Professional Documents

Culture Documents

JSA For Rebar Works Includes Working in Scaffolding

JSA For Rebar Works Includes Working in Scaffolding

Uploaded by

Mohammed MinhajOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSA For Rebar Works Includes Working in Scaffolding

JSA For Rebar Works Includes Working in Scaffolding

Uploaded by

Mohammed MinhajCopyright:

Available Formats

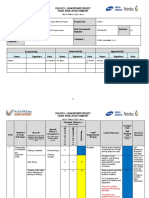

JOB SAFETY ANALYSIS WORKSHEET

Part 1: Job Particulars Page 1 of _____

JOB TITLE / AIM: Cutting and bending of re-bar both manually and mechanically and installation steel work onto foundation.(Work on scaffolding)

JSA DATE:05-09-2006 JSA NO./ REVISION: Rev

SUPERVISOR/ JSA LEADER: M. Shoaib SCRIBE: Abdullah Khan/Masood Memon

PARTICIPANTS: Abdullah Khan/Farhan Abbas/ Qoraish/ Dean

LIST ASSOCIATED PROCEDURES/WORK INSTRUCTIONS OR TEMPORARY WIs:

Attach copies of any relevant documentation/ drawings.

Part 2: Job Safety Analysis

Job Steps:

1. Mobilization of tools, equipment and workers

2. Re bar sizing, cutting and bending

3. Installation of steel work

4. Work on scaffolding

5. Mobilizations and Demobilization

Alternatives Considered: N/A Approve: 31/05/06

Now undertake the JSA and record in the table below. Use prompts on JSA Prompt Sheet and Hazard Checklist PA-HSEC-02-040-002-F03.

Part 3: Contingency Plans. Standard PPE,SFirst aid kit must be present at the area and the Hse personnel is the first response in case of

emergency

Pakistan Asset Team Approved: AHMED HASEEB PA-HSEC-02-040-002-F01

BHP Billiton Checked: NAJEEB MALIK Attached to: PA-HSEC-02-040-002-P

Originator: SYED FAHEEM Rev: 1 Issue: 13/05/05 Page 1 of 4

JOB SAFETY ANALYSIS WORKSHEET

Part 4: Review. After the job has been completed, JSA leader should note: any hazards, which were identified in the original JSA? Any practices

that need to be captured in the OMS? List action items, changes, and transfer any changes to the Change Management system.

File: 10.30

JSA No: JOB TITLE:

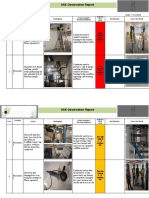

Step Describe Job Step Potential Hazards Hazard Controls

No (Copy from part 2 of form) (Use Hazard Checklist)

1 Mobilization of tools, equipment and Unauthorised equipment/tools brought out to All electrical tools and equipment should be

workers site inspected and colour coded prior coming to site.

Miscommunication Supervisor to explain job and JSA via toolbox

meeting. Only when all workers understand have

them sign the back of JSA

Back injury Proper manual handling of material

Slip, trip and fall Ensure pathway is clear

2 Re bar sizing ,cutting and bending Unauthorized personnel operation machinery Machinery to be operated by authorized person

hand only,

Equipment failure/Fire Daily inspection is required for all equipment. A

fire extinguisher should be on location. During

work any defects noticed on tools or equipment

Pakistan Asset Team PA-HSEC-02-040-002-F01

BHP Billiton Page 2 of 4

JOB SAFETY ANALYSIS WORKSHEET

JSA No: JOB TITLE:

Step Describe Job Step Potential Hazards Hazard Controls

No (Copy from part 2 of form) (Use Hazard Checklist)

should be reported to the supervisor.

Loose clothing Hi Vest should be taken off and all loose clothing

should be secured.

Personnel injury The minimum PPE must be worn. Which includes

safety glasses, face shield, hard hat gloves ect. The

area should be barricade off as to keep

unauthorized persons away.

Ensure grinders do not have positive locks and

guards must be in place.

Installation of steel work Protruding re bar All protruding re bar should be cap with approved

re bar caps.

Scorpions the job Gloves must be worn while tying re bar. After the

wire is cut the shape point (scorpions) should be

tapped down. If worker receives cut from wires or

re bars it should be reported to the supervisor.

Awkward positions/ back injury If work is in Workers will be oriented about the proper posture

an awkward position frequent break will be and positioning during the execution of the job.

needed.

Access and access to work area Ensure work Area with excavation/holes to be barricaded

area is kept clear from binding wires and steel.

When tying steel on ground worker should not

Pakistan Asset Team PA-HSEC-02-040-002-F01

BHP Billiton Page 3 of 4

JOB SAFETY ANALYSIS WORKSHEET

JSA No: JOB TITLE:

Step Describe Job Step Potential Hazards Hazard Controls

No (Copy from part 2 of form) (Use Hazard Checklist)

walk on the steel directly.

Heat Exhaustion Periodic rest in required. There should be

sufficient shade and water available on the work

front.

3. Work on scaffolding Fall hazards Using specific body harness

Trip Hazards All the walkways on the scaffold should be clear

Pakistan Asset Team PA-HSEC-02-040-002-F01

BHP Billiton Page 4 of 4

You might also like

- BIO102 Practice ExamDocument10 pagesBIO102 Practice ExamKathy YuNo ratings yet

- Steel Works Inc - Case StudyDocument24 pagesSteel Works Inc - Case Studymwaqasiqbal100% (1)

- PPE Request Form (New)Document1 pagePPE Request Form (New)Syafrial AnasNo ratings yet

- AITAS 8th Doctor SourcebookDocument192 pagesAITAS 8th Doctor SourcebookClaudio Caceres100% (14)

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document3 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair VanmazhyNo ratings yet

- Brahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysisDocument2 pagesBrahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysiszebmechNo ratings yet

- 675Document2 pages675Rameese MuhammedNo ratings yet

- Copy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Document5 pagesCopy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Viron BaxhiaNo ratings yet

- Index: Cv. Dira Utama SejahteraDocument12 pagesIndex: Cv. Dira Utama SejahteraFreshop SurabayaNo ratings yet

- Schedule For Inspection Nov 19Document1 pageSchedule For Inspection Nov 19Siddharth RanaNo ratings yet

- JSA #19 - Heavy Lifting in Hazardous AreaDocument1 pageJSA #19 - Heavy Lifting in Hazardous AreaMock ProjectNo ratings yet

- TRA FOR FRT - Rev.S2-2 (Recovered)Document31 pagesTRA FOR FRT - Rev.S2-2 (Recovered)rodman823No ratings yet

- Risk Assessment of Confined Space (CS) Entry:: Job Safety Analysis Worksheet DOC: CS/RA-01 Revision 1Document2 pagesRisk Assessment of Confined Space (CS) Entry:: Job Safety Analysis Worksheet DOC: CS/RA-01 Revision 1Dheeraj Kapoor /QOGIL/QuippoworldNo ratings yet

- SWMS Power FloatDocument10 pagesSWMS Power FloatSam LimNo ratings yet

- Hadeed JSA Shearing Machine InstallationDocument11 pagesHadeed JSA Shearing Machine InstallationDhanu NikkuNo ratings yet

- HIRA AssessmentDocument25 pagesHIRA AssessmentPanchdev KumarNo ratings yet

- Working at Heights Translab and PBDocument1 pageWorking at Heights Translab and PBCIDI Avida Towers VergeNo ratings yet

- Jsa For Manual Lifting of ObjectsDocument2 pagesJsa For Manual Lifting of ObjectsOgunwa Emmanuel100% (1)

- Project HSE Monthly Activity Plan: OH&S Management SystemDocument1 pageProject HSE Monthly Activity Plan: OH&S Management SystemBhagat Deepak100% (1)

- 3.ceiling Installation JSA ADocument2 pages3.ceiling Installation JSA APijah AhmadNo ratings yet

- RD Mine Hira (Vehicle and Driving) Location Risk Identification Control Measure Implementation Verification of Control MeasureDocument3 pagesRD Mine Hira (Vehicle and Driving) Location Risk Identification Control Measure Implementation Verification of Control Measureananthu.u100% (1)

- Fall Protection Plan Template DownloadDocument3 pagesFall Protection Plan Template Downloadabdalla el-saadaneyNo ratings yet

- Assessment For CCTV System Testing & CommissioningDocument5 pagesAssessment For CCTV System Testing & CommissioningAnonymousNo ratings yet

- Risk Assessment of Manual HandlingDocument2 pagesRisk Assessment of Manual HandlingMAB AliNo ratings yet

- Bionil-9021 MSDSDocument4 pagesBionil-9021 MSDSNagpur Boys Clan gaming100% (1)

- HSE Close Out ReportDocument4 pagesHSE Close Out ReportVijayakumar KarunanidhiNo ratings yet

- MSIHC RulesDocument61 pagesMSIHC RulesAMAN PRATEEK DaradNo ratings yet

- Master JSA 2052U Blower Removal & Installation Manual LiftingDocument6 pagesMaster JSA 2052U Blower Removal & Installation Manual LiftingOvais FarooqNo ratings yet

- Machine GuardingDocument13 pagesMachine GuardingSwayam SARIT SatpathyNo ratings yet

- JSA - Chop Off Machine For Cutting.Document6 pagesJSA - Chop Off Machine For Cutting.RajuNo ratings yet

- Concrete Placement and PaintingDocument4 pagesConcrete Placement and PaintingSoumin Thomas100% (1)

- JSA For New EmployeesDocument20 pagesJSA For New EmployeesNilayNo ratings yet

- JHA Formation Preparation or Leveling.Document2 pagesJHA Formation Preparation or Leveling.Mark Buendia100% (1)

- JSA GrinderAngleDocument2 pagesJSA GrinderAngleslamet_rNo ratings yet

- All JSAsDocument88 pagesAll JSAsQamar KhanNo ratings yet

- Job Safety & Environment Analysis: Revision NoDocument3 pagesJob Safety & Environment Analysis: Revision NonishanthNo ratings yet

- Al-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetDocument3 pagesAl-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetMustafa hse JafferNo ratings yet

- Topic For TBMDocument19 pagesTopic For TBMdauxomNo ratings yet

- MSDS - Asada Threading Oiil Red - ENDocument7 pagesMSDS - Asada Threading Oiil Red - ENnghiaNo ratings yet

- Roof Sheeting JSADocument6 pagesRoof Sheeting JSAJogendra BeharaNo ratings yet

- JSA - Crane Setuppdf PDFDocument12 pagesJSA - Crane Setuppdf PDFChoko ChokriNo ratings yet

- Jha Clarke Engine PumpDocument4 pagesJha Clarke Engine Pumpperquino oasanNo ratings yet

- Safety GuidelinesDocument20 pagesSafety GuidelinesDagnachew TassewNo ratings yet

- Working at Height Is One of The Hazardous OccupationsDocument6 pagesWorking at Height Is One of The Hazardous OccupationsHemaNo ratings yet

- Job Safety Analysis (Jsa) : Fabrication Works, Welding Works Using Power Tools, Hand Tools, Welding Machine WapstechDocument3 pagesJob Safety Analysis (Jsa) : Fabrication Works, Welding Works Using Power Tools, Hand Tools, Welding Machine WapstechMohamedSaidNo ratings yet

- Part 3 ObservationsDocument7 pagesPart 3 ObservationsAmjadNo ratings yet

- JHA For Work PermitDocument1 pageJHA For Work PermitShahid RazaNo ratings yet

- JSA EmployeesDocument2 pagesJSA EmployeesburhanNo ratings yet

- ZFP Sor 2022-12-7Document6 pagesZFP Sor 2022-12-7irfan shafiqueNo ratings yet

- Octopus Jsa For Fusion WeldingDocument2 pagesOctopus Jsa For Fusion WeldingOgunwa EmmanuelNo ratings yet

- WPRA No. 2221-TK-61-273 - Scaffolding Erection and DismatlingDocument4 pagesWPRA No. 2221-TK-61-273 - Scaffolding Erection and DismatlingMohamed RizwanNo ratings yet

- Dyer JSA - Brazing CopperDocument2 pagesDyer JSA - Brazing Copperdawn yatesNo ratings yet

- Safe Work Method Statement: One World Place Manila, 32nd ST, Taguig, Metro ManilaDocument6 pagesSafe Work Method Statement: One World Place Manila, 32nd ST, Taguig, Metro Manilanani ferrerNo ratings yet

- 142 Jsa Modify To 2 Inch MPW-2 To Reactor 2 Piping LineDocument6 pages142 Jsa Modify To 2 Inch MPW-2 To Reactor 2 Piping LineMohd KhaidirNo ratings yet

- ISC-JSA Grouting Works For Shared FenceDocument4 pagesISC-JSA Grouting Works For Shared FenceSameer AlmahboubNo ratings yet

- Hira - NRV ServicingDocument11 pagesHira - NRV ServicingAbzad HussainNo ratings yet

- SDS - Fenomastic Enamel Semigloss - English (Uk) - DubaiDocument5 pagesSDS - Fenomastic Enamel Semigloss - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- Panipat Refinery & Petrochemical Complex Job Safety AnalysisDocument6 pagesPanipat Refinery & Petrochemical Complex Job Safety AnalysisSaiyad RiyazaliNo ratings yet

- Safe Work Practice Dozer OperatorsDocument4 pagesSafe Work Practice Dozer OperatorsMuhammad Ashraf AhmadNo ratings yet

- HIRA - Copper Pipe Brazing WorkDocument2 pagesHIRA - Copper Pipe Brazing Workyogeshraut1910No ratings yet

- 24c Physicians RecommendationDocument1 page24c Physicians RecommendationMohammed MinhajNo ratings yet

- 08i Supbook Month2Document1 page08i Supbook Month2Mohammed MinhajNo ratings yet

- 13c Medical ConsultationDocument1 page13c Medical ConsultationMohammed MinhajNo ratings yet

- 27o Open Hole Grating PermitDocument1 page27o Open Hole Grating PermitMohammed MinhajNo ratings yet

- 08d Supbook ToolboxDocument2 pages08d Supbook ToolboxMohammed MinhajNo ratings yet

- 17b SubConEvalDocument5 pages17b SubConEvalMohammed MinhajNo ratings yet

- 24 Respiratory ProtectionDocument11 pages24 Respiratory ProtectionMohammed MinhajNo ratings yet

- 21 Personal Protective EquipmentDocument4 pages21 Personal Protective EquipmentMohammed MinhajNo ratings yet

- 13 Medical FirstAidDocument14 pages13 Medical FirstAidMohammed MinhajNo ratings yet

- 27e Hot Tap PermitDocument1 page27e Hot Tap PermitMohammed MinhajNo ratings yet

- 08b Supbook JSADocument1 page08b Supbook JSAMohammed MinhajNo ratings yet

- 27a Cold Work PermitDocument1 page27a Cold Work PermitMohammed MinhajNo ratings yet

- 20 Competent PersonDocument2 pages20 Competent PersonMohammed MinhajNo ratings yet

- 04d-Employee Safety DeclarationDocument1 page04d-Employee Safety DeclarationMohammed MinhajNo ratings yet

- 27I Hazardous Energy Control Survey PermitDocument1 page27I Hazardous Energy Control Survey PermitMohammed MinhajNo ratings yet

- 13b Medical Report EmployerDocument1 page13b Medical Report EmployerMohammed MinhajNo ratings yet

- 16f Material EntryDocument1 page16f Material EntryMohammed MinhajNo ratings yet

- 16h Vehicle StickerDocument1 page16h Vehicle StickerMohammed MinhajNo ratings yet

- 20a Comtepent Person FormDocument2 pages20a Comtepent Person FormMohammed MinhajNo ratings yet

- 07c Injured Job DescriptionDocument1 page07c Injured Job DescriptionMohammed MinhajNo ratings yet

- 07b First Aid LogDocument1 page07b First Aid LogMohammed MinhajNo ratings yet

- 16i Equipment PassDocument1 page16i Equipment PassMohammed MinhajNo ratings yet

- 05d EquipmentrepDocument1 page05d EquipmentrepMohammed MinhajNo ratings yet

- 07 RecordKeepingDocument3 pages07 RecordKeepingMohammed MinhajNo ratings yet

- 07d EmplinjuryrepDocument2 pages07d EmplinjuryrepMohammed MinhajNo ratings yet

- 16e Material ExitDocument1 page16e Material ExitMohammed MinhajNo ratings yet

- 27g Night Work PermitDocument1 page27g Night Work PermitMohammed Minhaj100% (1)

- 16a AuthorisedSignatureDocument1 page16a AuthorisedSignatureMohammed MinhajNo ratings yet

- 07h Week Stats SumDocument1 page07h Week Stats SumMohammed MinhajNo ratings yet

- 24b Supplemental Information GuideDocument1 page24b Supplemental Information GuideMohammed MinhajNo ratings yet

- Acs42 Config GuideDocument214 pagesAcs42 Config GuideOtia ObaNo ratings yet

- Shudha Dairy Summer ProjectDocument231 pagesShudha Dairy Summer ProjectAbhishek Kumar83% (12)

- Portable Fire ExtinguisherDocument44 pagesPortable Fire ExtinguisherjohainaNo ratings yet

- Department of Computer Applications MC1802-Software Project Management Question BankDocument9 pagesDepartment of Computer Applications MC1802-Software Project Management Question BankSuhin Vimal RajNo ratings yet

- Pricerfileinterfacespecification Pfi4Document34 pagesPricerfileinterfacespecification Pfi4nthgrNo ratings yet

- Goat Milk Marketing Feasibility Study Report - Only For ReferenceDocument40 pagesGoat Milk Marketing Feasibility Study Report - Only For ReferenceSurajSinghal100% (1)

- Stay Where You Are' For 21 Days: Modi Puts India Under LockdownDocument8 pagesStay Where You Are' For 21 Days: Modi Puts India Under LockdownshivendrakumarNo ratings yet

- Risks Factors LBP Young AthletesDocument9 pagesRisks Factors LBP Young AthletesCONSTANZA PATRICIA BIANCHI ALCAINONo ratings yet

- Metro Manila Skyway Stage 3 - Toll Regulatory BoardDocument2 pagesMetro Manila Skyway Stage 3 - Toll Regulatory BoardKenneth Paul DalusongNo ratings yet

- Diass New Module 1 2022Document6 pagesDiass New Module 1 2022sheridan dimaanoNo ratings yet

- International Trade TheoriesDocument38 pagesInternational Trade Theoriestrustme77No ratings yet

- 2nd Puc Biology Reasoning Questions ZoologyDocument4 pages2nd Puc Biology Reasoning Questions ZoologynomanNo ratings yet

- LP4 KwanzaaDocument8 pagesLP4 KwanzaaJoaquinNo ratings yet

- (Springer Finance) Dr. Manuel Ammann (Auth.) - Credit Risk Valuation - Methods, Models, and Applications-Springer Berlin Heidelberg (2001)Document258 pages(Springer Finance) Dr. Manuel Ammann (Auth.) - Credit Risk Valuation - Methods, Models, and Applications-Springer Berlin Heidelberg (2001)Amel AmarNo ratings yet

- Study Guide: Reading Comprehension & Sample Test QuestionsDocument12 pagesStudy Guide: Reading Comprehension & Sample Test QuestionsRhymer Indico MendozaNo ratings yet

- Contemp Final ReviewerDocument8 pagesContemp Final ReviewerKen ManilayNo ratings yet

- RDGFGDocument4 pagesRDGFGRobin SinghNo ratings yet

- Heermm ToolDocument18 pagesHeermm ToolJuan PabloNo ratings yet

- 4 Lista Teme Disertatie 2020-2021 BSCMC EnglezaDocument3 pages4 Lista Teme Disertatie 2020-2021 BSCMC EnglezaqawsfawsfNo ratings yet

- Inergen System Operation and Maintenance InstructionDocument16 pagesInergen System Operation and Maintenance InstructionchuminhNo ratings yet

- 1 - DS SATK Form - Initial Application of LTO 1.2Document4 pages1 - DS SATK Form - Initial Application of LTO 1.2cheska yahniiNo ratings yet

- CBT 10 Principles FelyDocument12 pagesCBT 10 Principles FelyRoh NaldzNo ratings yet

- GCED GraphDocument1 pageGCED GraphWan Redzwan KadirNo ratings yet

- Future Trends in European Public Administration and Management: An Outside-In PerspectiveDocument45 pagesFuture Trends in European Public Administration and Management: An Outside-In PerspectivevickyNo ratings yet

- Me 218 Bprojectdescription 1112Document6 pagesMe 218 Bprojectdescription 1112api-310813713No ratings yet

- RelatórioDocument1 pageRelatórioneveshelenaliceNo ratings yet

- Cardiac Imaging CasesDocument278 pagesCardiac Imaging Casesandrew100% (2)