Professional Documents

Culture Documents

Frequency Converter, Basics: ABB Industry Oy

Frequency Converter, Basics: ABB Industry Oy

Uploaded by

Puneet JoshiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Frequency Converter, Basics: ABB Industry Oy

Frequency Converter, Basics: ABB Industry Oy

Uploaded by

Puneet JoshiCopyright:

Available Formats

Frequency converter, basics

input DC-busbar output mechanical process

rectifier inverter Motor gear

= M3

=

loss 0,5% 1,5% 4...15% 1..5%

100% P = 3 * U N * Iin * cos λ P = U DC*IDC

P = 3 * U * I * cos ϕ = ω *M

in DC

out P m 78 - 93 %

Voltage is constant Voltage is constant Voltage is proportional Process defines the

Current is proportional Current is proportional to the frequency load torque and

to the power to the power Current is proportional speed

Powerfactor is to torque and excitation

about 0,95 Powerfactor is

proportional to the load

ABB Industry Oy basic4e.ppt 1

Start-up current is smaller with converter

start-up situation With constant torque With constant torque

the line current the motor current

line current

in % 700 alternates but the is also constant and

voltage is constant the voltage alternates

600

direct

connection

500 P P

U U U I

400 I I

I U

300

star-delta

P P

200

100

speed speed

frequency converter

0 = M3

0 speed 100% =

ABB Industry Oy basic4e.ppt 2

Torque-frequency, an example

300 Kippmoment

Peak torque

250 Continuous

Drehmoment,

torque

kontinuierlich

200

M/MN

T/TN

150

100

50

0

0 10 20 30 40 50 60 70 80 90

f/Hz

ABB Industry Oy basic4e.ppt 3

Relation between motor values and frequency

value p.u. value per unit values

constant field weakening area

flux

T = const. P2 = const. P2 = 1/n

speed n n/nN

n/nN

voltage U U/UN f/fN

1 U/UN

flux Φ Φ/ΦN

Φ/ΦN

fN/f

0

0 fN fG f

ABB Industry Oy basic4e.ppt 4

Relation between motor values and frequency

size p.u. value per unit values

constant field weakening area

flux

T = const. P2 = const. P2 = 1/n

max. torque. Tk/TkN

Tk TkN Tk/TkN

I/IN

IN

current I I/IN

(fN/f)2

TN T/TN

torque. T T/TN T ≤ 0,7 * Tk

fN/f

0

0 fN fG f

ABB Industry Oy basic4e.ppt 5

Power factor for PWM-converter for combustion gas fan

600 100

reactive power

savings 90 power factor

500 80 (%)

in kVAr

400 70

60

reactive power

300 saving kVAr 50

power factor in 40

200 30

direct use

100 power factor with 20

PWM-converter 10

0 0

50 60 70 80 90 100 110 120 130 140

factory output power (MW)

ABB Industry Oy basic4e.ppt 11

Efficiency and losses

Converter losses

(thermal)

input power

(electrical)

output power

efficiency η =

input power

motor losses output power

(thermal) (mechanical)

ABB Industry Oy basic4e.ppt 12

Efficiency, converter with15 kW motor

motor efficiency = 90%, cos φ = 0.82, (15 kW)

efficiency

100%

90%

80%

converter, cT

70%

60% converter, qT

50%

40% converter

+ motor, cT

30%

converter

20% + motor, qT

10%

cT = constant torque

0% qT = quadrat. torque

0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100

motor speed (% from the nominal)

ABB Industry Oy basic4e.ppt 13

Regenerative braking

electrical energy motor as

generator

Net M

3

line converter motor converter mechanical

energy

ABB Industry Oy basic4e.ppt 14

Braking to resistor

line rectifier motor converter motor as

generator

Net M

3

mechanical

electrical energy

energy CH braking chopper

braking resistor

ABB Industry Oy basic4e.ppt 15

Effects to the net

1.50

U total wave

1.00

basic wave

0.50

0.00

0

5. harmonic

-0.50

-1.00

-1.50

ABB Industry Oy basic4e.ppt 17

Net effects with choke in the intermediate circuit

measurements: converters from 5 manufacturer

A = with big choke, B und C = with smaller choke, D and E = without choke

current harmonics (%)

140

120

100

80

60

40

20

0

A B C D E

ABB Industry Oy basic4e.ppt 18

You might also like

- Blakley Calculator V2.1a - 0Document19 pagesBlakley Calculator V2.1a - 0PauloRicardoNo ratings yet

- Solga KatalogDocument40 pagesSolga KatalogMOHAMMEDNo ratings yet

- Lionet Lovey: Pattern by Mila Kralina (Ds - Mouse)Document9 pagesLionet Lovey: Pattern by Mila Kralina (Ds - Mouse)Fátima Hunter100% (3)

- EEE2003 - Electromechanical Energy Conversion Lab: School of Electrical EngineeringDocument7 pagesEEE2003 - Electromechanical Energy Conversion Lab: School of Electrical EngineeringAkshit VSNo ratings yet

- EEE2003 - Electromechanical Energy Conversion Lab: School of Electrical EngineeringDocument9 pagesEEE2003 - Electromechanical Energy Conversion Lab: School of Electrical EngineeringAkshit VSNo ratings yet

- SMT1050 PDFDocument7 pagesSMT1050 PDFAli ShanNo ratings yet

- 4.1 General Device Data: 4.1.1 Analog InputsDocument4 pages4.1 General Device Data: 4.1.1 Analog InputsEbrahim ArzaniNo ratings yet

- Inrush Current Tutorial Session: IEEE Standards Transformers Committee Oct 15, 2001 Orlando, FloridaDocument12 pagesInrush Current Tutorial Session: IEEE Standards Transformers Committee Oct 15, 2001 Orlando, FloridaputrasejahtraNo ratings yet

- Dato Ventilador EBMDocument5 pagesDato Ventilador EBMMatias ReinaNo ratings yet

- MT 212Document2 pagesMT 21222bec032No ratings yet

- Corrections To ES-XW7T-1A278-AC: Corrections Are Shown in RedDocument3 pagesCorrections To ES-XW7T-1A278-AC: Corrections Are Shown in RedE-RegisNo ratings yet

- Uno Atom Single MPPT enDocument2 pagesUno Atom Single MPPT enismailkarakas07No ratings yet

- Review of How Motor WorksDocument52 pagesReview of How Motor WorksgeniunetNo ratings yet

- D2D160 Be02 11Document6 pagesD2D160 Be02 11Wilber RojasNo ratings yet

- Silicon Bi-Directional Trigger Device BR100/03 LLD: General Description Quick Reference DataDocument4 pagesSilicon Bi-Directional Trigger Device BR100/03 LLD: General Description Quick Reference DataMaria JerezNo ratings yet

- X ErCharProtDocument10 pagesX ErCharProtNavaneethakrishnan MurugesanNo ratings yet

- A4D450AO1809Document6 pagesA4D450AO1809adeNo ratings yet

- What Are The Types of Potential Transformer (PT) ? Describe EachDocument7 pagesWhat Are The Types of Potential Transformer (PT) ? Describe EachFEMAE DOMANEONo ratings yet

- BFP, BP, CEP & CW Pumps PDFDocument138 pagesBFP, BP, CEP & CW Pumps PDFsrikanth100% (1)

- Electrical Machines EE-260: Instructor: DR Mehmood AlamDocument31 pagesElectrical Machines EE-260: Instructor: DR Mehmood AlamSaif Ur RehmanNo ratings yet

- Ee 316 - Electrical Machines 1 Week 8: ISUE-EIE-Syl-014 Revision: 02 Effectivity: August 1, 2020Document5 pagesEe 316 - Electrical Machines 1 Week 8: ISUE-EIE-Syl-014 Revision: 02 Effectivity: August 1, 2020Laurence Abrogena AlmazanNo ratings yet

- Motor PassoDocument1 pageMotor PassoHevert TwynsterNo ratings yet

- 1.5ke Series: FeaturesDocument4 pages1.5ke Series: FeaturesJose Miguel Rodriguez CarreñoNo ratings yet

- Lect 32 33 CycloconverterDocument37 pagesLect 32 33 CycloconverterVishal MeghwarNo ratings yet

- Sample Investigatory ProjectDocument13 pagesSample Investigatory ProjectDhruv ChauhanNo ratings yet

- PMM MotorDocument31 pagesPMM MotorMohamed MostafaNo ratings yet

- Mcc-1 Electrical LoadDocument1 pageMcc-1 Electrical Loadكرم عمروNo ratings yet

- AC/AC Convertor Using DC-Modulation For Single Phase Induction MotorDocument9 pagesAC/AC Convertor Using DC-Modulation For Single Phase Induction MotorInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Tip142t Tip147tDocument5 pagesTip142t Tip147tRaduNo ratings yet

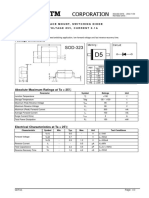

- DatasheetDocument4 pagesDatasheetGrupo EpufmNo ratings yet

- Lecture Slide of TransformersDocument104 pagesLecture Slide of Transformersf20221267No ratings yet

- (2011) Experiment M: 1. AimsDocument9 pages(2011) Experiment M: 1. AimsIbrahim ShaibuNo ratings yet

- KSG-4.6K-DM / KSG-4.9K-DM / KSG-5K-DM / KSG-5.2K-DM: String Grid-Tied PV Inverter NG Grid-Tied PV InverterDocument1 pageKSG-4.6K-DM / KSG-4.9K-DM / KSG-5K-DM / KSG-5.2K-DM: String Grid-Tied PV Inverter NG Grid-Tied PV InvertergodinsideNo ratings yet

- Ebmpapst 07082019 A4D350AA0601 KM96928 - 1620780Document7 pagesEbmpapst 07082019 A4D350AA0601 KM96928 - 1620780rickyngsNo ratings yet

- Blue-G Three Phase Series: PV On-Grid String InverterDocument2 pagesBlue-G Three Phase Series: PV On-Grid String InvertergodinsideNo ratings yet

- Brake Test On DC Shunt MachineDocument9 pagesBrake Test On DC Shunt MachineNagendrababu VasaNo ratings yet

- Fan Rotor BobinéDocument5 pagesFan Rotor BobinéChrist Rodney MAKANANo ratings yet

- Current TransformersDocument21 pagesCurrent TransformersTaskNo ratings yet

- L-4 (DK) (Pe) ( (Ee) Nptel) 4Document5 pagesL-4 (DK) (Pe) ( (Ee) Nptel) 4GagneNo ratings yet

- Experiment 2: Speed Behavior of The Shunt-Wound DC Motor at Flux ShuntingDocument3 pagesExperiment 2: Speed Behavior of The Shunt-Wound DC Motor at Flux ShuntingChattha GNo ratings yet

- Finch 11 BrochureDocument2 pagesFinch 11 BrochureProject1 Tech7No ratings yet

- Datasheet PDFDocument2 pagesDatasheet PDFAknova TsaniataNo ratings yet

- Simulation Analysis of Inrush Current of Three Phase Transformer Based On MATLABDocument3 pagesSimulation Analysis of Inrush Current of Three Phase Transformer Based On MATLABDon NepalNo ratings yet

- The Transformer Is A Device Used For Converting A Low Alternating Voltage To A High Alternating Voltage or Vice-Versa.Document20 pagesThe Transformer Is A Device Used For Converting A Low Alternating Voltage To A High Alternating Voltage or Vice-Versa.Minakshi SharmaNo ratings yet

- BAW56Document4 pagesBAW563109828876No ratings yet

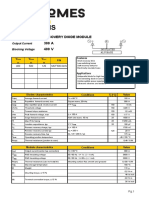

- MCF300.04IS: Insulated Fast Recovery Diode Module 300 A 400 VDocument4 pagesMCF300.04IS: Insulated Fast Recovery Diode Module 300 A 400 VAnonymous nC9gpUWPNo ratings yet

- 1MRG012025 en Application Note DC Overcurrent Protection Using Shunt Converter and MIM InputDocument6 pages1MRG012025 en Application Note DC Overcurrent Protection Using Shunt Converter and MIM Inputkarim_ouakliNo ratings yet

- Induction Motor Scalar Control (Squirrel Cage) : MEP 1422 Electric DrivesDocument22 pagesInduction Motor Scalar Control (Squirrel Cage) : MEP 1422 Electric DrivesmitalipmNo ratings yet

- BEE3233 7 Transformer Protection STUDocument21 pagesBEE3233 7 Transformer Protection STUDilina Iroshan DissanayakeNo ratings yet

- Design Example IntusoftDocument6 pagesDesign Example IntusoftCataNo ratings yet

- 019-VFD Installation - Air Lock MachineDocument4 pages019-VFD Installation - Air Lock MachineZubaeer Bin ShamsNo ratings yet

- S4e350 Ao02 98Document5 pagesS4e350 Ao02 98Arnold Olivares GomezNo ratings yet

- 2.simulation of Single Phase Full Bridge Converter Using LTspiceDocument10 pages2.simulation of Single Phase Full Bridge Converter Using LTspiceabcdefg0% (1)

- Three Phase Energy Meter - Counter Type: FeaturesDocument6 pagesThree Phase Energy Meter - Counter Type: FeaturesAbhinandan JainNo ratings yet

- EG1108 T6 - Ans PDFDocument8 pagesEG1108 T6 - Ans PDFLeong ssNo ratings yet

- RS401L LuguangElectronicDocument2 pagesRS401L LuguangElectronicvvvvzzzzzNo ratings yet

- 1 Operating Parameters: NOTE For User On The Online HelpDocument24 pages1 Operating Parameters: NOTE For User On The Online HelpVargas GuerreroNo ratings yet

- Test Report - RET 650Document3 pagesTest Report - RET 650Abhishek RajputNo ratings yet

- S6D800 Af05 03Document6 pagesS6D800 Af05 03El PestoNo ratings yet

- WS24P4N3 W03010148GDocument6 pagesWS24P4N3 W03010148GYonni RamirezNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Analysis and Design of Multicell DC/DC Converters Using Vectorized ModelsFrom EverandAnalysis and Design of Multicell DC/DC Converters Using Vectorized ModelsNo ratings yet

- ABB Drives: Acs800 Trouble Shooting Operating Instruction 3afeDocument13 pagesABB Drives: Acs800 Trouble Shooting Operating Instruction 3afePuneet JoshiNo ratings yet

- Basic Parts of AC-converter: ABB Industry OyDocument2 pagesBasic Parts of AC-converter: ABB Industry OyPuneet JoshiNo ratings yet

- ACS800 Multidrive 6-And 12 - Pulse OperationDocument3 pagesACS800 Multidrive 6-And 12 - Pulse OperationPuneet JoshiNo ratings yet

- Evolution of Drives: ABB Industry OyDocument16 pagesEvolution of Drives: ABB Industry OyPuneet JoshiNo ratings yet

- Benefits of AC-motorDocument12 pagesBenefits of AC-motorPuneet JoshiNo ratings yet

- Why A Variable Speed Drive?: ABB Industry OyDocument6 pagesWhy A Variable Speed Drive?: ABB Industry OyPuneet JoshiNo ratings yet

- ACS800 Electronic BoardsDocument27 pagesACS800 Electronic BoardsPuneet Joshi100% (1)

- Academic Translation, Vocabulary, ReadingDocument573 pagesAcademic Translation, Vocabulary, ReadingEce GürtekinNo ratings yet

- The 100 V1.1 BOM (My Version)Document2 pagesThe 100 V1.1 BOM (My Version)vekelet399No ratings yet

- Rototherm Group Product Catalogue 2016Document40 pagesRototherm Group Product Catalogue 2016Charles OnyechereNo ratings yet

- Pubertad Precoz NEJMDocument12 pagesPubertad Precoz NEJMAdrianaGallardoTapiaNo ratings yet

- Ut Slides.Document114 pagesUt Slides.Y ShameyaNo ratings yet

- Iot Based Real Time Potholes Detection System Using Image Processing TechniquesDocument5 pagesIot Based Real Time Potholes Detection System Using Image Processing TechniquesanjaleemanageNo ratings yet

- Examen de NES Inglés B - APROBADODocument12 pagesExamen de NES Inglés B - APROBADOJuanMa DiazNo ratings yet

- Artist Contract TemplateDocument4 pagesArtist Contract TemplateIonut LenghenNo ratings yet

- G.O. Rt. No. 431Document2 pagesG.O. Rt. No. 431teja.1606No ratings yet

- What Is Bacteria - What Are BacteriaDocument15 pagesWhat Is Bacteria - What Are BacteriaFernando OssNo ratings yet

- Lesson 2. The Tourist Market and SegmentationDocument13 pagesLesson 2. The Tourist Market and SegmentationDonna BanuagNo ratings yet

- Food Industry JFCDocument31 pagesFood Industry JFCJheanniver Nablo-PeñaNo ratings yet

- The Best Film About InformantsDocument11 pagesThe Best Film About InformantsSilviuSerbanNo ratings yet

- Bridging Course Contemporary Culture Assingment 2Document4 pagesBridging Course Contemporary Culture Assingment 2Shahhana BegumNo ratings yet

- Muscle-Building Cookbook - Lose Fat, Build Muscle - Ovs To Help You Get The Body You Want - Nancy SilvermanDocument75 pagesMuscle-Building Cookbook - Lose Fat, Build Muscle - Ovs To Help You Get The Body You Want - Nancy Silvermanscribd2100% (1)

- 4ES0 02 Rms 20120823Document9 pages4ES0 02 Rms 20120823Phyu Sin WinNo ratings yet

- Mounthly PT. EBS - KPI MAINTENANCE UNIT JANUARI 2019Document210 pagesMounthly PT. EBS - KPI MAINTENANCE UNIT JANUARI 2019albert svensenNo ratings yet

- Structure of WaterDocument31 pagesStructure of WaterMwangi BonfaceNo ratings yet

- 0080calibration MultipleDocument10 pages0080calibration MultiplePanneer SelvamNo ratings yet

- Konica Minolta Di1611-2011 Service ManualDocument427 pagesKonica Minolta Di1611-2011 Service ManualcontrafortNo ratings yet

- Wiley - Modern Thermodynamics - From Heat Engines To Dissipative Structures, 2nd Edition - 978-1-118-37181-7Document2 pagesWiley - Modern Thermodynamics - From Heat Engines To Dissipative Structures, 2nd Edition - 978-1-118-37181-7JubairAhmedNo ratings yet

- Modular OT WorksDocument67 pagesModular OT WorksNandagopal DhakshinamoorthyNo ratings yet

- Tamara Bassam Abu Alwan: Visual Artist, PainterDocument2 pagesTamara Bassam Abu Alwan: Visual Artist, PainterTamara BellNo ratings yet

- Satire in Verse - The Rape of The LockDocument3 pagesSatire in Verse - The Rape of The LockSelene troncosoNo ratings yet

- Unit-2: Linear Data Structure StackDocument37 pagesUnit-2: Linear Data Structure StackDivyes P100% (1)

- Key Issues ReflectionDocument7 pagesKey Issues ReflectionLee SuarezNo ratings yet

- Co2 04Document16 pagesCo2 04Poojitha BondalapatiNo ratings yet

- CIBIL Consent FormDocument4 pagesCIBIL Consent FormKuldeep BatraNo ratings yet