Professional Documents

Culture Documents

Clutches Technical Data

Clutches Technical Data

Uploaded by

Nicolás CarboniOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Clutches Technical Data

Clutches Technical Data

Uploaded by

Nicolás CarboniCopyright:

Available Formats

10-2015

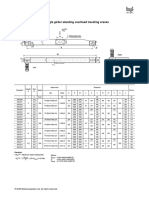

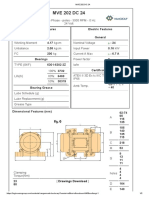

Electromagnetic Stationary Field Multi-Disc Clutch

Clutch with outer driver for torque transmission between shaft and free wheeling gear part.

For oil operation, coil voltage 24 V DC This clutch is specially suited for speed engagement of machines or

Self-adjustment by magnetic flux permeating the disc stack. equipment used in automated production lines.

Special disc design for lowest possible idling torque. Precise clutch engagement and release, and thereby exact control of

Wear resisting alloyed and heat treated discs. the required operation, are maintained throughout long-term operation

Effective heat dissipation by peripheral friction faces. periods.

Available in special design suitable for cumbustion-engine applications.

Vertical mounting, only when ordered with application guidelines.

b1

Side A Outer driver 1

p1

x

w

k

l1

Side B

12

0°

12

0°

s

c1

c2

h

a

g

d

f

l2

p2 Outer driver 2

not bored

b2

FOV FOV FOV FOV FOV FOV FOV FOV FOV FOV

Data and Dimensions

1,2 2,5 5 10 20 40 80 160 315 630

Static torque Nm 25 50 100 200 400 800 1600 3200 6300 12600

Dynamic torque Nm 12,5 25 50 100 200 400 800 1600 3200 6300

Idling torque Nm 0,1 0,2 0,3 0,6 1,0 2,0 4,0 6,0 10 20

Friction work per engagement kJ 5,9 9,6 15 22 44 89 143 278 520 1000

Thermal capacity W 57 87 120 170 330 550 765 1230 1750 3000

Speed maximum min-1 4000 3850 3650 3500 3200 2900 2400 1900 1400 1000

Torque-time constant 1) s 0,18 0,22 0,28 0,35 0,43 0,61 0,90 1,30 1,80 2,40

Disengagement time 2) s 0,07 0,08 0,09 0,12 0,14 0,16 0,20 0,26 0,32 0,40

Coil power consumption at 20 °C W 25 25 30 50 65 75 75 95 150 170

Mass moment of inertia side A 10-3 kgm2 0,4 0,7 1,4 3,3 7,0 17 42 130 288 780

Mass moment of inertia side B 10-3 kgm2 0,35 0,7 1,9 4,0 8,8 28 65 180 525 1790

Mass (weight) kg 1,6 2 3 4 8 14 23 43 75 140

øa mm 90 99 112 133 161 200 237 292 357 452

b1 mm 38 41 48 53 63 75 88 99 122 147

b2 mm 43 47 54 61 71 83 98 112 134 162

ø c 1 H7 mm 65 74 84 102 124 152 190 230 285 370

ø c 2 min H7 mm 20 20 25 30 35 40 50 60 70 90

ø d H7 mm 10 ... 20 10 ... 25 12 ... 30 15 ... 40 20 ... 50 25 ... 60 30 ... 70 40 ... 90 50 ... 100 70 ... 130

øf mm 25 30 35 45 55 70 80 105 130 160

øg mm 74 84 98 118 140 172 210 257 316 407

øh mm 83 92 107 127 152 189 224 277 342 432

k / ø m rough bored for dowel mm M5 / 4 M5 / 5 M6 / 6 M6 / 6 M8 / 8 M8 / 8 M10 / 10 M12 / 12 M16 / 16 M16 / 20

l1 mm 4 4 5 6 7 8 9 11 13 14

l2 mm 4 5 6 8 8 10 12 15 15 18

p1 mm 26 27,5 32 37 42 54 60 67 85 105

p2 mm 31 33,5 38 45 50 62 70 80 97 120

r mm 14 16 18 19 25 30 35 42 50 62

s mm 36 39 45 50 60 70 83 94 116 141

w/x mm 22 / 54 22 / 53 22 / 49 22 / 45 30 / 40 30 / 75 30 / 64 40 / 84 40 / 71 40 / 59

Keyway DIN 6885 - 2 - 1 1 1 1 1 2 2 2 2 2

1) up to 60% of full torque rate 2) drop to 10% of full torque rate

10-2015

Electromagnetic Stationary Field Multi-Disc Clutch

Clutch with outer driver for torque transmission between shaft and free wheeling gear part.

For dry operation, coil voltage 24 V DC This clutch is specially suited for external gearbox installation.

Clutch with adjustable air gap. In main drives for operation of power driven units, for example pumps

Suited for operating sequences with precise torque control. compressors, and other machinery.

High energy absorption by wear resistant steel- / sinter discs. In positioning drives for the control of feed motions.

Effective heat dissipation by peripheral friction faces. The accurate engagement response of the clutch with thereby given

For lowest idling torque non-magnetic discs can be provided. exact operational control remains unchanged for a longtime period.

Vertical mounting, only when ordered with application guidelines. Available in special design suitable for cumbustion-engine applications.

Side A b1 Outer driver 1

p1

x

k

i w

Side B

l1

0°

12

12

s u

0°

c1

c2

a

h

g

e

d

l2

p2 Outer driver 2

not bored

b2

FMV FMV FMV FMV FMV FMV FMV FMV FMV FMV

Data and Dimensions

1,2 2,5 5 10 20 40 80 160 315 630

Static torque Nm 20 40 80 160 320 630 1250 2500 5000 10000

Dynamic torque Nm 12 25 50 100 200 400 800 1600 3200 6300

Idling torque Nm 0,04 0,06 0,1 0,2 0,4 0,6 1,0 1,6 2,4 3,6

Friction work per engagement kJ 2,4 4,8 10 12,5 20 40 63 120 150 250

Thermal capacity W 40 54 80 110 135 220 270 410 490 790

Speed maximum min-1 4000 3850 3650 3500 3200 2900 2400 1900 1400 1000

Torque-time constant 1) s 0,15 0,18 0,20 0,25 0,30 0,40 0,50 0,75 1,30 2,00

Disengagement time 2) s 0,05 0,06 0,07 0,08 0,09 0,10 0,15 0,20 0,25 0,30

Coil power consumption at 20 °C W 15 22 25 35 35 60 75 105 105 105

10-3 kgm2

Mass moment of inertia side A 0,4 0,7 1,4 3,3 7,0 17 42 130 288 780

10-3 kgm2

Mass moment of inertia side B 0,5 1,1 2,2 5,5 13 34 90 228 713 2375

Mass (weight) kg 1,6 2 3 4 8 14 23 43 75 140

øa mm 90 99 115 136 161 200 237 292 357 452

b1 mm 44,5 46,5 52,5 56 66 78 91,5 102,5 127 152

b2 mm 50 53 60 64 74 90 101,5 115,5 139 167

ø c 1 H7 mm 65 74 84 102 124 152 190 230 285 370

ø c 2 min H7 mm 20 20 25 30 35 40 50 60 70 90

ø d H7 mm 10 ... 20 10 ... 25 12 ... 30 15 ... 40 20 ... 50 25 ... 60 30 ... 70 40 ... 90 50 ... 100 70 ... 130

øe mm 32 37 43 52 62 82 88 113 138 168

øg mm 74 84 98 118 140 172 210 257 316 407

øh mm 81 90 105 125 150 186 221 274 338 426

i airgap (clutch engaged) mm 0,15 - 0,25 0,15 - 0,25 0,20 - 0,30 0,25 - 0,30 0,25 - 0,30 0,25 - 0,30 0,30 - 0,50 0,30 - 0,50 0,30 - 0,50 0,30 - 0,50

k / ø m rough bored for dowel mm M5 / 4 M5 / 5 M6 / 6 M6 / 6 M8 / 8 M8 / 8 M10 / 10 M12 / 12 M16 / 16 M16 / 20

l1 mm 4 5 5 5 7 8 11 11 13 14

l2 mm 4 5 6 8 8 12 12 15 15 18

p1 mm 25 27,5 32 37 42 54 60 67 85 105

p2 mm 32 34 39 45 50 66 70 80 97 120

s mm 40,5 42,5 48,5 50 60 72 83 94 116 141

u mm 2,5 2,5 2,5 3 3 3 3,5 3,5 5 5

w/x mm 22 / 54 22 / 53 22 / 49 22 / 45 22 / 40 30 / 75 30 / 64 40 / 84 40 / 71 40 / 59

Keyway DIN 6885 - 2 - 1 1 1 1 1 2 2 2 2 2

1) up to 60% of full torque rate 2) drop to 10% of full torque rate

10-2015

Electromagnetic Multi-Disc Clutch

Clutch with outer driver for torque transmission between shaft and free wheeling gear part.

For oil and dry operation, coil voltage 24 V DC The clutch is suited for external gear application, but also used, with oil

Clutch with adjustable gap. lubrication, in gears.

Suited for speed and feed engagements. The magnetic flux does not circulate through the disc stack, this makes it

High energy absorbtion by wear resistant steel- / sinter discs. possible to use non magnetic friction material for high power and torque

Effective heat dissipation by peripheral friction faces. load at the lowest wear rate.

For horizontal mounting. Current intake through slip ring and return through earth connection (-).

Seite B

Seite A h l Available in special design suitable for cumbustion-engine applications.

i

m

° 60

60 °

f

g

d

a

e

c

k

b

LMS LMS LMS LMS LMS LMS LMS LMS LMS LMS LMS LMS

Data and Dimensions

1,6 2,5 4 6,3 10 16 25 40 63 100 160 250

Static torque Nm 25 40 63 100 160 250 400 630 1000 1600 2500 4000

wet operation

Dynamic torque Nm 16 25 40 63 100 160 250 400 630 1000 1600 2500

Idling torque Nm 0,1 0,2 0,3 0,35 0,45 0,6 0,8 1,1 2,2 3,5 5 10

Friction work per engagement kJ 10 15 20 25 35 40 70 90 150 250 300 500

Thermal capacity W 90 120 130 170 250 330 450 550 770 1000 1250 1600

Static torque Nm 40 80 120 180 300 500 800 1200 1800 3000 5000 8000

dry operation

Dynamic torque Nm 25 50 80 120 200 320 500 800 1200 2000 3200 5000

Idling torque Nm 0,05 0,08 0,12 0,16 0,25 0,4 0,5 0,6 1 1,4 1,6 2,4

Friction work per engagement kJ 2,5 4 5 6 8 12 18 25 35 60 80 110

Thermal capacity W 30 45 50 70 90 110 150 200 300 400 550 700

Speed maximum min -1 3800 3500 3500 3200 3000 2600 2300 2100 1900 1700 1500 1300

Coil power consumption at 20° C W 25 28 32 34 45 54 63 75 85 110 140 155

Mass moment of inertia side A 10 -3 kgm 2 0,7 1,3 1,4 2,6 4,5 8 15 22 42 80 160 380

Mass moment of inertia side B 10 -3 kgm 2 1,5 2,6 3 6,5 10,5 17 32 60 115 250 500 1000

Mass (weight) kg 2 2,6 2,9 4 5,5 7,5 11 14,5 21 33 45 75

øa mm 100 110 120 132 145 160 180 200 230 255 295 340

b mm 45 48 52 55 58 62 68 76 86 100 115 132

øc mm 97 112 115 133 147 158 180 198 235 265 290 355

ø d max H7 mm 25 30 32 35 42 48 55 60 70 80 90 120

ø e min H7 mm 50 50 50 60 70 80 90 100 100 110 140 180

f mm 42 45 48 50 53 57 63 70 80 92 107 122

øg mm 85 90 100 105 120 135 155 170 200 235 260 305

h mm 5 5 6 7 7 7 8 9 10 12 14 15

i air gap (clutch engaged) mm 0,3 0,3 0,3 0,3 0,35 0,4 0,45 0,5 0,6 0,7 0,8 0,9

k mm 5,5 5,5 5,5 5,5 5,5 5,5 6 6 6 8,5 8,5 8,5

l mm 8 8 8 8 8 8 8 8 8 10 10 10

m mm M6 M6 M6 M8 M8 M8 M 10 M10 M12 M12 M16 M16

Keyway z x y at d max mm 8 x 3,3 10 x 3,3 10 x 3,3 10 x 3,3 12 x 3,3 14 x 3,8 16 x 4,3 18 x 4,4 29 x 4,9 22 x 5,4 25 x 5,4 32 x 7,4

You might also like

- Chapter 1 Construction Equipment Management SC Sharma - pdf.YQZCBNiH8liAKOjoJX6psxzm6iHrfLnJDocument70 pagesChapter 1 Construction Equipment Management SC Sharma - pdf.YQZCBNiH8liAKOjoJX6psxzm6iHrfLnJSelam Teklay100% (4)

- D475a BulldozerDocument1,548 pagesD475a Bulldozertincho_0026100% (3)

- Konica Minolta Bizhub C220 C280 C360 Parts CatalogDocument113 pagesKonica Minolta Bizhub C220 C280 C360 Parts CatalogYury Kobzar100% (10)

- Data-Sheet Drum Brake RT - 200220 - enDocument1 pageData-Sheet Drum Brake RT - 200220 - enRFTNo ratings yet

- Raider 125 LE PricelistDocument9 pagesRaider 125 LE PricelistRichel Joy Samaniego Santiago75% (4)

- Speed Twin Clutch DSG S - Tronic AudiDocument88 pagesSpeed Twin Clutch DSG S - Tronic Audikepler2775% (4)

- GorillaBac Owners Manual PDFDocument33 pagesGorillaBac Owners Manual PDFRobertNo ratings yet

- Automotive Acronyms and AbbreviationsDocument20 pagesAutomotive Acronyms and Abbreviationssampapa33% (3)

- Vespa GTS300 Super Owners ManualDocument82 pagesVespa GTS300 Super Owners Manuallynhaven1No ratings yet

- 4transmission System ENGLISG-955NDocument44 pages4transmission System ENGLISG-955NGeorge Jhonson100% (3)

- DCMOTOR - Transmotec Datasheet J - 5 SeriesDocument1 pageDCMOTOR - Transmotec Datasheet J - 5 Seriestanaya.rpsNo ratings yet

- It6430 0908 - BSV NDocument20 pagesIt6430 0908 - BSV NgunarxNo ratings yet

- YEZ-Conical Brake MotorDocument3 pagesYEZ-Conical Brake MotorMech MallNo ratings yet

- COOLPLUS-Glc - GLL Oil Cooler Heat ExchangerDocument4 pagesCOOLPLUS-Glc - GLL Oil Cooler Heat ExchangerCOOLPLUS OIL COOLERNo ratings yet

- Crescendo PDFDocument1 pageCrescendo PDFindra_idroNo ratings yet

- Layout Ducting & Perhitungan Kapasitas BFQ MC-182Document10 pagesLayout Ducting & Perhitungan Kapasitas BFQ MC-182MakhturNo ratings yet

- Elastomer Jaw Couplings Ringfeder GWE 5104: Servo-Insert Coupling With Clamping Hubs and Dual SlitsDocument2 pagesElastomer Jaw Couplings Ringfeder GWE 5104: Servo-Insert Coupling With Clamping Hubs and Dual Slitsselva rajNo ratings yet

- Cm400dy 50HDocument3 pagesCm400dy 50HMiguel GalvánNo ratings yet

- Marathon LDocument16 pagesMarathon LmohamedNo ratings yet

- Nokia 220 Charging Section240329155220Document2 pagesNokia 220 Charging Section240329155220kashi kashiNo ratings yet

- AlternatorDocument3 pagesAlternatorRafaa AbdelkaderNo ratings yet

- Abb-02-Ics-Das-Enf-000-00001-00 Z-03Document2 pagesAbb-02-Ics-Das-Enf-000-00001-00 Z-03mvdeole7056No ratings yet

- Mercedes Benz 950 Wiring Diagram For AlternatorDocument3 pagesMercedes Benz 950 Wiring Diagram For AlternatorRyan Mac IntoshNo ratings yet

- Ultrasonic Testing of Materials 133Document1 pageUltrasonic Testing of Materials 133joNo ratings yet

- Electromagnetic Two Disc, Spring Set BrakeDocument1 pageElectromagnetic Two Disc, Spring Set BrakeAnonymous Ts0uMLFOJNo ratings yet

- C09 KFB e PDFDocument1 pageC09 KFB e PDFAbdulNo ratings yet

- Components Double Stand Over TravelDocument1 pageComponents Double Stand Over TravelKovács EndreNo ratings yet

- Physical and Piezoelectric Properties of APC MaterialsDocument2 pagesPhysical and Piezoelectric Properties of APC MaterialsTrương Anh DuyNo ratings yet

- Wiring Diagrams 2 - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . - .Document12 pagesWiring Diagrams 2 - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . - .Ali özkanlıNo ratings yet

- Bar Bending ScheduleDocument18 pagesBar Bending ScheduleDivya ShahNo ratings yet

- Mot-An-S en 20160403Document9 pagesMot-An-S en 20160403DARIONo ratings yet

- Hoverboard 6 Mekotron hb-0060k E-Board Repair InfoDocument7 pagesHoverboard 6 Mekotron hb-0060k E-Board Repair InfoElison QuezadaNo ratings yet

- Datasheet Sandvik 199l enDocument3 pagesDatasheet Sandvik 199l enpedro rojasNo ratings yet

- Design of Short Column For Axial Load and MomentDocument5 pagesDesign of Short Column For Axial Load and Momentភារម្យ អេងNo ratings yet

- PractiCAM ReducersDocument1 pagePractiCAM Reducersalexcaron25No ratings yet

- AD 61 - 55 Retarder: Technical SpecificationsDocument8 pagesAD 61 - 55 Retarder: Technical SpecificationsStiven Martinez ValenciaNo ratings yet

- Sandvik 25.22.2.Lmn: (Welding Wire)Document3 pagesSandvik 25.22.2.Lmn: (Welding Wire)Anonymous w6TIxI0G8lNo ratings yet

- Components Single Stand Over TravelDocument1 pageComponents Single Stand Over TravelKovács EndreNo ratings yet

- Coupling 20241Document2 pagesCoupling 20241Quản Lê ĐìnhNo ratings yet

- Span 1: Showroom SahiwalDocument2 pagesSpan 1: Showroom Sahiwalanon_388492125No ratings yet

- Sizing Criteria For Cylinders and Servocylinders: F (P A - P A) 10 (N) F (P A - P A) 10 (N) F (P - P) A 10 (N)Document5 pagesSizing Criteria For Cylinders and Servocylinders: F (P A - P A) 10 (N) F (P A - P A) 10 (N) F (P - P) A 10 (N)Mohammed bakrimNo ratings yet

- Experiment No Title:: School of Electrical EngineeringDocument15 pagesExperiment No Title:: School of Electrical EngineeringAkshit VSNo ratings yet

- Schematic - How To Make A Current Booster Circuit - 2022-10-18Document1 pageSchematic - How To Make A Current Booster Circuit - 2022-10-18Gilberto VidalNo ratings yet

- TCD 2013, 2200 090 KW TCD 2013 L04 2V Q680 Tier3Document1 pageTCD 2013, 2200 090 KW TCD 2013 L04 2V Q680 Tier3Michael BogdanNo ratings yet

- Stihl MS360 IPLDocument17 pagesStihl MS360 IPLPedro Luis Garrido100% (1)

- En 1717sr DFFDocument1 pageEn 1717sr DFFIsael CJNo ratings yet

- NewCurves LTMDocument5 pagesNewCurves LTMRBS GROUP ENQUIRIESNo ratings yet

- SQJ992EP: Vishay SiliconixDocument11 pagesSQJ992EP: Vishay SiliconixcqlNo ratings yet

- Man 7g50meDocument18 pagesMan 7g50meSalih Tuğrul SarıNo ratings yet

- Decon (Screw) WS SeriesDocument5 pagesDecon (Screw) WS Serieszuigh899gNo ratings yet

- Wuxy Trummy CatalogDocument4 pagesWuxy Trummy CatalogMartin RomeroNo ratings yet

- Camfix Std.Document1 pageCamfix Std.alecandro_90No ratings yet

- 12V Simple Single Supply Amp - BindDocument14 pages12V Simple Single Supply Amp - BindArlene B. NoceteNo ratings yet

- Ds Ah 00658800Document2 pagesDs Ah 00658800acorkeryuNo ratings yet

- Sk1000 v220 s110 7.5kw V10+traccion EstandarDocument11 pagesSk1000 v220 s110 7.5kw V10+traccion Estandarrggb123gmailcomNo ratings yet

- 20GMM10BR001 Rev00Document1 page20GMM10BR001 Rev00Avak ArmeniNo ratings yet

- Design Kit: Class D Audio Amplifier Using IRS2092Document48 pagesDesign Kit: Class D Audio Amplifier Using IRS2092bob doleNo ratings yet

- AC Servomotor 110SFDocument4 pagesAC Servomotor 110SFrumenNo ratings yet

- E10018d2-Eng LINCOLNDocument1 pageE10018d2-Eng LINCOLNBenfil ViernezNo ratings yet

- WK 450 540 Check Valve Type S: DM /min Up To 260 Up To 31,5 Mpa Ns 6 To 30Document4 pagesWK 450 540 Check Valve Type S: DM /min Up To 260 Up To 31,5 Mpa Ns 6 To 30Gizem MuhendislikNo ratings yet

- Compass - VCC Imu - VCC VDD - 5V - IN: 1 Watt Heater For Offboard Sensors 200 Ma LoadDocument6 pagesCompass - VCC Imu - VCC VDD - 5V - IN: 1 Watt Heater For Offboard Sensors 200 Ma LoadguidoNo ratings yet

- Chumaceras SKFF-220Document1 pageChumaceras SKFF-220milaNo ratings yet

- Taper Lock V PulleysDocument14 pagesTaper Lock V PulleysblazevicvilkoNo ratings yet

- Nedal Alloy Datasheet en AW 6005ADocument1 pageNedal Alloy Datasheet en AW 6005Aankur panwarNo ratings yet

- 4 - Spur GearsDocument8 pages4 - Spur GearsAnil YildizNo ratings yet

- AVR China 2346GA2491-6GA2492-V1.2.0.0-Manual-V2.0 - ENDocument20 pagesAVR China 2346GA2491-6GA2492-V1.2.0.0-Manual-V2.0 - ENoscar caceres0% (1)

- MVE 202 DC 24: Drawings DownloadDocument2 pagesMVE 202 DC 24: Drawings DownloadAmol SarinNo ratings yet

- Naval BrassDocument1 pageNaval BrassAugusto Gabriel Flores ManzanedaNo ratings yet

- Etl1286 - 990 RSV Tuono My06Document90 pagesEtl1286 - 990 RSV Tuono My06Oscar OrdazzoNo ratings yet

- Catalogo de Peças Kasinski Comet GTR250 Injeção Eletrônica .Document58 pagesCatalogo de Peças Kasinski Comet GTR250 Injeção Eletrônica .Rafa100% (1)

- A 4 Af 1Document3 pagesA 4 Af 1a_gz_spNo ratings yet

- Catalogo de Partes Hero Splendor Ismart 14Document63 pagesCatalogo de Partes Hero Splendor Ismart 14Yessenia Chavez BernedoNo ratings yet

- BodyDocument83 pagesBodyarunantony100% (1)

- Nitrox 125 Picture Book 2010 12 09Document80 pagesNitrox 125 Picture Book 2010 12 09Gloria RamirezNo ratings yet

- 605Document24 pages605usamaNo ratings yet

- A750-A761E VacTestGuideDocument5 pagesA750-A761E VacTestGuidebyungchul kimNo ratings yet

- IHC Integrated Monitoring and Control System FS 8064Document87 pagesIHC Integrated Monitoring and Control System FS 8064Roga29No ratings yet

- Manual 6a32Document24 pagesManual 6a32Buho FielNo ratings yet

- Maping Detail MC 5 by BranchDocument101 pagesMaping Detail MC 5 by BranchChairunnisa IINo ratings yet

- 7-11 Endurance Racer-Cycleworld Dec 88Document11 pages7-11 Endurance Racer-Cycleworld Dec 88Matheus Zambon MenezesNo ratings yet

- Portfolio of Mechanical SystemDocument44 pagesPortfolio of Mechanical SystemChalani NeranjanaNo ratings yet

- 450-43le Aisin Seiki PDFDocument6 pages450-43le Aisin Seiki PDFBillyNo ratings yet

- Spare Parts Catalog Hfc1035kd - d836Document465 pagesSpare Parts Catalog Hfc1035kd - d836أحمد العابد80% (5)

- FZS600 Owners ManualDocument105 pagesFZS600 Owners ManualjonboynzNo ratings yet

- Practical Manual of AD - 363, Automobile or Automotive TransmissionDocument57 pagesPractical Manual of AD - 363, Automobile or Automotive TransmissionMuhammad AsifNo ratings yet

- $RTB9Z6RDocument18 pages$RTB9Z6RAnonymous EUhwQEvdNo ratings yet

- Pin Assignment of Plug Connection A22 X4: Figure LegendDocument2 pagesPin Assignment of Plug Connection A22 X4: Figure LegendYassin HijaziNo ratings yet

- Parts Manual: L1806D Wheeled LoaderDocument7 pagesParts Manual: L1806D Wheeled LoaderPeetNo ratings yet

- TM 9-816 AUTOCAR U 7144Document280 pagesTM 9-816 AUTOCAR U 7144Advocate100% (1)