Professional Documents

Culture Documents

O2X1 Panametrics Oxygen Transmitter Datasheet

O2X1 Panametrics Oxygen Transmitter Datasheet

Uploaded by

dingOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

O2X1 Panametrics Oxygen Transmitter Datasheet

O2X1 Panametrics Oxygen Transmitter Datasheet

Uploaded by

dingCopyright:

Available Formats

GE

Sensing & Inspection Technologies

O2X1

Panametrics Oxygen

Transmitter

Applications Features

An oxygen transmitter for use in: • Intrinsically safe

• Heat treating and bright annealing • Two-wire, loop-powered 4 to 20 mA transmitter

• Process monitoring of gaseous monomers • Proven galvanic fuel cell O2 sensor technology

• Pure gaseous hydrocarbon streams • Programmable ranges for ppm and percent

oxygen

• Inert welding gases

• Microprocessor-based, all-digital technology for

• Glove box leak detection reliable operation

• Ambient air monitor • Continuous monitoring

• Low maintenance

• Economical and compact

Panametrics Oxygen Transmitter Control at the Tip of a Finger

The O2X1 is a highly reliable and cost-effective two-wire, The rugged O2X1 is controlled by a microprocessor that

loop-powered transmitter with a linearized 4 to 20 mA enables the user to select the range, trim outputs and

output. It measures oxygen in four ppm ranges (10; 100; perform calibration. Programming is easily done using the

1,000 and 10,000 ppm) and three percentage ranges (1, three-button keypad and the three light-emitting diodes

10, and 25%). All ranges are user-programmable. This (LEDs). These switches allow complete functionality in

compact transmitter uses proven sensor technology hazardous areas when equipped with an MTL706 barrier.

to accurately measure O2 in a variety of gases, even in

hazardous environments.

Installation Flexibility

Proven Sensor Technology The compact O2X1, with its built-in microprocessor, is

designed to fit easily into any installation site. The O2X1

The O2X1’s oxygen sensor is an advanced galvanic can be installed right at the sampling point, whereas

fuel cell that provides superior performance, accuracy, other transmitters must be rack or panel mounted.

stability and long life. The cell’s innovative design

eliminates the potential for negative signal output,

reduces sources of contamination and eliminates Sample Systems

electrolyte leakage.

In addition to standard features and options, GE offers

The cell is unaffected by other background gases or a full line of sample handling systems for a variety

hydrocarbons and is compatible with acid gases (OX-2 of applications. If needed, GE can design and build a

and OX-4 cells). Recovery from air at low ppm levels takes sample conditioning system to meet unique application

just a few minutes. Because the cell is self-contained, requirements. Please contact GE for details.

little maintenance is required. There is no electrolyte to

change or electrodes to clean. Oxygen Sensor Interference Gases

Intrinsically Safe Gas OX-1 and OX-5, OX-2, ppm OX-3, % OX-4%

ppm Cont. Cont. Cont. Int. (1) Cont. Int.

When equipped with the optional MTL706 barriers, the H2S <5 ppm <10 ppm 0.0005% 0.01% 0.001% 0.1%

O2X1 can be mounted in a hazardous (classified) location SO3 <10 ppm <10 ppm 0.01% 0.1% 0.01% 0.1%

as defined by the National Electrical Code (NEC). The SO2 <10 ppm (3) 0.01% 0.1% (3) (3)

O2X1 316 stainless steel package is FM approved as

HCI <1000 ppm (3) 0.1% 1.0% (3) (3)

intrinsically safe for use in Class I, II, III; Division 1; Groups

HCN <1000 ppm (3) 0.1% 1.0% (3) (3)

A,B,C,D,E, F&G hazardous (indoor/outdoor) Type 4X

CO2 <1000 ppm (3) 0.1% 20% (3) (3)

locations, and is certified by BASEEFA II 1 G EEx ia IIC T4

(Tamb = –20°C to +60°C) NO2 (2) (2) (2) (2) (2) (2)

CL2 (2) (2) (2) (2) (2) (2)

Cont. = Continuous, Int. = Intermittent

(1) Recommended maximum exposure 30 minutes followed by flushing with

ambient air for equal period

(2) Minimal effect on sensor performance, but produces signal interference of

1:2 ratio

(3) Minimal effect on sensor performance

O2X1 Field Programmable

Measurement Ranges

Specifications • Ppm sensors:

– 0 to 10 ppmv O2 (OX-1 or OX-2 in 316 stainless steel

package only)

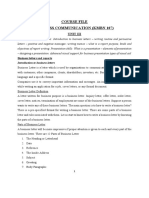

Intrinsically Safe (IS) Installation – 0 to 100 ppmv O2

Intrinsically safe installations require an MTL706 zener – 0 to 1000 ppmv O2

barrier, one IS cable and one non-IS cable. – 0 to 10,000 ppmv O2

• Percent sensors:

– 0% to 1% O2

Power Requirements

– 0% to 10% O2

24 to 28 VDC at 50 mA

– 0% to 25% O2

Cable

Accuracy

• OCI-*F-T5 in hazardous area: Two-conductor, twisted

• ±1% of span at calibration point

pair with connector; 22 AWG; 1100 ft (335 m) maximum

• ±2% of span at the calibration point for the 0 to 10

cable length

ppmv range (OX-1 or OX-2 in 316 stainless steel

• OCG-*F-0 in non-hazardous (safe) area:

package only)

Three-conductor; 22 AWG; 4000 ft (1219 m) maximum

cable length

Repeatability

• ±1% of span

Output

• ±2% of span for the 0 to 10 ppmv range (OX-1 or OX-2

Total load must equal 250 Ω ±5%

in 316 stainless steel package only)

Non-Hazardous (Safe) Installation Resolution

No zener barrier is used. ±0.1% of span

Process Wetted Materials Linearity

• SS process unit: 316 stainless steel, Viton® O-ring and ±2% of span

polytetrafluoroethylene

• Delrin® process unit: Delrin, Viton O-ring and Operating Temperature

polytetrafluoroethylene 32°F to 113°F (0°C to 45°C)

• Ambient air monitoring unit: Delrin, Viton O-ring and

polytetrafluoroethylene

Ambient Temperature Effect

±3% of reading over operating temperature range

Power Requirements

9 to 28 VDC loop powered, 0.6 W max

Sample Pressure

Vented to atmosphere during operation and calibration

Cable

OCG-*F-T5: 2 conductor, twisted pair with connector;

22 AWG; 0.04 Ω/ft; 4000 ft (1219 m) maximum cable

Atmospheric Pressure Effect

±0.13% of reading per mmHg (directly proportional to

length

absolute pressure). During calibration, pressure and flow

must be kept constant.

Output

Max. load (Ω) = [40 Ω x (PSV – 8)] – RC where:

PSV = power supply voltage in VDC, and

Process Connection

• 316 stainless steel and Delrin process units: 1/8 in NPT

RC = cable resistance (22 AWG cable has 0.04 Ω/ft)

inlet and outlet

• Ambient air monitoring unit: None

Example:

Given a 24 VDC power supply and a 1000 ft (305 m)

cable (22 AWG, 0.04 Ω/ft),

RC = 1000 ft x 0.04 Ω/ft = 40 Ω

Max. load = [40 x (24 – 8)] – 40

= [40 x 16] – 40

= 600 Ω

Sample Flow Rate Order and Calibration Information

1.0 SCFH (500 cc/min) recommended for process units

Electrical Classification/Certification Record selected option in blank indicated at bottom of form.

O2X1 Oxygen Transmitter

• Weatherproof, 316 stainless steel and Delrin process Sensor

packages only: Type 4X/IP66 0 None

• Intrinsically safe, 316 stainless steel package only: Class 1 Standard ppm, 0 to 10 ppm

2 Acid ppm, 0 to 10, 100 and 1000 ppm

I, II, III; Division 1; Group A,B,C,D,E,F&G;

3 Standard %

FM/CSA 4 Acid %

II 1 G EEx ia IIC T4 5 Standard ppm, 0 to 100 and 1000 ppm

(Tamb = –20°C to +60°C); Package

0 316 stainless steel process FM/CSA

BAS01ATEX1094X

1 Delrin process

316 stainless steel ATEX compliance with EN50104 from 2 Delrin ambient air monitoring

32°F to 104°F (0°C to 40°C) 3 316 stainless steel process ATEX

9 316 stainless steel general purpose

European Compliance

O2X1 – __ __ Use this number to order product

Complies with EMC Directive 89/336/EEC OX Spare Oxygen Sensor

Sensor

1 Standard ppm, 0 to 10 ppm

2 Acid ppm, 0 to 10, 100 and 1000 ppm

3 Standard %

4 Acid %

5 Standard ppm, 0 to 100 and 1000 ppm

OX – __ Use this number to order product

Hazardous Location Non-Hazardous (Safe) Location

ZBB

bus bar

Power supply

Red 24V

Black

3 1

O2X1 Transmitter

4 2

24V return

Green

MTL706

barrier Black

Red

OCB-*F-T5

IS cable IS

ground

*Specify cable length in ft(m) - R1 +

1. Equipment connected to barrier inputs must not use or Green

generate more than 250V. OCB-*F-0

2. Total load of R1 + R2 must equal 250Ω ±5%. non-IS cable

R2

Power supply

Red 24V

O2X1 Transmitter

24V return

Black 4 to 20 mA

analog input

OCB-*F-T5

non-IS cable device

*Specify cable length in ft(m)

Maximum load of analog input device is dependent on

power supply voltage and cable resistance.

O2X1 intrinsically safe installation (top) and non-hazardous (safe) installation (bottom).

www.gesensinginspection.com

920-040D

© 2009 General Electric Company. All Rights Reserved. Specifications are subject to change without notice. GE is a registered trademark of General Electric Company. Other company or product

names mentioned in this document may be trademarks or registered trademarks of their respective companies, which are not affiliated with GE.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Manolo Fortich Christian AcademyDocument10 pagesManolo Fortich Christian AcademyYan YanNo ratings yet

- Salt in Crude - ORB P600APR14Document4 pagesSalt in Crude - ORB P600APR14dingNo ratings yet

- APX Panametrics Paramagnetic Oxygen Analyzer PDFDocument4 pagesAPX Panametrics Paramagnetic Oxygen Analyzer PDFdingNo ratings yet

- PT878 Portable Ultrasonic Flow Meter DatasheetDocument8 pagesPT878 Portable Ultrasonic Flow Meter DatasheetdingNo ratings yet

- Sentinel Liquid Custody Transfer Flow Meter DatasheetDocument8 pagesSentinel Liquid Custody Transfer Flow Meter DatasheetdingNo ratings yet

- Rheonik Coriolis Flow Meters BrochureDocument12 pagesRheonik Coriolis Flow Meters BrochuredingNo ratings yet

- Womb As OasisDocument18 pagesWomb As OasisMaria Paula SuarezNo ratings yet

- Factoring Flow Sheet PDFDocument7 pagesFactoring Flow Sheet PDFReginald LopezNo ratings yet

- Formulation Development and Compatibility Study of Dexketoprofen Injection Used in The Management of Post-Operative PainDocument7 pagesFormulation Development and Compatibility Study of Dexketoprofen Injection Used in The Management of Post-Operative PainAdeeva MaulidaNo ratings yet

- Steam Air Ejector Performance and Its Dimensional ParametersDocument296 pagesSteam Air Ejector Performance and Its Dimensional ParametersGuru Raja Ragavendran NagarajanNo ratings yet

- P Block Elements Group 15Document79 pagesP Block Elements Group 1515 Kabir Sharma 10 HNo ratings yet

- MK17C01-Group 3-MKT328m-Final Report DIFFERENTDocument14 pagesMK17C01-Group 3-MKT328m-Final Report DIFFERENTTran Minh Quy (K17 QN)No ratings yet

- DNA For The Defense BarDocument192 pagesDNA For The Defense BarshaninroseNo ratings yet

- Durastor Tank Brochure PDFDocument8 pagesDurastor Tank Brochure PDFhamadaniNo ratings yet

- 03 - Information PackagesDocument13 pages03 - Information Packagesyusi cantikNo ratings yet

- BỘ ĐỀ IELTS SPEAKING QUÝ 1-2023Document14 pagesBỘ ĐỀ IELTS SPEAKING QUÝ 1-2023phuongNo ratings yet

- Yama Zatdaw: MyanmarDocument3 pagesYama Zatdaw: MyanmarC.N. KrishnaNo ratings yet

- FOI 20210117 1 Data SetDocument82 pagesFOI 20210117 1 Data Setabrar mahir SahilNo ratings yet

- Music LPDocument3 pagesMusic LPLeann VictorianoNo ratings yet

- Decribing Connections Between Historical EventsDocument4 pagesDecribing Connections Between Historical Eventsapi-334916201No ratings yet

- KB Shape CodesDocument9 pagesKB Shape CodesPrashanth TNo ratings yet

- BC KMBN107 Unit 3Document26 pagesBC KMBN107 Unit 3Rizwan SaifiNo ratings yet

- Elastomeric Fibres - Fibres With Elastic CapabilityDocument5 pagesElastomeric Fibres - Fibres With Elastic Capability9043785763No ratings yet

- Assignment#2 Submitted To: Dr. Aliya Submitted By: Issma Munir Abbasi MS-SP-19-REL-013Document3 pagesAssignment#2 Submitted To: Dr. Aliya Submitted By: Issma Munir Abbasi MS-SP-19-REL-013issma abbasiNo ratings yet

- MINI2-2 Ravens Under The Midday SunDocument40 pagesMINI2-2 Ravens Under The Midday SunKen JacobsenNo ratings yet

- Ivory Standalone (PC) User GuideDocument5 pagesIvory Standalone (PC) User GuideToshiro NakagauaNo ratings yet

- 4 - The Finite Volume Method For Convection-Diffusion Problems - 2Document25 pages4 - The Finite Volume Method For Convection-Diffusion Problems - 2Abaziz Mousa OutlawZzNo ratings yet

- Digital Bangladesh PresentationDocument16 pagesDigital Bangladesh PresentationMd. Zahid HossainNo ratings yet

- Economic Zoology: Learning ObjectivesDocument8 pagesEconomic Zoology: Learning ObjectiveshamzaNo ratings yet

- Protocols and Methodologies in Basic Science and Clinical Cardiac MRI (PDFDrive)Document445 pagesProtocols and Methodologies in Basic Science and Clinical Cardiac MRI (PDFDrive)Roberto DuniNo ratings yet

- Conclusion ParagraphDocument7 pagesConclusion Paragraphapi-334926654No ratings yet

- Lab Education English Mock Exam - Question Answer BookDocument14 pagesLab Education English Mock Exam - Question Answer BookMichelle ChungNo ratings yet

- BUET Undergraduate Admission Test 2019-2020: Department Allocation (6th Run) of Admitted Candidates (Engineering & URP)Document20 pagesBUET Undergraduate Admission Test 2019-2020: Department Allocation (6th Run) of Admitted Candidates (Engineering & URP)AnasNo ratings yet

- Joint Patterns - Retaining WallDocument3 pagesJoint Patterns - Retaining WallFeby Adryan SitorusNo ratings yet

- Social Studies K-5Document75 pagesSocial Studies K-5SriniNo ratings yet