Professional Documents

Culture Documents

Bri-Steel Pipe Schedule

Bri-Steel Pipe Schedule

Uploaded by

N ROriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bri-Steel Pipe Schedule

Bri-Steel Pipe Schedule

Uploaded by

N RCopyright:

Available Formats

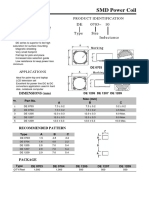

BRI-STEEL MANUFACTURING

2125 - 64 AVE EDMONTON AB T6P 1Z4

PH: (780) 469-6603

FAX: (780) 469-6986

www.bri-steel.com

BOLD figues =

wall thickness (inches) ASME PIPE SCHEDULES Italic figures =

weight (lbs) per foot

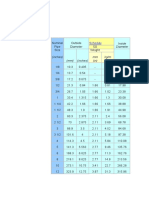

Pipe O.D. TRUE TRUE 40s & TRUE 80s & TRUE

Size

5s 10s 20 30 60 100 120 140 160 XXH

in. (mm) 5 10 STD 40 XH 80

0.405 0.035 0.049 0.049 0.057 0.068 0.068 0.095 0.095

1/8 (10.8) 0.138 0.186 0.186 0.212 0.245 0.245 0.315 0.315

0.540 0.049 0.065 0.065 0.073 0.088 0.088 0.119 0.119

1/4 (13.7) 0.257 0.330 0.330 0.364 0.425 0.425 0.535 0.535

0.675 0.049 0.065 0.065 0.073 0.091 0.091 0.126 0.126

3/8 (17.1) 0.328 0.424 0.424 0.470 0.568 0.568 0.739 0.739

0.840 0.065 0.065 0.083 0.083 0.095 0.109 0.109 0.147 0.147 0.187 0.294

1/2 (21.3) 0.538 0.538 0.671 0.671 0.757 0.851 0.851 1.088 1.088 1.304 1.714

1.050 0.065 0.065 0.083 0.083 0.095 0.113 0.113 0.154 0.154 0.218 0.308

3/4 (26.7) 0.684 0.684 0.857 0.857 0.970 1.131 1.131 1.474 1.474 1.937 2.441

1.315 0.065 0.065 0.109 0.109 0.114 0.133 0.133 0.179 0.179 0.250 0.358

1 (33.4) 0.868 0.868 1.404 1.404 1.464 1.679 1.679 2.172 2.172 2.844 3.659

1.660 0.065 0.065 0.109 0.109 0.117 0.140 0.140 0.191 0.191 0.250 0.382

1 1/4 (42.2) 1.107 1.107 1.806 1.806 1.930 2.273 2.273 2.997 2.997 3.765 5.214

1.900 0.065 0.065 0.109 0.109 0.125 0.145 0.145 0.200 0.200 0.281 0.400

1 1/2 (48.3) 1.274 1.274 2.087 2.087 2.372 2.718 2.718 3.631 3.631 4.859 6.408

2.375 0.065 0.065 0.109 0.109 0.125 0.154 0.154 0.218 0.218 0.344 0.436

2 (60.3) 1.604 1.604 2.638 2.638 3.007 3.653 3.653 5.022 5.022 7.462 9.029

2.875 0.083 0.083 0.120 0.120 0.188 0.203 0.203 0.276 0.276 0.375 0.552

2 1/2 (73.0) 2.475 2.475 3.531 3.531 5.400 5.793 5.793 7.661 7.661 10.01 13.70

3.500 0.083 0.083 0.120 0.120 0.188 0.216 0.216 0.300 0.300 0.437 0.600

3 (88.9) 3.029 3.029 4.332 4.332 6.656 7.576 7.576 10.25 10.25 14.32 18.58

4.000 0.083 0.083 0.120 0.120 0.188 0.226 0.226 0.318 0.318 0.636

3 1/2 (101.6) 3.472 3.472 4.970 4.970 7.661 9.109 9.109 12.51 12.51 22.85

4.500 0.083 0.083 0.120 0.120 0.188 0.237 0.237 0.281 0.337 0.337 0.437 0.531 0.674

4 (114.3) 3.915 3.915 5.613 5.613 8.666 10.79 10.79 12.66 14.98 14.98 19.01 22.51 27.54

5.000 0.247 0.355 0.710

4 1/2 (127.0) 12.53 17.61 32.53

5.563 0.109 0.109 0.134 0.134 0.258 0.258 0.375 0.375 0.500 0.625 0.750

5 (141.3) 6.349 6.349 7.770 7.770 14.62 14.62 20.78 20.78 27.04 32.96 38.55

6.625 0.109 0.109 0.134 0.134 0.280 0.280 0.432 0.432 0.562 0.718 0.864

6 (168.3) 7.585 7.585 9.289 9.289 18.97 18.97 28.57 28.57 36.39 45.30 53.16

8.625 0.109 0.109 0.148 0.148 0.250 0.277 0.322 0.322 0.406 0.500 0.500 0.593 0.718 0.812 0.906 0.875

8 (219.1) 9.914 9.914 13.40 13.40 22.36 24.70 28.55 28.55 35.64 43.39 43.39 50.87 60.63 67.76 74.69 72.42

10.750 0.134 0.134 0.165 0.165 0.250 0.307 0.365 0.365 0.500 0.500 0.593 0.718 0.843 1.000 1.125 1.000

10 (273.0) 15.19 15.19 18.65 18.65 28.04 34.24 40.48 40.48 54.74 54.74 64.33 76.93 89.2 104.1 115.7 104.1

12.750 0.156 0.165 0.180 0.180 0.250 0.330 0.375 0.406 0.562 0.500 0.687 0.843 1.000 1.125 1.312 1.000

12 (323.9) 21.07 22.18 24.20 24.20 33.38 43.77 49.56 53.53 73.16 65.42 88.51 107.2 125.5 139.7 160.3 125.5

14.000 0.156 0.188 0.250 0.312 0.375 0.375 0.437 0.593 0.500 0.750 0.937 1.093 1.250 1.406 1.000

14 (355.6) 23.06 27.73 36.71 45.68 54.57 54.57 63.67 84.91 72.09 106.1 130.7 150.7 170.2 189.1 138.8

16.000 0.165 0.188 0.250 0.312 0.375 0.375 0.500 0.656 0.500 0.843 1.031 1.218 1.437 1.593 1.000

16 (406.4) 27.90 31.75 42.05 52.36 62.58 62.58 82.77 107.5 82.77 136.5 164.8 192.3 223.5 245.1 160.2

18.000 0.165 0.188 0.250 0.312 0.437 0.375 0.562 0.750 0.500 0.937 1.156 1.375 1.562 1.781 1.000

18 (457) 31.43 35.76 47.39 59.03 82.06 70.59 104.8 138.2 93.45 170.8 208.0 244.1 274.2 308.5 181.6

20.000 0.188 0.218 0.250 0.375 0.500 0.375 0.593 0.812 0.500 1.031 1.281 1.500 1.750 1.968 1.000

20 (508) 39.78 46.05 52.73 78.60 104.1 78.60 122.9 166.4 104.1 208.9 256.1 296.4 341.1 379.0 202.9

22.000 0.188 0.250 0.375 0.500 0.375 0.875 0.500 1.125 1.375 1.625 1.875 2.125 1.000

22 (559) 43.80 58.07 86.61 114.8 86.61 197.4 114.8 250.8 302.9 353.6 403.0 451.1 224.3

24.000 0.218 0.250 0.250 0.375 0.562 0.375 0.687 0.968 0.500 1.218 1.531 1.812 2.062 2.343 1.000

24 (610) 55.37 63.41 63.41 94.62 140.8 94.62 171.2 238.1 125.5 296.4 367.4 429.4 483.1 541.9 245.6

26.000 0.312 0.500 0.375 0.500 1.000

26 (660) 85.60 136.2 102.6 136.2 267.0

28.000 0.312 0.500 0.625 0.375 0.500 1.000

28 (711) 92.26 146.8 182.7 110.6 147.0 288.4

30.000 0.250 0.312 0.312 0.500 0.625 0.375 0.500 1.000

30 (762) 79.43 98.93 98.93 157.5 196.1 118.6 157.5 309.7

32.000 0.312 0.500 0.625 0.375 0.688 0.500 1.000

32 (813) 105.6 168.2 209.4 126.7 230.1 168.2 331.1

34.000 0.312 0.500 0.625 0.375 0.688 0.500 1.000

34 (864) 112.3 178.9 222.8 134.7 244.8 179.1 352.4

36.000 0.312 0.625 0.375 0.750 0.500 1.000

36 (914) 118.9 236.1 142.7 282.3 189.6 373.8

40.000 0.375 0.500 1.000

40 (1016) 158.7 210.9 416.5

42.000 0.375 0.500 1.000

42 (1067) 166.7 221.6 437.9

48.000 0.375 0.500 1.000

48 (1219) 190.7 253.6 502.0

60.000 0.375 0.500 1.000

60 (1524)

Bri-Steel Manufacturing Production Range

238.8 317.73 630.1

72.000 0.500 1.000

72 (1829) 381.8 758.3

CONSISTENCY - RELIABILITY - EXCELLENT WORKMANSHIP

BRI-STEEL MANUFACTURING

2125 - 64 AVE EDMONTON AB T6P 1Z4

PH: (780) 469-6603

FAX: (780) 469-6986

www.bri-steel.com

BRI-STEEL MANUFACTURING SPECIFICATIONS

ASTM/ASME A/SA53 CSA Z245.1

Welded & Seamless Steel Pipe Steel Pipe

Gr.A: 30 ksi (205 MPa) YS, 48 ksi (330 MPa) UTS, Not Impact Tested Gr.241: 241-495 MPa YS, 414-760 MPa UTS

Gr.B: 35 ksi (240 MPa) YS, 60 ksi (415 MPa) UTS, Not Impact Tested Gr.290: 290-495 MPa YS, 414-760 MPa UTS

NPS 14 to 36 SMLS, All Wall Thicknesses Gr.359: 359-530 MPa YS, 455-760 MPa UTS

Must Complete one of Hydrotesting, UT or ET Gr.386: 386-540 MPa YS, 490-760 MPa UTS

End Finishes: Plain End, Bevel Gr.414: 414-565 MPa YS, 517-760 MPa UTS

Gr.448: 448-600 MPa YS, 531-760 MPa UTS

ASTM/ASME A/SA106 Grade B/C Category I: Not Impact Tested

Category II: Impact 27J *; 60% Shear

Seamless Steel Pipe for High Temperature Service

Category III: Impact 27J *; No Shear Requirement

Gr.B: 35 ksi (240 MPa) YS, 60 ksi (415 MPa) UTS, Not Impact Tested

* End User specifies the test temperature.

Gr.C: 40 ksi (275 MPa) YS, 70 ksi (485 MPa) UTS, Not Impact Tested

NPS 14 to 36 SMLS, All Wall Thicknesses

NPS 14 to 36 SMLS, All Wall Thicknesses

Hydrostatic Testing and UT are Mandatory

Must Complete one of Hydrotesting, UT or ET

End Finishes: Plain End, Bevel

End Finishes: Plain End, Bevel

End Finishes: Plain End, Bevel

ASTM/ASME A/SA333 Grade 6 NACE MR0175 / ISO 15156

Seamless & Welded Steel Pipe for Low Temp Service Materials for Use in H2S-Containing Environments

in Oil & Gas Production

Gr.6: 35 ksi (240 MPa) YS, 60 ksi (415 MPa) TS, Impact 18J at -45°C

Refer to MR0175/ISO 15156-2 Annex A2 for Region 3 Applications

NPS 14 to 36 SMLS, All Wall Thicknesses

For carbon and low-alloy hot-rolled SMLS pipe steels, the following apply

Must Complete one of Hydrottesting, UT or ET

Max 1% Ni, Max 22 HRC Hardness, No cold work permitted

End Finishes: Plain End, Bevel

API 5L NACE MR0103

Specification for Line Pipe Materials Resistant to Sulphide Stress Cracking in

Corrosive Petroleum Refining Environments

Gr.B PSL1: 35.5ksi (245MPa) YS, 60.2ksi (415MPa) UTS, Not Impact Tested

Gr.X42 PSL1: 42.1ksi (290MPa) YS, 60.2ksi (415MPa) UTS, Not Impact Tested For carbon and low-alloy SMLS pipe steels, the following apply

Gr.X46 PSL1: 46.4ksi (320MPa) YS, 63.1ksi (435MPa) UTS, Not Impact Tested Max 1% Ni, Max 22 HRC Hardness, No cold work permitted

Gr.X52 PSL1: 52.2ksi (360MPa) YS, 66.7ksi (460MPa) UTS, Not Impact Tested

Gr.X56 PSL1: 56.6ksi (390MPa) YS, 71.1ksi (490MPa) UTS, Not Impact Tested

Gr.X60 PSL1: 60.2ksi (415MPa) YS, 75.4ksi (520MPa) UTS, Not Impact Tested

Gr.X65 PSL1: 65.3ksi (450MPa) YS, 77.6ksi (535MPa) UTS, Not Impact Tested

Gr.B PSL2: 35.5ksi (245MPa) YS, 60.2ksi (415MPa) UTS, Impact 27J at 0ºC

Gr.X42 PSL2: 42.1ksi (290MPa) YS, 60.2ksi (415MPa) UTS, Impact 27J at 0ºC

NPS 14 to 36 SMLS, All Wall Thicknesses

Hydrostatic Testing is Mandatory, UT & ET when specified by end user

End Finishes: Plain End, Bevel

CONSISTENCY - RELIABILITY - EXCELLENT WORKMANSHIP

You might also like

- Mole Conversions Mazefor Reviewor AssessmentDocument9 pagesMole Conversions Mazefor Reviewor AssessmentAsiaNo ratings yet

- Kelly Pipe Chart (Updated)Document1 pageKelly Pipe Chart (Updated)joesamsoNo ratings yet

- CFE 2015 Mexico Sesimic RequirementsDocument24 pagesCFE 2015 Mexico Sesimic RequirementsTommaso PasconNo ratings yet

- LiquiTint BrochureDocument4 pagesLiquiTint BrochuregicacmNo ratings yet

- Project AramDocument13 pagesProject AramAram Nasih MuhammadNo ratings yet

- Pipe ScheduleDocument2 pagesPipe ScheduleRajeev ChandelNo ratings yet

- Tablas de CañeriasDocument11 pagesTablas de CañeriascesarNo ratings yet

- Tabel Ukuran NPS - DN All Pipe SizeDocument2 pagesTabel Ukuran NPS - DN All Pipe SizeVirgus Wira YJ Umbai100% (1)

- Tubing Pipe Dimensions Weight ChartDocument1 pageTubing Pipe Dimensions Weight ChartTahiruddin AhmedNo ratings yet

- NPT Joint Strength TableDocument1 pageNPT Joint Strength TablerodrigoperezsimoneNo ratings yet

- (In) (In) : Outside Diameter ScheduleDocument2 pages(In) (In) : Outside Diameter SchedulemusaveerNo ratings yet

- (In) (In) : Schedule 10 20 30 STD 40 60 XS 80 100 120 140 160 XXS Nominal Pipe Size Outside Diameter Wall Thickness (In)Document1 page(In) (In) : Schedule 10 20 30 STD 40 60 XS 80 100 120 140 160 XXS Nominal Pipe Size Outside Diameter Wall Thickness (In)dimaszrizkiNo ratings yet

- Tabel Ukuran PipaDocument8 pagesTabel Ukuran PipaAhmad SofandiNo ratings yet

- Nominal Pipe Size: Navigation SearchDocument5 pagesNominal Pipe Size: Navigation Searchnemi90No ratings yet

- Ma Pipe Dimensions and WeightsDocument1 pageMa Pipe Dimensions and WeightsKirkNo ratings yet

- ASA Standard Pipe ScheduleDocument20 pagesASA Standard Pipe ScheduleMULAYAM SINGH YADAVNo ratings yet

- WMWA Aluminum Seamless Bus Pipe SpecsDocument3 pagesWMWA Aluminum Seamless Bus Pipe Specsadrian PerezNo ratings yet

- 304 L 316 L Stainless Steel Pipe Tube Wall Thickness and WeightDocument7 pages304 L 316 L Stainless Steel Pipe Tube Wall Thickness and WeightaliNo ratings yet

- Nps Tables For Selected Sizes NPS To NPS 3Document4 pagesNps Tables For Selected Sizes NPS To NPS 3POWERNo ratings yet

- De1207 220Document2 pagesDe1207 220Stoica VictorNo ratings yet

- Howell Copper Pipe Tube DimensionsDocument1 pageHowell Copper Pipe Tube Dimensionsदिपक शेळकेNo ratings yet

- MS PIPE SIZE CHART - PDF - Pipe (Fluid Conveyance)Document6 pagesMS PIPE SIZE CHART - PDF - Pipe (Fluid Conveyance)Gunter BraunkinderNo ratings yet

- Adb Road 10 & 40mm New P.WDocument3 pagesAdb Road 10 & 40mm New P.WPhani PitchikaNo ratings yet

- Nominal Pipe Size - WikipediaDocument23 pagesNominal Pipe Size - WikipediaPrakashNo ratings yet

- Tubing Data Card: Oilfiled Equipment Marketing, IncDocument1 pageTubing Data Card: Oilfiled Equipment Marketing, IncWenyerMillanGonzalezNo ratings yet

- Pipe Schedule Chart InchDocument1 pagePipe Schedule Chart InchLeroy Ambrosio GabineteNo ratings yet

- Screw Bolt and NutDocument7 pagesScrew Bolt and NutsutarnoNo ratings yet

- Pipeschedule 2018 PDFDocument2 pagesPipeschedule 2018 PDFJee SelvaNo ratings yet

- SMD Power Coil: FerrocoreDocument2 pagesSMD Power Coil: FerrocorePuiu BercioiuNo ratings yet

- Resistance and Reactance Per KM of Copper and Aluminium Cables LFDocument2 pagesResistance and Reactance Per KM of Copper and Aluminium Cables LFTheophilus AmaraNo ratings yet

- Conexion de Acero Al Carbono Lap Joint Stub EndsDocument3 pagesConexion de Acero Al Carbono Lap Joint Stub EndsVictor MuñozNo ratings yet

- SS - CS Pipe DimensionDocument3 pagesSS - CS Pipe DimensionKailasNo ratings yet

- Steel Pipe Dimensions - ANSI Schedule 40Document3 pagesSteel Pipe Dimensions - ANSI Schedule 40StevenAronNo ratings yet

- AG PipeScheduleDocument1 pageAG PipeScheduleHamzaNoumanNo ratings yet

- Calculation For 450Mm Pipe Culvert Capacity: Velocity, V Capacity, QDocument11 pagesCalculation For 450Mm Pipe Culvert Capacity: Velocity, V Capacity, QAnonymous O404LiV4CNo ratings yet

- Boru Caplari DN Nps SCHDocument1 pageBoru Caplari DN Nps SCHKoray BAYAZITNo ratings yet

- PETR 3134 Codes and Specifications in The Petroleum IndustryDocument18 pagesPETR 3134 Codes and Specifications in The Petroleum IndustrynuvanNo ratings yet

- Polycab Cables Price List 2021Document4 pagesPolycab Cables Price List 2021Ulhas Vajre75% (4)

- Copper Pipes To BS EN 1057Document12 pagesCopper Pipes To BS EN 1057wkcNo ratings yet

- HP Piping SystemDocument1 pageHP Piping SystemNicolás Cuevas SandovalNo ratings yet

- SUMA Fitting Data SheetDocument11 pagesSUMA Fitting Data SheetDeddy TambunanNo ratings yet

- NP-Product CatalogueDocument252 pagesNP-Product CatalogueSebastian Przybylowicz100% (1)

- MILLIMDocument3 pagesMILLIMRhap Lumaban0% (1)

- Price-List Polycab Industrial Flexible CablesDocument4 pagesPrice-List Polycab Industrial Flexible Cablesusama zedanNo ratings yet

- Sistemas de BombeoDocument10 pagesSistemas de BombeoEl chavo MetaleroNo ratings yet

- Gauge Weight ChartDocument4 pagesGauge Weight ChartLandel SmithNo ratings yet

- Pipe Schedule ImperialDocument1 pagePipe Schedule ImperialDan ClarkeNo ratings yet

- British Standard ThreadsDocument1 pageBritish Standard ThreadsНиколай ЛевицкийNo ratings yet

- Tabla de Tuberia Asme B 36 10 PDFDocument32 pagesTabla de Tuberia Asme B 36 10 PDFGustavo XochihuaNo ratings yet

- Isolated Footing: Fy DF 15 415 130 FOT Pu Mux Muy BC DC Req. A (KN) (KN-M) (KN-M) (MM) (MM) (FT) (FT) (M) (M) F PDocument7 pagesIsolated Footing: Fy DF 15 415 130 FOT Pu Mux Muy BC DC Req. A (KN) (KN-M) (KN-M) (MM) (MM) (FT) (FT) (M) (M) F PSakar ShresthaNo ratings yet

- Isolated Footing: Fy DF 15 415 130 FOT Pu Mux Muy BC DC Req. A (KN) (KN-M) (KN-M) (MM) (MM) (FT) (FT) (M) (M) F PDocument7 pagesIsolated Footing: Fy DF 15 415 130 FOT Pu Mux Muy BC DC Req. A (KN) (KN-M) (KN-M) (MM) (MM) (FT) (FT) (M) (M) F Prockey shresthaNo ratings yet

- 016 - (Abs) Pipe Class 15Document1 page016 - (Abs) Pipe Class 15hentai savemeNo ratings yet

- Nominal Pipe Size Chart in Inch and MMDocument2 pagesNominal Pipe Size Chart in Inch and MMMehman NasibovNo ratings yet

- AASHTO FLexible Pavement Design Procedure (Tables 1-6 To 1-10)Document4 pagesAASHTO FLexible Pavement Design Procedure (Tables 1-6 To 1-10)Chezka C. BernabeNo ratings yet

- 0 Cal SeismicDocument237 pages0 Cal SeismicanammominNo ratings yet

- Pipe Schedule Table PDFDocument16 pagesPipe Schedule Table PDFAlaa edine SmaaliNo ratings yet

- Pipe Schedule Table PDFDocument16 pagesPipe Schedule Table PDFJuanPérezNo ratings yet

- Dimensões Das TubulaçõesDocument2 pagesDimensões Das TubulaçõesAlice Boll AltieriNo ratings yet

- BoltsDocument16 pagesBoltsJJGM120100% (1)

- ANSI B36.10 Steel PipesDocument8 pagesANSI B36.10 Steel Pipesphoneme79No ratings yet

- Low Voltage Power Cable Technical Data A.C. Resistance, Reactance and Impedance Rated Voltage: 600/1000VDocument2 pagesLow Voltage Power Cable Technical Data A.C. Resistance, Reactance and Impedance Rated Voltage: 600/1000VSemih Cem İlikNo ratings yet

- Standard Pipe Schedule 40 ASTM A 53 Grades A and BDocument2 pagesStandard Pipe Schedule 40 ASTM A 53 Grades A and Btarek eidNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Abac M600 - Instrument Manifolds PDFDocument16 pagesAbac M600 - Instrument Manifolds PDFFernanda CamargoNo ratings yet

- Lecture04 Pneumatic and Hydraulic Actuator-2Document41 pagesLecture04 Pneumatic and Hydraulic Actuator-2Ilyana Sahira MurizanNo ratings yet

- Two Applications of Gravimetric Titration: Simple, Buret-Free, and High PrecisionDocument3 pagesTwo Applications of Gravimetric Titration: Simple, Buret-Free, and High PrecisionFiona TiwonNo ratings yet

- Sulfuric Acid, 96% W/W: Safety Data SheetDocument8 pagesSulfuric Acid, 96% W/W: Safety Data SheetLindi PraditaNo ratings yet

- Is 4457 2007 PDFDocument27 pagesIs 4457 2007 PDFParameswaran MadhuNo ratings yet

- NOx Reduction MethodsDocument7 pagesNOx Reduction Methodsmithunsingh90No ratings yet

- Groundwater in Geochemical ExplorationDocument20 pagesGroundwater in Geochemical Explorationjavicol70No ratings yet

- Drug StudyDocument4 pagesDrug Studysilverblade36No ratings yet

- Toxicology ReportsDocument14 pagesToxicology ReportsBruno Garcia MontagniniNo ratings yet

- Jaocs 2013 AbDocument8 pagesJaocs 2013 AbNelma GomesNo ratings yet

- Class Xi Chemistry Ut I 2019 20 1Document6 pagesClass Xi Chemistry Ut I 2019 20 1GaneshNo ratings yet

- Test Requisition Contract - Concrete: Gulf Ready MixDocument1 pageTest Requisition Contract - Concrete: Gulf Ready MixVikash KumarNo ratings yet

- Takara Bio Lenti-X Concentrator Material Safety Data SheetDocument8 pagesTakara Bio Lenti-X Concentrator Material Safety Data SheetMildred MondayNo ratings yet

- 72T/D Ro Seawater Desalination Equipment: Technical ProposalDocument12 pages72T/D Ro Seawater Desalination Equipment: Technical ProposalMicah Ironfalcon ArceñoNo ratings yet

- Cameron CatalogueDocument28 pagesCameron CatalogueDaniel Quijada LucarioNo ratings yet

- GJ 11Document7 pagesGJ 11vijayakumarNo ratings yet

- The Bush Mechanic - DIY Beeswax Foundation Mould PDFDocument6 pagesThe Bush Mechanic - DIY Beeswax Foundation Mould PDFpeugeniu_1No ratings yet

- Meldin 7000 PDFDocument10 pagesMeldin 7000 PDFa100acomNo ratings yet

- Pereira de Abreu 2012Document43 pagesPereira de Abreu 2012RocioNo ratings yet

- Dual Shield 7000a1Document1 pageDual Shield 7000a1Gokul RajanNo ratings yet

- Lucite International Review 0810Document43 pagesLucite International Review 0810Shang LeeNo ratings yet

- Excel Flowsheeting TutorialDocument2 pagesExcel Flowsheeting TutorialYoga Anugrah PratamaNo ratings yet

- Tutorial 2 Electrochem A2Document9 pagesTutorial 2 Electrochem A2Nur Dinah Alesha Mohd Ali ZarNo ratings yet

- Company Name: Master Berber IncDocument8 pagesCompany Name: Master Berber IncYuanTing LimNo ratings yet

- Material Safety Data Sheet: TolueneDocument6 pagesMaterial Safety Data Sheet: TolueneRAJNo ratings yet

- COA-Medium Chain Triglycerides (MCT) Oil Powder (1060405)Document3 pagesCOA-Medium Chain Triglycerides (MCT) Oil Powder (1060405)santoso w pratama100% (1)

- Mfe QBDocument4 pagesMfe QBV VikasNo ratings yet