Professional Documents

Culture Documents

Prod Update c7000

Prod Update c7000

Uploaded by

Tan JaiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Prod Update c7000

Prod Update c7000

Uploaded by

Tan JaiCopyright:

Available Formats

tech 9P7390

Background:

This disc has historically been manufactured in F37 elastomer material and while it

does demonstrate several excellent properties in the right environment, however it

does not have any thermal tolerance or ‘abuse’ factor.

PRODUCT UPDATE

Based on requests from the marketplace to develop an alternative material for this

and other difficult applications we are now able to offer this disc in C7000 material.

C7000 is a complex carbon composite material which demonstrates a stable

co-efficient of friction under high load conditions. It has been proven to work very

successfully in arduous military transmissions where high energy and temperature

are the norm.

Groove Pattern:

Waffle groove pattern which is machined to a consistent width and depth for optimum

oil flow

Preparation:

The disc is required to soak in the transmission oil prior to fitment.

Mating Material:

Identical - SAE1065 steel with a surface finish of 20 micro inch or better.

C7000

PAPER

F37 Elastomer

Unit 5, Eden Court, Eden Way,

Leighton Buzzard, England LU7 4FY

Tel: +44 1525 376700 Fax: +44 1525 377170

www.frictionmarketing.co.uk

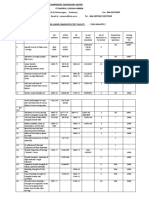

9P7390 C7000

tech

CARBON FRICTION MATERIAL

600

3500

500

400

PRODUCT UPDATE

2500

300

N/m rpm

200 1500

100

500

0

-100 -500

1000 cycle 5000 cycle Speed

TORQUE TRACE

CHANGE OF DYNAMIC COEFFICIENT OF FRICTION

Total cycles 10,000 cycles

Inertia 0.04 kgf·m·sec^2

Dynamic rpm 2940

Friction facing dimensions Ø133.5mm × Ø99.0mm

Friction surfaces 4

Unit energy 0.74J/�

Unit pressure 2.0 Mpa

Oil type TO-4

Oil temperature 90ºC(±5ºC)

Arrangement pDpDp

TEST CONDITION

Note: F37 and 9P7390 are for reference / identification only.

Unit 5, Eden Court, Eden Way,

Leighton Buzzard, England LU7 4FY C7000 - 2 - 300909

Tel: +44 1525 376700 Fax: +44 1525 377170

www.frictionmarketing.co.uk

You might also like

- Miyaco CrossDocument127 pagesMiyaco CrossTan Jai100% (1)

- 2011 Hyundai Service FiltersDocument18 pages2011 Hyundai Service FiltersTan JaiNo ratings yet

- 2-Rafael-TDS-625 Sand Dryer doc-CIFDocument20 pages2-Rafael-TDS-625 Sand Dryer doc-CIFRafael ObusanNo ratings yet

- Water Pumps: Automotive Applications CatalogueDocument80 pagesWater Pumps: Automotive Applications CatalogueTan JaiNo ratings yet

- Qatif Method Statement GroutingDocument13 pagesQatif Method Statement GroutingelbaraniNo ratings yet

- Dimond Wheel BrochureDocument7 pagesDimond Wheel BrochurejogibhavinNo ratings yet

- Landing Gear Material ProcessingDocument19 pagesLanding Gear Material ProcessingPriyabrata DasNo ratings yet

- Silkolene Pro 4 XP RangeDocument2 pagesSilkolene Pro 4 XP Rangelamchanh.mauNo ratings yet

- Eutectic 29029Document2 pagesEutectic 29029Imam SitumeangNo ratings yet

- Bronze Putty: Technical Data SheetDocument2 pagesBronze Putty: Technical Data SheetSharad ShahNo ratings yet

- High Performance Backing Compound: Technical Data SheetDocument2 pagesHigh Performance Backing Compound: Technical Data SheetNiku SamarthNo ratings yet

- Tm4 Sumo HD: Motor / Inverter SystemDocument2 pagesTm4 Sumo HD: Motor / Inverter SystemFire Library0% (1)

- Interlloy Grade 1045 Carbon Steel BarDocument3 pagesInterlloy Grade 1045 Carbon Steel BarPRASHANT KANTENo ratings yet

- Coatings 09 00812 s001Document9 pagesCoatings 09 00812 s001cavoixanh89No ratings yet

- Technical Guide For Steel & Stainless Steel Turning - Seco Tools PDFDocument20 pagesTechnical Guide For Steel & Stainless Steel Turning - Seco Tools PDFwilsonNo ratings yet

- Pure Epoxy Fx-E400: Technical Data SheetDocument7 pagesPure Epoxy Fx-E400: Technical Data SheetRana Ahmad Aamir100% (1)

- Ip9183 R1Document4 pagesIp9183 R1jeffinNo ratings yet

- Exceed™ XP 8358 Series: Performance PolymerDocument2 pagesExceed™ XP 8358 Series: Performance PolymerMaram YasserNo ratings yet

- AIM Solder Surface-Mount-Epoxy Data-Sheet 0523Document2 pagesAIM Solder Surface-Mount-Epoxy Data-Sheet 0523ivanshitov2015No ratings yet

- Relief Valve (Line) : SpecificationsDocument2 pagesRelief Valve (Line) : Specificationseshopmanual TigaNo ratings yet

- PMMA Resist - Product InformationDocument8 pagesPMMA Resist - Product InformationMałgosiaSikora-JasińskaNo ratings yet

- FINEXDocument24 pagesFINEXBikram Kumar SinghNo ratings yet

- Exceed XP 8784 SeriesDocument2 pagesExceed XP 8784 SeriesAli RazuNo ratings yet

- Product Data: Hexply 200Document4 pagesProduct Data: Hexply 200MirceaNo ratings yet

- CNPC CPP W725ef TDSDocument1 pageCNPC CPP W725ef TDScallzrNo ratings yet

- Exceed™ XP 8784 Series: Performance PolymerDocument2 pagesExceed™ XP 8784 Series: Performance PolymerMaram YasserNo ratings yet

- Titanium Putty HPDocument2 pagesTitanium Putty HPDivyanshu GuptaNo ratings yet

- SDS Sika CombinedDocument12 pagesSDS Sika Combinedcday10126No ratings yet

- MetaCeram-25040.. Castollin EutecticDocument2 pagesMetaCeram-25040.. Castollin EutecticAndrés MolinaNo ratings yet

- Grasa AeroShell 5Document2 pagesGrasa AeroShell 5epesanoNo ratings yet

- Brushable CeramicDocument2 pagesBrushable CeramicDivyanshu GuptaNo ratings yet

- 420 Martensitic Stainless Steel BarDocument4 pages420 Martensitic Stainless Steel BarAHMED FATHINo ratings yet

- Optigear 1100 RangeDocument3 pagesOptigear 1100 RangeResistenciaDisidenteNo ratings yet

- TDS Molylube SF 100 Semi Synthetic Open Gear Lubricant PDFDocument3 pagesTDS Molylube SF 100 Semi Synthetic Open Gear Lubricant PDFGilmer CaceresNo ratings yet

- Mohawk Riserlite Indoor Outdoor Fiber CableDocument2 pagesMohawk Riserlite Indoor Outdoor Fiber CablecolinyNo ratings yet

- Billerud Crownboard Craft Tech Data Sheet 2022.10.12Document1 pageBillerud Crownboard Craft Tech Data Sheet 2022.10.12mohamed fayedNo ratings yet

- Molykote D-321R DowCorning DatasheetDocument2 pagesMolykote D-321R DowCorning DatasheetalbertoNo ratings yet

- Sika Monotop 412myDocument4 pagesSika Monotop 412mysaifulsabdinNo ratings yet

- ENG Oiles 500 SJDocument6 pagesENG Oiles 500 SJRendra Maha Putra JfNo ratings yet

- Oiles 500 Självsmörjande Glidlager 8190 - v2Document6 pagesOiles 500 Självsmörjande Glidlager 8190 - v2Nisam OdavdeNo ratings yet

- Loctite Ea 934na Aero (Known As Hysol Ea 934na) - TdsDocument5 pagesLoctite Ea 934na Aero (Known As Hysol Ea 934na) - TdspokleNo ratings yet

- Composites Test Facilities Madrass PDFDocument18 pagesComposites Test Facilities Madrass PDFNikesh ThammishettiNo ratings yet

- Colmonoy 5-S Data SheetDocument2 pagesColmonoy 5-S Data SheetLuis Hernandez50% (2)

- Taconic EZ-IO-F The Next Generation Spread Weave LaminateDocument6 pagesTaconic EZ-IO-F The Next Generation Spread Weave LaminatejackNo ratings yet

- Exceed™ XP 8656MK: Performance PolymerDocument2 pagesExceed™ XP 8656MK: Performance PolymerCristian RodriguezNo ratings yet

- Carter EpDocument2 pagesCarter EpNguyễn Quang HưngNo ratings yet

- Exceed™ XP 8318MJ: Performance PolymerDocument2 pagesExceed™ XP 8318MJ: Performance PolymerMaram YasserNo ratings yet

- Powerking CompactorDocument4 pagesPowerking CompactorwaterkingkorNo ratings yet

- Bel Ray Molylube Ultra Open Gear Lubricant PDS 12june2023 1Document2 pagesBel Ray Molylube Ultra Open Gear Lubricant PDS 12june2023 1xxx yyyNo ratings yet

- Teranap 431 TP 4m (En)Document2 pagesTeranap 431 TP 4m (En)Franco Saenz SolisNo ratings yet

- Cermet Piston Rings PDFDocument20 pagesCermet Piston Rings PDFRobert CostacheNo ratings yet

- Metco®601NS 10-141Document11 pagesMetco®601NS 10-141張政雄No ratings yet

- RTP 299 X 90078 SSC 63023Document2 pagesRTP 299 X 90078 SSC 63023kls.thorodinsonNo ratings yet

- Fosroc Nitoflor TF5000: Constructive SolutionsDocument4 pagesFosroc Nitoflor TF5000: Constructive SolutionsVincent JavateNo ratings yet

- 4140 High Tensile Steel PDFDocument3 pages4140 High Tensile Steel PDFFikri SiplhoNo ratings yet

- SM750Document2 pagesSM750Gantungan KulkasNo ratings yet

- OSB Technical InformationDocument10 pagesOSB Technical InformationPrattyNo ratings yet

- FT TOTAL CARTER EP 1500-2200-3000 (Anglais)Document1 pageFT TOTAL CARTER EP 1500-2200-3000 (Anglais)Olivier DupNo ratings yet

- Lithium Complex Red Ep 2Document2 pagesLithium Complex Red Ep 2mcnpopaNo ratings yet

- Capacidad de 300 KG A 2000 KG: Células de CargaDocument2 pagesCapacidad de 300 KG A 2000 KG: Células de CargaMetano TanoNo ratings yet

- FT Grease 6Document2 pagesFT Grease 6Amine AmineNo ratings yet

- Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIIFrom EverandAdvanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIITatsuki OhjiNo ratings yet

- Ceramic Materials for Energy Applications VIFrom EverandCeramic Materials for Energy Applications VIHua-Tay LinNo ratings yet

- Series 51 and 51-1 Bent Axis Motors: Service ManualDocument60 pagesSeries 51 and 51-1 Bent Axis Motors: Service ManualTan JaiNo ratings yet

- Every Rule. Rewritten.: For Industrial Applications Tier 3/stage IiiaDocument6 pagesEvery Rule. Rewritten.: For Industrial Applications Tier 3/stage IiiaTan JaiNo ratings yet

- 2011 Hyundai Service BucketDocument93 pages2011 Hyundai Service BucketTan JaiNo ratings yet

- Series 20 Axial Piston Motors: Technical InformationDocument16 pagesSeries 20 Axial Piston Motors: Technical InformationTan JaiNo ratings yet

- Options: CatalogueDocument11 pagesOptions: CatalogueTan JaiNo ratings yet

- Series 20 Axial Piston Pumps: Technical InformationDocument20 pagesSeries 20 Axial Piston Pumps: Technical InformationTan JaiNo ratings yet

- Description P/N Application SpecificationDocument1 pageDescription P/N Application SpecificationTan JaiNo ratings yet

- Automotive Compressor Magnetic Clutch Bearings: Malex Corporation LimitedDocument2 pagesAutomotive Compressor Magnetic Clutch Bearings: Malex Corporation LimitedTan JaiNo ratings yet

- Automotive Clutch Release Bearings: Malex Corporation LimitedDocument6 pagesAutomotive Clutch Release Bearings: Malex Corporation LimitedTan JaiNo ratings yet

- Core-Oil CoolerDocument3 pagesCore-Oil CoolerTan JaiNo ratings yet

- Malex: Automotive WheelDocument226 pagesMalex: Automotive WheelTan JaiNo ratings yet

- EasyConn For 24V-TrailerDocument44 pagesEasyConn For 24V-TrailerTan JaiNo ratings yet

- Product Information: Selection of Hydraulic and Pneumatic SealsDocument4 pagesProduct Information: Selection of Hydraulic and Pneumatic SealsTan JaiNo ratings yet

- Product InformationDocument4 pagesProduct InformationTan JaiNo ratings yet

- Product Overview: NavigatorofsealingtechnologyDocument48 pagesProduct Overview: NavigatorofsealingtechnologyTan JaiNo ratings yet

- Installation MaterialDocument82 pagesInstallation MaterialTan JaiNo ratings yet

- 20089241657407055Document4 pages20089241657407055Tan JaiNo ratings yet

- 201011151131467055Document48 pages201011151131467055Tan JaiNo ratings yet

- Range Expansion LightingDocument52 pagesRange Expansion LightingTan JaiNo ratings yet

- Blades and End Bits For KOMATSU®Document2 pagesBlades and End Bits For KOMATSU®Tan JaiNo ratings yet

- Book List - 2017 - 2018 Sanskriti School Class - NurseryDocument7 pagesBook List - 2017 - 2018 Sanskriti School Class - Nurserylalitarani_05No ratings yet

- Marco Galaxy MX7 Recessed Downlighting Catalog 1982Document4 pagesMarco Galaxy MX7 Recessed Downlighting Catalog 1982Alan MastersNo ratings yet

- Welding Shop AssignmentDocument15 pagesWelding Shop AssignmentArslan100% (1)

- Detail of Engineer Facilities Quantity Rate Diff in Amount BOQ Actual Origional Up Lifted BOQ Qty's Actual Qty'sDocument2 pagesDetail of Engineer Facilities Quantity Rate Diff in Amount BOQ Actual Origional Up Lifted BOQ Qty's Actual Qty'sfluretNo ratings yet

- Astm D7409 15 2020Document2 pagesAstm D7409 15 20201984garunNo ratings yet

- Tylose H 200000 YP2Document1 pageTylose H 200000 YP2YASHICA VAITTIANATHANNo ratings yet

- DANA LITHIUM BASE EP GREASE PDS - by DANA LUBRICANTS UAEDocument1 pageDANA LITHIUM BASE EP GREASE PDS - by DANA LUBRICANTS UAEankurdanaNo ratings yet

- Bracker Short Staple SpinningDocument53 pagesBracker Short Staple SpinningRamesh IyerNo ratings yet

- Model 656 2-1/2" (63mm), 4" (100mm) and 6" (160mm) Open Front Stainless Steel GaugesDocument6 pagesModel 656 2-1/2" (63mm), 4" (100mm) and 6" (160mm) Open Front Stainless Steel GaugesDaniel CernaNo ratings yet

- Weight Loss Corrosion Study of Some Metals in AcidDocument8 pagesWeight Loss Corrosion Study of Some Metals in AcidAdisya Yuliasari RohimanNo ratings yet

- Sharp Water PurifierDocument26 pagesSharp Water PurifierOM Prakash Chandra50% (2)

- Is 334Document9 pagesIs 334sbarwal9No ratings yet

- Characteristics Applications: Wax Resin - Flat Head Thermal Transfer RibbonDocument2 pagesCharacteristics Applications: Wax Resin - Flat Head Thermal Transfer RibbonHector GarciaNo ratings yet

- Cemax 303: Grinding Aid and Pack Set Inhibitor For CementsDocument2 pagesCemax 303: Grinding Aid and Pack Set Inhibitor For CementsAmr RagabNo ratings yet

- Intro To Butyl AcrylateDocument2 pagesIntro To Butyl AcrylatemeimeiliuNo ratings yet

- ACSR Rail ZTTDocument6 pagesACSR Rail ZTTAntony Cesar Caballero IbarraNo ratings yet

- Astm C1688C1688M.4631Document4 pagesAstm C1688C1688M.4631Thayane SoaresNo ratings yet

- Kazys Petkevicius Julius Christauska PDFDocument6 pagesKazys Petkevicius Julius Christauska PDFJulio Andrés Casal RamosNo ratings yet

- A-Z of Plastics Manufacturing ProcessesDocument3 pagesA-Z of Plastics Manufacturing Processesrohitkhanna1180No ratings yet

- PMMA Denture Base Material Enhancement: A Review of Fiber, Filler, and Nanofiller AdditionDocument12 pagesPMMA Denture Base Material Enhancement: A Review of Fiber, Filler, and Nanofiller AdditionPhoebe DavidNo ratings yet

- Verma Toys Leona Bebe PDFDocument28 pagesVerma Toys Leona Bebe PDFSILVIA ROMERO100% (4)

- ICI Concrete Cube Strength Competition Test Report 2013Document18 pagesICI Concrete Cube Strength Competition Test Report 2013RonyJoyNo ratings yet

- Klübersynth GH 6 Oils: Synthetic Gear and High Temperature OilsDocument8 pagesKlübersynth GH 6 Oils: Synthetic Gear and High Temperature OilsFabrizzio_ValerNo ratings yet

- Tkis Elt 8353 LD 00008 - 000 - 00Document1 pageTkis Elt 8353 LD 00008 - 000 - 00Muhammed Abo-FandoodNo ratings yet

- OPSS - Muni 310 Nov17 Construction Specification For Hot Mix AsphaltDocument30 pagesOPSS - Muni 310 Nov17 Construction Specification For Hot Mix Asphaltming_zhu10No ratings yet

- Sthamex - Afff: Aqueous Film Forming Foam ConcentrateDocument2 pagesSthamex - Afff: Aqueous Film Forming Foam ConcentrateForum PompieriiNo ratings yet

- Site P&ID Sulfuric-Acid-PlantDocument5 pagesSite P&ID Sulfuric-Acid-PlantUday ChauhanNo ratings yet

- Viscosity-Classifications Astm d2422Document8 pagesViscosity-Classifications Astm d2422Francisco TipanNo ratings yet

- WAXESDocument2 pagesWAXESPra YogaNo ratings yet