessShankar kumar royNo ratings yet

- Indole Synthesis - Something Old, Something NewDocument13 pagesIndole Synthesis - Something Old, Something NewShankar kumar royNo ratings yet

- 21.) Potassium Oxalate: (A) Manufacturing ProcessDocument2 pages21.) Potassium Oxalate: (A) Manufacturing ProcessShankar kumar roy100% (1)

- 20.) Calcium Gluconate: - (A) Manufacturing ProcessDocument2 pages20.) Calcium Gluconate: - (A) Manufacturing ProcessShankar kumar royNo ratings yet

- 19.) Copper Gluconate: - (A) Manufacturing ProcessDocument2 pages19.) Copper Gluconate: - (A) Manufacturing ProcessShankar kumar royNo ratings yet

- Standard Operating ProcedureDocument8 pagesStandard Operating ProcedureShankar kumar royNo ratings yet

- Parahydroxy Acetophenone SynthesisDocument1 pageParahydroxy Acetophenone SynthesisShankar kumar royNo ratings yet

- Facility and AHU ValidationDocument63 pagesFacility and AHU ValidationShankar kumar roy100% (3)

- Ethoxy CarbazepineDocument27 pagesEthoxy CarbazepineShankar kumar royNo ratings yet

17) Calcium Propionate Manufacturing Process

17) Calcium Propionate Manufacturing Process

Uploaded by

Shankar kumar roy100%(3)100% found this document useful (3 votes)

981 views2 pagesThe document summarizes the manufacturing process for calcium propionate. Calcium hydroxide and propionic acid are mixed in a vessel with process water. The mixture is heated for 3 hours to allow the chemical reaction to occur, forming calcium propionate and water. The calcium propionate solution is then cooled, filtered, centrifuged, dried, and pulverized. The mother liquor is reused in the next batch. The process uses 398 kg of calcium hydroxide, 795.5 kg of propionic acid, and 1000 kg of fresh water to produce 1000 kg of calcium propionate.

Original Description:

Original Title

17) Calcium Propionate manufacturing process

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document summarizes the manufacturing process for calcium propionate. Calcium hydroxide and propionic acid are mixed in a vessel with process water. The mixture is heated for 3 hours to allow the chemical reaction to occur, forming calcium propionate and water. The calcium propionate solution is then cooled, filtered, centrifuged, dried, and pulverized. The mother liquor is reused in the next batch. The process uses 398 kg of calcium hydroxide, 795.5 kg of propionic acid, and 1000 kg of fresh water to produce 1000 kg of calcium propionate.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

100%(3)100% found this document useful (3 votes)

981 views2 pages17) Calcium Propionate Manufacturing Process

17) Calcium Propionate Manufacturing Process

Uploaded by

Shankar kumar royThe document summarizes the manufacturing process for calcium propionate. Calcium hydroxide and propionic acid are mixed in a vessel with process water. The mixture is heated for 3 hours to allow the chemical reaction to occur, forming calcium propionate and water. The calcium propionate solution is then cooled, filtered, centrifuged, dried, and pulverized. The mother liquor is reused in the next batch. The process uses 398 kg of calcium hydroxide, 795.5 kg of propionic acid, and 1000 kg of fresh water to produce 1000 kg of calcium propionate.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

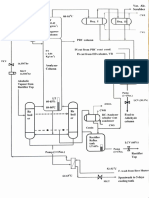

17.

)Calcium Propionate:

(A)Manufacturing Process:

Take Process Water in vessel. Add Propionic Acid . Then charge calcium Hydroxide slowly as Lotwise.

Then under stirring heat it for 3 hrs. If reaction completed. Then cool it and unload in Nutch Filter.

Then centrifuge and drying and pulverise. Calcium Propionate packed in bag.ML will be reused in

next batch.

(B)Chemical Reaction:

Ca(OH)2 + 2C2H5 COOH Ca (C 2H5COO)2 + 2 H2O

74.09 2 x 74.07 186.22 2 x18

(C) Process Flow Chart:

Propionic Acid : 795.5 kgs

Calcium Hydroxide:398 kgs

Fresh water: 1000 Lit

Vessel

ML Recycle: 900 lit ML +100 lit Water.

Nutch Filter ML Use in next batch: 600Ltr

Centrifuge ML use in next batch: 300Ltr

Water loss 293.5 Ltr during drying.

Dryer

Pulverise

Packed

Finish Product: Calcium Propionate 1000

Water Consumption:100 lit/Mt Calcium

Propionate Waste Water Generation: Nil

SR.NO Name Of Raw INPUT Name Of OUTPUT QTY IN KG

. Materials QTY IN KG Materials

1 Calcium Hydroxide 398 Mother Liquor 900 for reuse

2 Propionic Acid 795.5

3 Water 1000 Water loss in 293.5 KG

drying

4 Calcium 1000 KG

Propionate

TOTAL 2193.5 Kg 2193.5 KG

You might also like

- 60 KLPD Grain-Based Distillery - A SnapshotDocument9 pages60 KLPD Grain-Based Distillery - A SnapshotAmrit Agarwal100% (2)

- Monoglycerides and Free Glycerol: ObjectiveDocument5 pagesMonoglycerides and Free Glycerol: ObjectiveJuan OlivaNo ratings yet

- Shimadzu LC 2010Document20 pagesShimadzu LC 2010Cooordinación Metrologia Nutermía sas100% (1)

- Product Information: Belsperse 164 - High Performance Dispersant For Industrial Water SystemsDocument2 pagesProduct Information: Belsperse 164 - High Performance Dispersant For Industrial Water SystemsEti SureniNo ratings yet

- Sion CalculationDocument387 pagesSion CalculationHena AgrawalNo ratings yet

- Standard Test Methods of Sampling and Chemical Analysis of Chlorine-Containing Bleaches (ASTM) (VERRRRR)Document3 pagesStandard Test Methods of Sampling and Chemical Analysis of Chlorine-Containing Bleaches (ASTM) (VERRRRR)DiplomadoEnTecnicasCromatograficasNo ratings yet

- Practical Handbook OnDocument47 pagesPractical Handbook OnSleepyHead ˋωˊ100% (1)

- Operation and Cleaning of Glass Lined ReactorDocument2 pagesOperation and Cleaning of Glass Lined ReactorDrVishwanatha HN100% (1)

- Design of A PipeRing Type of Sparger For A Bubble Column Reactor PDFDocument8 pagesDesign of A PipeRing Type of Sparger For A Bubble Column Reactor PDFAshkanHosseini100% (1)

- Exp - S10A - Forced Draft Tray DryerDocument6 pagesExp - S10A - Forced Draft Tray DryerSenthilNathanNo ratings yet

- .. PDF SugarDocument34 pages.. PDF SugarSnehal Badwaik100% (1)

- 18.) Calcium Stearate: (A) Manufacturing ProcessDocument2 pages18.) Calcium Stearate: (A) Manufacturing ProcessShankar kumar royNo ratings yet

- 20.) Calcium Gluconate: - (A) Manufacturing ProcessDocument2 pages20.) Calcium Gluconate: - (A) Manufacturing ProcessShankar kumar royNo ratings yet

- 21.) Potassium Oxalate: (A) Manufacturing ProcessDocument2 pages21.) Potassium Oxalate: (A) Manufacturing ProcessShankar kumar roy100% (1)

- Boiler KPI Webinar SlidesDocument45 pagesBoiler KPI Webinar SlidesEscobar ValderramaNo ratings yet

- Clear Shaveng Gel VsDocument1 pageClear Shaveng Gel Vsahmed lasdNo ratings yet

- Sodium and Methods of Test: Potassium SilicatesDocument12 pagesSodium and Methods of Test: Potassium SilicatesAnuradhaPatraNo ratings yet

- Raw Salt: 1-Determination of Ca & MGDocument8 pagesRaw Salt: 1-Determination of Ca & MGmohamed azzamNo ratings yet

- Antiscalant Technical SheetDocument4 pagesAntiscalant Technical SheetBenjamin MillerNo ratings yet

- Calcium Propionate IS MethodDocument13 pagesCalcium Propionate IS MethodkapilNo ratings yet

- Experiment A1: Continuous Stirred Tank Reactor: Department of Chemical EngineeringDocument4 pagesExperiment A1: Continuous Stirred Tank Reactor: Department of Chemical EngineeringChuchayLucasNo ratings yet

- Glycerine Vaccum Distillation PDFDocument6 pagesGlycerine Vaccum Distillation PDFPravin Agalave100% (1)

- III Sem ICTDocument56 pagesIII Sem ICToctoviancletusNo ratings yet

- Production of Erythromycine With Reference PDFDocument117 pagesProduction of Erythromycine With Reference PDFClaChristina100% (1)

- EIA Manual - Distilleries (MoEF 2010) PDFDocument230 pagesEIA Manual - Distilleries (MoEF 2010) PDFomung lalchandaniNo ratings yet

- Acrylic Acid MSDS: Section 1: Chemical Product and Company IdentificationDocument6 pagesAcrylic Acid MSDS: Section 1: Chemical Product and Company Identificationzaaba100% (1)

- Calcium PropionateDocument8 pagesCalcium PropionateGaganpreet KaurNo ratings yet

- Ethyl AcrylateDocument4 pagesEthyl AcrylateFirdaus ImamNo ratings yet

- Purity of AmmoniaDocument2 pagesPurity of AmmoniaAjay Patel100% (1)

- Certificate of Analysis Gelatin Powder: Test SpecificationDocument1 pageCertificate of Analysis Gelatin Powder: Test SpecificationSerly AlizahNo ratings yet

- India Standard For STPPDocument32 pagesIndia Standard For STPPNurhafizah Abd JabarNo ratings yet

- Standard Operating Procedure For The Parr 1261 Bomb CalorimeterDocument2 pagesStandard Operating Procedure For The Parr 1261 Bomb CalorimeterShurlandJamesJr.100% (1)

- Addrill Ea (HS) : The Advanced Drilling FluidDocument1 pageAddrill Ea (HS) : The Advanced Drilling FluidamistalokNo ratings yet

- EPA-Method-3771 Potassium Iodite-Iodate STD SolutionDocument3 pagesEPA-Method-3771 Potassium Iodite-Iodate STD SolutionZiauddeen NoorNo ratings yet

- Aoac 975.08 FluorurosDocument1 pageAoac 975.08 FluorurosNeidys Sanchez100% (1)

- Iodine Value Determination Porim Test MethodDocument2 pagesIodine Value Determination Porim Test MethodAdawiyah Ali100% (1)

- Sodium Silicate 30mtperdayDocument5 pagesSodium Silicate 30mtperdaySubrata BanerjeeNo ratings yet

- Chapter 5 Molecular Diffusion in Biological Solutions & GelsDocument14 pagesChapter 5 Molecular Diffusion in Biological Solutions & Gelsrushdi100% (2)

- Practical Project: Production of Mango Powder From MangoDocument12 pagesPractical Project: Production of Mango Powder From MangoTakreem SindhuNo ratings yet

- Sop For MeeDocument1 pageSop For MeeChirag Dobariya100% (1)

- Glycerine DeterminationDocument3 pagesGlycerine DeterminationorganodieselNo ratings yet

- Analytical Test ProcedureDocument48 pagesAnalytical Test Procedureamirul Islam100% (1)

- The Use of Polymers To Improve Control of Calcium Phosphonate and Calcium Carbonate in High StressedDocument23 pagesThe Use of Polymers To Improve Control of Calcium Phosphonate and Calcium Carbonate in High Stressedwilmar100% (1)

- Sodium Tripolyphosphate D ChinaDocument11 pagesSodium Tripolyphosphate D ChinaKarem Jeanette Saenz BernalNo ratings yet

- Calcium Chloride DihydrateDocument2 pagesCalcium Chloride DihydrateMulayam Singh YadavNo ratings yet

- Short Path DistillationDocument12 pagesShort Path Distillationup4all33% (3)

- Enteric Coated Aspirin Tablets FinalDocument72 pagesEnteric Coated Aspirin Tablets Finalronak_panchal_21No ratings yet

- Material Standard FOR Inhibitor For Hydrochloric Acid AS: IPS-M-TP-673Document7 pagesMaterial Standard FOR Inhibitor For Hydrochloric Acid AS: IPS-M-TP-673RezaNo ratings yet

- Rice Training Module - SalesDocument25 pagesRice Training Module - SalesRamesh NairNo ratings yet

- Multi Pressure DistillationDocument19 pagesMulti Pressure DistillationHardik ChauhanNo ratings yet

- AOCS DB 2-48Document1 pageAOCS DB 2-48Asadulhaq Ali HamidiNo ratings yet

- Food Chemistry: Bénédicte Van Steertegem, Bram Pareyt, Kristof Brijs, Jan A. DelcourDocument7 pagesFood Chemistry: Bénédicte Van Steertegem, Bram Pareyt, Kristof Brijs, Jan A. DelcourDiego PinaresNo ratings yet

- COA and MSDS DM WaterDocument4 pagesCOA and MSDS DM WaterPRadeep Jain100% (1)

- Magnesium Acetate: - (A) Manufacturing ProcessDocument2 pagesMagnesium Acetate: - (A) Manufacturing ProcessShankar kumar royNo ratings yet

- 19.) Copper Gluconate: - (A) Manufacturing ProcessDocument2 pages19.) Copper Gluconate: - (A) Manufacturing ProcessShankar kumar royNo ratings yet

- Flowdiagram of Disperse Blue 79Document4 pagesFlowdiagram of Disperse Blue 79kanji63No ratings yet

- 0 0 1211812181211ManufacturingProcessDocument17 pages0 0 1211812181211ManufacturingProcessLUISNo ratings yet

- Isolation of Potassium Carbonate From Banana Plant (Musa Balbisiana)Document17 pagesIsolation of Potassium Carbonate From Banana Plant (Musa Balbisiana)zawNo ratings yet

- Presentation On DM PlantDocument16 pagesPresentation On DM PlantVenkat Dora100% (4)

- Acid Purification and RecoveryDocument4 pagesAcid Purification and RecoverythiagoNo ratings yet

- 4,7-Dichloroquinoline: Molecular Formula: Molecular Weight: Cas NumberDocument5 pages4,7-Dichloroquinoline: Molecular Formula: Molecular Weight: Cas NumberShankar kumar royNo ratings yet

- Magnesium Acetate: - (A) Manufacturing ProcessDocument2 pagesMagnesium Acetate: - (A) Manufacturing ProcessShankar kumar royNo ratings yet

- 18.) Calcium Stearate: (A) Manufacturing ProcessDocument2 pages18.) Calcium Stearate: (A) Manufacturing ProcessShankar kumar royNo ratings yet

- Indole Synthesis - Something Old, Something NewDocument13 pagesIndole Synthesis - Something Old, Something NewShankar kumar royNo ratings yet

- 21.) Potassium Oxalate: (A) Manufacturing ProcessDocument2 pages21.) Potassium Oxalate: (A) Manufacturing ProcessShankar kumar roy100% (1)

- 20.) Calcium Gluconate: - (A) Manufacturing ProcessDocument2 pages20.) Calcium Gluconate: - (A) Manufacturing ProcessShankar kumar royNo ratings yet

- 19.) Copper Gluconate: - (A) Manufacturing ProcessDocument2 pages19.) Copper Gluconate: - (A) Manufacturing ProcessShankar kumar royNo ratings yet

- Standard Operating ProcedureDocument8 pagesStandard Operating ProcedureShankar kumar royNo ratings yet

- Parahydroxy Acetophenone SynthesisDocument1 pageParahydroxy Acetophenone SynthesisShankar kumar royNo ratings yet

- Facility and AHU ValidationDocument63 pagesFacility and AHU ValidationShankar kumar roy100% (3)

- Ethoxy CarbazepineDocument27 pagesEthoxy CarbazepineShankar kumar royNo ratings yet