Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

165 viewsIatf Activities

Iatf Activities

Uploaded by

Wizard tube and Engineered componentThis document outlines a road map and timeline for an organization to achieve IATF 16949 certification. It lists 68 activities related to quality management system requirements that need to be addressed, including documenting processes, conducting audits and reviews, addressing nonconformities, and ensuring training and customer satisfaction. Responsibilities for completing the activities and target dates are assigned to prepare for the certification audit.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You might also like

- Guidelines For Control PlanDocument4 pagesGuidelines For Control PlanArjun Rathore100% (1)

- FANUC Series 0+-PF: Operator'S ManualDocument1,182 pagesFANUC Series 0+-PF: Operator'S ManualYogendra SaxenaNo ratings yet

- Red Bin Analysis FormatDocument1 pageRed Bin Analysis FormatPRABHAT RANJAN50% (2)

- Ref Flow Charts Layout InspectionDocument1 pageRef Flow Charts Layout Inspectionrajesh.bNo ratings yet

- IATF 16949 2016 Mandatory ProcedureDocument1 pageIATF 16949 2016 Mandatory Procedureshivendrakumar100% (3)

- Manufacturing Process Audit Report: Customer Part No. Part Name Line/Area/ PorcessDocument1 pageManufacturing Process Audit Report: Customer Part No. Part Name Line/Area/ PorcessNaresh kumarNo ratings yet

- Sop SeDocument60 pagesSop SemanttupandeyNo ratings yet

- Procedure: Measurement System Analysis ExecutionDocument1 pageProcedure: Measurement System Analysis Executionaslam100% (1)

- 4 M Change ProcedureDocument2 pages4 M Change ProcedureManasi shinde100% (1)

- Software Orchestration Tool Manual: Release 3.0 - April 2020 8AL90559USAE Ed. 01Document52 pagesSoftware Orchestration Tool Manual: Release 3.0 - April 2020 8AL90559USAE Ed. 01Talhaoui Zakaria67% (3)

- Cohrance Audit Summary Report: Date:-Part Name:-PIN BALANCER Part Number: - Customer NameDocument2 pagesCohrance Audit Summary Report: Date:-Part Name:-PIN BALANCER Part Number: - Customer NamePrakash kumarTripathiNo ratings yet

- 4M Change Intimation Sheet Abnormal SituationDocument1 page4M Change Intimation Sheet Abnormal SituationDhananjay Patil100% (1)

- Wi SPCDocument4 pagesWi SPCSujeet Kumar100% (1)

- Process Audit - Sheet New ......Document1 pageProcess Audit - Sheet New ......MUKESH KUMAR100% (1)

- P13-Process For APQPDocument6 pagesP13-Process For APQPBangali Singh100% (1)

- Bgl-Fm-Qa - Red Bin Analysis RuleDocument1 pageBgl-Fm-Qa - Red Bin Analysis RuleMohit SinghNo ratings yet

- C8 TurtleDiagramCustomerFeedbackProcess顾客反馈过程乌龟图 EnDocument1 pageC8 TurtleDiagramCustomerFeedbackProcess顾客反馈过程乌龟图 EnBAlaNo ratings yet

- Initial Supply ControlDocument3 pagesInitial Supply ControlKuldeep Chauhan100% (2)

- Route Card Implementation (In In-House and Supplier)Document10 pagesRoute Card Implementation (In In-House and Supplier)Manoharar RNo ratings yet

- All Standards - Comparison MatrixDocument15 pagesAll Standards - Comparison MatrixaadmaadmNo ratings yet

- Error Proofing QSP-37 REV 00Document3 pagesError Proofing QSP-37 REV 00BRPLNo ratings yet

- 3.6 Initial SupplyDocument2 pages3.6 Initial SupplySunil Kumar92% (12)

- TMT Procedure - Management Review P2Document1 pageTMT Procedure - Management Review P2sumanNo ratings yet

- Required Documents For IATF - 16949Document5 pagesRequired Documents For IATF - 16949Rajesh Sahasrabuddhe50% (2)

- Ipc & Ipp Logbook or FlowDocument8 pagesIpc & Ipp Logbook or FlowKaran Malhi100% (1)

- Control Plan For Lighting ProductDocument6 pagesControl Plan For Lighting ProductpapplionNo ratings yet

- APQP (27) ElementsDocument31 pagesAPQP (27) Elementssam1hi5No ratings yet

- Format No - Qf-As-02 - Daily Production Log BookDocument2 pagesFormat No - Qf-As-02 - Daily Production Log BookDisha ShahNo ratings yet

- COMP-OPP-03 Procedure For Product Identification, Traceability and Inspection MarkingDocument4 pagesCOMP-OPP-03 Procedure For Product Identification, Traceability and Inspection MarkingISODCC DSPINo ratings yet

- 4M Change MatrixDocument1 page4M Change MatrixAnkit SainiNo ratings yet

- 06.supplier QMS Development Audit ChecklistDocument5 pages06.supplier QMS Development Audit ChecklistvishvendanNo ratings yet

- Anicon Flowcontrols LLP Procedure: Procedure Name Department Responsibility Clause NO Target DateDocument9 pagesAnicon Flowcontrols LLP Procedure: Procedure Name Department Responsibility Clause NO Target DateAnicon Flowcontols llpNo ratings yet

- 7.2.3 A List of Internal Auditors QMSDocument2 pages7.2.3 A List of Internal Auditors QMSPrakash kumarTripathiNo ratings yet

- Past Defect History 2021Document10 pagesPast Defect History 2021RahulNo ratings yet

- Process Wise Level Wise Skill Req. For Opr.Document1 pageProcess Wise Level Wise Skill Req. For Opr.Prakash kumarTripathiNo ratings yet

- Control of Non-Conforming ProductsDocument10 pagesControl of Non-Conforming ProductsSachin KumbharNo ratings yet

- QP - NPD - 07 Procedure For Change ManagementDocument3 pagesQP - NPD - 07 Procedure For Change ManagementMASU BRAKE PADS QANo ratings yet

- CAPA Thread OutDocument80 pagesCAPA Thread OutRohtash fastnerNo ratings yet

- ASP-NPD-04 (Process of Product Safety)Document5 pagesASP-NPD-04 (Process of Product Safety)akash.vd.1603No ratings yet

- QAD Procedure - Inspection & Testing (Inprocess & Final Inspection)Document1 pageQAD Procedure - Inspection & Testing (Inprocess & Final Inspection)suman100% (2)

- ISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical SpecificationDocument52 pagesISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical Specificationsupady5751No ratings yet

- QMS Formats PDFDocument11 pagesQMS Formats PDFBhavin SukhadiyaNo ratings yet

- 5.6 MRM Minutes 2020Document7 pages5.6 MRM Minutes 2020Musyoka Urbanus100% (1)

- COMP-OPP-01 Procedure For Control and Validation of ProductionDocument4 pagesCOMP-OPP-01 Procedure For Control and Validation of ProductionISODCC DSPINo ratings yet

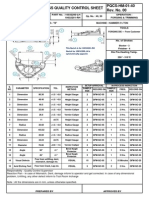

- PQCS Tube Flange Rough - ForgingDocument1 pagePQCS Tube Flange Rough - ForgingBalram JiNo ratings yet

- F MR 20B 4M Criteria NewDocument4 pagesF MR 20B 4M Criteria NewBangali Singh100% (1)

- Updated Closer IATFDocument8 pagesUpdated Closer IATFSandeep Verma100% (1)

- Tharaj Castings PVT - ltd.-1st & 2nd Phase PresentationDocument58 pagesTharaj Castings PVT - ltd.-1st & 2nd Phase PresentationAnkur DhirNo ratings yet

- 4M Change Tracking SheetDocument1 page4M Change Tracking SheetKanaiya Jha83% (6)

- 7.process Wise Level Wise Required OKDocument3 pages7.process Wise Level Wise Required OKPrakash kumarTripathiNo ratings yet

- Road Map For IATF 16949 R-6 UpdatedDocument1 pageRoad Map For IATF 16949 R-6 UpdatedRavi javali100% (1)

- Shriram Pistons & Rings LTD, Pathredi: Layered Audit Check Sheet Monthly (Plant Hod)Document5 pagesShriram Pistons & Rings LTD, Pathredi: Layered Audit Check Sheet Monthly (Plant Hod)deepak sharma100% (1)

- Toaz - Info Red Bin Analysis Procedure PRDocument4 pagesToaz - Info Red Bin Analysis Procedure PRRohit QualityNo ratings yet

- Procedure For EcnDocument8 pagesProcedure For EcnChintamani GiramkarNo ratings yet

- MSIL Audit Cheklist 16Document22 pagesMSIL Audit Cheklist 16Pravin Balasaheb GunjalNo ratings yet

- Coherence PlanDocument2 pagesCoherence PlanAman JasujaNo ratings yet

- MFG Process Audit ReportDocument1 pageMFG Process Audit ReportBASAVA ENGINEERINGNo ratings yet

- Vendor System Audit Report (Final) - Technico Ind., Bawal (T043)Document17 pagesVendor System Audit Report (Final) - Technico Ind., Bawal (T043)Ankit SainiNo ratings yet

- Required Doc For IATFDocument3 pagesRequired Doc For IATFAbhayNo ratings yet

- 48 Point Ppap Check SheetDocument39 pages48 Point Ppap Check SheetSanjay KumarNo ratings yet

- Procedure For NPD HandoverDocument1 pageProcedure For NPD HandoverTushar Wagh100% (1)

- Add Standalone NIM ClientsDocument3 pagesAdd Standalone NIM ClientsSandria MiguelNo ratings yet

- 1653630939954-Codal Life of Railway AssetsDocument4 pages1653630939954-Codal Life of Railway AssetsSSE ROCNo ratings yet

- Multithreading and Generic ProgrammingDocument58 pagesMultithreading and Generic ProgrammingmahalakshmiNo ratings yet

- John StachurskiDocument9 pagesJohn StachurskiferrypangaribuanNo ratings yet

- Islem BenFraj CV Sep 2021Document1 pageIslem BenFraj CV Sep 2021saraaNo ratings yet

- Challenges Encountered by Computer Shop Owners in Marikina City Basis For DevelopmentDocument23 pagesChallenges Encountered by Computer Shop Owners in Marikina City Basis For DevelopmentAngelo MedinaNo ratings yet

- Mos Excel 2016 - Core Practice Exam 1 RawDocument7 pagesMos Excel 2016 - Core Practice Exam 1 RawNhư LanNo ratings yet

- TCM Commissioning ChecklistDocument4 pagesTCM Commissioning ChecklistHiro ItoNo ratings yet

- Mysql AssociateDocument41 pagesMysql AssociateearnhimNo ratings yet

- Chapter - 5 - v8.0 Part 1-FAZDocument63 pagesChapter - 5 - v8.0 Part 1-FAZMuhammad RafiNo ratings yet

- BIM 2nd Semester SyllabusDocument20 pagesBIM 2nd Semester SyllabusRachana ShresthaNo ratings yet

- Database Connectivity Using ADODCDocument6 pagesDatabase Connectivity Using ADODCRiya JainNo ratings yet

- Chapter One: 1. Introduction To OperationsDocument213 pagesChapter One: 1. Introduction To OperationsKidist Alemu100% (3)

- Fuller P. Beginning Power BI For Business Users 2023Document455 pagesFuller P. Beginning Power BI For Business Users 2023Luis Carlos FidalgoNo ratings yet

- Mod 2 Notes CryptoDocument66 pagesMod 2 Notes CryptoMahalaxmi GinnamNo ratings yet

- White Paper: Business Analytics and The Data Complexity MatrixDocument6 pagesWhite Paper: Business Analytics and The Data Complexity MatrixWILFRED TSI-KAHNo ratings yet

- Computer GraphicsDocument14 pagesComputer Graphicsgirum sisayNo ratings yet

- Department of Education Region 3Document3 pagesDepartment of Education Region 3Jhavong ThreezeroNo ratings yet

- P. (/ ( /SL//,/..// /t... /,// (T..//T) : T.T /L) 'Hot (t1'/'Document4 pagesP. (/ ( /SL//,/..// /t... /,// (T..//T) : T.T /L) 'Hot (t1'/'Raine Buenaventura-EleazarNo ratings yet

- WBS Codes in Microsoft Project 2019Document4 pagesWBS Codes in Microsoft Project 2019muhammad iqbalNo ratings yet

- Builders Field Guide - Entire - Guide PDFDocument167 pagesBuilders Field Guide - Entire - Guide PDFSubramaniam ChandrasekaranNo ratings yet

- ICT Paper FinalDocument13 pagesICT Paper Finalshihamh haniffaNo ratings yet

- Orm NotesDocument9 pagesOrm NotesArmaan DurraniNo ratings yet

- The 'File Is Too Large For Destination File System' On USB OR External Hard DriveDocument9 pagesThe 'File Is Too Large For Destination File System' On USB OR External Hard DrivePaul KatemaNo ratings yet

- The New Seven Tools PDFDocument49 pagesThe New Seven Tools PDFsalanziNo ratings yet

- Training Load and Player Monitoring in High-Level Football: Current Practice and PerceptionsDocument8 pagesTraining Load and Player Monitoring in High-Level Football: Current Practice and PerceptionsJOEL MUÑOZNo ratings yet

- User GuidesDocument88 pagesUser GuidesThaj MohaideenNo ratings yet

- Bauhn 4k TV PDFDocument56 pagesBauhn 4k TV PDFLuca JohnNo ratings yet

Iatf Activities

Iatf Activities

Uploaded by

Wizard tube and Engineered component0 ratings0% found this document useful (0 votes)

165 views6 pagesThis document outlines a road map and timeline for an organization to achieve IATF 16949 certification. It lists 68 activities related to quality management system requirements that need to be addressed, including documenting processes, conducting audits and reviews, addressing nonconformities, and ensuring training and customer satisfaction. Responsibilities for completing the activities and target dates are assigned to prepare for the certification audit.

Original Description:

List of Mandatory documents

Original Title

IATF ACTIVITIES

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines a road map and timeline for an organization to achieve IATF 16949 certification. It lists 68 activities related to quality management system requirements that need to be addressed, including documenting processes, conducting audits and reviews, addressing nonconformities, and ensuring training and customer satisfaction. Responsibilities for completing the activities and target dates are assigned to prepare for the certification audit.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

0 ratings0% found this document useful (0 votes)

165 views6 pagesIatf Activities

Iatf Activities

Uploaded by

Wizard tube and Engineered componentThis document outlines a road map and timeline for an organization to achieve IATF 16949 certification. It lists 68 activities related to quality management system requirements that need to be addressed, including documenting processes, conducting audits and reviews, addressing nonconformities, and ensuring training and customer satisfaction. Responsibilities for completing the activities and target dates are assigned to prepare for the certification audit.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

You are on page 1of 6

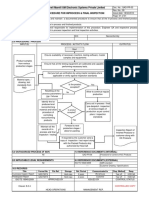

ROAD MAP FOR IATF CERITIFICATION AUDIT

SL.NO ACTIVITIES RESPONSIBILITY TARGET DATE

1 Scope of the quality management system (clause 4.3)

Documented process for the management of product safety

2 related products and manufacturing processes (clause

4.4.1.2)

3 Quality policy (clause 5.2)

4 Responsibilities and authorities to ensure that customer

requirements are met (clause 5.3.1)

5 Results of risk analysis (clause 6.1.2.1)

6 Preventive action record (clause 6.1.2.2)

7 Contingency plan (clause 6.1.2.3)

8 Quality objectives (clause 6.2)

9 Records of customer acceptance of alternative

measurement methods (clause 7.1.5.1.1)

10 Documented process for managing

calibration/verification records (clause 7.1.5.2.1)

11 Maintenance and calibration record (clause 7.1.5.2.1)

Documented process for identification of training needs

12 including awareness and achieving awareness (clause

7.2.1)

13 Documented process to verify competence of internal

auditors (clause 7.2.3)

14 List of qualified internal auditors (clause 7.2.3)

15 Documented information on trainer’s competency

(clause 7.2.3)

16 Documented information on employee’s awareness

(clause 7.3.1)

17 Documented process to motivate employees (clause

7.3.2)

18 Quality manual (clause 7.5.1.1)

19 Record retention policy (clause 7.5.3.2.1)

Documented process for review, distribution and

20 implementation of customer engineering

standards/specifications (clause 7.5.3.2.2)

21 Registry of customer complaints (clause 8.2)

22 Product/service requirements review records (clause

8.2.3.2)

23 Procedure for design and development (clause 8.3.1.1)

24 Record about design and development outputs review

(clause 8.3.2)

25 Documented information on software development

capability self-assessment (clause 8.3.2.3)

26 Records about product design and development inputs

(clause 8.3.3.1)

27 Records about manufacturing process design input

requirements (clause 8.3.3.2)

28 Document a process to identify special characteristics

(clause 8.3.3.3)

29 Records of design and development controls (clause

8.3.4)

30 Documented product approval (clause 8.3.4.4)

31 Records of design and development outputs (clause

8.3.5)

32 Manufacturing process design output (clause 8.3.5.2)

33 Design and development changes records (clause

8.3.6)

34 Documented approval or waiver of the customer

regarding the changes in design (clause 8.3.6.1)

35 Documented revision level of software and hardware as

part of the change record (clause 8.3.6.1)

36 Documented supplier selection process (clause 8.4.1.2)

Documented process to identify and control externally

37 provided processes, products and services (clause

8.4.2.1)

Documented process to ensure compliance with

38 statutory and regulatory requirements of purchased

processes, products and services (clause 8.4.2.2)

39 Documented process and criteria for supplier

evaluation (clause 8.4.2.4)

40 Records of second-party audit reports (clause

8.4.2.4.1)

41 Characteristics of product to be produced and service

to be provided (clause 8.5.1)

42 Control plan (8.5.1.1)

43 Total productive maintenance system (clause 8.5.1.5)

44 Records of traceability (clause 8.5.2.1)

45 Records about customer property (clause 8.5.3)

46 Production/service provision change control records

(clause 8.5.6)

47 Documented process to control and react to changes in

product realization (clause 8.5.6.1)

48 Documented approval by the customer prior to

implementation of the change (clause 8.5.6.1)

49 Documented process for management of the use of

alternate control methods (clause 8.5.6.1.1)

50 Record of conformity of product/service with

acceptance criteria (clause 8.6)

51 Record of expiration date or quantity authorized under

concession (clause 8.7.1.1)

52 Documented process for rework confirmation (clause

8.7.1.4)

53 Record on disposition of reworked product (clause

8.7.1.4)

54 Documented process for repair confirmation (clause

8.7.1.5)

55 Record of customer authorization for concession of the

product to be repaired (clause 8.7.1.5)

56 Notification to the customer about the nonconformity

(clause 8.7.1.6)

57 Documented process for disposition of nonconforming

product (clause 8.7.1.7)

58 Record of nonconforming outputs (clause 8.7.2)

59 Monitoring and measurement results (clause 9.1.1)

60 Internal audit program (clause 9.2)

61 Results of internal audits (clause 9.2)

62 Documented internal audit process (clause 9.2.2.1)

63 Results of the management review (clause 9.3)

64 Action plan when customer performance targets are

not met (clause 9.3.3.1)

65 Results of corrective actions (clause 10.1)

66 Documented process for problem solving (clause

10.2.3)

67 Documented process to determine the use of error-

proofing methodologies (clause 10.2.4)

68 Documented process for continual improvement

(clause 10.3.1)

STATUS

You might also like

- Guidelines For Control PlanDocument4 pagesGuidelines For Control PlanArjun Rathore100% (1)

- FANUC Series 0+-PF: Operator'S ManualDocument1,182 pagesFANUC Series 0+-PF: Operator'S ManualYogendra SaxenaNo ratings yet

- Red Bin Analysis FormatDocument1 pageRed Bin Analysis FormatPRABHAT RANJAN50% (2)

- Ref Flow Charts Layout InspectionDocument1 pageRef Flow Charts Layout Inspectionrajesh.bNo ratings yet

- IATF 16949 2016 Mandatory ProcedureDocument1 pageIATF 16949 2016 Mandatory Procedureshivendrakumar100% (3)

- Manufacturing Process Audit Report: Customer Part No. Part Name Line/Area/ PorcessDocument1 pageManufacturing Process Audit Report: Customer Part No. Part Name Line/Area/ PorcessNaresh kumarNo ratings yet

- Sop SeDocument60 pagesSop SemanttupandeyNo ratings yet

- Procedure: Measurement System Analysis ExecutionDocument1 pageProcedure: Measurement System Analysis Executionaslam100% (1)

- 4 M Change ProcedureDocument2 pages4 M Change ProcedureManasi shinde100% (1)

- Software Orchestration Tool Manual: Release 3.0 - April 2020 8AL90559USAE Ed. 01Document52 pagesSoftware Orchestration Tool Manual: Release 3.0 - April 2020 8AL90559USAE Ed. 01Talhaoui Zakaria67% (3)

- Cohrance Audit Summary Report: Date:-Part Name:-PIN BALANCER Part Number: - Customer NameDocument2 pagesCohrance Audit Summary Report: Date:-Part Name:-PIN BALANCER Part Number: - Customer NamePrakash kumarTripathiNo ratings yet

- 4M Change Intimation Sheet Abnormal SituationDocument1 page4M Change Intimation Sheet Abnormal SituationDhananjay Patil100% (1)

- Wi SPCDocument4 pagesWi SPCSujeet Kumar100% (1)

- Process Audit - Sheet New ......Document1 pageProcess Audit - Sheet New ......MUKESH KUMAR100% (1)

- P13-Process For APQPDocument6 pagesP13-Process For APQPBangali Singh100% (1)

- Bgl-Fm-Qa - Red Bin Analysis RuleDocument1 pageBgl-Fm-Qa - Red Bin Analysis RuleMohit SinghNo ratings yet

- C8 TurtleDiagramCustomerFeedbackProcess顾客反馈过程乌龟图 EnDocument1 pageC8 TurtleDiagramCustomerFeedbackProcess顾客反馈过程乌龟图 EnBAlaNo ratings yet

- Initial Supply ControlDocument3 pagesInitial Supply ControlKuldeep Chauhan100% (2)

- Route Card Implementation (In In-House and Supplier)Document10 pagesRoute Card Implementation (In In-House and Supplier)Manoharar RNo ratings yet

- All Standards - Comparison MatrixDocument15 pagesAll Standards - Comparison MatrixaadmaadmNo ratings yet

- Error Proofing QSP-37 REV 00Document3 pagesError Proofing QSP-37 REV 00BRPLNo ratings yet

- 3.6 Initial SupplyDocument2 pages3.6 Initial SupplySunil Kumar92% (12)

- TMT Procedure - Management Review P2Document1 pageTMT Procedure - Management Review P2sumanNo ratings yet

- Required Documents For IATF - 16949Document5 pagesRequired Documents For IATF - 16949Rajesh Sahasrabuddhe50% (2)

- Ipc & Ipp Logbook or FlowDocument8 pagesIpc & Ipp Logbook or FlowKaran Malhi100% (1)

- Control Plan For Lighting ProductDocument6 pagesControl Plan For Lighting ProductpapplionNo ratings yet

- APQP (27) ElementsDocument31 pagesAPQP (27) Elementssam1hi5No ratings yet

- Format No - Qf-As-02 - Daily Production Log BookDocument2 pagesFormat No - Qf-As-02 - Daily Production Log BookDisha ShahNo ratings yet

- COMP-OPP-03 Procedure For Product Identification, Traceability and Inspection MarkingDocument4 pagesCOMP-OPP-03 Procedure For Product Identification, Traceability and Inspection MarkingISODCC DSPINo ratings yet

- 4M Change MatrixDocument1 page4M Change MatrixAnkit SainiNo ratings yet

- 06.supplier QMS Development Audit ChecklistDocument5 pages06.supplier QMS Development Audit ChecklistvishvendanNo ratings yet

- Anicon Flowcontrols LLP Procedure: Procedure Name Department Responsibility Clause NO Target DateDocument9 pagesAnicon Flowcontrols LLP Procedure: Procedure Name Department Responsibility Clause NO Target DateAnicon Flowcontols llpNo ratings yet

- 7.2.3 A List of Internal Auditors QMSDocument2 pages7.2.3 A List of Internal Auditors QMSPrakash kumarTripathiNo ratings yet

- Past Defect History 2021Document10 pagesPast Defect History 2021RahulNo ratings yet

- Process Wise Level Wise Skill Req. For Opr.Document1 pageProcess Wise Level Wise Skill Req. For Opr.Prakash kumarTripathiNo ratings yet

- Control of Non-Conforming ProductsDocument10 pagesControl of Non-Conforming ProductsSachin KumbharNo ratings yet

- QP - NPD - 07 Procedure For Change ManagementDocument3 pagesQP - NPD - 07 Procedure For Change ManagementMASU BRAKE PADS QANo ratings yet

- CAPA Thread OutDocument80 pagesCAPA Thread OutRohtash fastnerNo ratings yet

- ASP-NPD-04 (Process of Product Safety)Document5 pagesASP-NPD-04 (Process of Product Safety)akash.vd.1603No ratings yet

- QAD Procedure - Inspection & Testing (Inprocess & Final Inspection)Document1 pageQAD Procedure - Inspection & Testing (Inprocess & Final Inspection)suman100% (2)

- ISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical SpecificationDocument52 pagesISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical Specificationsupady5751No ratings yet

- QMS Formats PDFDocument11 pagesQMS Formats PDFBhavin SukhadiyaNo ratings yet

- 5.6 MRM Minutes 2020Document7 pages5.6 MRM Minutes 2020Musyoka Urbanus100% (1)

- COMP-OPP-01 Procedure For Control and Validation of ProductionDocument4 pagesCOMP-OPP-01 Procedure For Control and Validation of ProductionISODCC DSPINo ratings yet

- PQCS Tube Flange Rough - ForgingDocument1 pagePQCS Tube Flange Rough - ForgingBalram JiNo ratings yet

- F MR 20B 4M Criteria NewDocument4 pagesF MR 20B 4M Criteria NewBangali Singh100% (1)

- Updated Closer IATFDocument8 pagesUpdated Closer IATFSandeep Verma100% (1)

- Tharaj Castings PVT - ltd.-1st & 2nd Phase PresentationDocument58 pagesTharaj Castings PVT - ltd.-1st & 2nd Phase PresentationAnkur DhirNo ratings yet

- 4M Change Tracking SheetDocument1 page4M Change Tracking SheetKanaiya Jha83% (6)

- 7.process Wise Level Wise Required OKDocument3 pages7.process Wise Level Wise Required OKPrakash kumarTripathiNo ratings yet

- Road Map For IATF 16949 R-6 UpdatedDocument1 pageRoad Map For IATF 16949 R-6 UpdatedRavi javali100% (1)

- Shriram Pistons & Rings LTD, Pathredi: Layered Audit Check Sheet Monthly (Plant Hod)Document5 pagesShriram Pistons & Rings LTD, Pathredi: Layered Audit Check Sheet Monthly (Plant Hod)deepak sharma100% (1)

- Toaz - Info Red Bin Analysis Procedure PRDocument4 pagesToaz - Info Red Bin Analysis Procedure PRRohit QualityNo ratings yet

- Procedure For EcnDocument8 pagesProcedure For EcnChintamani GiramkarNo ratings yet

- MSIL Audit Cheklist 16Document22 pagesMSIL Audit Cheklist 16Pravin Balasaheb GunjalNo ratings yet

- Coherence PlanDocument2 pagesCoherence PlanAman JasujaNo ratings yet

- MFG Process Audit ReportDocument1 pageMFG Process Audit ReportBASAVA ENGINEERINGNo ratings yet

- Vendor System Audit Report (Final) - Technico Ind., Bawal (T043)Document17 pagesVendor System Audit Report (Final) - Technico Ind., Bawal (T043)Ankit SainiNo ratings yet

- Required Doc For IATFDocument3 pagesRequired Doc For IATFAbhayNo ratings yet

- 48 Point Ppap Check SheetDocument39 pages48 Point Ppap Check SheetSanjay KumarNo ratings yet

- Procedure For NPD HandoverDocument1 pageProcedure For NPD HandoverTushar Wagh100% (1)

- Add Standalone NIM ClientsDocument3 pagesAdd Standalone NIM ClientsSandria MiguelNo ratings yet

- 1653630939954-Codal Life of Railway AssetsDocument4 pages1653630939954-Codal Life of Railway AssetsSSE ROCNo ratings yet

- Multithreading and Generic ProgrammingDocument58 pagesMultithreading and Generic ProgrammingmahalakshmiNo ratings yet

- John StachurskiDocument9 pagesJohn StachurskiferrypangaribuanNo ratings yet

- Islem BenFraj CV Sep 2021Document1 pageIslem BenFraj CV Sep 2021saraaNo ratings yet

- Challenges Encountered by Computer Shop Owners in Marikina City Basis For DevelopmentDocument23 pagesChallenges Encountered by Computer Shop Owners in Marikina City Basis For DevelopmentAngelo MedinaNo ratings yet

- Mos Excel 2016 - Core Practice Exam 1 RawDocument7 pagesMos Excel 2016 - Core Practice Exam 1 RawNhư LanNo ratings yet

- TCM Commissioning ChecklistDocument4 pagesTCM Commissioning ChecklistHiro ItoNo ratings yet

- Mysql AssociateDocument41 pagesMysql AssociateearnhimNo ratings yet

- Chapter - 5 - v8.0 Part 1-FAZDocument63 pagesChapter - 5 - v8.0 Part 1-FAZMuhammad RafiNo ratings yet

- BIM 2nd Semester SyllabusDocument20 pagesBIM 2nd Semester SyllabusRachana ShresthaNo ratings yet

- Database Connectivity Using ADODCDocument6 pagesDatabase Connectivity Using ADODCRiya JainNo ratings yet

- Chapter One: 1. Introduction To OperationsDocument213 pagesChapter One: 1. Introduction To OperationsKidist Alemu100% (3)

- Fuller P. Beginning Power BI For Business Users 2023Document455 pagesFuller P. Beginning Power BI For Business Users 2023Luis Carlos FidalgoNo ratings yet

- Mod 2 Notes CryptoDocument66 pagesMod 2 Notes CryptoMahalaxmi GinnamNo ratings yet

- White Paper: Business Analytics and The Data Complexity MatrixDocument6 pagesWhite Paper: Business Analytics and The Data Complexity MatrixWILFRED TSI-KAHNo ratings yet

- Computer GraphicsDocument14 pagesComputer Graphicsgirum sisayNo ratings yet

- Department of Education Region 3Document3 pagesDepartment of Education Region 3Jhavong ThreezeroNo ratings yet

- P. (/ ( /SL//,/..// /t... /,// (T..//T) : T.T /L) 'Hot (t1'/'Document4 pagesP. (/ ( /SL//,/..// /t... /,// (T..//T) : T.T /L) 'Hot (t1'/'Raine Buenaventura-EleazarNo ratings yet

- WBS Codes in Microsoft Project 2019Document4 pagesWBS Codes in Microsoft Project 2019muhammad iqbalNo ratings yet

- Builders Field Guide - Entire - Guide PDFDocument167 pagesBuilders Field Guide - Entire - Guide PDFSubramaniam ChandrasekaranNo ratings yet

- ICT Paper FinalDocument13 pagesICT Paper Finalshihamh haniffaNo ratings yet

- Orm NotesDocument9 pagesOrm NotesArmaan DurraniNo ratings yet

- The 'File Is Too Large For Destination File System' On USB OR External Hard DriveDocument9 pagesThe 'File Is Too Large For Destination File System' On USB OR External Hard DrivePaul KatemaNo ratings yet

- The New Seven Tools PDFDocument49 pagesThe New Seven Tools PDFsalanziNo ratings yet

- Training Load and Player Monitoring in High-Level Football: Current Practice and PerceptionsDocument8 pagesTraining Load and Player Monitoring in High-Level Football: Current Practice and PerceptionsJOEL MUÑOZNo ratings yet

- User GuidesDocument88 pagesUser GuidesThaj MohaideenNo ratings yet

- Bauhn 4k TV PDFDocument56 pagesBauhn 4k TV PDFLuca JohnNo ratings yet