Professional Documents

Culture Documents

IDC SOP # 10 RIH With DC's and Drill Pipe (Bit On Bottom)

IDC SOP # 10 RIH With DC's and Drill Pipe (Bit On Bottom)

Uploaded by

kareemOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IDC SOP # 10 RIH With DC's and Drill Pipe (Bit On Bottom)

IDC SOP # 10 RIH With DC's and Drill Pipe (Bit On Bottom)

Uploaded by

kareemCopyright:

Available Formats

IRAQI DRILLING COMPANY”IDC”

SOP / Task Risk Assessment / TBT

Document Name: DM-43 Activity: RIH with DC’s, HWDP and Drill Pipe (Bit

Revision No. #10 on Bottom)

Task Supervisor Name: Position:

Signature: Date:

General Guidelines

Task Supervisor shall be competent to perform / supervise the activity

Task Supervisor to ensure the steps in this SOP are relevant to the task

Task Supervisor must sign document acknowledging review with crew

Task Supervisor must ensure a TBT is conducted with all relevant crew members to ensure

they are aware of their Responsibilities, Job Steps, Hazards and Precautions

Task Supervisor to ensure all persons involved with task sign the document

The Task Supervisor shall oversee the entire activity, if the Task Supervisor leaves the work

site, the job Stops or an alternate competent person is nominated as the new Task

Supervisor

If the activity changes:

o Stop the job

o Review the change and ensure an adequate plan is in place before restarting the job

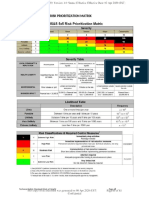

Task Risk Assessment - Refer to detailed job steps

No

Basic Steps Hazard Precaution

.

1 RIH with Drill Collars Well Control Ensure well controls and fluid level

and Bit WAH/Falling checks is monitored and full

Potential Dropped Objects Make sure proper fall arrestors and

Unsafe Lifting operations climb assists are used by derrick men

Pinch points, hand injuries when going to and from monkey

Struck by or caught between board and while POOH

pipe and tongs Derrick man to be trained and

Hand injury while installing competency assessed for working at

dog collar the monkey board

Derrick man to follow Working at

Heights procedures

Register the ascent into the Working

Aloft Register

Respect the Red Zone management

system

Anytime the blocks are moving the

floor hands to clear the floor

Use rope to tail in the stands, never

stand in front of the stand’s

direction of movement

Beware of hand placement when

stabbing stands and using drill collar

Utilize tong handles when operating

tongs

Ensure correct lifting equipment is

used when running tubulars

Safe body placement when

operating tongs

Never place hands under dog collar

when installing or removing

2 RIH with HWDP Well Control Same Precautions in Step 1

WAH/Falling

Potential Dropped Objects

Unsafe Lifting operations

Pinch points, hand injuries

Struck by or caught between

pipe and tongs

3 RIH with Drill Pipe Well Control Same Precautions in Step 1

WAH/Falling

Potential Dropped Objects

Unsafe Lifting operations

Pinch points, hand injuries

Struck by or caught between

pipe and tongs

Documents required for performing job

PTW Additional Risk Assessment Energy Isolation Cert. Lifting Cert.

Lift Plan Rescue Plan Man Riding Cert.

Additional Documents Explain: Complete working aloft register if tools required in derrick

Required Equipment / Tools

Item Item Item

Hydraulic Tongs Slips Tailing ropes

Chain Tongs Elevators

TBT Attendees: (All personnel involved in task must sign)

Names Position Signature

Detailed SOP Job Steps

Step 1: RIH with Drill Collars and Bit

Task Supervisor to hold pre-job safety meeting to review job steps, hazards and precautions

with personnel

Close blind rams. Hang sign on weight indicator and conduct Flow checks while out of hole

Prepare for running DC’s by ensuring rig floor is clear of tripping and slipping hazards and

check tongs, slips and elevators to ensure good condition and correct size of tools

Ensure PTW and Rescue Plan in place prior to derrick man ascending derrick

Unlock the blocks, put on the balance strap and position the elevators towards the derrick

man

Send blocks up for the first stand of drill collars and derrick man signals driller when to stop

blocks. Derrick man to use monkey board winch to let out collar, positions into elevator and

latches them closed around first drill collar

Driller picks up slowly on the blocks until pin end of DC is up about one foot off the rig floor

The derrick man lets the DC in and floor hands controlling bottom with a rope, slipping rope

to allow bottom of DC to come towards rotary table. Remove winch and rope from around

drill collar

Screw the bit sub on bottom of drill collar if not already on, install float if required and screw

on bit. Small bits can be made up by hand. Big bits are to be set into bit breakers in rotary

table. Reverse rotary table and put draw works back into forward

Torque up bit and bit sub to the recommended / correct torque value

With everybody clear, bleed pressure w/ choke, Open blind rams

Remove bushings if in rotary, lower bit and first stand of Drill collar into well and replace

bushing. If bushing is already out set slips around drill collar, install safety clamp

Send the returns to the trip tank to monitor the returns to ensure correct volumes, alert

driller if not OK

Open elevators and send blocks up derrick to connect to next stand of drill collar, pick up

and stab into the stump. Screw the top stand in with chain tongs. Follow steps above when

tailing in DC

Place tongs around connection and tighten connection to recommended torque. Stand away

from tongs to torque

Pick up to neutral weight of drill collars, remove safety clamp and continue to pick up on DC

to pull slips. Lower drill collar into hole and repeat above steps until all drill collars have been

run

Step 2: RIH with HWDP

Change elevators to run HWDP and install balance strap. Ensure correct size elevators are

selected

Send the blocks to the derrick man to latch onto first stand of Heavy Weight Drill Pipe

(HWDP). Ensure use of ropes to control bottom of HWDP

Screw on cross over from DC to HWDP on bottom of HWDP stand. Torque the crossover and

HWDP to correct value with tongs

Stab crossover into the stump and make up with chain tongs

Position tongs across connection and torque crossover and HWDP to correct value

Remove dog collar and put away, pull slips as driller picks up and change slips to fit HWDP

Lower first stand of HWDP into well, set slips at correct height, open elevators and repeat

steps to run rest of HWDP into hole

Step 3: RIH with Drill Pipe

If applicable change elevators to fit drill pipe and reinstall balance strap. If not continue with

elevators used for HWDP

Position the elevators and send blocks up to latch onto first stand of drill pipe. Adjust speed

of blocks so derrick man can safely latch elevators onto DP. When derrick man latches onto

DP the momentum of the blocks should bring the stand just high enough to stab in the

stump. Ensure personnel are in position to control bottom of DP

Position DP over stump and stab in. Pull on spinner & spin in the joint. Position tongs across

connection and make up to recommended torque

Pick up on DP while pulling slips and RIH with DP stand. Repeat steps until DP reaches

needed depth

Flow check and fill pipe as required. Normal is filling every 2000 feet

You might also like

- Bitcoin To $1M, Ethereum To $180,000 by 2030 ARKDocument1 pageBitcoin To $1M, Ethereum To $180,000 by 2030 ARKOwen HalpertNo ratings yet

- Skid Steer (Generic) : Job Safety AnalysisDocument2 pagesSkid Steer (Generic) : Job Safety AnalysisNanthan GanesNo ratings yet

- JSA For Crawler Crane Installation FormDocument3 pagesJSA For Crawler Crane Installation FormDaniel Prakoso50% (2)

- 3074 - Use of Genie Man LiftDocument1 page3074 - Use of Genie Man Liftcmrig74No ratings yet

- JSA Installation of Equipment For Electrical and InstrumentDocument3 pagesJSA Installation of Equipment For Electrical and InstrumentHong Hai Pham80% (5)

- JSA Steel Erection ManliftsDocument1 pageJSA Steel Erection Manliftsrudygoot100% (1)

- JSA DrillingDocument4 pagesJSA DrillingAmalNo ratings yet

- JHA - Lifting ACUs With 60 Ton CraneDocument2 pagesJHA - Lifting ACUs With 60 Ton Cranescottie MailauNo ratings yet

- Belt Conveyor Bearing InspectionDocument3 pagesBelt Conveyor Bearing InspectionKarthikeyan MNo ratings yet

- Safety: JOB AnalysisDocument4 pagesSafety: JOB AnalysisAjay kumar100% (1)

- IDC SOP # 11 POOH With DP, DC's and BitDocument3 pagesIDC SOP # 11 POOH With DP, DC's and Bitkareem100% (1)

- IDC SOP # 13 POOH With DP, DC's and BitDocument4 pagesIDC SOP # 13 POOH With DP, DC's and BitkareemNo ratings yet

- IDC SOP # XX Laying Down Drill Pipe From DerrickDocument4 pagesIDC SOP # XX Laying Down Drill Pipe From DerrickkareemNo ratings yet

- IDC SOP # 10 Operation of The Pipe SpinnerDocument2 pagesIDC SOP # 10 Operation of The Pipe SpinnerkareemNo ratings yet

- Break Out and Laying Down BhaDocument3 pagesBreak Out and Laying Down BhakhurramNo ratings yet

- SOP-17-Installation and Disassembly of CatwalkDocument7 pagesSOP-17-Installation and Disassembly of CatwalkDQE040 HSSENo ratings yet

- Ast Jsa - Piping FabricationDocument3 pagesAst Jsa - Piping Fabricationmd_rehan_2No ratings yet

- S.No Job Steps Hazards Preventative Measures Responsible PersonDocument3 pagesS.No Job Steps Hazards Preventative Measures Responsible Personmd_rehan_2No ratings yet

- SOP-4-Making Up & Break Out BHADocument8 pagesSOP-4-Making Up & Break Out BHADQE040 HSSENo ratings yet

- MS Connecting Bridge Erection ACPLDocument16 pagesMS Connecting Bridge Erection ACPLRaju BiswasNo ratings yet

- Cut and Slip Drilling LineDocument32 pagesCut and Slip Drilling Lineali abbasNo ratings yet

- Daqing Petroleum Iraq Branch Job Safety Analysis 工作安全分析: HSE-MS record No. 22Document4 pagesDaqing Petroleum Iraq Branch Job Safety Analysis 工作安全分析: HSE-MS record No. 22khurramNo ratings yet

- Rigging Amp Lifting Handbook NSLDocument7 pagesRigging Amp Lifting Handbook NSLAkram BadranNo ratings yet

- InjuryDocument2 pagesInjurykhurramNo ratings yet

- BHA - HandlingDocument2 pagesBHA - HandlingAvinash MathewNo ratings yet

- Capstan (OSRV) SOPDocument7 pagesCapstan (OSRV) SOPakbar muslimNo ratings yet

- HydrotestingDocument4 pagesHydrotestingDarwin De ChavezNo ratings yet

- Ehv SWP Form Lifting Lowering Operation PDF NewDocument3 pagesEhv SWP Form Lifting Lowering Operation PDF NewSn AhsanNo ratings yet

- Jsa CPBDocument3 pagesJsa CPBmd maroofNo ratings yet

- SWMS (Cable Glanding and Termination )Document6 pagesSWMS (Cable Glanding and Termination )PRIYESH . K. PRIYANNo ratings yet

- RA HSE 12 001 Process Rev03Document3 pagesRA HSE 12 001 Process Rev03zarni77No ratings yet

- JSA 48-Man Basket Lifting and MovingDocument3 pagesJSA 48-Man Basket Lifting and MovinggolusinghdataNo ratings yet

- JSA #19 - Heavy Lifting in Hazardous AreaDocument1 pageJSA #19 - Heavy Lifting in Hazardous AreaMock ProjectNo ratings yet

- JB GG Work Method Statement 2023Document1 pageJB GG Work Method Statement 2023Melissa GrayNo ratings yet

- Fall PreventionsDocument16 pagesFall PreventionsRajesh gp100% (1)

- Water Tank Cleaning TRADocument5 pagesWater Tank Cleaning TRAyehia sayedNo ratings yet

- Risk Assessment For Installation of Water Supply SystemDocument2 pagesRisk Assessment For Installation of Water Supply Systemمقاول تكييف كهرباء وصحيNo ratings yet

- Shifting and Loading Unloading of MaterialDocument4 pagesShifting and Loading Unloading of MaterialAdilMunirNo ratings yet

- FPS 015 - Installation of valvesREV1Document4 pagesFPS 015 - Installation of valvesREV1grantNo ratings yet

- SOP Erection TC PDFDocument3 pagesSOP Erection TC PDFRashidi Rahman0% (1)

- Swms HotworksDocument3 pagesSwms HotworksKim Ryan PomarNo ratings yet

- Upper Mast Section Lifting PlanDocument7 pagesUpper Mast Section Lifting PlanDurgham Adel EscanderNo ratings yet

- JSA For Piping-Hydro TestDocument10 pagesJSA For Piping-Hydro TestMuthu AlaguRajNo ratings yet

- JSA For Lifting of StripperDocument4 pagesJSA For Lifting of StripperMohammed MinhajNo ratings yet

- FM-QHSSE-122-R05 - Checklist Man Riding OperationDocument2 pagesFM-QHSSE-122-R05 - Checklist Man Riding OperationSARFARAZ KHANNo ratings yet

- Working at Height (Lifting Gear Inspection)Document1 pageWorking at Height (Lifting Gear Inspection)Hamdi RafiekNo ratings yet

- DQE SOP-183-Upper Substructure DisassemblyDocument8 pagesDQE SOP-183-Upper Substructure DisassemblyDQE040 HSSENo ratings yet

- VND - Openxmlformats Officedocument - Wordprocessingml.document&rendition 1Document13 pagesVND - Openxmlformats Officedocument - Wordprocessingml.document&rendition 1Raju BiswasNo ratings yet

- Jsa For Chemical Ware HouseDocument4 pagesJsa For Chemical Ware Housesalauddin0mohammedNo ratings yet

- Risk Assesment For Lighting Protection SystemDocument2 pagesRisk Assesment For Lighting Protection SystemAsfand AyazNo ratings yet

- RISK/IMPACT ASSESSMENT (To Be Used Both Occupation Health, Safety & Environment)Document3 pagesRISK/IMPACT ASSESSMENT (To Be Used Both Occupation Health, Safety & Environment)Sijo RajanNo ratings yet

- MSRA Door ReplacementDocument3 pagesMSRA Door ReplacementBala KrishnanNo ratings yet

- Crane Safety Training CLP. 15.11.2016 .Pps PDFDocument117 pagesCrane Safety Training CLP. 15.11.2016 .Pps PDFJSW Bellary, Project100% (1)

- Hira Work at Height-1Document4 pagesHira Work at Height-1Optimistic anonymousNo ratings yet

- Job Hazard Analysis SampleDocument1 pageJob Hazard Analysis SampleLevy Vikko GasconNo ratings yet

- Crane Safety Rev 1Document4 pagesCrane Safety Rev 1RAMANo ratings yet

- KKD-SAMUR-HSEJHA-004 JHA LIFTING Revised UPDATE 30.7.2013Document5 pagesKKD-SAMUR-HSEJHA-004 JHA LIFTING Revised UPDATE 30.7.2013Fadzli MaddyNo ratings yet

- Job Safety Analysis - Cone ErectionDocument6 pagesJob Safety Analysis - Cone ErectionEslam lotfy- Eslam elsadatNo ratings yet

- BOP - Nipple Down 006Document2 pagesBOP - Nipple Down 006Avinash MathewNo ratings yet

- Aeroplane Flight Training: Lesson Plans for Students & Instructors With Questions - Plus a Lot MoreFrom EverandAeroplane Flight Training: Lesson Plans for Students & Instructors With Questions - Plus a Lot MoreRating: 3 out of 5 stars3/5 (2)

- Dor - 25 09 2022 - WQ1 223 - Idc 143 4Document1 pageDor - 25 09 2022 - WQ1 223 - Idc 143 4kareemNo ratings yet

- BOP Configuration 9.625inch Mud CrossDocument2 pagesBOP Configuration 9.625inch Mud CrosskareemNo ratings yet

- Waiting On Daylight Waiting On Mast Leg Pad InspectionDocument1 pageWaiting On Daylight Waiting On Mast Leg Pad InspectionkareemNo ratings yet

- Po 4510089832Document2 pagesPo 4510089832kareemNo ratings yet

- Workover Daily Report WQ1-039Document3 pagesWorkover Daily Report WQ1-039kareem100% (1)

- Daily Operation Report Date: 02/ 06 / 2021 Project: Exxon Mobil Location Area: WQ1 - 053 ROW: 82 Country: IraqDocument18 pagesDaily Operation Report Date: 02/ 06 / 2021 Project: Exxon Mobil Location Area: WQ1 - 053 ROW: 82 Country: IraqkareemNo ratings yet

- Waiting On Daylight Waiting On Mast Leg Pad InspectionDocument1 pageWaiting On Daylight Waiting On Mast Leg Pad InspectionkareemNo ratings yet

- Dor 19-11-2019 FH#5 Idc45 18Document1 pageDor 19-11-2019 FH#5 Idc45 18kareemNo ratings yet

- Iraqi Drilling Company Daily Report Integrated Mangement System (IDCP08F4)Document1 pageIraqi Drilling Company Daily Report Integrated Mangement System (IDCP08F4)kareemNo ratings yet

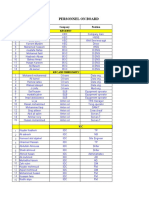

- Personnel On Board: No. Full Name Company Position LocationDocument4 pagesPersonnel On Board: No. Full Name Company Position LocationkareemNo ratings yet

- IDC SOP # XX Laying Down Drill Pipe From DerrickDocument4 pagesIDC SOP # XX Laying Down Drill Pipe From DerrickkareemNo ratings yet

- IDC SOP # 13 POOH With DP, DC's and BitDocument4 pagesIDC SOP # 13 POOH With DP, DC's and BitkareemNo ratings yet

- IDC SOP # 10 Operation of The Pipe SpinnerDocument2 pagesIDC SOP # 10 Operation of The Pipe SpinnerkareemNo ratings yet

- IDC SOP #2 Pressure Test of The StandpipeDocument5 pagesIDC SOP #2 Pressure Test of The StandpipekareemNo ratings yet

- IDC SOP # 11 POOH With DP, DC's and BitDocument3 pagesIDC SOP # 11 POOH With DP, DC's and Bitkareem100% (1)

- JKSSB Class IV (28 Feb 2021) EnglishDocument12 pagesJKSSB Class IV (28 Feb 2021) Englishmirziya711No ratings yet

- 2003 Corkscrew Bike Trail StudyDocument25 pages2003 Corkscrew Bike Trail StudyJoey KulkinNo ratings yet

- 978 1 5275 0785 2 SampleDocument30 pages978 1 5275 0785 2 SampleJacob AlonzoNo ratings yet

- Power of The BloodDocument14 pagesPower of The BloodEturnal BrandsNo ratings yet

- ISCDL - Problem Statements For State Level HackthonDocument6 pagesISCDL - Problem Statements For State Level HackthonSarvesh DubeyNo ratings yet

- Chapter 03-A - 20111108094508Document29 pagesChapter 03-A - 20111108094508Heri YantiNo ratings yet

- El Volcan MombachoDocument10 pagesEl Volcan MombachoYossuara PittiNo ratings yet

- Exp3 DissolutionstudiesofparacetamolDocument5 pagesExp3 DissolutionstudiesofparacetamolTHARSHINI MURUGAIAHNo ratings yet

- The Polarization of Light: Experiment 3Document4 pagesThe Polarization of Light: Experiment 3Mujeeb UllahNo ratings yet

- Sony KV 13TR27 Chasis.P 3BDocument29 pagesSony KV 13TR27 Chasis.P 3BTereza Yamileth Coto ENo ratings yet

- Feb 3 Questions Nuclear WasteDocument4 pagesFeb 3 Questions Nuclear WastedcudfhiudfiuNo ratings yet

- Kuz Ram ModelDocument1 pageKuz Ram Modelcrystal 2810100% (1)

- Quiz - Lab Safety and ApparatusDocument1 pageQuiz - Lab Safety and ApparatusJohn Kristoffer RoblezaNo ratings yet

- 4G Wireless PresentationDocument26 pages4G Wireless PresentationArjun ShankaNo ratings yet

- Revised LRS BRS Booklet-2015-2016Document14 pagesRevised LRS BRS Booklet-2015-2016undyingNo ratings yet

- Sistemas de Refrigeracion Industrial en AmoniacoDocument102 pagesSistemas de Refrigeracion Industrial en AmoniacoDiego Trinidad100% (8)

- Industry Alloted Property NoidaDocument193 pagesIndustry Alloted Property Noidaavinashtyagi0% (1)

- Surveying 1Document2 pagesSurveying 1haes.sisonNo ratings yet

- Arrow Metal Brochure - Perforated MetalDocument12 pagesArrow Metal Brochure - Perforated MetalSterlingNo ratings yet

- Falcon Combination Oven S Series User ManualDocument50 pagesFalcon Combination Oven S Series User Manualخالد التريكيNo ratings yet

- Peugeot 206 P Dag Owners ManualDocument119 pagesPeugeot 206 P Dag Owners ManualAlex Rojas AguilarNo ratings yet

- I Rod Nu Bolt Product OverviewDocument6 pagesI Rod Nu Bolt Product Overviewjamehome85No ratings yet

- Fichas Tecnicas Tyco Amd-2Document4 pagesFichas Tecnicas Tyco Amd-2Isaac Yull AguilarNo ratings yet

- 2019 JC2 H2 Physics Anderson Serangoon Junior CollegeDocument90 pages2019 JC2 H2 Physics Anderson Serangoon Junior Collegeeternal vorceNo ratings yet

- Precast Concrete Technician Study GuideDocument37 pagesPrecast Concrete Technician Study Guidefree4bruceNo ratings yet

- Missing From SeriesDocument10 pagesMissing From SeriesSwapna EleswarapuNo ratings yet

- CYWGDocument19 pagesCYWGGerry EscañoNo ratings yet

- Ivf NiceDocument22 pagesIvf NiceDianne LabisNo ratings yet

- Kalkulasi Steam Trap MFO Rev 00Document20 pagesKalkulasi Steam Trap MFO Rev 00Rifka AisyahNo ratings yet