Professional Documents

Culture Documents

Burner Cast Iron Nozzles

Burner Cast Iron Nozzles

Uploaded by

Azril Dahari0 ratings0% found this document useful (0 votes)

9 views1 pageOriginal Title

Burner_Cast_Iron_Nozzles

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

9 views1 pageBurner Cast Iron Nozzles

Burner Cast Iron Nozzles

Uploaded by

Azril DahariCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

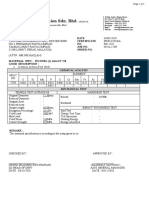

Burner Cast Iron Nozzles

Cast iron end-pieces of burner nozzles are used for low NOx burners and wide range

of pulverized coal burners also.

body of the nozzle. End-

piece thermal expansion is

compensated by expansion

gaps regularly distributed on

the end-piece circum-

ference.

All-welded end-pieces suffer

from shape deformations and Cast iron end-piece

burn-off, which reduce burner connection to the burner

Customer benefits: nozzle lifetime and deteriorate nozzle body is ensured by

burner performance. pins which are hanged in

steel nozzle body elements

Long time shape stability Cast iron end-pieces or by tooled pegs. This free

eliminate the above- connection of cast iron end-

mentioned disadvantage of piece and the steel nozzle

Easier replacement of burner all-welded nozzles and are body eliminates transferring

nozzle end-piece resistant against high thermal of thermal expansion forces

load. from the end-piece to the

nozzle body.

Comparable cost with all- Cast iron end-piece design

welded nozzle end-piece respects burner nozzle size For detailed information,

and design, with regard on please contact:

Long lifetime needed rigidity of nozzle and ALSTOM Power s.r.o.,

end-piece. Czech Republic

The nozzle end-piece is .

Cast iron end-pieces for burner casted in one piece and

nozzles are mainly used for includes all reinforcements,

pulverized coal NOx burners with swirl parts, hanger pins and

high thermal loads. connection part to the steel

Power

Power Service

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- MSS SP-83-2014 Class 3000 and 6000 Pipe Unions, Socket Welding and Threaded (Carbon Steel, Alloy Steel, Stainless Steels, and Nickel Alloys)Document16 pagesMSS SP-83-2014 Class 3000 and 6000 Pipe Unions, Socket Welding and Threaded (Carbon Steel, Alloy Steel, Stainless Steels, and Nickel Alloys)arnoldbatista55100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- List of Standard of Additive ManufacturingDocument13 pagesList of Standard of Additive ManufacturingAzril DahariNo ratings yet

- ASME B16 Standards For Pipes and FittingsDocument7 pagesASME B16 Standards For Pipes and FittingsEHT pipeNo ratings yet

- Calculation of Power ConsumptionDocument4 pagesCalculation of Power ConsumptionAzril DahariNo ratings yet

- "Fighting COVID - System Solutions": General AdvantagesDocument7 pages"Fighting COVID - System Solutions": General AdvantagesAzril DahariNo ratings yet

- Calculation Batna Watna NegoDocument4 pagesCalculation Batna Watna NegoAzril DahariNo ratings yet

- Numerical Simulation of Thermal Barrier Coating System Under Thermo-Mechanical LoadingsDocument6 pagesNumerical Simulation of Thermal Barrier Coating System Under Thermo-Mechanical LoadingsAzril DahariNo ratings yet

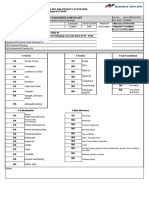

- Questionnaire For Manufacturer Evaluation-GenericDocument6 pagesQuestionnaire For Manufacturer Evaluation-GenericAzril DahariNo ratings yet

- (C) Prof. Dr. Md. Mujibur Rahman, Universiti Tenaga NasionalDocument3 pages(C) Prof. Dr. Md. Mujibur Rahman, Universiti Tenaga NasionalAzril DahariNo ratings yet

- Sahraoui2004 PDFDocument13 pagesSahraoui2004 PDFAzril DahariNo ratings yet

- 201 Ceramic Paste Tds rv1 PDFDocument3 pages201 Ceramic Paste Tds rv1 PDFAzril DahariNo ratings yet

- RacorVMT AquaPro Pumps BulletinDocument2 pagesRacorVMT AquaPro Pumps BulletinAzril DahariNo ratings yet

- Malaysia: Alstom Supervisor Rates Valid in 2008Document1 pageMalaysia: Alstom Supervisor Rates Valid in 2008Azril DahariNo ratings yet

- Regal BearingDocument104 pagesRegal BearingAzril DahariNo ratings yet

- Inconel (R)Document1 pageInconel (R)Azril DahariNo ratings yet

- My Summary of Rich Dad Poor DadDocument2 pagesMy Summary of Rich Dad Poor DadAzril DahariNo ratings yet

- Factsheet SGT-700 enDocument2 pagesFactsheet SGT-700 enAzril DahariNo ratings yet

- Basics About Rails: by (N.R. Kale) Axen/IricenDocument45 pagesBasics About Rails: by (N.R. Kale) Axen/IricenshujaNo ratings yet

- Goulds 3316 BulletinDocument12 pagesGoulds 3316 BulletinJesús DeveraNo ratings yet

- AISI 1045 SteelDocument3 pagesAISI 1045 Steelsenthil4youNo ratings yet

- Design of Joints General LectureDocument126 pagesDesign of Joints General LectureZarkovic011100% (2)

- A Simple Oscillating Steam Engine by H.Muncaster. G.A., B.O.M., Notes, Isometric View, Parts and AssembliesDocument1 pageA Simple Oscillating Steam Engine by H.Muncaster. G.A., B.O.M., Notes, Isometric View, Parts and AssembliesmiriNo ratings yet

- Ferro Alloys - AR - 2017 Plant & CapacityDocument28 pagesFerro Alloys - AR - 2017 Plant & CapacitysmithNo ratings yet

- Pipe Fittings & ValvesDocument15 pagesPipe Fittings & ValvesRam MurtyNo ratings yet

- Safety Is Our First Priority: Safety Components For Fall ProtectionDocument124 pagesSafety Is Our First Priority: Safety Components For Fall Protectioningeniera electricaNo ratings yet

- Custom 465 Stainless SteelDocument20 pagesCustom 465 Stainless SteelGrafton Montgomery100% (1)

- AFM Bronze AlloysDocument15 pagesAFM Bronze AlloysbrunizzaNo ratings yet

- Udayour EleDocument18 pagesUdayour EleJoshuaNo ratings yet

- ASME B16.9 (1992) INTERPRETATIONS - Factory-Made Wrought Buttwelding FittingsDocument13 pagesASME B16.9 (1992) INTERPRETATIONS - Factory-Made Wrought Buttwelding Fittingsbobuncle03No ratings yet

- Report Welding PoliDocument15 pagesReport Welding PoliSyahzlan IskandarNo ratings yet

- 04 HW Accs Zebra Conductor PDFDocument23 pages04 HW Accs Zebra Conductor PDFelsayedNo ratings yet

- WISS CSWIP Technology Multiple Choice Exam 2 Version A 18 August 2014Document8 pagesWISS CSWIP Technology Multiple Choice Exam 2 Version A 18 August 2014rinhycraNo ratings yet

- Alchemist Guide ProductionsDocument23 pagesAlchemist Guide ProductionsNovi NovianNo ratings yet

- Punch Tech DataDocument3 pagesPunch Tech DataanjanmaheshNo ratings yet

- Nonmetallic Flat Gaskets For Pipe Flanges: ASME B16.21-2011Document2 pagesNonmetallic Flat Gaskets For Pipe Flanges: ASME B16.21-2011amr kouranyNo ratings yet

- Tension Test Discussion CompleteDocument3 pagesTension Test Discussion CompleteUsman ishaq100% (1)

- Experiment 2 KnittingDocument2 pagesExperiment 2 KnittingAvanish YadavNo ratings yet

- Form - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageDocument2 pagesForm - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageMvomoNo ratings yet

- Webforge Access Systems Brochure PDFDocument36 pagesWebforge Access Systems Brochure PDFmuathNo ratings yet

- SCI Merchant Steel Fittings PDFDocument6 pagesSCI Merchant Steel Fittings PDFMohammed ZabiNo ratings yet

- Index: Brammer Standard Online Catalog - Industrial MaterialsDocument43 pagesIndex: Brammer Standard Online Catalog - Industrial MaterialsSai dineshNo ratings yet

- What Is Welding. History of WeldingDocument11 pagesWhat Is Welding. History of WeldingNell Sabas AdolfoNo ratings yet

- CLASS 251031-KS: DEP 31.38.01.12-Gen Class 251031-KS, Rev. H Page 1 of 12Document12 pagesCLASS 251031-KS: DEP 31.38.01.12-Gen Class 251031-KS, Rev. H Page 1 of 12SaguesoNo ratings yet

- Fundamentals of Machine DesignDocument36 pagesFundamentals of Machine DesignthirumalaikumaranNo ratings yet

- AMS 5571 J-2012 - Eng.Document6 pagesAMS 5571 J-2012 - Eng.Tetiana100% (1)