Professional Documents

Culture Documents

CBT No 016 Corrosion Protection I I

CBT No 016 Corrosion Protection I I

Uploaded by

Henry Funda, JrCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Fiat Doblo Cargo Workshop Manual PDFDocument2 pagesFiat Doblo Cargo Workshop Manual PDFsalih pişkin0% (9)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Pre-Final Examination: Prepared By: Marife G. Ventura Page - 1Document5 pagesPre-Final Examination: Prepared By: Marife G. Ventura Page - 1Princess Dayana Madera AtabayNo ratings yet

- Old Age Pension VeteranDocument2 pagesOld Age Pension VeteranLADY LYN SANTOSNo ratings yet

- Linux IPv6 How ToDocument164 pagesLinux IPv6 How ToAri SetianiNo ratings yet

- BRSM Class Test ExamDocument3 pagesBRSM Class Test ExamFernando SidikNo ratings yet

- Java Practical FileDocument84 pagesJava Practical FileDivyangnaNo ratings yet

- University of Cebu - CE Review: Geotechnical Eng'G Phases of Soil and ClassificationDocument7 pagesUniversity of Cebu - CE Review: Geotechnical Eng'G Phases of Soil and Classificationjovar jumao-asNo ratings yet

- Debt InstrumentsDocument1 pageDebt InstrumentsKijeka HandumonNo ratings yet

- Manual DVRDocument73 pagesManual DVRjavriverNo ratings yet

- Devoir de Synthèse N°1 - Anglais - 2ème Lettres (2019-2020) Mme Rahmeni JamilaDocument5 pagesDevoir de Synthèse N°1 - Anglais - 2ème Lettres (2019-2020) Mme Rahmeni JamilaSassi LassaadNo ratings yet

- YarnsDocument38 pagesYarnsAbhinav VermaNo ratings yet

- Introduction of Korean 1000MW USC BoilerDocument27 pagesIntroduction of Korean 1000MW USC BoilerDiego Martínez FernándezNo ratings yet

- Hot-Rolled Carbon, Low-Alloy, High-Strength Low-Alloy, and Alloy Steel Floor PlatesDocument10 pagesHot-Rolled Carbon, Low-Alloy, High-Strength Low-Alloy, and Alloy Steel Floor PlatesSama UmateNo ratings yet

- Understanding The Self Module 2Document11 pagesUnderstanding The Self Module 2Glory NeriNo ratings yet

- Python CodeDocument7 pagesPython CodeAmogh VarshneyNo ratings yet

- MBM019-1407 Launching of 60Hz Chilled Water Ceiling Cassette MCKE-EW (H) SeriesDocument9 pagesMBM019-1407 Launching of 60Hz Chilled Water Ceiling Cassette MCKE-EW (H) SeriesLeonardo Martinho DobrianskyjNo ratings yet

- Ultrasonic Testing of Materials 155Document1 pageUltrasonic Testing of Materials 155joNo ratings yet

- DN670 Ductile Iron Manhole Cover D400 EN124Document11 pagesDN670 Ductile Iron Manhole Cover D400 EN124munisipalcastings100% (1)

- Drama 30 Year Plan RittingerDocument2 pagesDrama 30 Year Plan Rittingerapi-490177257No ratings yet

- 1 - DS SATK Form - Initial Application of LTO 1.2Document4 pages1 - DS SATK Form - Initial Application of LTO 1.2cheska yahniiNo ratings yet

- KITEPDocument207 pagesKITEPMarleneAgustinNo ratings yet

- Prototype TutorialDocument451 pagesPrototype TutorialMariela DemarkNo ratings yet

- Catalog MotoreductoareDocument20 pagesCatalog MotoreductoareNitzu Holhorea CornelNo ratings yet

- Acs42 Config GuideDocument214 pagesAcs42 Config GuideOtia ObaNo ratings yet

- Me 218 Bprojectdescription 1112Document6 pagesMe 218 Bprojectdescription 1112api-310813713No ratings yet

- Methods of Teaching (Handouts)Document3 pagesMethods of Teaching (Handouts)Даша ГалкаNo ratings yet

- Extractor de Probetas DEMTECHDocument2 pagesExtractor de Probetas DEMTECHPaul Alex Quiroz BarrionuevoNo ratings yet

- Contemp Final ReviewerDocument8 pagesContemp Final ReviewerKen ManilayNo ratings yet

- RDGFGDocument4 pagesRDGFGRobin SinghNo ratings yet

- Automotive Radar - MATLAB & SimulinkDocument3 pagesAutomotive Radar - MATLAB & SimulinkAdfgatLjsdcolqwdhjpNo ratings yet

CBT No 016 Corrosion Protection I I

CBT No 016 Corrosion Protection I I

Uploaded by

Henry Funda, JrOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CBT No 016 Corrosion Protection I I

CBT No 016 Corrosion Protection I I

Uploaded by

Henry Funda, JrCopyright:

Available Formats

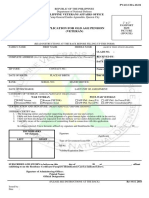

CBT NO 016 CORROSION PROTECTION I I

What is the minimum number of degrees centigrade the steel temperature must be above the

dew point before paint application? 3°C

Why is fresh water washing important before commencing paint application? To remove

soluble salts

What piece of equipment would be the most effective in removing corrosion from difficult

corners or angled areas? Needle gun

Why should the use of long lines be avoided, if possible, during spray application? Risk of

pressure drops

The main contaminants in a Marine environment are SALT, CORROSION, MOISTURE, OIL &

GREASE, DUST AND HULL FOULING. What is the most efficient method of removing HULL

FOULING? High Pressure Water Washing.

Which of the following statements best describes one of the main advantages of

Hydroblasting with fresh water as opposed to Dry Abrasive Blasting? As well as removing

corrosion products it also removes salt contamination.

A large area of exposed deck is to be blasted to an agreed standard of SA2 before

application of an epoxy paint system. In the vicinity of some pipes where difficult access

means that the blasting is not able to remove all the corrosion. What do you do? Discuss the

various options with the contractor.

Which are the 3 factors, which help contribute to correct performance of a paint system.

The Paint itself

Proper Surface Preparation

Proper Application of Paint

The wet film of paint, which is applied, bears a direct relationship to the final dry film

thickness of the coating. Taking wet film measurements can be very important. Why is it

important to take these measurements as quickly as possible? To obtain as close a reading to

the actual wet film as possible.

When using Airless Spray equipment what are the 3 most important safety rules to observe?

Do not point the gun at anyone or pull trigger when bare hands or fingers are close to the spray

outlet tip

Do not snag the paint lines or drag them over sharp edges

Always wear the correct personal protective equipment

Paint is applied to a deck in the morning. Each morning the air temperature is 7ºC. In early

afternoon the temperature of the air rises to 23ºC. You are told that the maximum

overcoating time for the paint coating is 36 hours at 20ºC and 48 hours at 10ºC. In this case,

what maximum overcoating time do you allow? You consult the paint suppliers representative

Which are the 3 factors which influence the length of time from finishing an antifouling

coating to the flooding of the dry-dock?

Ventilation

Drying time

Temperature

During a drydock paint application why only check dft’s on spot blasted areas, how do you

check the antifouling thickness? Spot blasted areas are the only areas coated from the steel

surface upwards - you control the antifouling thickness by controlling the distribution.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Fiat Doblo Cargo Workshop Manual PDFDocument2 pagesFiat Doblo Cargo Workshop Manual PDFsalih pişkin0% (9)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Pre-Final Examination: Prepared By: Marife G. Ventura Page - 1Document5 pagesPre-Final Examination: Prepared By: Marife G. Ventura Page - 1Princess Dayana Madera AtabayNo ratings yet

- Old Age Pension VeteranDocument2 pagesOld Age Pension VeteranLADY LYN SANTOSNo ratings yet

- Linux IPv6 How ToDocument164 pagesLinux IPv6 How ToAri SetianiNo ratings yet

- BRSM Class Test ExamDocument3 pagesBRSM Class Test ExamFernando SidikNo ratings yet

- Java Practical FileDocument84 pagesJava Practical FileDivyangnaNo ratings yet

- University of Cebu - CE Review: Geotechnical Eng'G Phases of Soil and ClassificationDocument7 pagesUniversity of Cebu - CE Review: Geotechnical Eng'G Phases of Soil and Classificationjovar jumao-asNo ratings yet

- Debt InstrumentsDocument1 pageDebt InstrumentsKijeka HandumonNo ratings yet

- Manual DVRDocument73 pagesManual DVRjavriverNo ratings yet

- Devoir de Synthèse N°1 - Anglais - 2ème Lettres (2019-2020) Mme Rahmeni JamilaDocument5 pagesDevoir de Synthèse N°1 - Anglais - 2ème Lettres (2019-2020) Mme Rahmeni JamilaSassi LassaadNo ratings yet

- YarnsDocument38 pagesYarnsAbhinav VermaNo ratings yet

- Introduction of Korean 1000MW USC BoilerDocument27 pagesIntroduction of Korean 1000MW USC BoilerDiego Martínez FernándezNo ratings yet

- Hot-Rolled Carbon, Low-Alloy, High-Strength Low-Alloy, and Alloy Steel Floor PlatesDocument10 pagesHot-Rolled Carbon, Low-Alloy, High-Strength Low-Alloy, and Alloy Steel Floor PlatesSama UmateNo ratings yet

- Understanding The Self Module 2Document11 pagesUnderstanding The Self Module 2Glory NeriNo ratings yet

- Python CodeDocument7 pagesPython CodeAmogh VarshneyNo ratings yet

- MBM019-1407 Launching of 60Hz Chilled Water Ceiling Cassette MCKE-EW (H) SeriesDocument9 pagesMBM019-1407 Launching of 60Hz Chilled Water Ceiling Cassette MCKE-EW (H) SeriesLeonardo Martinho DobrianskyjNo ratings yet

- Ultrasonic Testing of Materials 155Document1 pageUltrasonic Testing of Materials 155joNo ratings yet

- DN670 Ductile Iron Manhole Cover D400 EN124Document11 pagesDN670 Ductile Iron Manhole Cover D400 EN124munisipalcastings100% (1)

- Drama 30 Year Plan RittingerDocument2 pagesDrama 30 Year Plan Rittingerapi-490177257No ratings yet

- 1 - DS SATK Form - Initial Application of LTO 1.2Document4 pages1 - DS SATK Form - Initial Application of LTO 1.2cheska yahniiNo ratings yet

- KITEPDocument207 pagesKITEPMarleneAgustinNo ratings yet

- Prototype TutorialDocument451 pagesPrototype TutorialMariela DemarkNo ratings yet

- Catalog MotoreductoareDocument20 pagesCatalog MotoreductoareNitzu Holhorea CornelNo ratings yet

- Acs42 Config GuideDocument214 pagesAcs42 Config GuideOtia ObaNo ratings yet

- Me 218 Bprojectdescription 1112Document6 pagesMe 218 Bprojectdescription 1112api-310813713No ratings yet

- Methods of Teaching (Handouts)Document3 pagesMethods of Teaching (Handouts)Даша ГалкаNo ratings yet

- Extractor de Probetas DEMTECHDocument2 pagesExtractor de Probetas DEMTECHPaul Alex Quiroz BarrionuevoNo ratings yet

- Contemp Final ReviewerDocument8 pagesContemp Final ReviewerKen ManilayNo ratings yet

- RDGFGDocument4 pagesRDGFGRobin SinghNo ratings yet

- Automotive Radar - MATLAB & SimulinkDocument3 pagesAutomotive Radar - MATLAB & SimulinkAdfgatLjsdcolqwdhjpNo ratings yet