Professional Documents

Culture Documents

6001191B CH4 Standards Print PDF

6001191B CH4 Standards Print PDF

Uploaded by

Yeferson Mauricio Rodriguez RodriguezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6001191B CH4 Standards Print PDF

6001191B CH4 Standards Print PDF

Uploaded by

Yeferson Mauricio Rodriguez RodriguezCopyright:

Available Formats

Chapter 4:

Standards

Standards are used to give a baseline performance that needs to be met in order to ensure the safe use of

medical equipment. A medical equipment maintenance program needs to meet or exceed all local standards.

All relevant standards should be reviewed to ensure program compliance. The following Chapter discusses

some standards that biomedical personnel should be familiar with.

IEC 60601-1

The International Electrotechnical Commission, IEC, is a worldwide organization that promotes global stan-

dardization in the electronics industry. IEC 60601-1, titled Medical electrical equipment - Part 1: General

requirements for basic safety and essential performance, addresses medical equipment design in relation

to safety and serves as the foundation for safe manufacturing practices. This standard is mainly used in the

design and manufacture of medical equipment.

In 2005, the third edition of 60601-1 was published. The goal of the standard is to provide general

requirements for medical device safety assurance, and serves as the foundation for more specific standards.

This edition combines product requirements with manufacturing processes, such as risk management, and

addresses essential performance, including parts of the device that come in direct contact and can harm the

patient and/or operator.

The rationale behind the standard is to identify specific hazards associated with medical equipment and

to define an acceptable level of risk for each hazard. Additionally, it provides an objective test to determine

if the risks have been acceptably minimized, without defining how to minimize risks. This standard is not

intended to be used alone, as it addresses general safety issues applied broadly across medical equipment.

More specific standards need to be applied, depending on the medical equipment.

The 60601 family of standards contains collateral and particular standards. Collateral standards contain

requirements in addition to the parent standard. These standards are general in nature, like the parent

standard, and are applicable to all medical equipment. Particular standards contain requirements that are

exceptions to the parent and collateral standards. These types of standards are specific to a device type. IEC

60601 is the parent standard. Collateral standards are labeled as 60601-1-xx and particular standards are

labeled as 60601-2-xx, with xx denoting a specific document.

IEC 60601-1 is mainly used by manufacturers of medical equipment. Medical equipment that is manu-

factured to this standard has been subjected to rigorous safety and performance tests and has met quality

assurance specifications.

IEC 62353

IEC 62353 is an international standard published by the International Electrotechnical Commission, a world-

wide organization that promotes global standardization in the electronics industry. The standard addresses

the testing of medical equipment before first use, after servicing, or periodic safety inspections.

The standard specifies how to test for electrical safety and gives limits for acceptable measurements. Spe-

cific tests for measuring the protective earth resistance, leakage current, applied part leakage current, and

insulation resistance are outlined. These terms are defined as:

Protective earth resistance

Often referred to as ground wire resistance. Resistance between any conductive part of the equipment and

the protective connector of the main power supply plug, the protective connector of the appliance inlet, or

the protective conductor permanently connected to the supply mains.

Equipment leakage current

Current flowing from the supply mains to earth through the protective earth conductor and accessible con-

ductive parts.

©University of Vermont Chapter 4: Standards 11

Applied part leakage current

Often referred to as lead leakage, the current flowing from the supply mains and accessible conductive parts

to the applied parts, or patient leads.

Insulation resistance

The resistance of the insulation between the supply mains and protective earth, the supply mains and

accessible conductive parts, or the supply mains and the patient leads. The insulation resistance is calcu-

lated by applying a voltage and measuring the resulting current.

IEC 62353 sets specific limits for electrical safety testing: the protective earth resistance should not exceed

300 mW, leakage current for Class I medical equipment should not exceed 500 µA using the direct measure-

ment method and leakage current for Class II medical equipment should not exceed 100 µA.

Electrical safety testing is discussed in detail in Chapter 5 of this manual, Electrical Safety. IEC 62353 goes

on to further specify that safety related functions of the equipment must be inspected. The standard does not

specify which functions need to be tested or how often, only that the device functionality should be tested.

The standard also specifies that safety inspections need to be documented.

NFPA 99

The National Fire Protection Agency is an international organization that advocates the consensus of codes

and standards for fire, electrical, and building safety. NFPA building codes have been adopted in the United

States. The standard NFPA 99, Standard for Health Care Facilities, establishes criteria to minimize the risk of

fire, explosion, and electrical hazards in health care facilities.

NFPA 99 covers nearly all aspects of fire safety in the hospital environment including building electrical

systems, vacuum and gas systems, and emergency management. It is important to note that this is a volun-

tary standard. However, many localities have adopted NFPA 99 as part of their fire codes.

NFPA 99 includes a Chapter on electrical equipment that is of particular interest to biomedical equipment

technicians. This Chapter specifically covers the performance, maintenance, and testing of electrical equip-

ment used within the hospital. Numerical criteria are given for electrical safety testing. NFPA 99 section 8.4

states that the ground wire resistance of medical equipment should be less than 0.5 W. It goes on to specify

the chassis leakage current should not exceed 300 µA.

The Joint Commission

The Joint Commission is a regulatory body that evaluates and accredits health care organizations in the

United States. The Joint Commission’s mission is to improve the safety and quality of healthcare provided to

the public. Currently, a system of unannounced surveys is used to promote continued compliance of the Joint

Commission’s regulations.

The Joint Commission releases annual National Patient Safety Goals relating to pertinent healthcare quality

issues. The National Patient Safety Goals are eventually included in the Joint Commission’s regulations. The

Joint Commission’s regulations include a chapter on the health care environment. This chapter specifically

addresses medical equipment, device maintenance, and how to minimize risk. A common benchmark used in

the United States is the completion of scheduled maintenance. The Joint Commission requires 100 percent of

life support equipment to receive scheduled maintenance and at least 90 percent of non-life support equip-

ment to receive scheduled maintenance.

ISO 9001

Published by the International Organization for Standardization, the ISO 9000 family of standards addresses

various aspects of quality management. Of particular interest is ISO 9001, which sets out the requirements of

a quality management system. The ISO 9000 standards are written in such a way as to be able to be applied

across any industry, and any size organization. The standard is based on a process approach to quality man-

agement and continual improvement of the organization, and is intended to produce consistent, high quality

products and services.

ISO 9001 has begun to be adopted into the health care industry in the United States. The DNV, Det Norske

Veritas, is another regulatory body for accrediting health care facilities, similar to the Joint Commission. They

received deemed status for accrediting health care facilities in the United States in 2008. Accreditation with

the DNV will lead to ISO certification for the health care facility.

12 Chapter 4: Standards ©University of Vermont

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 062 Manual Traffic Sign and Gantries NorwayDocument141 pages062 Manual Traffic Sign and Gantries NorwayNat Thana AnanNo ratings yet

- Chapter 14 Supply Chain ManagementDocument46 pagesChapter 14 Supply Chain Managementkatherine cabrera100% (1)

- APTK461Document1 pageAPTK461Eong Huat Corporation Sdn BhdNo ratings yet

- 10 InverseKinematicsDocument42 pages10 InverseKinematicsAland BravoNo ratings yet

- RbvsavlDocument3 pagesRbvsavlAland BravoNo ratings yet

- Buffer Overflow Attack "Document53 pagesBuffer Overflow Attack "Aland BravoNo ratings yet

- Information and Program: Robotics 1Document21 pagesInformation and Program: Robotics 1Aland BravoNo ratings yet

- HeapsDocument78 pagesHeapsAland BravoNo ratings yet

- Binary Search TreesDocument116 pagesBinary Search TreesAland BravoNo ratings yet

- Minimal Representations of Orientation Homogeneous TransformationsDocument14 pagesMinimal Representations of Orientation Homogeneous TransformationsAland BravoNo ratings yet

- Robotics1 MidTerm 2017-18 17.11.24Document6 pagesRobotics1 MidTerm 2017-18 17.11.24Aland BravoNo ratings yet

- Position and Orientation of Rigid Bodies: Robotics 1Document20 pagesPosition and Orientation of Rigid Bodies: Robotics 1Aland BravoNo ratings yet

- Index of Useful Resources For Spacecraft Dynamics: PythonDocument1 pageIndex of Useful Resources For Spacecraft Dynamics: PythonAland BravoNo ratings yet

- Robot Components:: Robotics 1Document27 pagesRobot Components:: Robotics 1Aland BravoNo ratings yet

- 02 ServiceRobotsDocument69 pages02 ServiceRobotsAland BravoNo ratings yet

- Coursenotes Lesson1Document59 pagesCoursenotes Lesson1Aland BravoNo ratings yet

- Notation Guide Spacecraft DynamicsDocument2 pagesNotation Guide Spacecraft DynamicsAland BravoNo ratings yet

- Momentum Exchange Devices SlidesDocument42 pagesMomentum Exchange Devices SlidesAland BravoNo ratings yet

- Kinetics Module 1 Lecture SlidesDocument30 pagesKinetics Module 1 Lecture SlidesAland BravoNo ratings yet

- Syllabus Robo3x: Robotics: FundamentalsDocument4 pagesSyllabus Robo3x: Robotics: FundamentalsAland BravoNo ratings yet

- Property of Penn Engineering, Vijay Kumar and Ani HsiehDocument61 pagesProperty of Penn Engineering, Vijay Kumar and Ani HsiehAland BravoNo ratings yet

- Property of Penn Engineering, Vijay Kumar and Ani HsiehDocument45 pagesProperty of Penn Engineering, Vijay Kumar and Ani HsiehAland BravoNo ratings yet

- Property of Penn Engineering, Vijay Kumar and Ani HsiehDocument65 pagesProperty of Penn Engineering, Vijay Kumar and Ani HsiehAland BravoNo ratings yet

- Video 7.1 Vijay KumarDocument24 pagesVideo 7.1 Vijay KumarAland BravoNo ratings yet

- Week5 All 11 20 2017Document99 pagesWeek5 All 11 20 2017Aland BravoNo ratings yet

- Vijay Kumar and Ani Hsieh: Video 1.1Document44 pagesVijay Kumar and Ani Hsieh: Video 1.1Aland BravoNo ratings yet

- 2423 SpecDocument50 pages2423 SpecAssistant EngineerNo ratings yet

- Electric Vehicles 2021 Website VersionDocument52 pagesElectric Vehicles 2021 Website VersionmaheshNo ratings yet

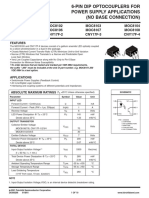

- 6-Pin Dip Optocouplers For Power Supply Applications Cny17f-2Document11 pages6-Pin Dip Optocouplers For Power Supply Applications Cny17f-2Jitendra SinghNo ratings yet

- Sicam 8 Sicam Hmi Software SolutionDocument130 pagesSicam 8 Sicam Hmi Software SolutionNilton Anderson Azambuja BertoldoNo ratings yet

- Database Client Installation Guide LinuxDocument84 pagesDatabase Client Installation Guide Linuxraiizii2No ratings yet

- AMADEUS Training Written Report - ALBADocument3 pagesAMADEUS Training Written Report - ALBAmikee albaNo ratings yet

- Project Report Hotel Management SystDocument63 pagesProject Report Hotel Management SystSubhash BajajNo ratings yet

- Prestige: Price As Built: $91,840Document8 pagesPrestige: Price As Built: $91,840J.D WorldclassNo ratings yet

- SIP5 Protection Recording V9.60 ManualDocument154 pagesSIP5 Protection Recording V9.60 ManualKlong WarakronNo ratings yet

- Change ControlDocument62 pagesChange ControlshivanagiriNo ratings yet

- Cisco Call Manager CUCM RTMTDocument338 pagesCisco Call Manager CUCM RTMTBinh NguyenNo ratings yet

- Principle of CarburetorDocument5 pagesPrinciple of Carburetorapi-279581498No ratings yet

- Python Tutorial PDFDocument155 pagesPython Tutorial PDFDiana RusuNo ratings yet

- Pspice Lab ManualDocument30 pagesPspice Lab ManualRijo Jackson TomNo ratings yet

- 2016-05 Brent Cross Cricklewood - OBJ-51 - M Axon PoEDocument31 pages2016-05 Brent Cross Cricklewood - OBJ-51 - M Axon PoEscribdstorageNo ratings yet

- Roxii v2.9 Rx1500 User-Guide Cli enDocument664 pagesRoxii v2.9 Rx1500 User-Guide Cli encarlosNo ratings yet

- ECS Fuel Gas Dual Fuel Engine Control SystemDocument12 pagesECS Fuel Gas Dual Fuel Engine Control SystemMr.Thawatchai hansuwanNo ratings yet

- Abraham Elijah Cv...Document2 pagesAbraham Elijah Cv...Elijah AbrahamNo ratings yet

- BV Requirement For UPS Back Up TimeDocument3 pagesBV Requirement For UPS Back Up TimeVishnu LalNo ratings yet

- EX9520ARAR Quick ManualDocument4 pagesEX9520ARAR Quick ManualSi ClaNo ratings yet

- Panasonic 325 Watt Module 96 Cell Hit Black Solar Panel Specs 3206694517Document2 pagesPanasonic 325 Watt Module 96 Cell Hit Black Solar Panel Specs 3206694517Vikrant PathaniaNo ratings yet

- Class X Ift Set2Document5 pagesClass X Ift Set2Harshith TataNo ratings yet

- Cs Fs Cs DM Cs Ar Cs At: CS Series Safety ModulesDocument2 pagesCs Fs Cs DM Cs Ar Cs At: CS Series Safety Modulesjavivi_75No ratings yet

- CICS Concepts and FaclitiesDocument18 pagesCICS Concepts and FaclitiesIvan PetrucciNo ratings yet

- Session 1 - Components and Process of CommunicationDocument36 pagesSession 1 - Components and Process of CommunicationPRATEEK JAGGI100% (1)

- Bodyflow - P2Ch/-P1Ch: Service ManualDocument24 pagesBodyflow - P2Ch/-P1Ch: Service ManualLevent yanmazNo ratings yet

- Slip-In Cartridge Valves LunchBox SessionsDocument5 pagesSlip-In Cartridge Valves LunchBox SessionsNguyễn ĐạtNo ratings yet