Professional Documents

Culture Documents

Cofmow Itp

Cofmow Itp

Uploaded by

Ajay HazarikaCopyright:

Available Formats

You might also like

- Site InstructionDocument2 pagesSite InstructionAjay Hazarika90% (10)

- Qms Manual Iso 9001 2015Document45 pagesQms Manual Iso 9001 2015Ajay Hazarika81% (16)

- NEBOSH IGC 3 ReportDocument49 pagesNEBOSH IGC 3 ReportAjay Hazarika78% (89)

- 201485-25000-QP-01-B Inspection Test Plan (ITP) For FRP Tank R0Document1 page201485-25000-QP-01-B Inspection Test Plan (ITP) For FRP Tank R0muchamad yasin100% (1)

- Blasting and Painting Inspection and Test PlanDocument3 pagesBlasting and Painting Inspection and Test PlanNnamdi Amadi80% (5)

- 04 HSE Inspection ChecklistDocument2 pages04 HSE Inspection ChecklistAjay Hazarika100% (4)

- AIAG-VDA Pfmea FormatDocument7 pagesAIAG-VDA Pfmea FormatJohn OoNo ratings yet

- Valves - Kirloskar BrothersDocument4 pagesValves - Kirloskar BrothersJaydev ChakrabortyNo ratings yet

- Dept of WR., Govt. of OdhishaDocument3 pagesDept of WR., Govt. of OdhishaNaveen NagisettiNo ratings yet

- Forward KinematicsDocument4 pagesForward KinematicsZafer Gök100% (1)

- ITP RefractoryDocument1 pageITP RefractoryADOFSLNo ratings yet

- FQP Field Quality Plan or ItpDocument30 pagesFQP Field Quality Plan or Itp9893203028No ratings yet

- Incoming Material ChecklistDocument1 pageIncoming Material ChecklistPrathvi Raj SinghNo ratings yet

- QAP-093-Dangote-IRP Rev1Document4 pagesQAP-093-Dangote-IRP Rev1MonaNo ratings yet

- 07 - Apollo - Iocl - Actuator GTV - R1Document1 page07 - Apollo - Iocl - Actuator GTV - R19893203028No ratings yet

- Staircases & HandrailsDocument2 pagesStaircases & HandrailsPavul RajNo ratings yet

- Control PlanDocument4 pagesControl PlanJosué PérezNo ratings yet

- QAP HMEL 7480000754 L08722A501-SignedDocument3 pagesQAP HMEL 7480000754 L08722A501-SignedSuyog GawandeNo ratings yet

- FQP For AAC Block WorkDocument1 pageFQP For AAC Block WorkHimanshu ChaudharyNo ratings yet

- QAP Final - ASSAMNZRMM11Document2 pagesQAP Final - ASSAMNZRMM11Jaspreet SinghNo ratings yet

- Field Quality Plan: KSK Power Company LimitedDocument6 pagesField Quality Plan: KSK Power Company LimitedGayatree RathoreNo ratings yet

- Ms QAPDocument6 pagesMs QAPArup karanNo ratings yet

- L - FA - Niel T. - WK 06 - Power Cable On Reel Continuity and IR Test.Document1 pageL - FA - Niel T. - WK 06 - Power Cable On Reel Continuity and IR Test.NIEL TANEDONo ratings yet

- ITP For Handrail WeldingDocument2 pagesITP For Handrail WeldingKumar AbhishekNo ratings yet

- Field Quality PlanDocument2 pagesField Quality PlanPurnima VermaNo ratings yet

- Raw Material & Bought Out Items InspectionDocument3 pagesRaw Material & Bought Out Items InspectionSuraj ShettyNo ratings yet

- RIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFDocument16 pagesRIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFSiriepathi SeetharamanNo ratings yet

- Quality Assurance Plan: Page 1 of 2 Vendor: Pump Model: Project: Quantity: CustomerDocument4 pagesQuality Assurance Plan: Page 1 of 2 Vendor: Pump Model: Project: Quantity: CustomerDeepak UpadhyayNo ratings yet

- QAP-NI-IJ-346-21 R1-MS New Eoan AssociatesDocument2 pagesQAP-NI-IJ-346-21 R1-MS New Eoan AssociatesParampreet singhNo ratings yet

- Qap - Iso - TankDocument2 pagesQap - Iso - TankMani MaNo ratings yet

- QAP For Ducting V1 R0Document1 pageQAP For Ducting V1 R0Hema NandhNo ratings yet

- Steam Trap QAPDocument2 pagesSteam Trap QAPPavul RajNo ratings yet

- L&T Hydrocarbon Engineering LimitedDocument2 pagesL&T Hydrocarbon Engineering LimitedAnonymous vchjQ9CQveNo ratings yet

- Inspection and Test Plan: One Sample For Every 100 Cum or Twice WeeklyDocument3 pagesInspection and Test Plan: One Sample For Every 100 Cum or Twice WeeklyAbhishek ShettyNo ratings yet

- Magnetic Level Gauge: DOC NO. QR/QC/F/14Document1 pageMagnetic Level Gauge: DOC NO. QR/QC/F/14sunshine dreamNo ratings yet

- QAP For MS FittingsDocument2 pagesQAP For MS FittingsMrityunjoy BarNo ratings yet

- QAP - ITP - Steel Girder ApproachDocument21 pagesQAP - ITP - Steel Girder ApproachPartha Gangopadhyay100% (1)

- Itp PRDSDocument3 pagesItp PRDSDwi Mulyanti Dwimulyantishop100% (1)

- Metallic Bellow QAPDocument2 pagesMetallic Bellow QAPPavul Raj100% (1)

- Prds & Piping QapDocument2 pagesPrds & Piping QapPavul RajNo ratings yet

- GS Peb QapDocument4 pagesGS Peb Qapshailendr12No ratings yet

- 3086 11939sampleQAPDocument1 page3086 11939sampleQAPSRIKANTA SAHOO-CUTNo ratings yet

- QAR-QD423-02 Balancing Testing Report For General Shaft - Flange - ImpellerDocument3 pagesQAR-QD423-02 Balancing Testing Report For General Shaft - Flange - Impellerkipak.s.at.uNo ratings yet

- Quality RequirementsDocument26 pagesQuality RequirementsDilip PatilNo ratings yet

- QAP - Revised at DyCEAnjiDocument23 pagesQAP - Revised at DyCEAnjiAman KumarNo ratings yet

- Steam Trap & Piston Valve Qap PDFDocument1 pageSteam Trap & Piston Valve Qap PDFajmainNo ratings yet

- Carpet LayingDocument7 pagesCarpet Layingparesh.ahirNo ratings yet

- ITP For Blasting and PaintingDocument9 pagesITP For Blasting and PaintingVinayaga MoorthiNo ratings yet

- Control Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Document4 pagesControl Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Himanshu MishraNo ratings yet

- Quantum of Check of Material&WorkmanshipDocument35 pagesQuantum of Check of Material&Workmanshipsanjay vidhateNo ratings yet

- SUPPORT (Scaph, Ducting) QAP R02 080822Document2 pagesSUPPORT (Scaph, Ducting) QAP R02 080822Pavul RajNo ratings yet

- Itp - Water ProofingDocument1 pageItp - Water ProofingUbaidullah KhanNo ratings yet

- Piping Qap R03 250822Document2 pagesPiping Qap R03 250822Pavul RajNo ratings yet

- SH 47Document1 pageSH 47keshav chaturvediNo ratings yet

- Vishwas Electroplaters: Control Plan For Acid Zinc Barrel Plating & Hexavalent PassivationDocument13 pagesVishwas Electroplaters: Control Plan For Acid Zinc Barrel Plating & Hexavalent PassivationAnonymous YptJ5iDNo ratings yet

- FQP For Brick WorkDocument1 pageFQP For Brick WorkHimanshu ChaudharyNo ratings yet

- MQAP - Long Rod InsulatorDocument8 pagesMQAP - Long Rod InsulatorRajitha BoppaNo ratings yet

- PIPING R04 101022 DraftDocument2 pagesPIPING R04 101022 DraftPavul RajNo ratings yet

- Aprroved QAP-1883-R01-15122022Document1 pageAprroved QAP-1883-R01-15122022Pavul RajNo ratings yet

- Quality Assurance Plan: Dover India PVT LTDDocument1 pageQuality Assurance Plan: Dover India PVT LTDDeepak UpadhyayNo ratings yet

- Quality Assurance Plan (Qap) For L.T.C.S. FittingsDocument2 pagesQuality Assurance Plan (Qap) For L.T.C.S. FittingsVIVEK TIWARINo ratings yet

- Project:: CGD Station Works at Sasaram & Aurangabad ProjectDocument5 pagesProject:: CGD Station Works at Sasaram & Aurangabad ProjectsubudhiprasannaNo ratings yet

- ITP Construction Jetty R0 PDFDocument4 pagesITP Construction Jetty R0 PDFanon_987276020100% (2)

- ITP For Pressure Vessel - Static EquipmentDocument8 pagesITP For Pressure Vessel - Static EquipmentReduddboyNo ratings yet

- Inspection and Test Plan FOR Dry Type Lighting TransformerDocument113 pagesInspection and Test Plan FOR Dry Type Lighting Transformermeraat100% (1)

- Plastics Testing and Characterization: Industrial ApplicationsFrom EverandPlastics Testing and Characterization: Industrial ApplicationsNo ratings yet

- Model Daily Report PDFDocument8 pagesModel Daily Report PDFAjay HazarikaNo ratings yet

- 04 HSE Inspection ChecklistDocument2 pages04 HSE Inspection ChecklistAjay Hazarika100% (1)

- Articulated Boom Risk and Hazard AssessmentDocument7 pagesArticulated Boom Risk and Hazard Assessmentjcs223No ratings yet

- N2XCY 1 X (1.5-800) MM 0.6/1 KVDocument5 pagesN2XCY 1 X (1.5-800) MM 0.6/1 KVCombox BlackNo ratings yet

- Topic 9 - Forum Question 1. Explain The Meaning of Communication and Describe What Is Non-Verbal CommunicationDocument3 pagesTopic 9 - Forum Question 1. Explain The Meaning of Communication and Describe What Is Non-Verbal CommunicationHadi azfar channelNo ratings yet

- Warhammer 40k - Codex - Errata - Dark Angels Q&A v2.0Document2 pagesWarhammer 40k - Codex - Errata - Dark Angels Q&A v2.0Jakub KalembaNo ratings yet

- Spherical Roller Thrust Bearing With Stamped Steel Cage: DimensionsDocument4 pagesSpherical Roller Thrust Bearing With Stamped Steel Cage: DimensionsLuis DanielNo ratings yet

- Add MathsDocument5 pagesAdd MathsDzul JefriNo ratings yet

- 2017 CenturionDocument2 pages2017 Centurionceo9871No ratings yet

- Capital BudgetingDocument35 pagesCapital Budgetingmurarimishra1750% (2)

- Engineering Graphics and VisualizationDocument35 pagesEngineering Graphics and Visualizationzain IshaqNo ratings yet

- AHU Design ExampleDocument2 pagesAHU Design ExampleShravanNo ratings yet

- Hay InfusionDocument5 pagesHay InfusionVeronica ZabalaNo ratings yet

- Crisp and ClearDocument5 pagesCrisp and ClearsandeepNo ratings yet

- Human Druid DND Simple Char PDFDocument1 pageHuman Druid DND Simple Char PDFMuhammad Fathul Al-AssalamNo ratings yet

- Disable Print Screen Key and All Keyboard Keys in ASP - Net PageDocument3 pagesDisable Print Screen Key and All Keyboard Keys in ASP - Net PagekhundaliniNo ratings yet

- Familiarity Questionnaire OCQ 90.2003Document5 pagesFamiliarity Questionnaire OCQ 90.2003yani0707No ratings yet

- Class 1Document21 pagesClass 1jayeda4sumonNo ratings yet

- Red OxDocument2 pagesRed Oxsun_rise_14No ratings yet

- Wind Load CalculationDocument13 pagesWind Load CalculationPre SheetNo ratings yet

- Republic of The Philippines Polytechnic University of The Philippines College of Education - Graduate StudiesDocument4 pagesRepublic of The Philippines Polytechnic University of The Philippines College of Education - Graduate StudiesJessa MolinaNo ratings yet

- Quarter by Numbers: Global HighlightsDocument37 pagesQuarter by Numbers: Global HighlightsAndreaNo ratings yet

- SM Piko-MpDocument92 pagesSM Piko-MpSamuel JACOBBONo ratings yet

- Acroname EnglishDocument44 pagesAcroname EnglishNissan NavaraNo ratings yet

- Chapter 9 CapacitorsDocument11 pagesChapter 9 CapacitorsnNo ratings yet

- VISHNU CV With ExperianceDocument2 pagesVISHNU CV With ExperianceoNo ratings yet

- Loans and AdvancesDocument9 pagesLoans and AdvancesidealworldNo ratings yet

- NAVIS ProblemDocument3 pagesNAVIS ProblemshanukawadugeNo ratings yet

- Anecdotal ReportDocument3 pagesAnecdotal ReportJulia Geonzon LabajoNo ratings yet

- HR One User Guide For Mobility V1.2Document34 pagesHR One User Guide For Mobility V1.2Mohammed QahtaniNo ratings yet

Cofmow Itp

Cofmow Itp

Uploaded by

Ajay HazarikaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cofmow Itp

Cofmow Itp

Uploaded by

Ajay HazarikaCopyright:

Available Formats

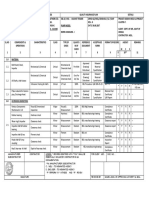

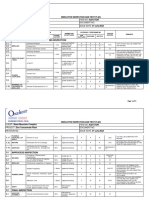

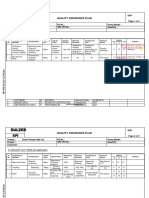

FIELD QUALITY PLAN

CONTRACTORES NAME AND ADDRESS:- ITEM DESCRIPTION QAP NO:- FQP-CIVIL- UK-01 Project:-Uttrakhand Projects

CIVIL WORKS ( SITE ACTIVITY) QAP Date :- 02.11.2019 Rev No. 01 Client: Uttrakhand Govt.

SR.NO. COMPONENTS TEST/CHECKS QUANTUM CHECKS ACCEPTANCE CRETERIA RECORD REFRENCE DOCUMENTS INSPECTION REMARKS

A INSPECTION OF INCOMING MATERIALS IR CLASS

CEMENT Review of MTC for Physical & once per batch Tech SPC/IS Manufactures Test Tech SPC/IS P

1 Chemical Analysis Certificate

Sieve Analysis For Each Vehicle before Unload

Flakiness & Elongation Monthly

Specific Gravity Monthly

2 COARSE & FINE AGGREGATE Bulk Density Seasonal/Monthly IS-383, IS-2386 LAB TEST REPORT Tech SPC/IS P

Crushing & Impact Value Monthly

Silt & Clay Content For Each Vehicle before Unload

Moisture Content As per Requirement

VISUAL INSPECTION Each Lot

3 BRICKS Dimension, Water Absorption, IS-1077, IS-2180 LAB TEST REPORT SPECS/DRGS. P

Compressive Strength & Each Lot

Effolorence

Chemical & Physical Analysis Review of MTC

Manufactures Test Tech SPC/IS As per grade

4 REINFORCEMENT P

Handling & Storage 100% Certificate mentionedby Designer

Rolling Margin Each Lot IS-1786/As Per Approved Make

B INSPECTION AT PROCESS

SURVEY Physical Dimensions,Level and General Engg

1 Fixing of Benchmarch 100% Specs/Drgs Practice SPECS/DRGS. P

EXCAVATION Physical Dimensions General Engg

2 100% Specs/Drgs Practice SPECS/DRGS. P

Bar Bending Schedule 100% As Per Grg/BBS General Engg

3 REINFORCEMENT SPECS/DRGS.

Bar Binding Random IS-2502 Practice P

FORM WORK VISUAL INSPECTION, Line & Specs/Drgs & IS-456,IS-6461 General Engg SPECS/DRGS. P

4 Level 100% Practice

Mix Ratio. W/C Ratio, Slump 1 Set ( 6 Cubes) per 50 CU.M/ 1 Set ( 6 Cubes)

IS-456,IS-516,IS-1199, IS-3025 Slump Register to be P

per Foundation, Slump Test shall be done on

Each Miller & IS-7861 Maintained SPECS/DRGS.

5 CONCRETE

For Each grade Intially once & IS-10262/IS-

Mix Design there after for Every Change of 456/Tech.Spec./Initial Cube Tech.Spec

Source Test Results before Use Design Mix Report P

BACK FILLING OMC & MDD Once per Source

6 Field Dry Density/ Compaction One Test Per Layer Foundation SPECS/DRGS. P

SOIL Test Filling IS-2720, Is -10379, Min 90 % General Engg

SAND Max & Min Dry Density Once per Source Compaction Practice

Soaking of Bricks, Visual

7 Brick Masonary Inspection, Mortar Thickness, General Engg SPECS/DRGS. P

Plumb & Mix Ratio 100% Tech SPC/ Approved drawings Practice

Mix Ratio,Slope ,Level,

8 FLOORING Tech Spec. General Engg SPECS/DRGS. P

Construction Joints & Finish

100% Practice

Material

Surface Prepration Physically

9 VITRIFIED TILE FLOORING As per Drgs./Tech. Specs. MTC SPECS/DRGS. P

Fixing

Line,Level & Slope As Per Spec.

SANITARY WORKS & WATER Material

10 Should be as per approved make. SPECS/DRGS. P

SUPPLY. ( FITTING & FIXTURES)

Relevent Formates/

FIXING As per Drgs./Tech. Specs. MTC'S

LEGENDS: W= Witness RM= Random R= Review

P= Perform RW= Random Witness

SUBMITED BY CHECKED BY ( CONSULTANT/ CLIENT) REVIEWED & APPROVED BY

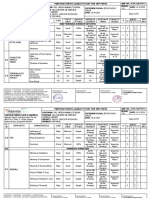

INSPECTION & TEST PLAN

PROJECT AUGUMENTATION OF POH CAPACITY FROM 400 TO 500 WAGONS PER MONTH At Wagon Repair Shop, Raip

SR.NO. COMPONENTS TEST/CHECKS QUANTUM OF CHECKS ACCEPTANCE CRETERIA

1 DISMANTLING WORKS /SITE CLEARANCE

Visual Inspection 100% Project Specification

De molishing of Brick work Stacking

1.1 and Disposal as Directed by Client

2 EARTHWORK

2.1 EXCAVATION Physical Dimension & Level 100% Project Specification

2.2 BACKFILLING Material Test - Soil As per Project Specifications Project Specification

(1) Gradation Analysis 1 set for existing embankment

(2) Atterberg’s limits - liquid limit & plastic limit 1 set per source of borrow material

(3) Optimum Moisture Content (OMC), Maximum Dry

Density (MDD)

Field Test Every Bed

(1) Alignment, Level, layer thickness, Every 500 sq m

(2) Field Compaction

2 MATERIALS FOR CONCRETE

2.1 CEMENT Material - (1) Cement

(1) Incoming Cement as per Approved Brand Every incoming lot Project Specification

(1) Review of MTC for Physical & Chemical Analysis for each incoming lot Project Specification

(2) All Physical & Chemical test 3rd Party Lab once in 3 months Project Specification

(3) Physical Tests at site lab for each batch received at site

A) Consistency

B) Initial & Final Setting time IS:12330/8112/12269/455/1489

C) Soundness

D) Fineness

E) Compressive Strength

(4) Storage once monthly age not more than 3 months

2.2 COARSE AGGREGATE Material - (2) Coarse Aggregate

(1) Sieve Analysis For Each Vehicle IS-383

(2) Flakiness & Elongation Monthly

(3) Specific Gravity Monthly

(4) Bulk Density Seasonal/Monthly

(5) Impact Value Monthly

2.3 FINE AGGREGATE Material - (3) Fine Aggregate IS 383

(1) Sieve Analysis For Each Vehicle

(2) Silt Content For Each Vehicle

2.4 WATER Material - (4) Water From the Source at the Begining of As Per IS: 456 & IS :3025

Work /Change of Source

Physical & Chemical test

2.5 ADMIXTURE Material - (5) Admixture

(1) Incoming Cement as per Approved Brand Every incoming lot Project Specification

(1) Review of MTC for Physical & Chemical Analysis for each incoming lot IS 9103

2.6 STEEL Material - (6) Steel

(1) Incoming Steel as per Approved Brand for each incoming lot IS 1786

(2) Review of MTC for Physical & Chemical Analysis for each incoming lot

(3) Rolling Margin for each incoming lot

(4) All Physical & Chemical test 3rd Party Lab 3 nos. 1 m samples for each dia

for every 100 MT per dia of steel

& change of source of material

3 FIELD TESTS FOR CONCRETE

3.1 REINFORCEMENT Placement of rebars & binding 100% Str. Drgs, Specs & IS-456, 2502

3.2 FORM WORK Visual Inspection of form 100% Str. Drgs, Specs & IS-456, 6461

Dimension check - Line, Level & Plumb

3.3 CONCRETE Mix Ratio. W/C Ratio, Slump Slump Test shall be done on Each IS-456,IS-516,IS-1199, IS-3025 & IS-

Miller 7861

Mix Constituents for each concrete TM as per Aprroved design mix

Workability - slump for each concrete TM as per Aprroved design mix,

Project Spec

IS 456

Concrete Compressive Strength 1 Set ( 6 Cubes) per 50 CU.M/ IS 456

1 Set ( 6 Cubes) per Foundation

Post Pour Concrete Check 100% dimension tolerance as per IS 456, no

concrete defect

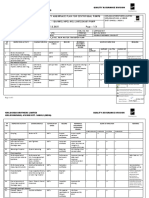

4 PERMANENT WAY

4.1 EARTHWORK

(subgrade& embankment) Material Test - Soil As per Project Specifications As per project Specification

(1) Gradation Analysis 1 set for existing embankment

(2) Atterberg’s limits - liquid limit & plastic 1 set per source of borrow

limit material

(3) Optimum Moisture Content (OMC), /5000 cum or strata change

Maximum Dry Density (MDD)

Field Test Every bed Within tolerances in spec

(1) Alignment, Level, thickness, width & slope Every Bed As per GFC

(2) Placement of geotextile / separator Every 500 sq m 98% MDD (subgrade)

(23 Field Compaction / 95% MDD (embankment)

4.2 BALLAST Material Test - Aggregate 1 sample per 100 cum

(1) Gradation Analysis stack/wagon Gradation Limits in spec

(2) Abrasion Value 1 sample per 2000 cum max 30%

(3) Aggregate Impact Value --do-- max 20%

(4) Water Absorption --do-- max 1%

Field Test

(1) Alignment, Level, Height, width & slope Every bed Within tolerances in spec

5 BLOCKWORK

5.1 Material Check Material (Block)

Dimensions,Compressive strength, Density & Maximum variation length +/-

Per lot / Batch

Drying Shrinkage 5mm, width and height +/- 3mm,

Density 551 to 650

Kg/m3 , Compressive

strength 4n/mm2 and

Dimensions,Compressive strength, Density & As per relevant IS Code/ one Thermal conductivity 0.24w/m.k

Drying Shrinkage sample for 10000 nos .

Once in starting of block work

Thermal Conductivity

activity

Material (Mortar/Adhesive)

Compressive strength / Adhesion Per lot / Batch > 7.5 N/mm2

Cement Mortar 1set every day randomly

5.2 Process Check Ensure block work is done as per Technical

Specification

- Soaking

- Ratio of Mortar

-Architechtural layout drawing Everyday's activities Drawing

- Plumb check - Initial & Final

- Raking of joints/ Joint thickness

- Doors and Window openings

- Reduced levels of sill/Lintel/Bottom

6 PLASTER WORK

6.1 Material Check Cement Every batch As per Indian Standard

Sand sieve analysis Daily 1 set As per Indian Standard

Mortar 1 set every day randomly As per Indian Standard

Water Proof Chemical Every batch As per manufacturer Specification

6.2 Process Check Ensure Plastering is done as per Tech Specification

Ensure that the plastering of Block Work shall be

of 'min 15mm thick for inside, min 6 mm for

celling and min 20mm for waterproof external

- Type of Plaster

- Mix proportion

- Plumb marks / Correction of Masonry(if any)

- Plaster thickness As Per IS :1661 / Method

- Chicken mesh fixing Every day Statement / Technical

- Base coat Specification

- Doors & Windows opening check

- Joint cut at straight line

- Joint Finishing

Ensure that the curing of plastering surface are

100%

carried out for 7days

ST PLAN

DOC. REF. No. FQP-CIVIL- RP-01

WAGONS PER MONTH At Wagon Repair Shop, Raipur

REVISION / DATE Rev No. 01 / 23.12.2019

INSPECTION

REFERENCE

RECORD DOCUMENTS

HYT IRCLASS COFMOW

Measurement Sheet/ Register Measurement Sheet/Register P W R/W

Survey record Project Specs P W R/W

Project Specs / IS 2836

Lab Test Report P W R/W

Checklist P W R/W

Field Test Report

P W R/W

MTC Register R R R

Test Report IS:12330/8112/12269/455/ R R R

1489

Lab Test Report P W R/W

IS:12330/8112/12269/455/

1489

P W R/W

Lab Test Report Tech SPC/IS-383, IS-2386 P W R/W

Lab Test Report Tech SPC/IS-383, IS-2386 P W R/W

Lab. Test Report IS: 456 & IS :3025 R R R

Project Specification P W W

MTC IS 9103 R R R

Project Specification P W R/W

IS1786

MTC R R R

Lab Test Report / Register P W R/W

Test Report R R R

Checklist Str. Drgs, Specs P W R/W

Checklist SPECS/DRGS. P W R/W

Slump Register to be Maintained SPECS/DRGS. W W R/W

checklist batch sheet P R R

checklist Project Spec P W R/W

IS 456

Lab test Report IS-456,IS-516,IS-1199, IS-3025 & P W R/W

IS-7861

checklist Project Spec, IS 456 P W R/W

Test Report Project Specifications/ P W R/W

Guideline No. GE: G-1 /

Indian Railways P Way

Manual/ Specification for

Ballast IRS GE-1

Checklist P W R/W

Field Test Report

Test Report P W R/W

Checklist P W R/W

P W R/W

MTC

IS 2185 Part 3-1985 , IS –

6441 (PART – I AND V)

P W R/W

P W R/W

Third Party Test Report

P W R/W

W R/W

MTC IS 2250 : 1981 P W R/W

Mortar cube Register IS 2250:1981 P W R/W

P W R/W

P W R/W

Technical Spec / As per

Check list P W R/W

Method Statement

P W R/W

P W R/W

P W R/W

P W R/W

MTC IS 12269, IS 8112 P W R/W

Test Report IS 1542 P W R/W

Mortar cube Register IS 2250:1981 P W R/W

MTC Manufacturer Spec R R R

Checklist P W R/W

P W R/W

P W R/W

P W R/W

Drawing / Technical Spec /

Method Statement P W R/W

P W R/W

P W R/W

P W R/W

P W R/W

P W R/W

You might also like

- Site InstructionDocument2 pagesSite InstructionAjay Hazarika90% (10)

- Qms Manual Iso 9001 2015Document45 pagesQms Manual Iso 9001 2015Ajay Hazarika81% (16)

- NEBOSH IGC 3 ReportDocument49 pagesNEBOSH IGC 3 ReportAjay Hazarika78% (89)

- 201485-25000-QP-01-B Inspection Test Plan (ITP) For FRP Tank R0Document1 page201485-25000-QP-01-B Inspection Test Plan (ITP) For FRP Tank R0muchamad yasin100% (1)

- Blasting and Painting Inspection and Test PlanDocument3 pagesBlasting and Painting Inspection and Test PlanNnamdi Amadi80% (5)

- 04 HSE Inspection ChecklistDocument2 pages04 HSE Inspection ChecklistAjay Hazarika100% (4)

- AIAG-VDA Pfmea FormatDocument7 pagesAIAG-VDA Pfmea FormatJohn OoNo ratings yet

- Valves - Kirloskar BrothersDocument4 pagesValves - Kirloskar BrothersJaydev ChakrabortyNo ratings yet

- Dept of WR., Govt. of OdhishaDocument3 pagesDept of WR., Govt. of OdhishaNaveen NagisettiNo ratings yet

- Forward KinematicsDocument4 pagesForward KinematicsZafer Gök100% (1)

- ITP RefractoryDocument1 pageITP RefractoryADOFSLNo ratings yet

- FQP Field Quality Plan or ItpDocument30 pagesFQP Field Quality Plan or Itp9893203028No ratings yet

- Incoming Material ChecklistDocument1 pageIncoming Material ChecklistPrathvi Raj SinghNo ratings yet

- QAP-093-Dangote-IRP Rev1Document4 pagesQAP-093-Dangote-IRP Rev1MonaNo ratings yet

- 07 - Apollo - Iocl - Actuator GTV - R1Document1 page07 - Apollo - Iocl - Actuator GTV - R19893203028No ratings yet

- Staircases & HandrailsDocument2 pagesStaircases & HandrailsPavul RajNo ratings yet

- Control PlanDocument4 pagesControl PlanJosué PérezNo ratings yet

- QAP HMEL 7480000754 L08722A501-SignedDocument3 pagesQAP HMEL 7480000754 L08722A501-SignedSuyog GawandeNo ratings yet

- FQP For AAC Block WorkDocument1 pageFQP For AAC Block WorkHimanshu ChaudharyNo ratings yet

- QAP Final - ASSAMNZRMM11Document2 pagesQAP Final - ASSAMNZRMM11Jaspreet SinghNo ratings yet

- Field Quality Plan: KSK Power Company LimitedDocument6 pagesField Quality Plan: KSK Power Company LimitedGayatree RathoreNo ratings yet

- Ms QAPDocument6 pagesMs QAPArup karanNo ratings yet

- L - FA - Niel T. - WK 06 - Power Cable On Reel Continuity and IR Test.Document1 pageL - FA - Niel T. - WK 06 - Power Cable On Reel Continuity and IR Test.NIEL TANEDONo ratings yet

- ITP For Handrail WeldingDocument2 pagesITP For Handrail WeldingKumar AbhishekNo ratings yet

- Field Quality PlanDocument2 pagesField Quality PlanPurnima VermaNo ratings yet

- Raw Material & Bought Out Items InspectionDocument3 pagesRaw Material & Bought Out Items InspectionSuraj ShettyNo ratings yet

- RIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFDocument16 pagesRIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFSiriepathi SeetharamanNo ratings yet

- Quality Assurance Plan: Page 1 of 2 Vendor: Pump Model: Project: Quantity: CustomerDocument4 pagesQuality Assurance Plan: Page 1 of 2 Vendor: Pump Model: Project: Quantity: CustomerDeepak UpadhyayNo ratings yet

- QAP-NI-IJ-346-21 R1-MS New Eoan AssociatesDocument2 pagesQAP-NI-IJ-346-21 R1-MS New Eoan AssociatesParampreet singhNo ratings yet

- Qap - Iso - TankDocument2 pagesQap - Iso - TankMani MaNo ratings yet

- QAP For Ducting V1 R0Document1 pageQAP For Ducting V1 R0Hema NandhNo ratings yet

- Steam Trap QAPDocument2 pagesSteam Trap QAPPavul RajNo ratings yet

- L&T Hydrocarbon Engineering LimitedDocument2 pagesL&T Hydrocarbon Engineering LimitedAnonymous vchjQ9CQveNo ratings yet

- Inspection and Test Plan: One Sample For Every 100 Cum or Twice WeeklyDocument3 pagesInspection and Test Plan: One Sample For Every 100 Cum or Twice WeeklyAbhishek ShettyNo ratings yet

- Magnetic Level Gauge: DOC NO. QR/QC/F/14Document1 pageMagnetic Level Gauge: DOC NO. QR/QC/F/14sunshine dreamNo ratings yet

- QAP For MS FittingsDocument2 pagesQAP For MS FittingsMrityunjoy BarNo ratings yet

- QAP - ITP - Steel Girder ApproachDocument21 pagesQAP - ITP - Steel Girder ApproachPartha Gangopadhyay100% (1)

- Itp PRDSDocument3 pagesItp PRDSDwi Mulyanti Dwimulyantishop100% (1)

- Metallic Bellow QAPDocument2 pagesMetallic Bellow QAPPavul Raj100% (1)

- Prds & Piping QapDocument2 pagesPrds & Piping QapPavul RajNo ratings yet

- GS Peb QapDocument4 pagesGS Peb Qapshailendr12No ratings yet

- 3086 11939sampleQAPDocument1 page3086 11939sampleQAPSRIKANTA SAHOO-CUTNo ratings yet

- QAR-QD423-02 Balancing Testing Report For General Shaft - Flange - ImpellerDocument3 pagesQAR-QD423-02 Balancing Testing Report For General Shaft - Flange - Impellerkipak.s.at.uNo ratings yet

- Quality RequirementsDocument26 pagesQuality RequirementsDilip PatilNo ratings yet

- QAP - Revised at DyCEAnjiDocument23 pagesQAP - Revised at DyCEAnjiAman KumarNo ratings yet

- Steam Trap & Piston Valve Qap PDFDocument1 pageSteam Trap & Piston Valve Qap PDFajmainNo ratings yet

- Carpet LayingDocument7 pagesCarpet Layingparesh.ahirNo ratings yet

- ITP For Blasting and PaintingDocument9 pagesITP For Blasting and PaintingVinayaga MoorthiNo ratings yet

- Control Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Document4 pagesControl Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Himanshu MishraNo ratings yet

- Quantum of Check of Material&WorkmanshipDocument35 pagesQuantum of Check of Material&Workmanshipsanjay vidhateNo ratings yet

- SUPPORT (Scaph, Ducting) QAP R02 080822Document2 pagesSUPPORT (Scaph, Ducting) QAP R02 080822Pavul RajNo ratings yet

- Itp - Water ProofingDocument1 pageItp - Water ProofingUbaidullah KhanNo ratings yet

- Piping Qap R03 250822Document2 pagesPiping Qap R03 250822Pavul RajNo ratings yet

- SH 47Document1 pageSH 47keshav chaturvediNo ratings yet

- Vishwas Electroplaters: Control Plan For Acid Zinc Barrel Plating & Hexavalent PassivationDocument13 pagesVishwas Electroplaters: Control Plan For Acid Zinc Barrel Plating & Hexavalent PassivationAnonymous YptJ5iDNo ratings yet

- FQP For Brick WorkDocument1 pageFQP For Brick WorkHimanshu ChaudharyNo ratings yet

- MQAP - Long Rod InsulatorDocument8 pagesMQAP - Long Rod InsulatorRajitha BoppaNo ratings yet

- PIPING R04 101022 DraftDocument2 pagesPIPING R04 101022 DraftPavul RajNo ratings yet

- Aprroved QAP-1883-R01-15122022Document1 pageAprroved QAP-1883-R01-15122022Pavul RajNo ratings yet

- Quality Assurance Plan: Dover India PVT LTDDocument1 pageQuality Assurance Plan: Dover India PVT LTDDeepak UpadhyayNo ratings yet

- Quality Assurance Plan (Qap) For L.T.C.S. FittingsDocument2 pagesQuality Assurance Plan (Qap) For L.T.C.S. FittingsVIVEK TIWARINo ratings yet

- Project:: CGD Station Works at Sasaram & Aurangabad ProjectDocument5 pagesProject:: CGD Station Works at Sasaram & Aurangabad ProjectsubudhiprasannaNo ratings yet

- ITP Construction Jetty R0 PDFDocument4 pagesITP Construction Jetty R0 PDFanon_987276020100% (2)

- ITP For Pressure Vessel - Static EquipmentDocument8 pagesITP For Pressure Vessel - Static EquipmentReduddboyNo ratings yet

- Inspection and Test Plan FOR Dry Type Lighting TransformerDocument113 pagesInspection and Test Plan FOR Dry Type Lighting Transformermeraat100% (1)

- Plastics Testing and Characterization: Industrial ApplicationsFrom EverandPlastics Testing and Characterization: Industrial ApplicationsNo ratings yet

- Model Daily Report PDFDocument8 pagesModel Daily Report PDFAjay HazarikaNo ratings yet

- 04 HSE Inspection ChecklistDocument2 pages04 HSE Inspection ChecklistAjay Hazarika100% (1)

- Articulated Boom Risk and Hazard AssessmentDocument7 pagesArticulated Boom Risk and Hazard Assessmentjcs223No ratings yet

- N2XCY 1 X (1.5-800) MM 0.6/1 KVDocument5 pagesN2XCY 1 X (1.5-800) MM 0.6/1 KVCombox BlackNo ratings yet

- Topic 9 - Forum Question 1. Explain The Meaning of Communication and Describe What Is Non-Verbal CommunicationDocument3 pagesTopic 9 - Forum Question 1. Explain The Meaning of Communication and Describe What Is Non-Verbal CommunicationHadi azfar channelNo ratings yet

- Warhammer 40k - Codex - Errata - Dark Angels Q&A v2.0Document2 pagesWarhammer 40k - Codex - Errata - Dark Angels Q&A v2.0Jakub KalembaNo ratings yet

- Spherical Roller Thrust Bearing With Stamped Steel Cage: DimensionsDocument4 pagesSpherical Roller Thrust Bearing With Stamped Steel Cage: DimensionsLuis DanielNo ratings yet

- Add MathsDocument5 pagesAdd MathsDzul JefriNo ratings yet

- 2017 CenturionDocument2 pages2017 Centurionceo9871No ratings yet

- Capital BudgetingDocument35 pagesCapital Budgetingmurarimishra1750% (2)

- Engineering Graphics and VisualizationDocument35 pagesEngineering Graphics and Visualizationzain IshaqNo ratings yet

- AHU Design ExampleDocument2 pagesAHU Design ExampleShravanNo ratings yet

- Hay InfusionDocument5 pagesHay InfusionVeronica ZabalaNo ratings yet

- Crisp and ClearDocument5 pagesCrisp and ClearsandeepNo ratings yet

- Human Druid DND Simple Char PDFDocument1 pageHuman Druid DND Simple Char PDFMuhammad Fathul Al-AssalamNo ratings yet

- Disable Print Screen Key and All Keyboard Keys in ASP - Net PageDocument3 pagesDisable Print Screen Key and All Keyboard Keys in ASP - Net PagekhundaliniNo ratings yet

- Familiarity Questionnaire OCQ 90.2003Document5 pagesFamiliarity Questionnaire OCQ 90.2003yani0707No ratings yet

- Class 1Document21 pagesClass 1jayeda4sumonNo ratings yet

- Red OxDocument2 pagesRed Oxsun_rise_14No ratings yet

- Wind Load CalculationDocument13 pagesWind Load CalculationPre SheetNo ratings yet

- Republic of The Philippines Polytechnic University of The Philippines College of Education - Graduate StudiesDocument4 pagesRepublic of The Philippines Polytechnic University of The Philippines College of Education - Graduate StudiesJessa MolinaNo ratings yet

- Quarter by Numbers: Global HighlightsDocument37 pagesQuarter by Numbers: Global HighlightsAndreaNo ratings yet

- SM Piko-MpDocument92 pagesSM Piko-MpSamuel JACOBBONo ratings yet

- Acroname EnglishDocument44 pagesAcroname EnglishNissan NavaraNo ratings yet

- Chapter 9 CapacitorsDocument11 pagesChapter 9 CapacitorsnNo ratings yet

- VISHNU CV With ExperianceDocument2 pagesVISHNU CV With ExperianceoNo ratings yet

- Loans and AdvancesDocument9 pagesLoans and AdvancesidealworldNo ratings yet

- NAVIS ProblemDocument3 pagesNAVIS ProblemshanukawadugeNo ratings yet

- Anecdotal ReportDocument3 pagesAnecdotal ReportJulia Geonzon LabajoNo ratings yet

- HR One User Guide For Mobility V1.2Document34 pagesHR One User Guide For Mobility V1.2Mohammed QahtaniNo ratings yet