Professional Documents

Culture Documents

ACumist-micronized-polyolefin-wax - Products-List

ACumist-micronized-polyolefin-wax - Products-List

Uploaded by

APEX SONCopyright:

Available Formats

You might also like

- Araldite 2015: Advanced MaterialsDocument6 pagesAraldite 2015: Advanced MaterialsFilipe Alberto MagalhaesNo ratings yet

- AEROSIL® 200: Description Typical ApplicationsDocument1 pageAEROSIL® 200: Description Typical ApplicationsAPEX SONNo ratings yet

- Wax Additives: High PerformanceDocument8 pagesWax Additives: High PerformanceAPEX SONNo ratings yet

- TDS MP3Document1 pageTDS MP3catpilar274No ratings yet

- DC 1000Document2 pagesDC 1000bassemreda72No ratings yet

- Cepsa Engranajes HPDocument1 pageCepsa Engranajes HPRamonNo ratings yet

- Turbine EngDocument1 pageTurbine EngPeter_Phee_341No ratings yet

- Five Star GroutDocument2 pagesFive Star GroutCHIMA ikechukwuNo ratings yet

- Ceramite T: Bauxite and Silicon Carbide Based Trowellable RefractoryDocument2 pagesCeramite T: Bauxite and Silicon Carbide Based Trowellable RefractorySHRINIVASAN GTKNo ratings yet

- ArChine AC-9907-68 (E)Document2 pagesArChine AC-9907-68 (E)Siti MustanirohNo ratings yet

- HM 500-1Document4 pagesHM 500-1Praveen Natalie HeynsberghNo ratings yet

- Cepsa Fundicol Hfu: Lubricants For Industrial UseDocument1 pageCepsa Fundicol Hfu: Lubricants For Industrial UseVladislav TrempoletsNo ratings yet

- EnergyShield Pro-DataSheetDocument2 pagesEnergyShield Pro-DataSheetantonio angaritaNo ratings yet

- Carbomastic 15 PDSDocument4 pagesCarbomastic 15 PDSRiyaz Basheer100% (1)

- Phenoline 187 Primer and FinishDocument2 pagesPhenoline 187 Primer and Finish이선엽No ratings yet

- Safety-Walk™ Cushion Matting 5270 - 5270E: Technical DataDocument3 pagesSafety-Walk™ Cushion Matting 5270 - 5270E: Technical DataMichael TadrosNo ratings yet

- Gear Oil - 90, 140, 80W90, 85W140Document2 pagesGear Oil - 90, 140, 80W90, 85W140Mouad EN-NAKORINo ratings yet

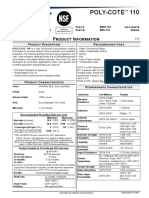

- Poly-Cote 110 (Aug'22)Document4 pagesPoly-Cote 110 (Aug'22)David cNo ratings yet

- Carboguard 193 PrimerDocument2 pagesCarboguard 193 Primerdibujante3No ratings yet

- GL XX Mobil SHC Elite SeriesDocument3 pagesGL XX Mobil SHC Elite SeriesFulkan HadiyanNo ratings yet

- Adeco Graphite Grease: Technical Data SheetDocument1 pageAdeco Graphite Grease: Technical Data SheetVelibor KaranovicNo ratings yet

- Hm-180c3p CFRP Fabric Epoxy Tds - HorseDocument8 pagesHm-180c3p CFRP Fabric Epoxy Tds - HorseRonald CatequistaNo ratings yet

- Tech Uddeholm Ramax HH ENDocument8 pagesTech Uddeholm Ramax HH ENwrh9rqr22vNo ratings yet

- Ramax Hh-Eng P 1604 E6Document8 pagesRamax Hh-Eng P 1604 E6venkithankamNo ratings yet

- Icr-6025 6027 (GP1)Document1 pageIcr-6025 6027 (GP1)duwiNo ratings yet

- BP Energrease LSDocument2 pagesBP Energrease LSsaddamNo ratings yet

- Foodmax Grease CAS S LSDocument2 pagesFoodmax Grease CAS S LSALFREDO CANTOS CORNEJONo ratings yet

- Girth Gear HD GreaseDocument2 pagesGirth Gear HD GreaseJuan RenteriaNo ratings yet

- Technical Details of Bonding ChemicalsDocument18 pagesTechnical Details of Bonding ChemicalsSangeet KarnaNo ratings yet

- Carter Ogl 1000 M PDFDocument1 pageCarter Ogl 1000 M PDFAnibal RiosNo ratings yet

- Hard Chrome Plated Bars and Tubes Cromax OvakoDocument12 pagesHard Chrome Plated Bars and Tubes Cromax Ovakoمعين الظفاريNo ratings yet

- Aluminium Casting Alloy (AL - Si12) : Home About Us Processes Design Quality Products Technical ContactDocument3 pagesAluminium Casting Alloy (AL - Si12) : Home About Us Processes Design Quality Products Technical Contactrafdinal.sNo ratings yet

- Poly Gear PG en PDFDocument2 pagesPoly Gear PG en PDFAlfredo CarlosNo ratings yet

- Interface Solutions Gasket MaterialsDocument7 pagesInterface Solutions Gasket MaterialsBerkah PowerindoNo ratings yet

- Phenoline 187 Finish PDSDocument2 pagesPhenoline 187 Finish PDSalejandroNo ratings yet

- Ceran-Xm-220 TDS v171128Document2 pagesCeran-Xm-220 TDS v171128phucdc095041No ratings yet

- VCAS Type GE White Pozzolans TDS 200601Document2 pagesVCAS Type GE White Pozzolans TDS 200601Seoudi AbdelhafidNo ratings yet

- Petronas Pressol: Premium Grade Air Compressor OilsDocument1 pagePetronas Pressol: Premium Grade Air Compressor OilsMujeeb SiddiqueNo ratings yet

- Cepsa Circulante 150Document1 pageCepsa Circulante 150RamonNo ratings yet

- Puma HD Drive Train 10W 30 40 50 TDSDocument2 pagesPuma HD Drive Train 10W 30 40 50 TDSHakim AmmorNo ratings yet

- Repsol DXR 8 - 1 v1 15w40Document1 pageRepsol DXR 8 - 1 v1 15w40thrharsrgNo ratings yet

- Sanitile 120 PDSDocument4 pagesSanitile 120 PDSDuongthithuydungNo ratings yet

- AA 3105-F Tread/Chequered Plates: Aluminium AlloyDocument1 pageAA 3105-F Tread/Chequered Plates: Aluminium AlloyAbolfazl HabibiNo ratings yet

- Foamglas Pipe Insulation: Specialty Products & Insulation CoDocument2 pagesFoamglas Pipe Insulation: Specialty Products & Insulation CoSteven ZukNo ratings yet

- Sinopec EP Golden GreaseDocument2 pagesSinopec EP Golden GreaseYoong TanNo ratings yet

- Corro-Coat PE-F Façade: Series 1301, 1303, 1307 and 1308Document2 pagesCorro-Coat PE-F Façade: Series 1301, 1303, 1307 and 1308girlie fabroNo ratings yet

- PDS KomAirDocument2 pagesPDS KomAireffendi.successNo ratings yet

- PDS - Zest Industrial Gear Oil EPDocument2 pagesPDS - Zest Industrial Gear Oil EPhimanshu lalwaniNo ratings yet

- Epibear: Technical DatasheetDocument3 pagesEpibear: Technical DatasheetBogdanBNo ratings yet

- Repsol Tauro PDFDocument1 pageRepsol Tauro PDFrandiNo ratings yet

- PETRONAS - Grease Li EP 0 - 10 10 2018Document3 pagesPETRONAS - Grease Li EP 0 - 10 10 2018Amira Shukor100% (1)

- IOCL Steel Conference 070618Document31 pagesIOCL Steel Conference 070618prasad24488No ratings yet

- WL CNG MOTOR ENGINE OIL PDS - AsdDocument1 pageWL CNG MOTOR ENGINE OIL PDS - AsdAung Myat ThuNo ratings yet

- Product Data Sheet: Akzonobel Powder CoatingsDocument3 pagesProduct Data Sheet: Akzonobel Powder CoatingsFerhat ÖzcanNo ratings yet

- Humiseal 1B31 English TdsDocument2 pagesHumiseal 1B31 English TdsLee HitchensNo ratings yet

- Reactamine 760: Selection & Specification DataDocument4 pagesReactamine 760: Selection & Specification DataPrakashNo ratings yet

- Bill Mosley John Bungey & Ray Hulse: Reinforced Concrete Design To EC2Document36 pagesBill Mosley John Bungey & Ray Hulse: Reinforced Concrete Design To EC2RyanWongJiaHanNo ratings yet

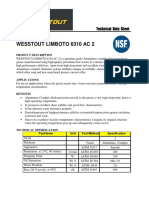

- TDS Wesstout Limboto 6310 ACDocument1 pageTDS Wesstout Limboto 6310 ACKristomiDerMarine-IngenieurNo ratings yet

- Transmissions To4 10w 30 and 50 en tcm14-189615Document1 pageTransmissions To4 10w 30 and 50 en tcm14-189615agung fals dwi cahyonoNo ratings yet

- Decorative Exterior Paints: Performance & Binder Design Trends in Asia PacificDocument27 pagesDecorative Exterior Paints: Performance & Binder Design Trends in Asia PacificAPEX SONNo ratings yet

- APCJ 2017oct Acronal ECO 7653Document4 pagesAPCJ 2017oct Acronal ECO 7653APEX SONNo ratings yet

- CCJ 2017nov Acronal ECO 7653Document7 pagesCCJ 2017nov Acronal ECO 7653APEX SONNo ratings yet

- Product List: Additives and Resins For Liquid CoatingsDocument12 pagesProduct List: Additives and Resins For Liquid CoatingsAPEX SONNo ratings yet

- The State of The Art in Raw Materials For The Building & Construction IndustryDocument22 pagesThe State of The Art in Raw Materials For The Building & Construction IndustryAPEX SONNo ratings yet

- Coatosil MP 200: Technical Data SheetDocument7 pagesCoatosil MP 200: Technical Data SheetAPEX SONNo ratings yet

- Acronal NX 3587 - Product InformationDocument3 pagesAcronal NX 3587 - Product InformationAPEX SONNo ratings yet

- Coatosil MP 200: Technical Data SheetDocument7 pagesCoatosil MP 200: Technical Data SheetAPEX SONNo ratings yet

- coatosil-mp-200-TDS - TR DÍNHDocument3 pagescoatosil-mp-200-TDS - TR DÍNHAPEX SONNo ratings yet

- AEROSIL® 200: Hydrophilic Fumed SilicaDocument2 pagesAEROSIL® 200: Hydrophilic Fumed SilicaAPEX SONNo ratings yet

- CoatOSil MP 200 Silane WB and SB CoatingsDocument8 pagesCoatOSil MP 200 Silane WB and SB CoatingsAPEX SONNo ratings yet

- Product Catalogue EN PDFDocument104 pagesProduct Catalogue EN PDFAPEX SONNo ratings yet

- Primal™ Gc-5 Er: Technical Data SheetDocument2 pagesPrimal™ Gc-5 Er: Technical Data SheetAPEX SONNo ratings yet

- Aerosil® 200 V: Densified Hydrophilic Fumed SilicaDocument2 pagesAerosil® 200 V: Densified Hydrophilic Fumed SilicaAPEX SONNo ratings yet

- Additives FOR Specialty Chemistry Formulations pER Function: Product ListDocument16 pagesAdditives FOR Specialty Chemistry Formulations pER Function: Product ListAPEX SONNo ratings yet

- Foamstar ST 2412: Formulation AdditivesDocument2 pagesFoamstar ST 2412: Formulation AdditivesAPEX SONNo ratings yet

- Foamaster Mo NDW: PropertiesDocument2 pagesFoamaster Mo NDW: PropertiesAPEX SONNo ratings yet

- P50 MSDSDocument9 pagesP50 MSDSAPEX SONNo ratings yet

- Waterborne Epoxy Coating SystemsDocument24 pagesWaterborne Epoxy Coating SystemsAPEX SONNo ratings yet

- Industrial Coatings: Recommended ProductsDocument2 pagesIndustrial Coatings: Recommended ProductsAPEX SONNo ratings yet

- Corotech V440 - TDS EN OKF PDFDocument3 pagesCorotech V440 - TDS EN OKF PDFAPEX SONNo ratings yet

- AquaPoly 250 TDSDocument1 pageAquaPoly 250 TDSAPEX SONNo ratings yet

- Reichhold: Coating Resins CatalogDocument35 pagesReichhold: Coating Resins CatalogAPEX SON100% (1)

- Industrial Floor Coatings: Recommended ProductsDocument2 pagesIndustrial Floor Coatings: Recommended ProductsAPEX SONNo ratings yet

- How To Disperse Micronized WaxDocument4 pagesHow To Disperse Micronized WaxAPEX SONNo ratings yet

- High Performance: Wax AdditivesDocument36 pagesHigh Performance: Wax AdditivesAPEX SONNo ratings yet

- Architectural Coatings: Recommended ProductsDocument2 pagesArchitectural Coatings: Recommended ProductsAPEX SONNo ratings yet

- Specialty Fine Powders and ExfoliantsDocument20 pagesSpecialty Fine Powders and ExfoliantsAPEX SONNo ratings yet

- Strontium ChlorideDocument3 pagesStrontium ChloridenishchayNo ratings yet

- Production of Antibiotics: Penicillin. StreptomycinDocument21 pagesProduction of Antibiotics: Penicillin. Streptomycinkayalsmitha33% (3)

- Shalisulphide: STP Limited Two Component Coal Tar Poly Sulphide SystemDocument2 pagesShalisulphide: STP Limited Two Component Coal Tar Poly Sulphide SystemPrashantBaruaNo ratings yet

- Introduction To Oil and GasDocument36 pagesIntroduction To Oil and GasPetroleum PetroleumNo ratings yet

- N, N-Diethyl M-Toluamide (OFF)Document3 pagesN, N-Diethyl M-Toluamide (OFF)Denisse Watt CuarterosNo ratings yet

- 9701/21/M/J/20 © Ucles 2020Document10 pages9701/21/M/J/20 © Ucles 2020Fire stormNo ratings yet

- Sample Paper at 2324 Class Viii p1 At+pcbm BioDocument4 pagesSample Paper at 2324 Class Viii p1 At+pcbm Biorameshhh1980No ratings yet

- Blotting Assignment by MPhil 5,12Document31 pagesBlotting Assignment by MPhil 5,12Amina ChNo ratings yet

- View JournalDocument1,079 pagesView JournalnamandamanNo ratings yet

- Price ListDocument38 pagesPrice ListERVINTIANo ratings yet

- Leybonol Lvo 210Document38 pagesLeybonol Lvo 210J. Carlos Alvarez C.No ratings yet

- Common Name of Organic CompoundsDocument7 pagesCommon Name of Organic CompoundsSuarNo ratings yet

- VermicompostingDocument19 pagesVermicompostingRitu JainNo ratings yet

- PFD Write UpDocument2 pagesPFD Write UpZeeshan WaheedNo ratings yet

- SKsen PaperDocument13 pagesSKsen PaperKoushik SenNo ratings yet

- Acceptability of Oregano and Lemon Grass Ready To Drink Tea: KeywordsDocument24 pagesAcceptability of Oregano and Lemon Grass Ready To Drink Tea: KeywordsJashley Munar HernandezNo ratings yet

- Chemical MediaDocument21 pagesChemical MediaBharath wajNo ratings yet

- Day 29 - Daily MCQ Workout - 40 Revision MCQsDocument5 pagesDay 29 - Daily MCQ Workout - 40 Revision MCQsnorah araujoNo ratings yet

- ™ Polyvinylidene Chloride (PVDC) Resins: SaranDocument6 pages™ Polyvinylidene Chloride (PVDC) Resins: SaranMichael Gonzales BaldeonNo ratings yet

- CIS1175 Compost PDFDocument8 pagesCIS1175 Compost PDFJoselyn Vanessa Seminario PeñaNo ratings yet

- Mobil Dte Oil Light MsdsDocument13 pagesMobil Dte Oil Light MsdsNaseemNo ratings yet

- Distribution of Acetic Acid Between Two Immiscible Solution by Simple Simple Methods PapooDocument11 pagesDistribution of Acetic Acid Between Two Immiscible Solution by Simple Simple Methods PapooHasnain SaifiNo ratings yet

- An Efficient and Sustainable Catalytic Reduction of Carbon-Carbon Multiple Bonds, Aldehydes, and Ketones Using Cu Nanoparticles Decorated Metal Organic FrameworkDocument12 pagesAn Efficient and Sustainable Catalytic Reduction of Carbon-Carbon Multiple Bonds, Aldehydes, and Ketones Using Cu Nanoparticles Decorated Metal Organic FrameworkCường NguyễnNo ratings yet

- Yeast Based Biorefineries For Oleochemical Production: SciencedirectDocument9 pagesYeast Based Biorefineries For Oleochemical Production: SciencedirectAnggaNo ratings yet

- prEN16723 2Document24 pagesprEN16723 2Ricardo Lourenço100% (1)

- BIOMASSA BIOETANOLDocument8 pagesBIOMASSA BIOETANOLhendy giritamaNo ratings yet

- 01403-22-23-Veera Speciality Coatings & Chemicals PDFDocument1 page01403-22-23-Veera Speciality Coatings & Chemicals PDFSiva prasadhNo ratings yet

- Erbicide LeguminoaseDocument28 pagesErbicide LeguminoaseliviugruiaNo ratings yet

- CHEM F311 Lecture 38 39 1,5-Dicarbonyl CompoundsDocument9 pagesCHEM F311 Lecture 38 39 1,5-Dicarbonyl Compoundsliving luxuriousNo ratings yet

- IUPAC Nomenclaute, Structural Isomerism & Practical Organic ChemistryDocument35 pagesIUPAC Nomenclaute, Structural Isomerism & Practical Organic ChemistryAmit Tiwari100% (1)

ACumist-micronized-polyolefin-wax - Products-List

ACumist-micronized-polyolefin-wax - Products-List

Uploaded by

APEX SONOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ACumist-micronized-polyolefin-wax - Products-List

ACumist-micronized-polyolefin-wax - Products-List

Uploaded by

APEX SONCopyright:

Available Formats

Honeywell ACumist® Micronized Polyolefin Waxes

Typical Properties

Mettler

Drop Acid #

Microns Point Density Hardness Mg KOH/g

Microns Maximum ASTM (g/cc) ASTM (dmm) ASTM

Product Avg (mv) (<99.90%) D-3954 D-1505 ASTM D-5 D-1386 Performance Advantages

High Density Oxidized Polyethylene Homopolymers • Surface functionality for water wettability and to promote

ACumist® A-6 6.0 to 7.5 22 adhesion to topcoats

ACumist® A-12 10.0 to 13.0 44 • Outstanding slip, abrasion resistance and toughness

137oC

ACumist® A-18 16.0 to 19.0 62 279oF 0.99 <0.5 26 to 40 • Controlled maximum particle size for a consistent grind

®

• For solvent, water and UV based systems

ACumist A-45 30.0 to 40.0 125

• Excellent matting without burnishing

139oC • Special FDA 175.300 compliant oxidized HDPE wax

ACumist® 1812 (2) 8.3 to 9.3 26

282oF

0.99 <0.5 16 to 19

• All comments above for “A” series also apply

Polyethylene Homopolymers • Insoluble in solvent and UV based systems at RT

ACumist® B-6 6.0 to 7.5 22 • Excellent abrasion resistance with good slip

ACumist® B-12 10.0 to 11.5 44 126oC • FDA 175.300 and other compliances

259oF 0.96 <1.0 Nil • Controlled maximum particle size for a consistent grind

ACumist® B-18 14.0 to 17.0 62

• Minimal gloss reduction

ACumist® C-3 3.5 to 4.2 13 • Insoluble in solvent and UV based systems at RT

ACumist® C-5 4.5 to 5.5 16 • Excellent slip with good abrasion resistance

121oC 0.95 <1.0 Nil • FDA 175.300 and other compliances

ACumist® C-12 10.0 to 13.0 44 250oF

62 • Controlled maximum particle size for a consistent grind

ACumist® C-18 14.0 to 17.0 • Good gloss retention for the smaller size grades

®

ACumist D-6 6.0 to 7.5 22

118oC

ACumist® D-9 8.0 to 10.0 31 0.94 <2.0 Nil • A good balance of properties and economy

244oF

ACumist® D-12 10.0 to 13.0 44

Polypropylene Homopolymer • High coefficient of friction for "non-skid" performance

ACumist® P-5 (2) 5.0 to 6.0 16 • Excellent abrasion resistance

ACumist® P-10 (2) 8.0 to 10.0 31 145oC 0.91 <0.5 Nil • Good matting performance

293oF • Controlled maximum particle size for a consistent grind

ACumist® P-20 (2) 18.0 to 22.0 88

Propylene Maleic Anhydride Copolymer • Copolymer functionality to promote adhesion to

o substrates and topcoats

® 152 C 87

ACumist 1863 (2) 6.0 to 7.5 22 0.93 <0.5 • Excellent non-slip and abrasion performance

306oF (SAP)

• For solvent, water and UV based systems

• Good matting performance

PTFE Modified Polyethylene

ACumist® 3105B (2) 6.0 to 7.5 22 126oC 0.98 • Enhanced slip and abrasion performance

®

ACumist 3205B (2)

6.0 to 7.5 22 259oF 1.10 • For higher performance applications

<0.5 Nil

121oC • Lowest particle size for thin film, high performance

ACumist® 3405 (2) 4.5 to 5.5 16

250oF

1.10

applications

Amide Modified Polyethylene • Provides sandability, matting with clarity, and soft feel

® (1,2) 143oC • Promotes slip and release in a wide range of coatings

ACumist 1528 6.0 to 7.5 22 0.97 <2.5 <5

289oF • Promotes gas release in powder coatings

(1) Developmental product. All properties are pending and subject to change. (2) Minimum order quantities and extended order lead times may apply.

OFFICES: Honeywell Europe / Middle East / Asia / Pacific

Corporate Headquarters Africa / India Honeywell

101 Columbia Road Honeywell Europe NV No.430, Li Bing Road

Morristown NJ, 07962 Specialty Additives Zhang Jiang, Hi-Tech Zone, Shanghai 201203

Tech Assistance: +1 973-455-5382 Haasrode Research Park China

Customer Service: +1 973-455-2145 Grauwmeer I Tel: +86 21-2894-2000

Toll Free in US: B-3001 Heverlee, Belgium Fax: +86 21-5855-3543

Tech Assistance: +1 800-451-9961 Tel: +32 16-391-211

Customer Service: +1 888-245-4738 Fax: +32 16-391-371

DISCLAIMER: Although all statements and information contained herein are believed to be accurate and reliable, they are presented without guarantee or

warranty of any kind, express or implied. Information provided herein does not relieve the user from the responsibility of carrying out its own tests and

experiments, and the user assumes all risks and liability for use of the information and results obtained. Statements or suggestions concerning the use of

materials and processes are made without representation or warranty that any such use is free of patent infringement and are not recommendations to

infringe any patent. The user should not assume that all toxicity data and safety measures are indicated herein or that other measures may not be required.

©2012 Honeywell International Inc. February 2012

You might also like

- Araldite 2015: Advanced MaterialsDocument6 pagesAraldite 2015: Advanced MaterialsFilipe Alberto MagalhaesNo ratings yet

- AEROSIL® 200: Description Typical ApplicationsDocument1 pageAEROSIL® 200: Description Typical ApplicationsAPEX SONNo ratings yet

- Wax Additives: High PerformanceDocument8 pagesWax Additives: High PerformanceAPEX SONNo ratings yet

- TDS MP3Document1 pageTDS MP3catpilar274No ratings yet

- DC 1000Document2 pagesDC 1000bassemreda72No ratings yet

- Cepsa Engranajes HPDocument1 pageCepsa Engranajes HPRamonNo ratings yet

- Turbine EngDocument1 pageTurbine EngPeter_Phee_341No ratings yet

- Five Star GroutDocument2 pagesFive Star GroutCHIMA ikechukwuNo ratings yet

- Ceramite T: Bauxite and Silicon Carbide Based Trowellable RefractoryDocument2 pagesCeramite T: Bauxite and Silicon Carbide Based Trowellable RefractorySHRINIVASAN GTKNo ratings yet

- ArChine AC-9907-68 (E)Document2 pagesArChine AC-9907-68 (E)Siti MustanirohNo ratings yet

- HM 500-1Document4 pagesHM 500-1Praveen Natalie HeynsberghNo ratings yet

- Cepsa Fundicol Hfu: Lubricants For Industrial UseDocument1 pageCepsa Fundicol Hfu: Lubricants For Industrial UseVladislav TrempoletsNo ratings yet

- EnergyShield Pro-DataSheetDocument2 pagesEnergyShield Pro-DataSheetantonio angaritaNo ratings yet

- Carbomastic 15 PDSDocument4 pagesCarbomastic 15 PDSRiyaz Basheer100% (1)

- Phenoline 187 Primer and FinishDocument2 pagesPhenoline 187 Primer and Finish이선엽No ratings yet

- Safety-Walk™ Cushion Matting 5270 - 5270E: Technical DataDocument3 pagesSafety-Walk™ Cushion Matting 5270 - 5270E: Technical DataMichael TadrosNo ratings yet

- Gear Oil - 90, 140, 80W90, 85W140Document2 pagesGear Oil - 90, 140, 80W90, 85W140Mouad EN-NAKORINo ratings yet

- Poly-Cote 110 (Aug'22)Document4 pagesPoly-Cote 110 (Aug'22)David cNo ratings yet

- Carboguard 193 PrimerDocument2 pagesCarboguard 193 Primerdibujante3No ratings yet

- GL XX Mobil SHC Elite SeriesDocument3 pagesGL XX Mobil SHC Elite SeriesFulkan HadiyanNo ratings yet

- Adeco Graphite Grease: Technical Data SheetDocument1 pageAdeco Graphite Grease: Technical Data SheetVelibor KaranovicNo ratings yet

- Hm-180c3p CFRP Fabric Epoxy Tds - HorseDocument8 pagesHm-180c3p CFRP Fabric Epoxy Tds - HorseRonald CatequistaNo ratings yet

- Tech Uddeholm Ramax HH ENDocument8 pagesTech Uddeholm Ramax HH ENwrh9rqr22vNo ratings yet

- Ramax Hh-Eng P 1604 E6Document8 pagesRamax Hh-Eng P 1604 E6venkithankamNo ratings yet

- Icr-6025 6027 (GP1)Document1 pageIcr-6025 6027 (GP1)duwiNo ratings yet

- BP Energrease LSDocument2 pagesBP Energrease LSsaddamNo ratings yet

- Foodmax Grease CAS S LSDocument2 pagesFoodmax Grease CAS S LSALFREDO CANTOS CORNEJONo ratings yet

- Girth Gear HD GreaseDocument2 pagesGirth Gear HD GreaseJuan RenteriaNo ratings yet

- Technical Details of Bonding ChemicalsDocument18 pagesTechnical Details of Bonding ChemicalsSangeet KarnaNo ratings yet

- Carter Ogl 1000 M PDFDocument1 pageCarter Ogl 1000 M PDFAnibal RiosNo ratings yet

- Hard Chrome Plated Bars and Tubes Cromax OvakoDocument12 pagesHard Chrome Plated Bars and Tubes Cromax Ovakoمعين الظفاريNo ratings yet

- Aluminium Casting Alloy (AL - Si12) : Home About Us Processes Design Quality Products Technical ContactDocument3 pagesAluminium Casting Alloy (AL - Si12) : Home About Us Processes Design Quality Products Technical Contactrafdinal.sNo ratings yet

- Poly Gear PG en PDFDocument2 pagesPoly Gear PG en PDFAlfredo CarlosNo ratings yet

- Interface Solutions Gasket MaterialsDocument7 pagesInterface Solutions Gasket MaterialsBerkah PowerindoNo ratings yet

- Phenoline 187 Finish PDSDocument2 pagesPhenoline 187 Finish PDSalejandroNo ratings yet

- Ceran-Xm-220 TDS v171128Document2 pagesCeran-Xm-220 TDS v171128phucdc095041No ratings yet

- VCAS Type GE White Pozzolans TDS 200601Document2 pagesVCAS Type GE White Pozzolans TDS 200601Seoudi AbdelhafidNo ratings yet

- Petronas Pressol: Premium Grade Air Compressor OilsDocument1 pagePetronas Pressol: Premium Grade Air Compressor OilsMujeeb SiddiqueNo ratings yet

- Cepsa Circulante 150Document1 pageCepsa Circulante 150RamonNo ratings yet

- Puma HD Drive Train 10W 30 40 50 TDSDocument2 pagesPuma HD Drive Train 10W 30 40 50 TDSHakim AmmorNo ratings yet

- Repsol DXR 8 - 1 v1 15w40Document1 pageRepsol DXR 8 - 1 v1 15w40thrharsrgNo ratings yet

- Sanitile 120 PDSDocument4 pagesSanitile 120 PDSDuongthithuydungNo ratings yet

- AA 3105-F Tread/Chequered Plates: Aluminium AlloyDocument1 pageAA 3105-F Tread/Chequered Plates: Aluminium AlloyAbolfazl HabibiNo ratings yet

- Foamglas Pipe Insulation: Specialty Products & Insulation CoDocument2 pagesFoamglas Pipe Insulation: Specialty Products & Insulation CoSteven ZukNo ratings yet

- Sinopec EP Golden GreaseDocument2 pagesSinopec EP Golden GreaseYoong TanNo ratings yet

- Corro-Coat PE-F Façade: Series 1301, 1303, 1307 and 1308Document2 pagesCorro-Coat PE-F Façade: Series 1301, 1303, 1307 and 1308girlie fabroNo ratings yet

- PDS KomAirDocument2 pagesPDS KomAireffendi.successNo ratings yet

- PDS - Zest Industrial Gear Oil EPDocument2 pagesPDS - Zest Industrial Gear Oil EPhimanshu lalwaniNo ratings yet

- Epibear: Technical DatasheetDocument3 pagesEpibear: Technical DatasheetBogdanBNo ratings yet

- Repsol Tauro PDFDocument1 pageRepsol Tauro PDFrandiNo ratings yet

- PETRONAS - Grease Li EP 0 - 10 10 2018Document3 pagesPETRONAS - Grease Li EP 0 - 10 10 2018Amira Shukor100% (1)

- IOCL Steel Conference 070618Document31 pagesIOCL Steel Conference 070618prasad24488No ratings yet

- WL CNG MOTOR ENGINE OIL PDS - AsdDocument1 pageWL CNG MOTOR ENGINE OIL PDS - AsdAung Myat ThuNo ratings yet

- Product Data Sheet: Akzonobel Powder CoatingsDocument3 pagesProduct Data Sheet: Akzonobel Powder CoatingsFerhat ÖzcanNo ratings yet

- Humiseal 1B31 English TdsDocument2 pagesHumiseal 1B31 English TdsLee HitchensNo ratings yet

- Reactamine 760: Selection & Specification DataDocument4 pagesReactamine 760: Selection & Specification DataPrakashNo ratings yet

- Bill Mosley John Bungey & Ray Hulse: Reinforced Concrete Design To EC2Document36 pagesBill Mosley John Bungey & Ray Hulse: Reinforced Concrete Design To EC2RyanWongJiaHanNo ratings yet

- TDS Wesstout Limboto 6310 ACDocument1 pageTDS Wesstout Limboto 6310 ACKristomiDerMarine-IngenieurNo ratings yet

- Transmissions To4 10w 30 and 50 en tcm14-189615Document1 pageTransmissions To4 10w 30 and 50 en tcm14-189615agung fals dwi cahyonoNo ratings yet

- Decorative Exterior Paints: Performance & Binder Design Trends in Asia PacificDocument27 pagesDecorative Exterior Paints: Performance & Binder Design Trends in Asia PacificAPEX SONNo ratings yet

- APCJ 2017oct Acronal ECO 7653Document4 pagesAPCJ 2017oct Acronal ECO 7653APEX SONNo ratings yet

- CCJ 2017nov Acronal ECO 7653Document7 pagesCCJ 2017nov Acronal ECO 7653APEX SONNo ratings yet

- Product List: Additives and Resins For Liquid CoatingsDocument12 pagesProduct List: Additives and Resins For Liquid CoatingsAPEX SONNo ratings yet

- The State of The Art in Raw Materials For The Building & Construction IndustryDocument22 pagesThe State of The Art in Raw Materials For The Building & Construction IndustryAPEX SONNo ratings yet

- Coatosil MP 200: Technical Data SheetDocument7 pagesCoatosil MP 200: Technical Data SheetAPEX SONNo ratings yet

- Acronal NX 3587 - Product InformationDocument3 pagesAcronal NX 3587 - Product InformationAPEX SONNo ratings yet

- Coatosil MP 200: Technical Data SheetDocument7 pagesCoatosil MP 200: Technical Data SheetAPEX SONNo ratings yet

- coatosil-mp-200-TDS - TR DÍNHDocument3 pagescoatosil-mp-200-TDS - TR DÍNHAPEX SONNo ratings yet

- AEROSIL® 200: Hydrophilic Fumed SilicaDocument2 pagesAEROSIL® 200: Hydrophilic Fumed SilicaAPEX SONNo ratings yet

- CoatOSil MP 200 Silane WB and SB CoatingsDocument8 pagesCoatOSil MP 200 Silane WB and SB CoatingsAPEX SONNo ratings yet

- Product Catalogue EN PDFDocument104 pagesProduct Catalogue EN PDFAPEX SONNo ratings yet

- Primal™ Gc-5 Er: Technical Data SheetDocument2 pagesPrimal™ Gc-5 Er: Technical Data SheetAPEX SONNo ratings yet

- Aerosil® 200 V: Densified Hydrophilic Fumed SilicaDocument2 pagesAerosil® 200 V: Densified Hydrophilic Fumed SilicaAPEX SONNo ratings yet

- Additives FOR Specialty Chemistry Formulations pER Function: Product ListDocument16 pagesAdditives FOR Specialty Chemistry Formulations pER Function: Product ListAPEX SONNo ratings yet

- Foamstar ST 2412: Formulation AdditivesDocument2 pagesFoamstar ST 2412: Formulation AdditivesAPEX SONNo ratings yet

- Foamaster Mo NDW: PropertiesDocument2 pagesFoamaster Mo NDW: PropertiesAPEX SONNo ratings yet

- P50 MSDSDocument9 pagesP50 MSDSAPEX SONNo ratings yet

- Waterborne Epoxy Coating SystemsDocument24 pagesWaterborne Epoxy Coating SystemsAPEX SONNo ratings yet

- Industrial Coatings: Recommended ProductsDocument2 pagesIndustrial Coatings: Recommended ProductsAPEX SONNo ratings yet

- Corotech V440 - TDS EN OKF PDFDocument3 pagesCorotech V440 - TDS EN OKF PDFAPEX SONNo ratings yet

- AquaPoly 250 TDSDocument1 pageAquaPoly 250 TDSAPEX SONNo ratings yet

- Reichhold: Coating Resins CatalogDocument35 pagesReichhold: Coating Resins CatalogAPEX SON100% (1)

- Industrial Floor Coatings: Recommended ProductsDocument2 pagesIndustrial Floor Coatings: Recommended ProductsAPEX SONNo ratings yet

- How To Disperse Micronized WaxDocument4 pagesHow To Disperse Micronized WaxAPEX SONNo ratings yet

- High Performance: Wax AdditivesDocument36 pagesHigh Performance: Wax AdditivesAPEX SONNo ratings yet

- Architectural Coatings: Recommended ProductsDocument2 pagesArchitectural Coatings: Recommended ProductsAPEX SONNo ratings yet

- Specialty Fine Powders and ExfoliantsDocument20 pagesSpecialty Fine Powders and ExfoliantsAPEX SONNo ratings yet

- Strontium ChlorideDocument3 pagesStrontium ChloridenishchayNo ratings yet

- Production of Antibiotics: Penicillin. StreptomycinDocument21 pagesProduction of Antibiotics: Penicillin. Streptomycinkayalsmitha33% (3)

- Shalisulphide: STP Limited Two Component Coal Tar Poly Sulphide SystemDocument2 pagesShalisulphide: STP Limited Two Component Coal Tar Poly Sulphide SystemPrashantBaruaNo ratings yet

- Introduction To Oil and GasDocument36 pagesIntroduction To Oil and GasPetroleum PetroleumNo ratings yet

- N, N-Diethyl M-Toluamide (OFF)Document3 pagesN, N-Diethyl M-Toluamide (OFF)Denisse Watt CuarterosNo ratings yet

- 9701/21/M/J/20 © Ucles 2020Document10 pages9701/21/M/J/20 © Ucles 2020Fire stormNo ratings yet

- Sample Paper at 2324 Class Viii p1 At+pcbm BioDocument4 pagesSample Paper at 2324 Class Viii p1 At+pcbm Biorameshhh1980No ratings yet

- Blotting Assignment by MPhil 5,12Document31 pagesBlotting Assignment by MPhil 5,12Amina ChNo ratings yet

- View JournalDocument1,079 pagesView JournalnamandamanNo ratings yet

- Price ListDocument38 pagesPrice ListERVINTIANo ratings yet

- Leybonol Lvo 210Document38 pagesLeybonol Lvo 210J. Carlos Alvarez C.No ratings yet

- Common Name of Organic CompoundsDocument7 pagesCommon Name of Organic CompoundsSuarNo ratings yet

- VermicompostingDocument19 pagesVermicompostingRitu JainNo ratings yet

- PFD Write UpDocument2 pagesPFD Write UpZeeshan WaheedNo ratings yet

- SKsen PaperDocument13 pagesSKsen PaperKoushik SenNo ratings yet

- Acceptability of Oregano and Lemon Grass Ready To Drink Tea: KeywordsDocument24 pagesAcceptability of Oregano and Lemon Grass Ready To Drink Tea: KeywordsJashley Munar HernandezNo ratings yet

- Chemical MediaDocument21 pagesChemical MediaBharath wajNo ratings yet

- Day 29 - Daily MCQ Workout - 40 Revision MCQsDocument5 pagesDay 29 - Daily MCQ Workout - 40 Revision MCQsnorah araujoNo ratings yet

- ™ Polyvinylidene Chloride (PVDC) Resins: SaranDocument6 pages™ Polyvinylidene Chloride (PVDC) Resins: SaranMichael Gonzales BaldeonNo ratings yet

- CIS1175 Compost PDFDocument8 pagesCIS1175 Compost PDFJoselyn Vanessa Seminario PeñaNo ratings yet

- Mobil Dte Oil Light MsdsDocument13 pagesMobil Dte Oil Light MsdsNaseemNo ratings yet

- Distribution of Acetic Acid Between Two Immiscible Solution by Simple Simple Methods PapooDocument11 pagesDistribution of Acetic Acid Between Two Immiscible Solution by Simple Simple Methods PapooHasnain SaifiNo ratings yet

- An Efficient and Sustainable Catalytic Reduction of Carbon-Carbon Multiple Bonds, Aldehydes, and Ketones Using Cu Nanoparticles Decorated Metal Organic FrameworkDocument12 pagesAn Efficient and Sustainable Catalytic Reduction of Carbon-Carbon Multiple Bonds, Aldehydes, and Ketones Using Cu Nanoparticles Decorated Metal Organic FrameworkCường NguyễnNo ratings yet

- Yeast Based Biorefineries For Oleochemical Production: SciencedirectDocument9 pagesYeast Based Biorefineries For Oleochemical Production: SciencedirectAnggaNo ratings yet

- prEN16723 2Document24 pagesprEN16723 2Ricardo Lourenço100% (1)

- BIOMASSA BIOETANOLDocument8 pagesBIOMASSA BIOETANOLhendy giritamaNo ratings yet

- 01403-22-23-Veera Speciality Coatings & Chemicals PDFDocument1 page01403-22-23-Veera Speciality Coatings & Chemicals PDFSiva prasadhNo ratings yet

- Erbicide LeguminoaseDocument28 pagesErbicide LeguminoaseliviugruiaNo ratings yet

- CHEM F311 Lecture 38 39 1,5-Dicarbonyl CompoundsDocument9 pagesCHEM F311 Lecture 38 39 1,5-Dicarbonyl Compoundsliving luxuriousNo ratings yet

- IUPAC Nomenclaute, Structural Isomerism & Practical Organic ChemistryDocument35 pagesIUPAC Nomenclaute, Structural Isomerism & Practical Organic ChemistryAmit Tiwari100% (1)