Professional Documents

Culture Documents

Lux Meter FT3424: Makio Kitazawa

Lux Meter FT3424: Makio Kitazawa

Uploaded by

Abid HussainOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lux Meter FT3424: Makio Kitazawa

Lux Meter FT3424: Makio Kitazawa

Uploaded by

Abid HussainCopyright:

Available Formats

1

Lux Meter FT3424

Lux Meter FT3424

Makio Kitazawa

Engineering Division 5, Engineering Department

Abstract—The Lux Meter FT3424, which qualifies as a

General Class AA device under JIS C 1609-1, has received

type approval (No. EE141) under Japan’s Measurement Act.

The instrument is an illuminometer that has the high-precision

luminosity characteristics required for use in plants where

next-generation lighting fixtures such as LEDs are

manufactured and in locations where such lighting has been

installed. This paper provides an overview of the product and

describes its features, architecture, and other characteristics.

I. INTRODUCTION

Illuminance is defined as a physical quantity that

expresses the brightness of light as perceived by the human

eye. One of its uses is as an indicator of brightness in school

classrooms and company offices, where it aids in judging

the proper amount of light. Illuminometers are used in such

settings.

In recent years, there has been a noteworthy move

toward broad adoption of LED lighting as a next-generation

lighting technology, creating numerous opportunities for

measuring illuminance in plants where LED lighting fixtures Appearance of the FT3424

are manufactured and in locations where such lighting has

been installed. Such applications require an illuminometer The standards that govern illuminometers have also

that qualifies as a General Class AA device under the evolved, with the old JIS C 1609-1 standard, which predated

general measuring instrument standard JIS C 1609-1:2006. widespread adoption of LED lighting, being scrapped in

However, the legacy Lux HiTester 3423 offered General 2006 and replaced with JIS C 1609:2006 for general

Class A performance under that standard, necessitating measuring instruments, as described in Section III-A below,

development of a General Class AA illuminometer that and JIS C 1609-2:2008 for specified measuring instruments

satisfies the category’s more rigorous requirements in such (those used in transaction or certification applications).

areas as spectral sensitivity characteristics. These changes comprise the backdrop against which

Hioki developed the Lux Meter FT3424 as a high-precision

II. OVERVIEW illuminometer that qualifies as a General Class AA device

Hioki developed the Lux HiTester 3421 in 1979 and under the JIS C 1609-1:2006 standard for general measuring

subsequently developed and launched the Digital Lux instruments and launched the device for use in a broad range

HiTester 3422 and the Lux HiTester 3423. A large number of applications, including next-generation lighting research

of these instruments remain in use in luminance and development, manufacture, and installation. The

measurement applications in such fields as lighting instrument has also received type approval under Japan’s

installation and facility management. In recent years, the Measurement Act, ensuring a high level of reliability when

industry has seen an increasingly diverse range of light used in transaction or certification applications.

source and light modulation technologies emerge for use in Hioki’s success in developing a high-precision

LED and other types of lighting, which are attracting luminosity filter played a major role in the development of

attention as next-generation lighting solutions, including the the FT3424.

adoption of pulse width modulation (PWM) technology. In

some cases, older illuminometers cannot be used with

pulsed light, which is characterized by large fluctuations in

illuminance (see Section V-C).

HIOKI Technical Notes Vol. 1 2015 No. 1

2

Lux Meter FT3424

III. FUNCTIONS AND FEATURES

In developing the FT3424, Hioki identified “usability in

the field” as a key product concept. The product was

developed with a strong awareness of the fact that it would

be used in the field despite being a precision optical

measuring instrument. With its color-coded control keys,

which provide operators with an intuitive understanding of

the necessary measurement functions, and a large LCD

designed to make illuminance values easy to read, the

FT3424 provides a readily approachable level of operability.

Thus equipped with an easy-to-read display and simple-to-

use controls, the FT3424 is an illuminometer that will help

boost work efficiency. Fig. 1. Separate Sensor and Display

A. General Class AA Qualification (JIS C 1609-1)

Compared to the old JIS standard, JIS C 1609-1

incorporates more rigorous requirements that match

illuminometers’ spectral sensitivity characteristics with their

luminosity characteristics. Specifically, the tolerance for the

divergence of relative spectral response characteristics in the

visible region from the standard spectral luminous efficiency

has been tightened to 3/4 of the level required by old JIS

standard. The FT3424 incorporates a redesigned illuminance

sensor that takes advantage of high-precision filter

technologies perfected during the development of the LED

Optical Meter TM6101 to deliver a luminosity filter whose

high level of precision ranks it among the best in the

industry. Since the illuminometer’s spectral sensitivity

characteristics approach the standard spectral luminous

efficiency, it can measure light sources with different light

spectra, for example LED lighting and organic EL lighting, Fig. 2. Mounting the Sensor on a Tripod

with a high degree of precision.

position. To accommodate such use, Hioki has provided a

B. Excellent Measurement Range Coverage screw hole on the back of the sensor so that it can be

mounted on a tripod as illustrated in Fig. 2.

The FT3424 provides an extensive selection of

measurement ranges, from a 20 lx range for low-illuminance

D. Timer Hold Function

measurement to a 200,000 lx range for high-illuminance

measurement. In particular, the 20 lx range delivers high The FT3424’s timer hold function fixes the illuminance

resolution of 0.01 lx, making it ideal for use in low- value once a preset time has elapsed after the TIMER key is

illuminance measurement in locations such as emergency pressed, allowing the measurement technician to move away

lighting and emergency exit signage, which are subject to from the measurement target where the illuminometer has

regulatory provisions in Japan’s Fire Service Act. been set up before the timer runs out. This function is

designed so that the technician’s own shadow does not

C. Separate Sensor and Display affect illuminance values.

The FT3424’s sensor and display can be undocked and

E. Memory Function

connected with the optional Connection Cable L9820 so that

the sensor to be positioned independently of the display. The FT3424’s internal memory can store up to 99 data

This capability is intended to accommodate the need to points.

place the sensor separately in lighting installations so that The instrument’s memory function saves the illuminance

the measurement technician’s own shadow does not affect value in the device’s internal memory each time the

illuminance values. As illustrated in Fig. 1, a technician can MEMORY key is pressed. Each saved data point is assigned

place the sensor in the measurement location and then check a number in the order it was saved, and the instrument can

the illuminance from a distance. store up to 99 such data points. The illuminance values

In lighting fixture manufacturing plants, measurements associated with particular data numbers can be recalled later

are often made after securing the sensor at a predefined for review.

HIOKI Technical Notes Vol. 1 2015 No. 1

3

Lux Meter FT3424

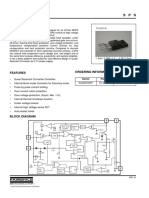

Sensor unit LCD Rubber Display unit

with back light key

I-V Range Buzzer

converter amplifier Low pass filter

Luminosity 16-bit D/A

Globe filter

A/D output

12-bit

Photo CPU

D/A

diode D-sub connecter

USB 2.0

Power

EEPROM

circuit

Fig. 3. Block Diagram

This function is convenient when using the instrument in

applications that require multiple measurements, for

example when carrying out illuminance measurement in

accordance with the Ministry of Education, Culture, Sports,

Science and Technology’s standard for school

environmental sanitation. When testing classrooms, the

technician must measure illuminance at nine predefined

locations and then verify that the minimum value is at least

300 lx (a value of 500 lx or greater is desirable) and that the

ratio of the maximum illuminance value to the minimum

illuminance value does not exceed 10:1. The FT3424’s

memory function can be used to save the nine illuminance

values to the instrument’s internal memory for later retrieval

so that a judgment can be made, or for batch transfer to a

computer using its USB communication functionality, which

is described below. Fig. 4. Recording Data Using USB Application Software

By combining the FT3424 with other recording and

F. USB Communication Functionality

measuring instruments via the D/A output terminal on its

The FT3424 can be connected to a computer via its USB side, it is possible to perform continuous illuminance

interface. Supported functionality includes transferring all measurement or record illuminance fluctuations.

data stored in the instrument’s internal memory to a

computer (see Section III-E), controlling the instrument via H. Protective Ridges for Sensor

application software, making measurements at a set interval,

and transferring data. Fig. 4 illustrates an example in which The design of the FT3424’s sensor unit is distinguished

the application software is being used to record data. by two protective ridges on the left and right sides of the

Illuminance values can be graphed so that fluctuations can unit that sit higher than the sensor’s light-sensing surface.

be visualized. These ridges protect the illuminance sensor from damage if

the sensor is placed upside-down on a floor, for example. In

Hioki expects this capability to find use in applications this way, the unit has been designed to protect the

in which fluctuations in illuminance must be recorded over illuminance sensor from scratches and dirt that would

extended periods of time and in testing of illuminance adversely affect measurement precision.

during the manufacture of lighting fixtures.

I. Type Approval (No. EE141)

G. D/A Output Functionality In a sign of its high level of reliability, the FT3424 has

The FT3424’s D/A output functionality enables it to received type approval. Under Japan’s Measurement Act,

convert displayed illuminance values into a voltage signal only illuminometers that have passed a verification process

for output to an external device. Illuminance values are can be used to make measurements that are used in

converted using 2 V DC for the maximum valid display of transaction or certification applications. In particular,

2,000 counts in each measurement range and output based illuminance measurements carried out as part of the

on the display refresh interval. installation or replacement of lighting fixtures in public

parks and on public roads must be made using an

HIOKI Technical Notes Vol. 1 2015 No. 1

4

Lux Meter FT3424

illuminometer that has passed such a verification process. Back case

The FT3424 has received a type approval number so that it

can be used in situations such as these where a verified

instrument is required.

IV. ARCHITECTURE

The FT3424 consists of a sensor unit that incorporates

the actual illuminance sensor and a display unit that

incorporates a large LCD display and operation keys. Fig. 3

provides a block diagram for the instrument.

Electrical board

A. Sensor Unit with Photo diode

The illuminance sensor on the sensor unit consists of a

light-collecting unit that incorporates a globe and a high- Shield

precision luminosity filter, and a board that incorporates a

light-sensing element. Fig. 5 illustrates how these parts have Collecting

structure part

been combined.

with Front case

After passing through the globe and high-precision luminosity filter

luminosity filter, incident light strikes the light-sensing

element, which generates current according to the human

eye’s luminosity. This current is miniscule, on the order of

several picoamperes for low illuminance values or several

dozen microamperes for high illuminance values. The

current is converted into a voltage signal by an I-V converter.

Globe

Fig. 6 illustrates an I-V converter that uses an amplifier.

The current generated by the light-sensing element flows to Fig. 5. Structural Diagram of the Sensor Unit

the output side of the amplifier via a feedback resistance. If

Analog switches

this current is I and the feedback resistance is R, the voltage

and Resistors

given by (I × R) will characterize the amplifier’s output. I

R

Despite the minuscule magnitude of this current, conversion

to a suitable voltage level is handled by means of feedback

resistance switching using analog switches since a wide

range of currents must be handled. The amplifier and analog

switch used here have been carefully chosen based on their

current-related characteristics so that the measurement

current is not affected. Photo

diode Voltage

Up to this point, signal processing has been handled by output

the sensor unit. In particular, the I-V converter has been

implemented using minuscule current measurement

Fig. 6. I-V Converter

technology, one of Hioki’s core strengths. By combining

circuit technology and filter technology, it is possible to

achieve stable measurement at low illuminance levels as 1) Measurement and display

well as measurement that can accommodate PWM- The electrical circuit acquires the voltage signal that

modulated light (see Section V-C below). corresponds to the illuminance from the sensor unit with an

A/D converter and transfers the resulting data to the CPU,

which converts the values into illuminance values by means

B. Display Unit of software processing. Illuminance values are displayed

In addition to a large LCD display and a number of key with four significant digits and up to 2,000 counts per range.

switches, the display unit incorporates a D/A output terminal Consequently, when an illuminance value exceeds 2,000 lx,

(mini-jack) and USB mini-receptacle on its side. On the rear it is converted and displayed with the lowermost digit fixed

is a compartment housing the two LR6 or R6 (AA) batteries to 0 (in the 20,000 lx range) or the two lowermost digits

that serve as the instrument’s power source. fixed to 00 (in the 200,000 lx range).

Compared to the sensor unit, the display unit has a 2) Power sources

simple structure. As illustrated in Fig. 7, this structure The FT3424 can operate on either of two power sources:

consists of two boards, a large LCD display, and key two LR6 or R6 (AA) batteries or USB bus power. When

switches that are sandwiched between front and back cases.

HIOKI Technical Notes Vol. 1 2015 No. 1

5

Lux Meter FT3424

operating on USB bus power, the circuit shuts off the supply

of power from the batteries. Metal fittings

The power supply circuit is designed to deliver a high Back case

level of efficiency while using less power and requiring

fewer electrical components. As a result, the instrument can

operate continuously for 120 hours (about three times the

Lux HiTester 3423’s 40 hours) when powered by R6 (AA) Metal fittings

manganese batteries or for about 300 hours when powered

by LR6 (AA) alkaline batteries.

3) USB communication Electrical

Hioki utilized the CPU’s built-in USB 2.0 module for board

USB communication in order to reduce the number of parts

in the instrument.

The circuit uses a novel design that lets it supply bus

Electrical

power even if USB communication capability is not being board

used, and it performs software processing. with LCD

4) D/A output unit

The D/A output unit outputs voltage data based on

illuminance values when the dedicated Output Cord 9094 is

connected to the instrument’s D/A output terminal. The Rubber key

circuit is designed so that the CPU monitors the D/A output

terminal and halts voltage output if the 9094 is not Battery

connected. case lid

5) Large LCD display

Anticipating use in the field, the instrument’s large LCD

display is equipped with a backlight. Unlike other measuring Front panel

Front case

instruments, the backlight on an instrument designed to

measure illuminance must not affect illuminance Fig. 7. Structural Diagram of the Display Unit

measurements. Consequently, the backlight only operates

when the display value is being held by the hold function or

the timer hold function while the instrument is in an

environment characterized by an illuminance of 750 lx or

less.

The illuminance measurement circuit operates

continuously, and the illuminometer’s status is monitored by

software so that the instrument can determine whether the

backlight can be operated without issue.

V. OPTICAL CHARACTERISTICS

This section describes the representative optical

characteristics of the proprietary high-precision luminosity

filter used by the FT3424.

A. Relative Spectral Response Characteristics in the Fig. 8. Relative Spectral Response Characteristics in the Visible Region

Visible Region

The human eye perceives green as bright and purple and As illustrated in Fig. 8, the FT3424’s relative spectral

red as dim, even if the light sources in question are emitting response characteristics resemble the spectral luminous

light at the same level of energy. The International efficiency. If the divergence f1’ from the spectral luminous

Commission on Illumination (CIE) has defined sensitivity to efficiency V (λ) as calculated using the equation for relative

the color (wavelength) of light in the form of spectral spectral sensitivity set forth in JIS C 1609-1:2006 is 6% or

luminous efficiency by averaging measurements taken using less, the device in question is considered to satisfy the

a large number of subjects. Spectral luminous efficiency in performance requirements for a General Class AA device.

the wavelength region of 360 nm to 830 nm According to JIS C 1609-1:2006, f1’ is calculated using

characteristically peaks at 555 nm. (1) and (2) below:

HIOKI Technical Notes Vol. 1 2015 No. 1

6

Lux Meter FT3424

λ2

λ S ' (λ) rel − V (λ) dλ

FT3424 samples' f1'

f1 ' = 1

λ2

× 100 (1)

Central value : 1.6%

λ1

V λ

( ) d λ

JIS C 1609-1:2006

λ2 Class AA Class A

λ P (λ) AV (λ) dλ upper limit upper limit

S ' (λ) rel = λ2

1

S (λ) rel (2)

λ

1

P (λ) A S (λ)rel dλ

P (λ)A: Relative spectral distribution of standard

illuminant A

V (λ): Spectral luminous efficiency 0 1 2 3 4 5 6 7 8 9

S (λ)rel: Relative spectral response f1' [%]

dλ: Measurement wavelength interval

λ 1: Visible wavelength region lower limit Fig. 9. Distribution of f1’ for FT3424 Test Samples

λ 2: Visible wavelength region upper limit

As illustrated in Fig. 9, the value f1’ for the FT3424 test

sample more than satisfies the 6% limit value for a General

Class AA device, indicating that the instrument delivers

excellent response sensitivity.

B. Oblique Incidence Characteristics

Since illuminance is defined as exposure to luminous

flux per unit of area, if the surface receiving the luminous

flux is positioned at the angle θ relative to the light source,

the illuminance will exhibit cosine characteristics by being

attenuated in proportion to cosθ. Fig. 10 illustrates the

FT3424’s oblique incidence characteristics.

According to JIS C 1609-1:2006, the angle of incidence

in the normal direction for an illuminometer’s light-sensing

surface is 0°, and the systematic divergence f2 exhibited by Fig. 10. Oblique Incidence Characteristics

the oblique incident light characteristics is calculated by

performing an oblique incident light test in which

illuminance values are read while positioning the light-

sensing unit in 10° increments in an area from 10° to 80°

around the vertical axis that passes through the intersection

Quantity

between the light-measuring axis and the measurement

reference surface. The performance of the illuminometer in

question can be determined based on the calculated f2 value.

f2 can be calculated using (3) and (4) below:

Y (θ)

f 2* (θ) = − 1 × 100 (3)

Y0 cosθ

Fig. 11. Distribution of f2 for FT3424 Test Samples

80゜π

f2 = 180゜ f 2* (θ) sin 2θdθ (4) As a result of this calculation, and as illustrated in Fig.

0 11, the value f2 for the FT3424 test sample more than

satisfies the 3% limit value for a General Class AA device,

θ : Angle of incidence (°) indicating that the instrument delivers excellent oblique

incidence characteristics.

HIOKI Technical Notes Vol. 1 2015 No. 1

7

Lux Meter FT3424

C. Effects of Pulsed Light

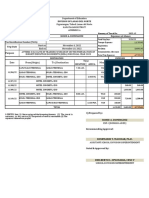

TABLE I. DEVIATION BETWEEN STEADY LIGHT AND PULSED LIGHT

Unlike steady lighting, whose light source is illuminated (40 HZ)

at all times, LED and many other recent lighting

technologies use PWM light modulation, which results in ON FT3424 Deviation [%]

Duty 20 200 2000 20000 200000

pulsed light created by repeatedly cycling the light source on [%] [lx] [lx] [lx] [lx] [lx]

and off. The legacy Lux HiTester 3423 was compatible with 1 −0.05 0.05 0.05 0.16 −0.28

steady light but not PWM-modulated light in some instances. 3 0.10 0.05 0.05 −0.16 −0.36

For example, the instrument indicated low illuminance 10 −0.05 0.00 0.00 0.20 0.26

values when used to test PWM-modulated light with 30 0.00 −0.10 0.05 −0.16 0.27

significant variations or low-duty pulsed light. The FT3424 90 0.00 0.16 0.00 0.00 0.00

can be used with low-duty pulsed light, and it can accurately 99 −0.05 −0.05 0.05 −0.05 −0.05

measure the illuminance of PWM-modulated light as well. 100 0.00 0.00 0.00 0.00 0.00

As an example, TABLE I lists the deviation between

measurements of steady light (for which the amount of light Pulse of controlled light sources

does not change) and measurements of pulsed light (for

which the on duty was changed, where “on” refers to the Old product's saturation point

light being on and “off” to its being off), both taken with the

FT3424. These results indicate that the instrument is little

affected by the saturation of pulsed light, as illustrated in Fig.

12. Even including slight fluctuations in the equipment and True value (FT3424's indicated value)

light source used in the test, the results reveal a deviation of

less than 0.5%. Old product's indicated value (3423)

Elapsed time

D. Temperature Characteristics

Under JIS C 1609-1:2006, General Class AA

instruments must have temperature characteristics such that Fig. 12. Effect of Pulsed Light Saturation

the deviation in luminance values at −10°C ±2°C (14.0°F

±3.6°F), 0°C ±2°C (32.0°F ±3.6°F), 10°C ±2°C (50.0°F

±3.6°F), 30°C ±2°C (86.0°F ±3.6°F), and 40°C ±2°C

(104.0°F ±3.6°F) is within ±3% using the value for 23°C

±2° (73.4°F ±3.6°F) as a reference. As illustrated in Fig. 13,

results for the FT3424 test sample indicate that the

instrument delivers performance within ±3% from −10°C to

40°C (14.0°F to 104.0°F). Hioki also carried out a

temperature characteristics test with an enlarged temperature

range from −20°C to 60°C (−4.0°F to 140.0°F) to reflect the

standard operating temperature range of its field measuring

instrument product group and were able to confirm that the

deviation is within ±1%.

E. Low-illuminance Range Linearity Fig. 13. Temperature Characteristics of FT3424 Test Sample

The broad coverage of the FT3424’s measurement

ranges was introduced in Section III-B as a key feature of

the instrument. Fig. 14 illustrates the linearity deviation for a

number of test samples in the low-illuminance 20 lx range,

which is particularly important. The maximum linearity

deviation values for the 20 lx range for all test samples were

within ±0.5%. These results demonstrate that the FT3424

delivers high-resolution, high-precision illuminance

measurement at low illuminance levels.

Fig. 14. Linearity Deviation in the 20 lx Range

HIOKI Technical Notes Vol. 1 2015 No. 1

8

Lux Meter FT3424

VII. CONCLUSION

VI. USE AS A LEGALLY AUTHORIZED ILLUMINOMETER The FT3424 is a high-precision illuminometer that

qualifies as a General Class AA device under JIS C 1609-

The FT3424 has received type approval from the 1:2006, and it has received type approval under the

Minister of Economy, Trade and Industry in accordance Measurement Act, signaling that it delivers the reliability

with the Measurement Act, and the instrument can be used required for use in transaction or certification applications.

in transaction or certification applications once it has been An extensive range of field measuring instrument design

subject to verification. Once an FT3424 has been verified, it technologies—one of Hioki’s core strengths—were

will bear the verification seal on its enclosure, enabling it to incorporated during the development process, yielding a

be used as a legally authorized illuminometer for a period of robust and easy-to-use product. Hioki expect the FT3424 to

two years. Once the verification period has ended, the see use as a reliable field measuring instrument in the same

instrument can be re-verified. broad range of fields as legacy illuminometers.

The FT3424 has received type approval as follows:

Model: FT3424 Kenji Nagai*1, Yuta Suzuki*2, Koji Morishita*3,

Type: Digital Fumio Narusawa*4, Tomoyuki Maruyama*4

Manufacturer: Hioki E.E. Corporation

Type approval number: No. EE141

Date of type approval: August 18, 2014 REFERENCES

[1] Narusawa, F. Hioki Lux Meter FT3424. Hikari Araiansu (Optical

Alliance). JAPAN INDUSTRIAL PUBLISHING CO., LTD. August

2014, vol. 25, no. 8, pp. 25-28. (Japanese).

[2] Kitazawa, M. The Society of Instrument and Control Engineers.

Keisoku Seigyo Gakkai, Chubu Shibu Sinpojiumu 2014,

Koenronbunshu. pp. 85-86. The Cubu Chapter, The Society of

Instrument and Control Engineers. (Japanese).

*1 Engineering Division 2, Engineering Department

*2 Engineering Division 5, Engineering Department

*3 Engineering Division 10, Engineering Department

*4 Research & Development Division 3, Research & Development

Department

HIOKI Technical Notes Vol. 1 2015 No. 1

You might also like

- Check Stub 1Document1 pageCheck Stub 1raheemtimo1No ratings yet

- Standard Operating Procedures NUMBER 2014-002: National Headquarters, Philippine National PoliceDocument6 pagesStandard Operating Procedures NUMBER 2014-002: National Headquarters, Philippine National PoliceStace Diane Deane Stefan60% (5)

- IEEE Research PaperDocument3 pagesIEEE Research PaperKishor Pawase0% (1)

- BUP Guideline 2013 09Document93 pagesBUP Guideline 2013 09FlankerSparrow67% (3)

- Iot Fundamentals: Digitial Assignment-1Document14 pagesIot Fundamentals: Digitial Assignment-1Geeth KuldeepNo ratings yet

- Trotec Lux bf06 PDFDocument1 pageTrotec Lux bf06 PDFAprilliana Kristina SihiteNo ratings yet

- Global Beam: Standard Sensors For AutomationDocument12 pagesGlobal Beam: Standard Sensors For AutomationfazalNo ratings yet

- Udt 3211 Sensor Rev 3.18.1Document1 pageUdt 3211 Sensor Rev 3.18.1cikaracakNo ratings yet

- BME 3111 S#1 Digital Filter DesignDocument20 pagesBME 3111 S#1 Digital Filter DesignSourav DebnathNo ratings yet

- BME 3111 S#1 Digital Filter DesignDocument20 pagesBME 3111 S#1 Digital Filter DesignSourav DebnathNo ratings yet

- Consumer/Industrial - Smart Smoke Detector: Application Note AbstractDocument10 pagesConsumer/Industrial - Smart Smoke Detector: Application Note AbstractFran Alisson SouzaNo ratings yet

- As7341 DS000504 3-00Document68 pagesAs7341 DS000504 3-00mek itoNo ratings yet

- Mitutoyo - Czujniki Linear Gage - E4174-542-572-575 - 2006 ENDocument60 pagesMitutoyo - Czujniki Linear Gage - E4174-542-572-575 - 2006 END.T.No ratings yet

- Magenta Molar Series FTIR Brochure M350 M350Plus M350 PortableDocument13 pagesMagenta Molar Series FTIR Brochure M350 M350Plus M350 PortableDeniRahayuYuniartoNo ratings yet

- SekonicL 358 L 558RBrochureDocument16 pagesSekonicL 358 L 558RBrochureCorneliu ModilcaNo ratings yet

- Light Meter With Analog Output Economical Light MeterDocument1 pageLight Meter With Analog Output Economical Light Meterrr aaNo ratings yet

- Color Light-to-Digital Converter With IR Filter: General DescriptionDocument40 pagesColor Light-to-Digital Converter With IR Filter: General DescriptionMahmudul HasanNo ratings yet

- Invenio Flyer enDocument2 pagesInvenio Flyer enErcx Hijo de AlgoNo ratings yet

- hioki-FT3424 FT3425 SheetDocument4 pageshioki-FT3424 FT3425 SheetJose Omar AlcantaraNo ratings yet

- Lab Report EE222Document5 pagesLab Report EE222Adil ShahidNo ratings yet

- Datasheet - Apr. 2013 - V1.0: Color Light-To-Digital Converter With IR FilterDocument32 pagesDatasheet - Apr. 2013 - V1.0: Color Light-To-Digital Converter With IR FilterTrinesh GowdaNo ratings yet

- Ke3 Cal Elc 0908 6078 - 0Document120 pagesKe3 Cal Elc 0908 6078 - 0SUBAS CHANDRA BEHERANo ratings yet

- tlp251tp1f CZRQFWLT 3jdJA1JqB PDFDocument80 pagestlp251tp1f CZRQFWLT 3jdJA1JqB PDFheribertosfaNo ratings yet

- Implementing Ultrasonic Ranging: Theory of OperationDocument19 pagesImplementing Ultrasonic Ranging: Theory of OperationMargaritoPitiminiNo ratings yet

- Field Devices - Flow Product Specifications: Foxboro Model IMT31A Magnetic Flow Signal ConverterDocument40 pagesField Devices - Flow Product Specifications: Foxboro Model IMT31A Magnetic Flow Signal Converterpablo emilio peronaNo ratings yet

- DigitalDocument48 pagesDigitalprajkumar324No ratings yet

- S1 TITAN Overview BrochureDocument8 pagesS1 TITAN Overview BrochurebenmedNo ratings yet

- Specbos 1211-2: Broadband Radiometer 350 1000 NMDocument2 pagesSpecbos 1211-2: Broadband Radiometer 350 1000 NMvarela820No ratings yet

- CHAPTER 1 - INTR-WPS OfficeDocument23 pagesCHAPTER 1 - INTR-WPS OfficeDavid NwankwereNo ratings yet

- HLK+LD2410+Life+Presence+Sensor+Module+Manual+V1 03 (220629)Document16 pagesHLK+LD2410+Life+Presence+Sensor+Module+Manual+V1 03 (220629)eou98305No ratings yet

- WAS-1923EN ReferenceDesignDocument10 pagesWAS-1923EN ReferenceDesignReginaldo souza santosNo ratings yet

- Digital Encoders 1.2Document6 pagesDigital Encoders 1.2controlorNo ratings yet

- Extech Instruments Corp., A Flir Co.Document5 pagesExtech Instruments Corp., A Flir Co.doriana gaetanoNo ratings yet

- Industrial LightingDocument34 pagesIndustrial Lightingrsgk75100% (2)

- Cat OptoNCDT enDocument36 pagesCat OptoNCDT enNikhil SharmaNo ratings yet

- Sekonic L 478 BrochureDocument8 pagesSekonic L 478 BrochureJordania Beatriz Pascual SueroNo ratings yet

- TMT84 DatasheetDocument22 pagesTMT84 DatasheetKERENSKINo ratings yet

- LX1108Document2 pagesLX1108Mikami TeruNo ratings yet

- Micronor Manual MR361-1Document20 pagesMicronor Manual MR361-1hs85m4nbpnNo ratings yet

- 343Document11 pages343i3abykiller3No ratings yet

- Hioki PQ3100 NotaDocument6 pagesHioki PQ3100 NotaNatali LopezNo ratings yet

- Tens or Series BrochureDocument8 pagesTens or Series BrochureDavis XiaoNo ratings yet

- LX 1108Document2 pagesLX 1108Alfredo Lopez CordovaNo ratings yet

- Luxometro LX1108 PDFDocument2 pagesLuxometro LX1108 PDFALEJANDRO IPATZINo ratings yet

- A Design of A Prototypic Hand-Talk Assistive Technology For The DumbDocument3 pagesA Design of A Prototypic Hand-Talk Assistive Technology For The Dumbsharanya_vancha100% (1)

- PyrometersDocument11 pagesPyrometersJOHNEDERSON PABLONo ratings yet

- Laurent 2013 PerformanceDocument13 pagesLaurent 2013 Performancetaras.yakymchukNo ratings yet

- Direct Digital Transfer: of Measuring ResultsDocument6 pagesDirect Digital Transfer: of Measuring ResultstcNo ratings yet

- Iot Based War Field Spying RobotDocument6 pagesIot Based War Field Spying RobotaryanNo ratings yet

- DalianYOKE-Product catalogue(漩涡)Document10 pagesDalianYOKE-Product catalogue(漩涡)muhammad umerNo ratings yet

- Seminar Hall Automation Using MicrocontrollerDocument3 pagesSeminar Hall Automation Using MicrocontrollerChiyan RanjithNo ratings yet

- Pyrometer Ardocell PQ PL enDocument12 pagesPyrometer Ardocell PQ PL enchief_of_stuffNo ratings yet

- Karta Danych - enDocument5 pagesKarta Danych - enwiruNo ratings yet

- Tracer Overview BrochureDocument8 pagesTracer Overview BrochureWoodrow FoxNo ratings yet

- LX1330B DatasheetDocument3 pagesLX1330B DatasheetAmanur AkashNo ratings yet

- Design and Analysis of A Three-Stage Decimation Filter For Signal Processing ApplicationsDocument6 pagesDesign and Analysis of A Three-Stage Decimation Filter For Signal Processing ApplicationsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Military RadarsDocument17 pagesMilitary RadarsAnurag ReddyNo ratings yet

- External - PPT - SportsStar Gen2.v1Document21 pagesExternal - PPT - SportsStar Gen2.v1LobooNo ratings yet

- Software Defined Radio: Enabling TechnologiesFrom EverandSoftware Defined Radio: Enabling TechnologiesWalter H.W. TuttlebeeNo ratings yet

- Ultrafast All-Optical Signal Processing DevicesFrom EverandUltrafast All-Optical Signal Processing DevicesDr. Hiroshi IshikawaRating: 5 out of 5 stars5/5 (1)

- Instrumentation and Test Gear Circuits ManualFrom EverandInstrumentation and Test Gear Circuits ManualRating: 5 out of 5 stars5/5 (1)

- Abid Hussain: ARAR Group of Companies, Lahore - Manager Technical & SupplyDocument2 pagesAbid Hussain: ARAR Group of Companies, Lahore - Manager Technical & SupplyAbid HussainNo ratings yet

- Physical Stock - Technical StoreDocument3 pagesPhysical Stock - Technical StoreAbid HussainNo ratings yet

- Abid Hussain: ARAR Group of Companies, Lahore - Manager Technical & Supply ChainDocument2 pagesAbid Hussain: ARAR Group of Companies, Lahore - Manager Technical & Supply ChainAbid HussainNo ratings yet

- Engineer / Supervisor: Skills RequiredDocument2 pagesEngineer / Supervisor: Skills RequiredAbid HussainNo ratings yet

- Abid Hussain: ARAR Group of Companies, LahoreDocument2 pagesAbid Hussain: ARAR Group of Companies, LahoreAbid HussainNo ratings yet

- Linen Collection Delivery Vehicle Movement Plan 08th Aug 2021 To 14th Aug 2021Document7 pagesLinen Collection Delivery Vehicle Movement Plan 08th Aug 2021 To 14th Aug 2021Abid HussainNo ratings yet

- THQ Shahpur - Civil, Electrical and Plumbing Work: SR - No. DescriptionDocument8 pagesTHQ Shahpur - Civil, Electrical and Plumbing Work: SR - No. DescriptionAbid HussainNo ratings yet

- MSHA 1st Merit ListDocument2 pagesMSHA 1st Merit ListAbid HussainNo ratings yet

- Entry Test Result EMBA 2021Document62 pagesEntry Test Result EMBA 2021Abid HussainNo ratings yet

- (F-TECH-06) Expense Form For Repair & Maintenance of HWM EquipmentDocument1 page(F-TECH-06) Expense Form For Repair & Maintenance of HWM EquipmentAbid HussainNo ratings yet

- (Clinical Psychologiest) : Maryam JamilDocument1 page(Clinical Psychologiest) : Maryam JamilAbid HussainNo ratings yet

- MCQs - CarpDocument3 pagesMCQs - CarpAbid HussainNo ratings yet

- Entry Test For MSDocument1 pageEntry Test For MSAbid HussainNo ratings yet

- RFP FOR OM OF Laundry 04 .12.2020 PDFDocument75 pagesRFP FOR OM OF Laundry 04 .12.2020 PDFAbid HussainNo ratings yet

- Linen Service Survey: On Site Inspection Worksheet: I. Laundry ProcessesDocument4 pagesLinen Service Survey: On Site Inspection Worksheet: I. Laundry ProcessesAbid HussainNo ratings yet

- Flat Work IronerDocument33 pagesFlat Work IronerAbid HussainNo ratings yet

- Ali Ahmad: Personal DetailsDocument2 pagesAli Ahmad: Personal DetailsAbid HussainNo ratings yet

- Questionnaire For LaundaryDocument3 pagesQuestionnaire For LaundaryAbid HussainNo ratings yet

- Ali Ahmad: Personal DetailsDocument2 pagesAli Ahmad: Personal DetailsAbid HussainNo ratings yet

- Questionnaire: 1. Name of Hospital DHQ Hospital LodhranDocument14 pagesQuestionnaire: 1. Name of Hospital DHQ Hospital LodhranAbid HussainNo ratings yet

- Hiring of Fumigation & Pest Control Services: Tender NoticeDocument1 pageHiring of Fumigation & Pest Control Services: Tender NoticeAbid HussainNo ratings yet

- IIARF CBOK Interacting With Audit Committees FEB 2016 PDFDocument16 pagesIIARF CBOK Interacting With Audit Committees FEB 2016 PDFArol RakotoNo ratings yet

- AlwarDocument58 pagesAlwarMonalisa MohantyNo ratings yet

- Contact UsDocument258 pagesContact UsSuplemento Deportivo100% (1)

- Always Clarify Clearance Via Voice If There Is ConfusionDocument2 pagesAlways Clarify Clearance Via Voice If There Is Confusionn kNo ratings yet

- Case 2 Environgard CorporationDocument5 pagesCase 2 Environgard CorporationutsavNo ratings yet

- Ecospet (Septic Tank) CertsDocument8 pagesEcospet (Septic Tank) CertsCalvin KewNo ratings yet

- Consumer Buying Behavior Towards Online Shopping: A Case Study of Daraz - PKDocument9 pagesConsumer Buying Behavior Towards Online Shopping: A Case Study of Daraz - PKMuzamil MushtaqNo ratings yet

- 5Q0765RTDocument10 pages5Q0765RTFuadNo ratings yet

- Brain ChildDocument8 pagesBrain ChildGabriel PiticasNo ratings yet

- BA Outline ChecklistDocument44 pagesBA Outline ChecklisttomNo ratings yet

- Design of Tower Foundations: $orarnarfDocument7 pagesDesign of Tower Foundations: $orarnarfjuan carlos molano toroNo ratings yet

- Introduction To Fruits and Vegetables 1122Document71 pagesIntroduction To Fruits and Vegetables 1122Dr-Uadal SinghNo ratings yet

- The Retail Industry in The GCCDocument13 pagesThe Retail Industry in The GCCNilgun EmremNo ratings yet

- Heating Systems in Buildings - Method For Calculation of System Energy Requirements and System Efficiencies - Part 1: GeneralDocument18 pagesHeating Systems in Buildings - Method For Calculation of System Energy Requirements and System Efficiencies - Part 1: GeneralMericNo ratings yet

- 1 2016 Reff2020Document13 pages1 2016 Reff2020Asmit PatelNo ratings yet

- The Tragedy of San Juanico-The LPG Disaster in History Most SevereDocument16 pagesThe Tragedy of San Juanico-The LPG Disaster in History Most SevereMohamed Tarek KamarNo ratings yet

- MSDS Ammonium MolybdateDocument6 pagesMSDS Ammonium MolybdateAuliarhamdaniNo ratings yet

- ApocultureDocument2 pagesApocultureZinan KakkodanNo ratings yet

- 97b0108n01 Intensity NCH-V IomDocument72 pages97b0108n01 Intensity NCH-V IomJulietina PerezNo ratings yet

- Introduction To Indirect Taxes Ch.IDocument6 pagesIntroduction To Indirect Taxes Ch.IpravinsankalpNo ratings yet

- Eticket PDFDocument2 pagesEticket PDFbimal mukhiyaNo ratings yet

- Reviewer in Police Personnel MGMT NEWDocument7 pagesReviewer in Police Personnel MGMT NEWcriminologyallianceNo ratings yet

- Grad Book 23Document146 pagesGrad Book 23Mostafa saber ELsadawyNo ratings yet

- School Principal ItineraryDocument3 pagesSchool Principal ItineraryKaren S. RoblesNo ratings yet

- Shakiba Hossan Tanha ID: 182011016: Mission Statement of 20 Companies: 1. Golden RoseDocument3 pagesShakiba Hossan Tanha ID: 182011016: Mission Statement of 20 Companies: 1. Golden RoseMohammed Farhad Hossain FahadNo ratings yet

- O DR Manager 201307Document2 pagesO DR Manager 201307Aziz Ur RehmanNo ratings yet

- Hazards Associated With Plant and Equipment (Including Non-Powered Plant and Hand Tools)Document7 pagesHazards Associated With Plant and Equipment (Including Non-Powered Plant and Hand Tools)وأكثرهم كارهونNo ratings yet