Professional Documents

Culture Documents

Excess Flow Valves For Flange Mounting in Container Service A3500 Series and A4500 Series

Excess Flow Valves For Flange Mounting in Container Service A3500 Series and A4500 Series

Uploaded by

LPG Equipment Consulting and ServicesCopyright:

Available Formats

You might also like

- Dokumen - Tips - Vertical Turbine Fire Pumps Section 1630 Wwwpeerlessxnetcomsalesmanualsfire PDFDocument59 pagesDokumen - Tips - Vertical Turbine Fire Pumps Section 1630 Wwwpeerlessxnetcomsalesmanualsfire PDFJuanHernandezNo ratings yet

- VR Milling V5 Help FileDocument168 pagesVR Milling V5 Help FileKleber AugustoNo ratings yet

- Multivalvula - 8593arDocument1 pageMultivalvula - 8593arCarlos Rafael Rondon AbreuNo ratings yet

- Excess Flow Valves For Vapor or Liquid A2137 Series and 2139 SeriesDocument1 pageExcess Flow Valves For Vapor or Liquid A2137 Series and 2139 SeriesDaniel Edward OmondiNo ratings yet

- Rego 7572fc Drenaje LiquidoDocument1 pageRego 7572fc Drenaje LiquidoDaniel MaldonadoNo ratings yet

- ASME Multivalves® For Vapor Withdrawal G8475RL Series Valves With Presto-Tap PG8475, PT7556 Series ValvesDocument1 pageASME Multivalves® For Vapor Withdrawal G8475RL Series Valves With Presto-Tap PG8475, PT7556 Series Valvesmohsen fatemiNo ratings yet

- 2011 - New - Product - Guide REGO PDFDocument8 pages2011 - New - Product - Guide REGO PDFJimmy RojasNo ratings yet

- lv5503b RegulatorDocument1 pagelv5503b RegulatorEmanuelCalmaYandocNo ratings yet

- Power Team CBT Series Cylinders - CatalogDocument1 pagePower Team CBT Series Cylinders - CatalogTitanplyNo ratings yet

- A7793a A7797aDocument1 pageA7793a A7797aCarlos Rafael Rondon AbreuNo ratings yet

- Semi-Internal "Pop-Action" Pressure Relief Valves For ASME Portable Containers 7583, 8684 and 8685 SeriesDocument1 pageSemi-Internal "Pop-Action" Pressure Relief Valves For ASME Portable Containers 7583, 8684 and 8685 Seriesأسامة حمدونىNo ratings yet

- NPR030 Vertical Bladder TankDocument4 pagesNPR030 Vertical Bladder TankLuis Joel Ramos RamosNo ratings yet

- BPI Zap TLok Headed Bar InstructionsDocument3 pagesBPI Zap TLok Headed Bar InstructionshectoriturbeNo ratings yet

- Alco ValvesDocument56 pagesAlco ValvesGuillermo de la Fuente SantiagoNo ratings yet

- Alco Valves RTG Brochure 01-07-2017 PDFDocument56 pagesAlco Valves RTG Brochure 01-07-2017 PDFGuillermo de la Fuente SantiagoNo ratings yet

- Alco Valves RTG Brochure Rev01-07.2017Document56 pagesAlco Valves RTG Brochure Rev01-07.2017linhNo ratings yet

- Reggo - LV4403BDocument1 pageReggo - LV4403BMauricio Esteban Castro BastíasNo ratings yet

- Service Guide-Trampas Cubeta Armstrong-Manual Rapracion, Instalacion, Deteccion de FallasDocument36 pagesService Guide-Trampas Cubeta Armstrong-Manual Rapracion, Instalacion, Deteccion de FallasJORGE ALBERTO PEREZ RAMIREZNo ratings yet

- STS PDFDocument1 pageSTS PDFIman praja firmansyahNo ratings yet

- Chek-Lok® Excess Flow Valves 7590U and 7591U Series: ApplicationDocument1 pageChek-Lok® Excess Flow Valves 7590U and 7591U Series: ApplicationLPG Equipment Consulting and ServicesNo ratings yet

- 30K in PDFDocument2 pages30K in PDFAnonymous DNM4ZINo ratings yet

- P - Alarm Check ValveDocument6 pagesP - Alarm Check ValvehadiNo ratings yet

- Excess Flow Valves - General InformationDocument7 pagesExcess Flow Valves - General Informationtranhonghakd5533No ratings yet

- Catalog C v5 PDFDocument80 pagesCatalog C v5 PDFAshokNo ratings yet

- Catalog C v5Document80 pagesCatalog C v5Sivi NallamothuNo ratings yet

- Needle ValvesDocument8 pagesNeedle Valvesleopoldo cobosNo ratings yet

- 2008 Banjo NO PRICE Catalog WebDocument165 pages2008 Banjo NO PRICE Catalog WebeduardoNo ratings yet

- Tapping Saddle DimensionsDocument4 pagesTapping Saddle DimensionsAnonymous IgzACaiNo ratings yet

- Cornell Pump Company Refrigerant Pump 2.5CBHDocument2 pagesCornell Pump Company Refrigerant Pump 2.5CBHJavier AffifNo ratings yet

- Orifice Plates PDFDocument3 pagesOrifice Plates PDFNacho.pNo ratings yet

- Valvula de Seguridad PRV Rego 2Document1 pageValvula de Seguridad PRV Rego 2Erick MontejoNo ratings yet

- Forging ToleranceDocument44 pagesForging Tolerancehisaj4uNo ratings yet

- Roto PDFDocument3 pagesRoto PDFKasnowo DiponegoroNo ratings yet

- Rotogauge PDFDocument3 pagesRotogauge PDFKasnowo DiponegoroNo ratings yet

- Asme Chill Water Buffer Tanks: Description: SpecificationsDocument1 pageAsme Chill Water Buffer Tanks: Description: SpecificationsRan NNo ratings yet

- CTR 004 Yardr 0008 enDocument3 pagesCTR 004 Yardr 0008 enAndy GarciaNo ratings yet

- Pipe Thread Types and DesignationsDocument2 pagesPipe Thread Types and DesignationsJenner Volnney Quispe ChataNo ratings yet

- Manual Valves Datasheet. Rev 1Document7 pagesManual Valves Datasheet. Rev 1eke23No ratings yet

- Keymc 0475 UsDocument2 pagesKeymc 0475 UsLuigui Franchesco del ValleNo ratings yet

- Split Coupled Vertical In-Line Pumps: File No.: Date: Supersedes: 43.10in DateDocument6 pagesSplit Coupled Vertical In-Line Pumps: File No.: Date: Supersedes: 43.10in DateSatawat phothinNo ratings yet

- 3165 Ta3169fDocument1 page3165 Ta3169fRenalyn TorioNo ratings yet

- Type 3510 1 and Type 3510 7 Pneumatic Control Valves Type 3510 Micro Flow ValveDocument12 pagesType 3510 1 and Type 3510 7 Pneumatic Control Valves Type 3510 Micro Flow Valvepaulo cesar f machadoNo ratings yet

- Quick Reference Guide For ValvesDocument1 pageQuick Reference Guide For ValvesEjaz Ahmed RanaNo ratings yet

- Power Team RLS-Series Cylinders - CatalogDocument1 pagePower Team RLS-Series Cylinders - CatalogTitanplyNo ratings yet

- "L4" Drive End: Operation - Assembly Instructions and Parts List ForDocument6 pages"L4" Drive End: Operation - Assembly Instructions and Parts List ForDavid Torres SibajaNo ratings yet

- Pompa Sentrifugal - Eta-NDocument6 pagesPompa Sentrifugal - Eta-Nnohan sanegaNo ratings yet

- Catalog PDFDocument72 pagesCatalog PDFVIVEK UPADHYAYNo ratings yet

- Model: A100: Flushing RingDocument2 pagesModel: A100: Flushing RingTÀi VÕNo ratings yet

- PIPING - VALVES - American Flow Control (Gate Valves) (8 PAGES)Document8 pagesPIPING - VALVES - American Flow Control (Gate Valves) (8 PAGES)fkhajehNo ratings yet

- Threaded Internal Valves For Bobtail Delivery Trucks, Transports and Stationary Storage Tanks A3213D SeriesDocument1 pageThreaded Internal Valves For Bobtail Delivery Trucks, Transports and Stationary Storage Tanks A3213D SeriesCarlos Rafael Rondon AbreuNo ratings yet

- PK Valve Page-13-17Document5 pagesPK Valve Page-13-17ICASA IngenieríaNo ratings yet

- Eliminador de AireDocument4 pagesEliminador de AiresusansueNo ratings yet

- Check and Relief ValvesDocument16 pagesCheck and Relief ValvesAdriana Herrera FloresNo ratings yet

- Power Team C-Series CylindersDocument2 pagesPower Team C-Series CylindersTitanplyNo ratings yet

- Vacuum Breakers Brochure (Metric)Document4 pagesVacuum Breakers Brochure (Metric)avgpaul100% (1)

- 007 (8.5) U Nadi MinDocument3 pages007 (8.5) U Nadi Mineieimoe.96mdyNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- BHMN 35002 IOM 19538G 0823 EnglishDocument24 pagesBHMN 35002 IOM 19538G 0823 EnglishLPG Equipment Consulting and ServicesNo ratings yet

- CF5000 03 06Document14 pagesCF5000 03 06LPG Equipment Consulting and ServicesNo ratings yet

- 120001RohrbruchvRBV EDocument1 page120001RohrbruchvRBV ELPG Equipment Consulting and ServicesNo ratings yet

- LCR iQ-InstallationDocument112 pagesLCR iQ-InstallationLPG Equipment Consulting and ServicesNo ratings yet

- 1584543837d2gym Katalog MasoneilanDocument24 pages1584543837d2gym Katalog MasoneilanLPG Equipment Consulting and ServicesNo ratings yet

- MASTERLOAD - Iq o4MAY2021 05042020Document8 pagesMASTERLOAD - Iq o4MAY2021 05042020LPG Equipment Consulting and ServicesNo ratings yet

- Stainless Steel Apollo ValvesDocument2 pagesStainless Steel Apollo ValvesLPG Equipment Consulting and ServicesNo ratings yet

- Group 14 : Strainers, Traps, Fine-Mesh Filters Filling Device For Methanol Drain DeviceDocument3 pagesGroup 14 : Strainers, Traps, Fine-Mesh Filters Filling Device For Methanol Drain DeviceLPG Equipment Consulting and ServicesNo ratings yet

- Right ItemDocument1 pageRight ItemLPG Equipment Consulting and ServicesNo ratings yet

- Masterload Series: The Next Generation Electronic RegisterDocument8 pagesMasterload Series: The Next Generation Electronic RegisterLPG Equipment Consulting and ServicesNo ratings yet

- AS4012LPG M5: 9 Meters 384.000 360º ManualDocument4 pagesAS4012LPG M5: 9 Meters 384.000 360º ManualLPG Equipment Consulting and ServicesNo ratings yet

- Chek-Lok® Excess Flow Valves 7590U and 7591U Series: ApplicationDocument1 pageChek-Lok® Excess Flow Valves 7590U and 7591U Series: ApplicationLPG Equipment Consulting and ServicesNo ratings yet

- Manuel Maintenance Pompes CorkenDocument88 pagesManuel Maintenance Pompes CorkenLPG Equipment Consulting and ServicesNo ratings yet

- Side Channel Pumps: Self-Priming, Multi-Stage TypeDocument5 pagesSide Channel Pumps: Self-Priming, Multi-Stage TypeLPG Equipment Consulting and ServicesNo ratings yet

- Group 15 : Relief Valves AccessoriesDocument4 pagesGroup 15 : Relief Valves AccessoriesLPG Equipment Consulting and ServicesNo ratings yet

- Group 19 : Shut-Off Valves Bypass Valves Three-Way Valves Quick-Acting Valves Solenoid Valves Ball ValvesDocument10 pagesGroup 19 : Shut-Off Valves Bypass Valves Three-Way Valves Quick-Acting Valves Solenoid Valves Ball ValvesLPG Equipment Consulting and ServicesNo ratings yet

- FAS NZ PumpSeriesTechnologyDocument2 pagesFAS NZ PumpSeriesTechnologyLPG Equipment Consulting and ServicesNo ratings yet

- Willy Resume-July .2016Document13 pagesWilly Resume-July .2016LPG Equipment Consulting and ServicesNo ratings yet

- Fas 13Document6 pagesFas 13LPG Equipment Consulting and ServicesNo ratings yet

- Group 21 : Compressors Pumps Accessories Complete Units and PackagesDocument11 pagesGroup 21 : Compressors Pumps Accessories Complete Units and PackagesLPG Equipment Consulting and ServicesNo ratings yet

- Fas 18Document17 pagesFas 18LPG Equipment Consulting and ServicesNo ratings yet

- Single Check Filler Valves For Storage Tanks With Supplementary Back Check Valves 3174C, 3194C and 6584CDocument1 pageSingle Check Filler Valves For Storage Tanks With Supplementary Back Check Valves 3174C, 3194C and 6584CLPG Equipment Consulting and ServicesNo ratings yet

- Group 12 : Excess Flow Valves Back Pressure Check ValvesDocument3 pagesGroup 12 : Excess Flow Valves Back Pressure Check ValvesLPG Equipment Consulting and ServicesNo ratings yet

- Multipurpose Valves For Liquid Withdrawal of LP-Gas and NH Containers A8017D & A8020DDocument1 pageMultipurpose Valves For Liquid Withdrawal of LP-Gas and NH Containers A8017D & A8020DLPG Equipment Consulting and ServicesNo ratings yet

- FAS Eng Catalogue - 2020 Lite FullDocument174 pagesFAS Eng Catalogue - 2020 Lite FullLPG Equipment Consulting and ServicesNo ratings yet

- External "Pop-Action" Supplementary Pressure Relief Valves For Small ASME Containers and DOT Cylinders 3127 and 3129 SeriesDocument1 pageExternal "Pop-Action" Supplementary Pressure Relief Valves For Small ASME Containers and DOT Cylinders 3127 and 3129 SeriesLPG Equipment Consulting and ServicesNo ratings yet

- Curriculum VitDocument4 pagesCurriculum Vit1dzrbtcom ProfessionalprogramminglanguageNo ratings yet

- I-V Characteristics of Diode and Zener DiodeDocument3 pagesI-V Characteristics of Diode and Zener Diodet19125 t19125No ratings yet

- 1987 Wienese The Performance of Diffuser Bagasse DewateringDocument4 pages1987 Wienese The Performance of Diffuser Bagasse DewateringAhmed AlfatihNo ratings yet

- Bridge Unit Bu3030 D386 Parts Location and ListDocument14 pagesBridge Unit Bu3030 D386 Parts Location and ListNickNo ratings yet

- Standard Gauge For Sheet and Plate Iron, Ted Pella, IncDocument2 pagesStandard Gauge For Sheet and Plate Iron, Ted Pella, IncBilal Arshad100% (1)

- Capacitación Ingeniería: Clase 4 Normas Calidades AceroDocument18 pagesCapacitación Ingeniería: Clase 4 Normas Calidades AcerogeracuajinaiNo ratings yet

- New York State Thruway LawsuitDocument11 pagesNew York State Thruway LawsuitWGRZ-TVNo ratings yet

- Soal Usek 76-150 (2015)Document14 pagesSoal Usek 76-150 (2015)Vahrus Nuril AlbiNo ratings yet

- Licensing Guide and Application For LicenceDocument16 pagesLicensing Guide and Application For LicenceZoraiz MirNo ratings yet

- Boiler Hydro Test 1Document7 pagesBoiler Hydro Test 1sambhu100% (1)

- Phases and SolutionsDocument105 pagesPhases and SolutionsMolina ThirumalNo ratings yet

- Kamran - 8 Ways To Migrate Your On-Premis Database To Oracle Cloud - ODev Yathra-1Document82 pagesKamran - 8 Ways To Migrate Your On-Premis Database To Oracle Cloud - ODev Yathra-1maiwand khishkiNo ratings yet

- Asme3d1 nb-5000Document12 pagesAsme3d1 nb-5000KHALED OSMANNo ratings yet

- 11 Tunnelling With Hidraulic Drills at Abajora Hidro Eletric Plant in NorwayDocument0 pages11 Tunnelling With Hidraulic Drills at Abajora Hidro Eletric Plant in Norwaycastille1956No ratings yet

- Air-Cooled ExchangersDocument45 pagesAir-Cooled ExchangersKrishanu SahaNo ratings yet

- Rajput Internal Combustion Engines PDFDocument522 pagesRajput Internal Combustion Engines PDFcaddies100% (1)

- General Us Lite PDFDocument179 pagesGeneral Us Lite PDF2791957No ratings yet

- Dash 3000/4000/5000 Patient Monitor: Service ManualDocument258 pagesDash 3000/4000/5000 Patient Monitor: Service Manualsergio ribeiroNo ratings yet

- Jeppview For Windows Jeppview For Windows: List of Pages in This Trip Kit General Information General InformationDocument11 pagesJeppview For Windows Jeppview For Windows: List of Pages in This Trip Kit General Information General InformationDoĞuŞ SaracNo ratings yet

- TTL Power Supply WithDocument2 pagesTTL Power Supply WithSérgio AndolfoNo ratings yet

- Hmine115 Workshop Practice Welding ProcessDocument72 pagesHmine115 Workshop Practice Welding ProcessGareth MashingaidzeNo ratings yet

- Electronic Volume Corrector RMGDocument47 pagesElectronic Volume Corrector RMGantoNo ratings yet

- Usama Bin Aslam (CV)Document1 pageUsama Bin Aslam (CV)Muhammad ArsalanNo ratings yet

- Pneumatic Control SystemfinalDocument6 pagesPneumatic Control Systemfinalneo100% (1)

- 采矿专业英语大全Document50 pages采矿专业英语大全Dino ChengNo ratings yet

- Spare Parts Catalogue: AXLE 20.43 REF: 572755Document8 pagesSpare Parts Catalogue: AXLE 20.43 REF: 572755marcelo sampaioNo ratings yet

- Fan 7316Document21 pagesFan 7316sontuyet82No ratings yet

- POWERMASTER Impact-SocketDocument30 pagesPOWERMASTER Impact-SocketManoj DoshiNo ratings yet

Excess Flow Valves For Flange Mounting in Container Service A3500 Series and A4500 Series

Excess Flow Valves For Flange Mounting in Container Service A3500 Series and A4500 Series

Uploaded by

LPG Equipment Consulting and ServicesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Excess Flow Valves For Flange Mounting in Container Service A3500 Series and A4500 Series

Excess Flow Valves For Flange Mounting in Container Service A3500 Series and A4500 Series

Uploaded by

LPG Equipment Consulting and ServicesCopyright:

Available Formats

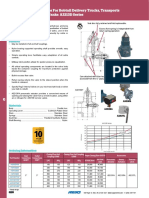

Excess Flow Valves for Flange Mounting in Container Service

A3500 Series and A4500 Series

Application

Designed for mounting in flanged tank connections with internal

threads in the bottom of a container. They may be used in filling,

withdrawal or vapor equalizing application. They provide high flow

capacity with low pressure drop to minimize pump inlet line cavitation.

If a riser pipe to the vapor space is used with these excess flow

valves, the minimum inside diameter of the riser pipe must be at least

two times the valve thread size in order not to restrict flow to the side

inlet ports.

Flange mounted excess flow valves are readily accessible for

servicing and completely enclosed and protected in event of fire.

Because there is no direct connection between external piping and

the valve, stresses imposed on piping will not affect the excess flow

valve.

A3500L4

Features

• Precision machined.

• Generous flow channels provide low pressure drop minimizing

cavitation in pump suction lines.

• Cotter pin prevents loss of spring retainer due to vibration in

service.

• Stainless steel spring provides consistent closing flow and long

service life.

Materials

Body.............................................................. Cadmium Plated Steel

Seat Disc....................................................... Cadmium Plated Steel

Stem.......................................................................... Stainless Steel

Spring........................................................................ Stainless Steel

F

Guide............................................................. Cadmium Plated Steel

Flanged Installation In Container PRODU

GO C

NOTE: The opening in the tank flange should be machined with a

10

RE

TS

¼”-45° chamfer at the outer edge. The thread should be tapped

one or two turns large as checked by a plug gauge. This and the

Y

undersize thread on the valve should permit the valve to be installed

10

NT

EA

Y

so that its outer face is at least flush with the outer edge of the flange. R WA R R A

The valve is screwed into this opening by fitting a ¼” flat metal piece

into the slot and turning until hand tight. A lubricant may be used, but

a luting compound is not necessary since this joint does not have to

be gas tight.

If any difficulty is experienced in “making up” the valve to fit flush, as

indicated, the thread in the tank flange can be tapped.

Design and construction of tank and flange must be in accordance

with the appropriate section of the ASME Pressure Vessel Code.

A3400L4, A3400L6,

Ordering Information A3500L4, A3500R6,

Key A3500N4, A3500T6,

Approximate Closing Flows* No. Description A3500P4 A3500V6 A4500Y8

A C Vapor SCFH (Propane) A Valve Size (NPT) 2” 3” 4”

Inlet B Effective D Liquid

B Tank Opening 3½” 4½” 5½”

Part Connection For Thread Threaded (GPM 25 PSIG

Number NPT Installation (Approx.) End To Port Propane) Inlet 100 PSIG Inlet C Thickness (min.) 1” 1¼” 13⁄8”

A3500L4 75 13,000 22,500 D Outside Diameter 6½” 8¼” 10”

A3500N4 2” ¾” 1 ⁄ ”

15 16 125 25,000 42,500 E Pipe Thread (NPT) 2” 3” 4”

A3500P4 150 30,500 52,000 Bolt Circle Dia. 5” 65⁄8” 77⁄8”

Slotted F

A3500R6 150 32,100 55,500 Number of Bolt Holes 8 8 8

Body 5⁄8” -11

A3500T6 3” 1” 19⁄16” 200 39,400 68,300 ¾” - 10 ¾” - 10

G Bolt Hole Thread

NC - 2 NC - 2 NC - 2

A3500V6 250 51,100 88,700

Bolt Hole Thread

A4500Y8 4” 11⁄16” 115⁄16” 500 89,000 154,000 H ¾” 1” 1⅛”

(min. eff.)

NOTE: Multiply flow rate by .94 to determine liquid butane flow and by .90 to determine liquid anhydrous ammonia flow.

* Based on horizontal installation of excess flow valve. Flows are slightly more when valves are installed with outlet up; slightly less when installed with outlet down.

100 RegO Dr. Elon, NC 27244 USA www.regoproducts.com +1 (336) 449-7707 F15

You might also like

- Dokumen - Tips - Vertical Turbine Fire Pumps Section 1630 Wwwpeerlessxnetcomsalesmanualsfire PDFDocument59 pagesDokumen - Tips - Vertical Turbine Fire Pumps Section 1630 Wwwpeerlessxnetcomsalesmanualsfire PDFJuanHernandezNo ratings yet

- VR Milling V5 Help FileDocument168 pagesVR Milling V5 Help FileKleber AugustoNo ratings yet

- Multivalvula - 8593arDocument1 pageMultivalvula - 8593arCarlos Rafael Rondon AbreuNo ratings yet

- Excess Flow Valves For Vapor or Liquid A2137 Series and 2139 SeriesDocument1 pageExcess Flow Valves For Vapor or Liquid A2137 Series and 2139 SeriesDaniel Edward OmondiNo ratings yet

- Rego 7572fc Drenaje LiquidoDocument1 pageRego 7572fc Drenaje LiquidoDaniel MaldonadoNo ratings yet

- ASME Multivalves® For Vapor Withdrawal G8475RL Series Valves With Presto-Tap PG8475, PT7556 Series ValvesDocument1 pageASME Multivalves® For Vapor Withdrawal G8475RL Series Valves With Presto-Tap PG8475, PT7556 Series Valvesmohsen fatemiNo ratings yet

- 2011 - New - Product - Guide REGO PDFDocument8 pages2011 - New - Product - Guide REGO PDFJimmy RojasNo ratings yet

- lv5503b RegulatorDocument1 pagelv5503b RegulatorEmanuelCalmaYandocNo ratings yet

- Power Team CBT Series Cylinders - CatalogDocument1 pagePower Team CBT Series Cylinders - CatalogTitanplyNo ratings yet

- A7793a A7797aDocument1 pageA7793a A7797aCarlos Rafael Rondon AbreuNo ratings yet

- Semi-Internal "Pop-Action" Pressure Relief Valves For ASME Portable Containers 7583, 8684 and 8685 SeriesDocument1 pageSemi-Internal "Pop-Action" Pressure Relief Valves For ASME Portable Containers 7583, 8684 and 8685 Seriesأسامة حمدونىNo ratings yet

- NPR030 Vertical Bladder TankDocument4 pagesNPR030 Vertical Bladder TankLuis Joel Ramos RamosNo ratings yet

- BPI Zap TLok Headed Bar InstructionsDocument3 pagesBPI Zap TLok Headed Bar InstructionshectoriturbeNo ratings yet

- Alco ValvesDocument56 pagesAlco ValvesGuillermo de la Fuente SantiagoNo ratings yet

- Alco Valves RTG Brochure 01-07-2017 PDFDocument56 pagesAlco Valves RTG Brochure 01-07-2017 PDFGuillermo de la Fuente SantiagoNo ratings yet

- Alco Valves RTG Brochure Rev01-07.2017Document56 pagesAlco Valves RTG Brochure Rev01-07.2017linhNo ratings yet

- Reggo - LV4403BDocument1 pageReggo - LV4403BMauricio Esteban Castro BastíasNo ratings yet

- Service Guide-Trampas Cubeta Armstrong-Manual Rapracion, Instalacion, Deteccion de FallasDocument36 pagesService Guide-Trampas Cubeta Armstrong-Manual Rapracion, Instalacion, Deteccion de FallasJORGE ALBERTO PEREZ RAMIREZNo ratings yet

- STS PDFDocument1 pageSTS PDFIman praja firmansyahNo ratings yet

- Chek-Lok® Excess Flow Valves 7590U and 7591U Series: ApplicationDocument1 pageChek-Lok® Excess Flow Valves 7590U and 7591U Series: ApplicationLPG Equipment Consulting and ServicesNo ratings yet

- 30K in PDFDocument2 pages30K in PDFAnonymous DNM4ZINo ratings yet

- P - Alarm Check ValveDocument6 pagesP - Alarm Check ValvehadiNo ratings yet

- Excess Flow Valves - General InformationDocument7 pagesExcess Flow Valves - General Informationtranhonghakd5533No ratings yet

- Catalog C v5 PDFDocument80 pagesCatalog C v5 PDFAshokNo ratings yet

- Catalog C v5Document80 pagesCatalog C v5Sivi NallamothuNo ratings yet

- Needle ValvesDocument8 pagesNeedle Valvesleopoldo cobosNo ratings yet

- 2008 Banjo NO PRICE Catalog WebDocument165 pages2008 Banjo NO PRICE Catalog WebeduardoNo ratings yet

- Tapping Saddle DimensionsDocument4 pagesTapping Saddle DimensionsAnonymous IgzACaiNo ratings yet

- Cornell Pump Company Refrigerant Pump 2.5CBHDocument2 pagesCornell Pump Company Refrigerant Pump 2.5CBHJavier AffifNo ratings yet

- Orifice Plates PDFDocument3 pagesOrifice Plates PDFNacho.pNo ratings yet

- Valvula de Seguridad PRV Rego 2Document1 pageValvula de Seguridad PRV Rego 2Erick MontejoNo ratings yet

- Forging ToleranceDocument44 pagesForging Tolerancehisaj4uNo ratings yet

- Roto PDFDocument3 pagesRoto PDFKasnowo DiponegoroNo ratings yet

- Rotogauge PDFDocument3 pagesRotogauge PDFKasnowo DiponegoroNo ratings yet

- Asme Chill Water Buffer Tanks: Description: SpecificationsDocument1 pageAsme Chill Water Buffer Tanks: Description: SpecificationsRan NNo ratings yet

- CTR 004 Yardr 0008 enDocument3 pagesCTR 004 Yardr 0008 enAndy GarciaNo ratings yet

- Pipe Thread Types and DesignationsDocument2 pagesPipe Thread Types and DesignationsJenner Volnney Quispe ChataNo ratings yet

- Manual Valves Datasheet. Rev 1Document7 pagesManual Valves Datasheet. Rev 1eke23No ratings yet

- Keymc 0475 UsDocument2 pagesKeymc 0475 UsLuigui Franchesco del ValleNo ratings yet

- Split Coupled Vertical In-Line Pumps: File No.: Date: Supersedes: 43.10in DateDocument6 pagesSplit Coupled Vertical In-Line Pumps: File No.: Date: Supersedes: 43.10in DateSatawat phothinNo ratings yet

- 3165 Ta3169fDocument1 page3165 Ta3169fRenalyn TorioNo ratings yet

- Type 3510 1 and Type 3510 7 Pneumatic Control Valves Type 3510 Micro Flow ValveDocument12 pagesType 3510 1 and Type 3510 7 Pneumatic Control Valves Type 3510 Micro Flow Valvepaulo cesar f machadoNo ratings yet

- Quick Reference Guide For ValvesDocument1 pageQuick Reference Guide For ValvesEjaz Ahmed RanaNo ratings yet

- Power Team RLS-Series Cylinders - CatalogDocument1 pagePower Team RLS-Series Cylinders - CatalogTitanplyNo ratings yet

- "L4" Drive End: Operation - Assembly Instructions and Parts List ForDocument6 pages"L4" Drive End: Operation - Assembly Instructions and Parts List ForDavid Torres SibajaNo ratings yet

- Pompa Sentrifugal - Eta-NDocument6 pagesPompa Sentrifugal - Eta-Nnohan sanegaNo ratings yet

- Catalog PDFDocument72 pagesCatalog PDFVIVEK UPADHYAYNo ratings yet

- Model: A100: Flushing RingDocument2 pagesModel: A100: Flushing RingTÀi VÕNo ratings yet

- PIPING - VALVES - American Flow Control (Gate Valves) (8 PAGES)Document8 pagesPIPING - VALVES - American Flow Control (Gate Valves) (8 PAGES)fkhajehNo ratings yet

- Threaded Internal Valves For Bobtail Delivery Trucks, Transports and Stationary Storage Tanks A3213D SeriesDocument1 pageThreaded Internal Valves For Bobtail Delivery Trucks, Transports and Stationary Storage Tanks A3213D SeriesCarlos Rafael Rondon AbreuNo ratings yet

- PK Valve Page-13-17Document5 pagesPK Valve Page-13-17ICASA IngenieríaNo ratings yet

- Eliminador de AireDocument4 pagesEliminador de AiresusansueNo ratings yet

- Check and Relief ValvesDocument16 pagesCheck and Relief ValvesAdriana Herrera FloresNo ratings yet

- Power Team C-Series CylindersDocument2 pagesPower Team C-Series CylindersTitanplyNo ratings yet

- Vacuum Breakers Brochure (Metric)Document4 pagesVacuum Breakers Brochure (Metric)avgpaul100% (1)

- 007 (8.5) U Nadi MinDocument3 pages007 (8.5) U Nadi Mineieimoe.96mdyNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- BHMN 35002 IOM 19538G 0823 EnglishDocument24 pagesBHMN 35002 IOM 19538G 0823 EnglishLPG Equipment Consulting and ServicesNo ratings yet

- CF5000 03 06Document14 pagesCF5000 03 06LPG Equipment Consulting and ServicesNo ratings yet

- 120001RohrbruchvRBV EDocument1 page120001RohrbruchvRBV ELPG Equipment Consulting and ServicesNo ratings yet

- LCR iQ-InstallationDocument112 pagesLCR iQ-InstallationLPG Equipment Consulting and ServicesNo ratings yet

- 1584543837d2gym Katalog MasoneilanDocument24 pages1584543837d2gym Katalog MasoneilanLPG Equipment Consulting and ServicesNo ratings yet

- MASTERLOAD - Iq o4MAY2021 05042020Document8 pagesMASTERLOAD - Iq o4MAY2021 05042020LPG Equipment Consulting and ServicesNo ratings yet

- Stainless Steel Apollo ValvesDocument2 pagesStainless Steel Apollo ValvesLPG Equipment Consulting and ServicesNo ratings yet

- Group 14 : Strainers, Traps, Fine-Mesh Filters Filling Device For Methanol Drain DeviceDocument3 pagesGroup 14 : Strainers, Traps, Fine-Mesh Filters Filling Device For Methanol Drain DeviceLPG Equipment Consulting and ServicesNo ratings yet

- Right ItemDocument1 pageRight ItemLPG Equipment Consulting and ServicesNo ratings yet

- Masterload Series: The Next Generation Electronic RegisterDocument8 pagesMasterload Series: The Next Generation Electronic RegisterLPG Equipment Consulting and ServicesNo ratings yet

- AS4012LPG M5: 9 Meters 384.000 360º ManualDocument4 pagesAS4012LPG M5: 9 Meters 384.000 360º ManualLPG Equipment Consulting and ServicesNo ratings yet

- Chek-Lok® Excess Flow Valves 7590U and 7591U Series: ApplicationDocument1 pageChek-Lok® Excess Flow Valves 7590U and 7591U Series: ApplicationLPG Equipment Consulting and ServicesNo ratings yet

- Manuel Maintenance Pompes CorkenDocument88 pagesManuel Maintenance Pompes CorkenLPG Equipment Consulting and ServicesNo ratings yet

- Side Channel Pumps: Self-Priming, Multi-Stage TypeDocument5 pagesSide Channel Pumps: Self-Priming, Multi-Stage TypeLPG Equipment Consulting and ServicesNo ratings yet

- Group 15 : Relief Valves AccessoriesDocument4 pagesGroup 15 : Relief Valves AccessoriesLPG Equipment Consulting and ServicesNo ratings yet

- Group 19 : Shut-Off Valves Bypass Valves Three-Way Valves Quick-Acting Valves Solenoid Valves Ball ValvesDocument10 pagesGroup 19 : Shut-Off Valves Bypass Valves Three-Way Valves Quick-Acting Valves Solenoid Valves Ball ValvesLPG Equipment Consulting and ServicesNo ratings yet

- FAS NZ PumpSeriesTechnologyDocument2 pagesFAS NZ PumpSeriesTechnologyLPG Equipment Consulting and ServicesNo ratings yet

- Willy Resume-July .2016Document13 pagesWilly Resume-July .2016LPG Equipment Consulting and ServicesNo ratings yet

- Fas 13Document6 pagesFas 13LPG Equipment Consulting and ServicesNo ratings yet

- Group 21 : Compressors Pumps Accessories Complete Units and PackagesDocument11 pagesGroup 21 : Compressors Pumps Accessories Complete Units and PackagesLPG Equipment Consulting and ServicesNo ratings yet

- Fas 18Document17 pagesFas 18LPG Equipment Consulting and ServicesNo ratings yet

- Single Check Filler Valves For Storage Tanks With Supplementary Back Check Valves 3174C, 3194C and 6584CDocument1 pageSingle Check Filler Valves For Storage Tanks With Supplementary Back Check Valves 3174C, 3194C and 6584CLPG Equipment Consulting and ServicesNo ratings yet

- Group 12 : Excess Flow Valves Back Pressure Check ValvesDocument3 pagesGroup 12 : Excess Flow Valves Back Pressure Check ValvesLPG Equipment Consulting and ServicesNo ratings yet

- Multipurpose Valves For Liquid Withdrawal of LP-Gas and NH Containers A8017D & A8020DDocument1 pageMultipurpose Valves For Liquid Withdrawal of LP-Gas and NH Containers A8017D & A8020DLPG Equipment Consulting and ServicesNo ratings yet

- FAS Eng Catalogue - 2020 Lite FullDocument174 pagesFAS Eng Catalogue - 2020 Lite FullLPG Equipment Consulting and ServicesNo ratings yet

- External "Pop-Action" Supplementary Pressure Relief Valves For Small ASME Containers and DOT Cylinders 3127 and 3129 SeriesDocument1 pageExternal "Pop-Action" Supplementary Pressure Relief Valves For Small ASME Containers and DOT Cylinders 3127 and 3129 SeriesLPG Equipment Consulting and ServicesNo ratings yet

- Curriculum VitDocument4 pagesCurriculum Vit1dzrbtcom ProfessionalprogramminglanguageNo ratings yet

- I-V Characteristics of Diode and Zener DiodeDocument3 pagesI-V Characteristics of Diode and Zener Diodet19125 t19125No ratings yet

- 1987 Wienese The Performance of Diffuser Bagasse DewateringDocument4 pages1987 Wienese The Performance of Diffuser Bagasse DewateringAhmed AlfatihNo ratings yet

- Bridge Unit Bu3030 D386 Parts Location and ListDocument14 pagesBridge Unit Bu3030 D386 Parts Location and ListNickNo ratings yet

- Standard Gauge For Sheet and Plate Iron, Ted Pella, IncDocument2 pagesStandard Gauge For Sheet and Plate Iron, Ted Pella, IncBilal Arshad100% (1)

- Capacitación Ingeniería: Clase 4 Normas Calidades AceroDocument18 pagesCapacitación Ingeniería: Clase 4 Normas Calidades AcerogeracuajinaiNo ratings yet

- New York State Thruway LawsuitDocument11 pagesNew York State Thruway LawsuitWGRZ-TVNo ratings yet

- Soal Usek 76-150 (2015)Document14 pagesSoal Usek 76-150 (2015)Vahrus Nuril AlbiNo ratings yet

- Licensing Guide and Application For LicenceDocument16 pagesLicensing Guide and Application For LicenceZoraiz MirNo ratings yet

- Boiler Hydro Test 1Document7 pagesBoiler Hydro Test 1sambhu100% (1)

- Phases and SolutionsDocument105 pagesPhases and SolutionsMolina ThirumalNo ratings yet

- Kamran - 8 Ways To Migrate Your On-Premis Database To Oracle Cloud - ODev Yathra-1Document82 pagesKamran - 8 Ways To Migrate Your On-Premis Database To Oracle Cloud - ODev Yathra-1maiwand khishkiNo ratings yet

- Asme3d1 nb-5000Document12 pagesAsme3d1 nb-5000KHALED OSMANNo ratings yet

- 11 Tunnelling With Hidraulic Drills at Abajora Hidro Eletric Plant in NorwayDocument0 pages11 Tunnelling With Hidraulic Drills at Abajora Hidro Eletric Plant in Norwaycastille1956No ratings yet

- Air-Cooled ExchangersDocument45 pagesAir-Cooled ExchangersKrishanu SahaNo ratings yet

- Rajput Internal Combustion Engines PDFDocument522 pagesRajput Internal Combustion Engines PDFcaddies100% (1)

- General Us Lite PDFDocument179 pagesGeneral Us Lite PDF2791957No ratings yet

- Dash 3000/4000/5000 Patient Monitor: Service ManualDocument258 pagesDash 3000/4000/5000 Patient Monitor: Service Manualsergio ribeiroNo ratings yet

- Jeppview For Windows Jeppview For Windows: List of Pages in This Trip Kit General Information General InformationDocument11 pagesJeppview For Windows Jeppview For Windows: List of Pages in This Trip Kit General Information General InformationDoĞuŞ SaracNo ratings yet

- TTL Power Supply WithDocument2 pagesTTL Power Supply WithSérgio AndolfoNo ratings yet

- Hmine115 Workshop Practice Welding ProcessDocument72 pagesHmine115 Workshop Practice Welding ProcessGareth MashingaidzeNo ratings yet

- Electronic Volume Corrector RMGDocument47 pagesElectronic Volume Corrector RMGantoNo ratings yet

- Usama Bin Aslam (CV)Document1 pageUsama Bin Aslam (CV)Muhammad ArsalanNo ratings yet

- Pneumatic Control SystemfinalDocument6 pagesPneumatic Control Systemfinalneo100% (1)

- 采矿专业英语大全Document50 pages采矿专业英语大全Dino ChengNo ratings yet

- Spare Parts Catalogue: AXLE 20.43 REF: 572755Document8 pagesSpare Parts Catalogue: AXLE 20.43 REF: 572755marcelo sampaioNo ratings yet

- Fan 7316Document21 pagesFan 7316sontuyet82No ratings yet

- POWERMASTER Impact-SocketDocument30 pagesPOWERMASTER Impact-SocketManoj DoshiNo ratings yet