Professional Documents

Culture Documents

LT Panel PDI SOP

LT Panel PDI SOP

Uploaded by

Shrikanth SolaCopyright:

Available Formats

You might also like

- TRANSFORMER Inspection ChecklistDocument3 pagesTRANSFORMER Inspection ChecklistWisnu Hartono94% (18)

- Switchboard Inspection ChecklistDocument2 pagesSwitchboard Inspection Checklistraza23971% (7)

- Inspection Checklist For SMDBs & MDBsDocument5 pagesInspection Checklist For SMDBs & MDBsShirish67% (3)

- Panel Inspection Report FormatDocument5 pagesPanel Inspection Report Formatp mahesh goud100% (2)

- E021-Checklist LT PanelDocument1 pageE021-Checklist LT Panelaudiihussain67% (3)

- LT PANEL Testing ProcedureDocument5 pagesLT PANEL Testing Procedureaslam shaikh71% (7)

- Method Statement For Testing & Commissioning of LV Switchgear PanelsDocument4 pagesMethod Statement For Testing & Commissioning of LV Switchgear Panelsvin ss75% (4)

- Electrical Control Panel Testing and Inspection ChecklisttDocument2 pagesElectrical Control Panel Testing and Inspection ChecklisttRanjit Singh100% (7)

- VFD Commissioning FormatDocument2 pagesVFD Commissioning FormatJun Lumayno100% (4)

- Pre-Commissioning Test of Transformer at SiteDocument2 pagesPre-Commissioning Test of Transformer at SiteMohammad Husain88% (8)

- Electrical Panel SOPDocument10 pagesElectrical Panel SOPRiyaZ55100% (2)

- Transformer Check ListDocument2 pagesTransformer Check ListKanhiya Prasad80% (5)

- Checklist For LT Cabel JointingDocument3 pagesChecklist For LT Cabel Jointingccsures100% (4)

- Earthpit Resistance Testing RecordsheetDocument1 pageEarthpit Resistance Testing RecordsheetawsomeNo ratings yet

- Pre-Commissioning Tests ChecklistDocument9 pagesPre-Commissioning Tests ChecklistIYAD100% (4)

- Checklist Control PanelDocument2 pagesChecklist Control PanelSaravana Kumar83% (23)

- Standard Operating Procedure - LT Panel - V01 - 02092010Document5 pagesStandard Operating Procedure - LT Panel - V01 - 02092010Karthik Mandya100% (3)

- Rmu Visual Inspection ChecklistDocument1 pageRmu Visual Inspection ChecklistJoe_Average100% (3)

- Check List For UPSDocument1 pageCheck List For UPSsiruslara6491100% (2)

- Overhauling of Electrical Motors: Novatex Limited SOP / E&I / 11Document4 pagesOverhauling of Electrical Motors: Novatex Limited SOP / E&I / 11OSAMA67% (3)

- Preventative Maintenance Checklist For Electrical Distribution SystemsDocument3 pagesPreventative Maintenance Checklist For Electrical Distribution SystemsSreeRam SP0% (1)

- KRA KPI DepartmentDocument6 pagesKRA KPI DepartmentShrikanth Sola100% (1)

- JF 4 1 Solution PDFDocument2 pagesJF 4 1 Solution PDFIndri Rahmayuni100% (1)

- Beat The SlotsDocument91 pagesBeat The Slotsxavros100% (2)

- Electrical Notes & Articles: Minimum Electrical Clearance As Per BS:162Document5 pagesElectrical Notes & Articles: Minimum Electrical Clearance As Per BS:162Shrikanth Sola100% (2)

- LT Panel SOP For Test ProcedureDocument5 pagesLT Panel SOP For Test ProcedureShrikanth Sola100% (2)

- Aoh Checklist LT and HT MotorDocument8 pagesAoh Checklist LT and HT MotorElectrical Team100% (1)

- Sop For Electrical SafetyDocument3 pagesSop For Electrical Safetyanoushia alvi100% (1)

- ELCB Testing ReportDocument1 pageELCB Testing ReportPradeep Yallanki100% (4)

- Checklist For LT PanelDocument13 pagesChecklist For LT PanelSanket Jain80% (5)

- 12-SOP For Cable TerminationsDocument2 pages12-SOP For Cable TerminationsAbhay Godbole80% (5)

- Checklist of Panels - 00047 NewDocument6 pagesChecklist of Panels - 00047 NewKarthick Natrajan100% (1)

- Transformer Daily Check ListDocument3 pagesTransformer Daily Check ListVatsavai Appala Narasimha Raju50% (8)

- Panel Board ChecklistDocument2 pagesPanel Board Checklistanon_67491042No ratings yet

- LT Panel SOP For Test ProcedureDocument5 pagesLT Panel SOP For Test ProcedureShrikanth Sola100% (2)

- Drilling Facilities: NORSOK Standard D-001Document70 pagesDrilling Facilities: NORSOK Standard D-001Well Control100% (1)

- LT Panel PDI SOPDocument4 pagesLT Panel PDI SOPShrikanth Sola100% (2)

- HT Panel ChecklistDocument1 pageHT Panel Checklisttango member0% (1)

- LT PANEL / PCC Checking List Dept: Electrical: Equipment Tag No: Incoming PCC Feeder No.: DateDocument3 pagesLT PANEL / PCC Checking List Dept: Electrical: Equipment Tag No: Incoming PCC Feeder No.: DateVelmurugan Chakkravarthy100% (4)

- HT Panel ChecklistDocument1 pageHT Panel ChecklistMahfuza MansuraNo ratings yet

- Maint - Check List - Oil Filled TransforsDocument2 pagesMaint - Check List - Oil Filled TransforsramNo ratings yet

- VCB Maint ChecklistDocument3 pagesVCB Maint ChecklistAshish MahapatraNo ratings yet

- Standard Operating Procedure - HT Panel - V01 - 022.04.2011Document5 pagesStandard Operating Procedure - HT Panel - V01 - 022.04.2011Karthik Mandya100% (1)

- Procedure of Maintenance of 415V BUSDocument2 pagesProcedure of Maintenance of 415V BUSVatsavai Appala Narasimha Raju100% (1)

- Risk Assessment (RA) : Part 1: Location DetailsDocument3 pagesRisk Assessment (RA) : Part 1: Location DetailsPandu Birumakovela0% (1)

- Switchgear ChecklistDocument2 pagesSwitchgear ChecklistAnonymous IeFbdsfCo100% (2)

- QAP - LT Panel PDFDocument8 pagesQAP - LT Panel PDFAkshay Ajay100% (2)

- Check List LT PanelDocument1 pageCheck List LT PanelAnil Patel100% (2)

- MCC and Panels Maintenance ProcedureDocument15 pagesMCC and Panels Maintenance ProcedureÁlvaro Manterola Lazcano100% (21)

- Installation Checklist For Earthing System & PV Yard LayoutDocument2 pagesInstallation Checklist For Earthing System & PV Yard LayoutCarla Vietor100% (1)

- Name of Project/Site: Contractor Name: Date:: RCCB Test RegisterDocument2 pagesName of Project/Site: Contractor Name: Date:: RCCB Test RegisterRísês ÃfrözNo ratings yet

- Checklist For DB InstallationDocument1 pageChecklist For DB InstallationSatya NaiduNo ratings yet

- Acdb - Function TestDocument4 pagesAcdb - Function TestDinesh Pitchaivel0% (1)

- HT Panel Test ReportDocument4 pagesHT Panel Test ReportItx Adi50% (2)

- 1-SOP For Operation of LV Panel PDFDocument21 pages1-SOP For Operation of LV Panel PDFFareh Khan100% (2)

- Electrical Safety Inspection Checklist-FDocument2 pagesElectrical Safety Inspection Checklist-FGyanendra Narayan Nayak89% (9)

- VCB Maintenance ReportDocument8 pagesVCB Maintenance ReportSatya Barik100% (3)

- Checklist For Erection of USSDocument3 pagesChecklist For Erection of USSsasikumarNo ratings yet

- 1 AcdbDocument9 pages1 AcdbmaheshknmNo ratings yet

- Electrical SMDB Check ListDocument2 pagesElectrical SMDB Check ListBabu100% (2)

- 11 - SOP For Earthing Pit and EarthingDocument15 pages11 - SOP For Earthing Pit and Earthingtryu frtgeuwNo ratings yet

- Power Engineering - Check List ACB, VCB, OCB, LT PANELDocument7 pagesPower Engineering - Check List ACB, VCB, OCB, LT PANELAnonymous mNQq7oj100% (1)

- Transformer Erection ChecklistDocument2 pagesTransformer Erection Checklistmohan babu100% (2)

- Grid Code TestingDocument52 pagesGrid Code TestingYahya DarNo ratings yet

- Checklist Control PanelDocument2 pagesChecklist Control PanelAnjar AjjaNo ratings yet

- CPPP Self Assessment Spot Welding (QHB037G) 1Document28 pagesCPPP Self Assessment Spot Welding (QHB037G) 1broNo ratings yet

- Check List For 33 KV Transmission Pole LineDocument4 pagesCheck List For 33 KV Transmission Pole LineShrikanth SolaNo ratings yet

- SL - No SL - No Action ItemsDocument3 pagesSL - No SL - No Action ItemsShrikanth SolaNo ratings yet

- A7 CSI Ku Module EL Inspection SpecificationDocument12 pagesA7 CSI Ku Module EL Inspection SpecificationShrikanth SolaNo ratings yet

- Generation Detail of Last One Year-19Document232 pagesGeneration Detail of Last One Year-19Shrikanth SolaNo ratings yet

- Quality Department Document StatusDocument3 pagesQuality Department Document StatusShrikanth SolaNo ratings yet

- Project DetailsDocument1,325 pagesProject DetailsShrikanth SolaNo ratings yet

- Trafo Oil Testing TypesDocument10 pagesTrafo Oil Testing TypesShrikanth SolaNo ratings yet

- LT Panel PDI SOPDocument4 pagesLT Panel PDI SOPShrikanth Sola100% (2)

- Transformer Oil & Its EvolutionDocument7 pagesTransformer Oil & Its EvolutionShrikanth SolaNo ratings yet

- Cell-To-Module Conversion Loss Simulation For Shingled-Cell ConceptDocument5 pagesCell-To-Module Conversion Loss Simulation For Shingled-Cell ConceptShrikanth SolaNo ratings yet

- ReadMeFirst PDFDocument9 pagesReadMeFirst PDFalkatafangiNo ratings yet

- Uji Kualitas Air Sumur Dengan Menggunakan Metode MPN (Most ProbableDocument5 pagesUji Kualitas Air Sumur Dengan Menggunakan Metode MPN (Most ProbableAulia RahmanNo ratings yet

- Unit-12 Pipe Flow ProblemsDocument16 pagesUnit-12 Pipe Flow ProblemsMohamed KamelNo ratings yet

- VR 24 SW 11Document9 pagesVR 24 SW 11rubenNo ratings yet

- Tutorial For Cadence SOC Encounter Place & RouteDocument28 pagesTutorial For Cadence SOC Encounter Place & Routeanon_248257978No ratings yet

- RCA SystemLink3Document9 pagesRCA SystemLink3JerônimoNo ratings yet

- Department of Mechnical Engineering: CreditsDocument6 pagesDepartment of Mechnical Engineering: CreditsRoshan Virat PandeyNo ratings yet

- PEST On ProtonDocument2 pagesPEST On ProtonStarvinder SinghNo ratings yet

- Room Assignment Civil Engineer Pampanga Apr2023Document62 pagesRoom Assignment Civil Engineer Pampanga Apr2023Jonathan YambaoNo ratings yet

- Fortigate 900D: Data SheetDocument4 pagesFortigate 900D: Data SheetAbdel MounaimNo ratings yet

- SP 100 EC: Data Sheet Eccentric Diaphragm Pumps For GasesDocument5 pagesSP 100 EC: Data Sheet Eccentric Diaphragm Pumps For GasesFrancisco RochaNo ratings yet

- Western Innovator 2013Document52 pagesWestern Innovator 2013Agustin CesanNo ratings yet

- Roberts NewWorldDocument59 pagesRoberts NewWorldSam RobertsNo ratings yet

- Edb 4672441 Eng UsDocument3 pagesEdb 4672441 Eng UsGrucito KonfyNo ratings yet

- Chapter 6 StaffingDocument33 pagesChapter 6 Staffingshah0205No ratings yet

- Sr. No. Activity Description Responsibility: 4.0 ActivitiesDocument1 pageSr. No. Activity Description Responsibility: 4.0 ActivitiesKamal SolankiNo ratings yet

- TYN606 TYN1006: 6A SCRDocument6 pagesTYN606 TYN1006: 6A SCRMohammed ImranNo ratings yet

- Component Locations: 324D Excavator Hydraulic System - AttachmentDocument2 pagesComponent Locations: 324D Excavator Hydraulic System - AttachmentWalterNo ratings yet

- PULSE V2.0 - New Features: Cyber Security Protection Enhancements UAG (Unity Application Generator)Document2 pagesPULSE V2.0 - New Features: Cyber Security Protection Enhancements UAG (Unity Application Generator)cyrus6_997303No ratings yet

- Woodward UG ActuatorDocument4 pagesWoodward UG ActuatorИгорь100% (2)

- Flexographic (2011) - Low ResDocument44 pagesFlexographic (2011) - Low ResChloe GroemeNo ratings yet

- Deepwater Horizon Oil SpillDocument24 pagesDeepwater Horizon Oil SpillRaymundo AlarconNo ratings yet

- Oneplus Vs XiaomiDocument2 pagesOneplus Vs XiaomiZi Jin ChengNo ratings yet

- Sangoma Vega 400G Digital Gateway DatasheetDocument2 pagesSangoma Vega 400G Digital Gateway Datasheetmaple4VOIPNo ratings yet

- V3F ManualDocument33 pagesV3F Manuallhoffman3No ratings yet

- Masonry Mortars PDFDocument20 pagesMasonry Mortars PDFHafeel Ahamed Ashraf Ali100% (2)

- Controlled Circulation PumpDocument5 pagesControlled Circulation PumpLakshminarayanNo ratings yet

LT Panel PDI SOP

LT Panel PDI SOP

Uploaded by

Shrikanth SolaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LT Panel PDI SOP

LT Panel PDI SOP

Uploaded by

Shrikanth SolaCopyright:

Available Formats

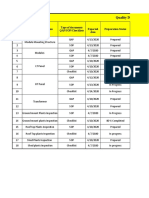

Title: SOP (Standard operating Procedure) for LT Panel PDI

FOURTH PARTNER ENERGY PVT. LTD

Fourth Partner House, Plot No: N46, House No: 4-9-10, HMT Nagar, Hyderabad – 500 076. India

T: +91-40-64631123| E-mail: info@fourthpartner.co | Website: www.fourthpartner.co

CIN No: U40108AP2010PTC070806

Following are the tests which were performed in LT Panel PDI:

Visual & Mechanical Checks:

● Check switchgear & all the components for any physical damage / defects.

● Check nameplate of panel with the actual/Approved design.

● Inspect enclosure’s for proper alignment, foundation and grounding.

● Inspect all covers, panel sections & doors for fixing along with painting.

● Check for proper alignment of primary and secondary contacts.

● Check components of the panel with the actual designs & BOM.

● Check for the Size of Busbar & verify Current carrying capacity.

● Check for operation of all mechanical interlocks.

● Check for tightness of all the bolted connections.

● Check for phasing connection of bus bar with the drawings.

● Perform mechanical check and visual inspection for breaker / Contractor as

per section.

● Perform mechanical check and visual inspection for instrument

transformers (CT’s) as per section.

● Perform mechanical check and visual inspection on all disconnect /

grounding switches as per section.

QA department

Prepared by Checked by Approved by

Quality team Souri Raju. R Mr.

Title: SOP (Standard operating Procedure) for LT Panel PDI

Insulation Resistance Test

The insulation resistance test is a DC evaluation test of the insulation and gives

a reliable indication of the presence of moisture, contamination or breakdown in

the insulation. This test also establishes a benchmark for future comparative

tests.

It includes panel enclosure, busbar, CT and circuit breaker. The following

precautions should be taken care, before starting the testing.

● A visual inspection to ensure the surface dust and moisture removal/ clear

from the component under test.

● Make sure the section is isolated from other joined system, which may feed to

other sections or circuits which aren’t under test.

● On testing, voltage shall be applied between one phase and other phases

connected with ground, testing shall be repeated for other phases as

mentioned above.

● Test voltage limits mentioned in table below:

Rated voltage Test Voltage

100-1000V AC/DC 1000V DC

>1000 to <5000V AC 2500V DC

> 5000V AC 5000V DC

QA department

Prepared by Checked by Approved by

Quality team Souri Raju. R Mr.

Title: SOP (Standard operating Procedure) for LT Panel PDI

Contact Resistance Test

Contacts are to be checked periodically, else resistance develops due to

frequent arcing, which decreases the contacts current carrying capability. This can

identify the quality mating of the contact surfaces and pivot points. Contact resistance

should be maintained as low as possible to reduce localized heating and power losses.

● Is to confirm the busbar joints are connected properly and tight.

● The test shall be done with CBs inserted and closed.

● Calculate the contact dc resistance among panels by applying 100A DC. This

will evolve busbar joint, CB contact resistance, CB cluster resistance, and CT

primary resistance (if applicable).

● The obtained results should be similar for all phases for each set of

measurement.

● Length of the measured track, rating of the busbar, CB and CT and

temperature or other influencing factors to be considered

High Voltage Test

● To determine the equipment is in proper condition to put in service, as it was

designed and to predict the healthy status or if deterioration is underway

which can shorten.

● To conduct the test all connections to the earth circuit should be removed.

● Furthermore, electronic equipment for control/ signal/ electronic instrument or

DC control equipment which are included in the control circuit, shall be

disconnected or removed during the test.

QA department

Prepared by Checked by Approved by

Quality team Souri Raju. R Mr.

Title: SOP (Standard operating Procedure) for LT Panel PDI

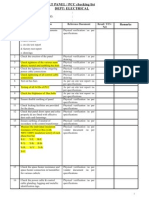

Acceptance Applicable/Not

A General checks Type of check criteria Applicable

1 Visual inspection Physical Witness

2 Dimensional check Measurement Witness

3 BOM check Verification Witness

4 Paint thickness check Measurement Witness

5 verification of type test certificates Verification Witness

verification of brought items test

6 certificates Verification Witness

7 Bus bar calculation sheet Verification Witness

8 Wiring check (Ferrules & connections) Verification Witness

9 Recommended protection relay settings Verification Witness

B Routine tests

Insulation resistance test (Before HV test &

1 after HV test) Measurement Witness

2 HV test Measurement Witness

3 Polarity test for CT's & PT's Measurement Witness

4 Primary injection test & Ration test Measurement

Breaker operational tests (Electrical &

5 Mechanical) Physical Witness

6 Functional tests Physical Witness

Numerical relay configuration & Functional

7 check Physical Witness

8 Sequential tests Physical Witness

Benefits of Switchgear Testing

● Reduce your business risks by meeting regulatory requirements and

standards.

● Increase quality and safety of your products and processes.

● Save time and costs.

● Shorten your time-to-market and increase market access by partnering with

an expert in regulatory requirements and standards.

QA department

Prepared by Checked by Approved by

Quality team Souri Raju. R Mr.

You might also like

- TRANSFORMER Inspection ChecklistDocument3 pagesTRANSFORMER Inspection ChecklistWisnu Hartono94% (18)

- Switchboard Inspection ChecklistDocument2 pagesSwitchboard Inspection Checklistraza23971% (7)

- Inspection Checklist For SMDBs & MDBsDocument5 pagesInspection Checklist For SMDBs & MDBsShirish67% (3)

- Panel Inspection Report FormatDocument5 pagesPanel Inspection Report Formatp mahesh goud100% (2)

- E021-Checklist LT PanelDocument1 pageE021-Checklist LT Panelaudiihussain67% (3)

- LT PANEL Testing ProcedureDocument5 pagesLT PANEL Testing Procedureaslam shaikh71% (7)

- Method Statement For Testing & Commissioning of LV Switchgear PanelsDocument4 pagesMethod Statement For Testing & Commissioning of LV Switchgear Panelsvin ss75% (4)

- Electrical Control Panel Testing and Inspection ChecklisttDocument2 pagesElectrical Control Panel Testing and Inspection ChecklisttRanjit Singh100% (7)

- VFD Commissioning FormatDocument2 pagesVFD Commissioning FormatJun Lumayno100% (4)

- Pre-Commissioning Test of Transformer at SiteDocument2 pagesPre-Commissioning Test of Transformer at SiteMohammad Husain88% (8)

- Electrical Panel SOPDocument10 pagesElectrical Panel SOPRiyaZ55100% (2)

- Transformer Check ListDocument2 pagesTransformer Check ListKanhiya Prasad80% (5)

- Checklist For LT Cabel JointingDocument3 pagesChecklist For LT Cabel Jointingccsures100% (4)

- Earthpit Resistance Testing RecordsheetDocument1 pageEarthpit Resistance Testing RecordsheetawsomeNo ratings yet

- Pre-Commissioning Tests ChecklistDocument9 pagesPre-Commissioning Tests ChecklistIYAD100% (4)

- Checklist Control PanelDocument2 pagesChecklist Control PanelSaravana Kumar83% (23)

- Standard Operating Procedure - LT Panel - V01 - 02092010Document5 pagesStandard Operating Procedure - LT Panel - V01 - 02092010Karthik Mandya100% (3)

- Rmu Visual Inspection ChecklistDocument1 pageRmu Visual Inspection ChecklistJoe_Average100% (3)

- Check List For UPSDocument1 pageCheck List For UPSsiruslara6491100% (2)

- Overhauling of Electrical Motors: Novatex Limited SOP / E&I / 11Document4 pagesOverhauling of Electrical Motors: Novatex Limited SOP / E&I / 11OSAMA67% (3)

- Preventative Maintenance Checklist For Electrical Distribution SystemsDocument3 pagesPreventative Maintenance Checklist For Electrical Distribution SystemsSreeRam SP0% (1)

- KRA KPI DepartmentDocument6 pagesKRA KPI DepartmentShrikanth Sola100% (1)

- JF 4 1 Solution PDFDocument2 pagesJF 4 1 Solution PDFIndri Rahmayuni100% (1)

- Beat The SlotsDocument91 pagesBeat The Slotsxavros100% (2)

- Electrical Notes & Articles: Minimum Electrical Clearance As Per BS:162Document5 pagesElectrical Notes & Articles: Minimum Electrical Clearance As Per BS:162Shrikanth Sola100% (2)

- LT Panel SOP For Test ProcedureDocument5 pagesLT Panel SOP For Test ProcedureShrikanth Sola100% (2)

- Aoh Checklist LT and HT MotorDocument8 pagesAoh Checklist LT and HT MotorElectrical Team100% (1)

- Sop For Electrical SafetyDocument3 pagesSop For Electrical Safetyanoushia alvi100% (1)

- ELCB Testing ReportDocument1 pageELCB Testing ReportPradeep Yallanki100% (4)

- Checklist For LT PanelDocument13 pagesChecklist For LT PanelSanket Jain80% (5)

- 12-SOP For Cable TerminationsDocument2 pages12-SOP For Cable TerminationsAbhay Godbole80% (5)

- Checklist of Panels - 00047 NewDocument6 pagesChecklist of Panels - 00047 NewKarthick Natrajan100% (1)

- Transformer Daily Check ListDocument3 pagesTransformer Daily Check ListVatsavai Appala Narasimha Raju50% (8)

- Panel Board ChecklistDocument2 pagesPanel Board Checklistanon_67491042No ratings yet

- LT Panel SOP For Test ProcedureDocument5 pagesLT Panel SOP For Test ProcedureShrikanth Sola100% (2)

- Drilling Facilities: NORSOK Standard D-001Document70 pagesDrilling Facilities: NORSOK Standard D-001Well Control100% (1)

- LT Panel PDI SOPDocument4 pagesLT Panel PDI SOPShrikanth Sola100% (2)

- HT Panel ChecklistDocument1 pageHT Panel Checklisttango member0% (1)

- LT PANEL / PCC Checking List Dept: Electrical: Equipment Tag No: Incoming PCC Feeder No.: DateDocument3 pagesLT PANEL / PCC Checking List Dept: Electrical: Equipment Tag No: Incoming PCC Feeder No.: DateVelmurugan Chakkravarthy100% (4)

- HT Panel ChecklistDocument1 pageHT Panel ChecklistMahfuza MansuraNo ratings yet

- Maint - Check List - Oil Filled TransforsDocument2 pagesMaint - Check List - Oil Filled TransforsramNo ratings yet

- VCB Maint ChecklistDocument3 pagesVCB Maint ChecklistAshish MahapatraNo ratings yet

- Standard Operating Procedure - HT Panel - V01 - 022.04.2011Document5 pagesStandard Operating Procedure - HT Panel - V01 - 022.04.2011Karthik Mandya100% (1)

- Procedure of Maintenance of 415V BUSDocument2 pagesProcedure of Maintenance of 415V BUSVatsavai Appala Narasimha Raju100% (1)

- Risk Assessment (RA) : Part 1: Location DetailsDocument3 pagesRisk Assessment (RA) : Part 1: Location DetailsPandu Birumakovela0% (1)

- Switchgear ChecklistDocument2 pagesSwitchgear ChecklistAnonymous IeFbdsfCo100% (2)

- QAP - LT Panel PDFDocument8 pagesQAP - LT Panel PDFAkshay Ajay100% (2)

- Check List LT PanelDocument1 pageCheck List LT PanelAnil Patel100% (2)

- MCC and Panels Maintenance ProcedureDocument15 pagesMCC and Panels Maintenance ProcedureÁlvaro Manterola Lazcano100% (21)

- Installation Checklist For Earthing System & PV Yard LayoutDocument2 pagesInstallation Checklist For Earthing System & PV Yard LayoutCarla Vietor100% (1)

- Name of Project/Site: Contractor Name: Date:: RCCB Test RegisterDocument2 pagesName of Project/Site: Contractor Name: Date:: RCCB Test RegisterRísês ÃfrözNo ratings yet

- Checklist For DB InstallationDocument1 pageChecklist For DB InstallationSatya NaiduNo ratings yet

- Acdb - Function TestDocument4 pagesAcdb - Function TestDinesh Pitchaivel0% (1)

- HT Panel Test ReportDocument4 pagesHT Panel Test ReportItx Adi50% (2)

- 1-SOP For Operation of LV Panel PDFDocument21 pages1-SOP For Operation of LV Panel PDFFareh Khan100% (2)

- Electrical Safety Inspection Checklist-FDocument2 pagesElectrical Safety Inspection Checklist-FGyanendra Narayan Nayak89% (9)

- VCB Maintenance ReportDocument8 pagesVCB Maintenance ReportSatya Barik100% (3)

- Checklist For Erection of USSDocument3 pagesChecklist For Erection of USSsasikumarNo ratings yet

- 1 AcdbDocument9 pages1 AcdbmaheshknmNo ratings yet

- Electrical SMDB Check ListDocument2 pagesElectrical SMDB Check ListBabu100% (2)

- 11 - SOP For Earthing Pit and EarthingDocument15 pages11 - SOP For Earthing Pit and Earthingtryu frtgeuwNo ratings yet

- Power Engineering - Check List ACB, VCB, OCB, LT PANELDocument7 pagesPower Engineering - Check List ACB, VCB, OCB, LT PANELAnonymous mNQq7oj100% (1)

- Transformer Erection ChecklistDocument2 pagesTransformer Erection Checklistmohan babu100% (2)

- Grid Code TestingDocument52 pagesGrid Code TestingYahya DarNo ratings yet

- Checklist Control PanelDocument2 pagesChecklist Control PanelAnjar AjjaNo ratings yet

- CPPP Self Assessment Spot Welding (QHB037G) 1Document28 pagesCPPP Self Assessment Spot Welding (QHB037G) 1broNo ratings yet

- Check List For 33 KV Transmission Pole LineDocument4 pagesCheck List For 33 KV Transmission Pole LineShrikanth SolaNo ratings yet

- SL - No SL - No Action ItemsDocument3 pagesSL - No SL - No Action ItemsShrikanth SolaNo ratings yet

- A7 CSI Ku Module EL Inspection SpecificationDocument12 pagesA7 CSI Ku Module EL Inspection SpecificationShrikanth SolaNo ratings yet

- Generation Detail of Last One Year-19Document232 pagesGeneration Detail of Last One Year-19Shrikanth SolaNo ratings yet

- Quality Department Document StatusDocument3 pagesQuality Department Document StatusShrikanth SolaNo ratings yet

- Project DetailsDocument1,325 pagesProject DetailsShrikanth SolaNo ratings yet

- Trafo Oil Testing TypesDocument10 pagesTrafo Oil Testing TypesShrikanth SolaNo ratings yet

- LT Panel PDI SOPDocument4 pagesLT Panel PDI SOPShrikanth Sola100% (2)

- Transformer Oil & Its EvolutionDocument7 pagesTransformer Oil & Its EvolutionShrikanth SolaNo ratings yet

- Cell-To-Module Conversion Loss Simulation For Shingled-Cell ConceptDocument5 pagesCell-To-Module Conversion Loss Simulation For Shingled-Cell ConceptShrikanth SolaNo ratings yet

- ReadMeFirst PDFDocument9 pagesReadMeFirst PDFalkatafangiNo ratings yet

- Uji Kualitas Air Sumur Dengan Menggunakan Metode MPN (Most ProbableDocument5 pagesUji Kualitas Air Sumur Dengan Menggunakan Metode MPN (Most ProbableAulia RahmanNo ratings yet

- Unit-12 Pipe Flow ProblemsDocument16 pagesUnit-12 Pipe Flow ProblemsMohamed KamelNo ratings yet

- VR 24 SW 11Document9 pagesVR 24 SW 11rubenNo ratings yet

- Tutorial For Cadence SOC Encounter Place & RouteDocument28 pagesTutorial For Cadence SOC Encounter Place & Routeanon_248257978No ratings yet

- RCA SystemLink3Document9 pagesRCA SystemLink3JerônimoNo ratings yet

- Department of Mechnical Engineering: CreditsDocument6 pagesDepartment of Mechnical Engineering: CreditsRoshan Virat PandeyNo ratings yet

- PEST On ProtonDocument2 pagesPEST On ProtonStarvinder SinghNo ratings yet

- Room Assignment Civil Engineer Pampanga Apr2023Document62 pagesRoom Assignment Civil Engineer Pampanga Apr2023Jonathan YambaoNo ratings yet

- Fortigate 900D: Data SheetDocument4 pagesFortigate 900D: Data SheetAbdel MounaimNo ratings yet

- SP 100 EC: Data Sheet Eccentric Diaphragm Pumps For GasesDocument5 pagesSP 100 EC: Data Sheet Eccentric Diaphragm Pumps For GasesFrancisco RochaNo ratings yet

- Western Innovator 2013Document52 pagesWestern Innovator 2013Agustin CesanNo ratings yet

- Roberts NewWorldDocument59 pagesRoberts NewWorldSam RobertsNo ratings yet

- Edb 4672441 Eng UsDocument3 pagesEdb 4672441 Eng UsGrucito KonfyNo ratings yet

- Chapter 6 StaffingDocument33 pagesChapter 6 Staffingshah0205No ratings yet

- Sr. No. Activity Description Responsibility: 4.0 ActivitiesDocument1 pageSr. No. Activity Description Responsibility: 4.0 ActivitiesKamal SolankiNo ratings yet

- TYN606 TYN1006: 6A SCRDocument6 pagesTYN606 TYN1006: 6A SCRMohammed ImranNo ratings yet

- Component Locations: 324D Excavator Hydraulic System - AttachmentDocument2 pagesComponent Locations: 324D Excavator Hydraulic System - AttachmentWalterNo ratings yet

- PULSE V2.0 - New Features: Cyber Security Protection Enhancements UAG (Unity Application Generator)Document2 pagesPULSE V2.0 - New Features: Cyber Security Protection Enhancements UAG (Unity Application Generator)cyrus6_997303No ratings yet

- Woodward UG ActuatorDocument4 pagesWoodward UG ActuatorИгорь100% (2)

- Flexographic (2011) - Low ResDocument44 pagesFlexographic (2011) - Low ResChloe GroemeNo ratings yet

- Deepwater Horizon Oil SpillDocument24 pagesDeepwater Horizon Oil SpillRaymundo AlarconNo ratings yet

- Oneplus Vs XiaomiDocument2 pagesOneplus Vs XiaomiZi Jin ChengNo ratings yet

- Sangoma Vega 400G Digital Gateway DatasheetDocument2 pagesSangoma Vega 400G Digital Gateway Datasheetmaple4VOIPNo ratings yet

- V3F ManualDocument33 pagesV3F Manuallhoffman3No ratings yet

- Masonry Mortars PDFDocument20 pagesMasonry Mortars PDFHafeel Ahamed Ashraf Ali100% (2)

- Controlled Circulation PumpDocument5 pagesControlled Circulation PumpLakshminarayanNo ratings yet