Professional Documents

Culture Documents

Properties of PVC & CPVC PIPE Fitting: Item Test Method SI Unit Unit PVC CPVC

Properties of PVC & CPVC PIPE Fitting: Item Test Method SI Unit Unit PVC CPVC

Uploaded by

sidsaleemCopyright:

Available Formats

You might also like

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)DiegoTierradentroNo ratings yet

- Catalog E - SCH80PipeSystem 9 33Document25 pagesCatalog E - SCH80PipeSystem 9 33Eric Steven MargateNo ratings yet

- CPVC PipesDocument24 pagesCPVC Pipeschaudhary osamaNo ratings yet

- Physical Properties of PVC CPVC PipeDocument1 pagePhysical Properties of PVC CPVC PipeBimal DeyNo ratings yet

- Kocetal K700 Property DataDocument1 pageKocetal K700 Property DataRanjan GnanaoliNo ratings yet

- Lexan™ 8010 Uncoated Polished Film DatasheetDocument3 pagesLexan™ 8010 Uncoated Polished Film DatasheetTeng Yan ChanNo ratings yet

- LG Chem - TDS - PC1201-15 - EngDocument2 pagesLG Chem - TDS - PC1201-15 - EngMamdouhNo ratings yet

- Solvay - Halar 513 LCDocument3 pagesSolvay - Halar 513 LCRenan GadioliNo ratings yet

- Polycarbonate Sheets Technical DataDocument1 pagePolycarbonate Sheets Technical DataLee HuiNo ratings yet

- KOPA KN126 enDocument1 pageKOPA KN126 enJagadeesh WaranNo ratings yet

- Abs-Er460 EngDocument2 pagesAbs-Er460 Engjdstore99No ratings yet

- Kpic Yuhwa p600Document1 pageKpic Yuhwa p600quanghoang10986No ratings yet

- LUPOY EU5002W (Eng) - TDS (ASTM)Document3 pagesLUPOY EU5002W (Eng) - TDS (ASTM)erayNo ratings yet

- 2.2.Tds Astm-Abs Lgchem Hi121Document2 pages2.2.Tds Astm-Abs Lgchem Hi121Wilda Sania MtNo ratings yet

- LEXAN™ Resin - 141 - Americas - Technical - Data - SheetDocument2 pagesLEXAN™ Resin - 141 - Americas - Technical - Data - Sheetrichardhe528000No ratings yet

- Virgin Ptfe DatasheetDocument1 pageVirgin Ptfe DatasheetFelipe Zúñiga ParedesNo ratings yet

- ABS LG HI21H. Rev.01Document2 pagesABS LG HI21H. Rev.01Ivan TimarevNo ratings yet

- TDS ASTM LM915 Eng 210923Document2 pagesTDS ASTM LM915 Eng 210923PrashaNo ratings yet

- LEXAN™ Resin - 241R - Americas - Technical - Data - SheetDocument2 pagesLEXAN™ Resin - 241R - Americas - Technical - Data - Sheetr92g5478cxNo ratings yet

- Mitsubishi Chemical Advanced Materials Acetron ® Food Grade Blue 50 POM-C Copolymer Acetal, Extruded (ASTM Datasheet)Document2 pagesMitsubishi Chemical Advanced Materials Acetron ® Food Grade Blue 50 POM-C Copolymer Acetal, Extruded (ASTM Datasheet)jose lealNo ratings yet

- Mitsubishi Chemical Advanced Materials Nylatron ® GSM Nylon, Cast Mos2 Filled Type 6 (Astm Product Data Sheet)Document2 pagesMitsubishi Chemical Advanced Materials Nylatron ® GSM Nylon, Cast Mos2 Filled Type 6 (Astm Product Data Sheet)Irwan SaputraNo ratings yet

- Mitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedDocument2 pagesMitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedJuan Orlando Loaiza MurilloNo ratings yet

- LEXAN™ Resin - 141R - Asia - Technical - Data - SheetDocument2 pagesLEXAN™ Resin - 141R - Asia - Technical - Data - SheetTruc Thao NguyenNo ratings yet

- LG Abs Af365bDocument2 pagesLG Abs Af365bPhung LucNo ratings yet

- TDS Nylon101Document2 pagesTDS Nylon101wilderness_666No ratings yet

- CYCOLOY™ Resin - MC1300 - Americas - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - MC1300 - Americas - Technical - Data - SheetJoseNo ratings yet

- Pmma-Lg Pmma Ih 830a (Natural)Document1 pagePmma-Lg Pmma Ih 830a (Natural)AVLight AutomotivesNo ratings yet

- SABIC Innovative Plastics Lexan® 940 PC: Polymer, Thermoplastic, Polycarbonate (PC)Document3 pagesSABIC Innovative Plastics Lexan® 940 PC: Polymer, Thermoplastic, Polycarbonate (PC)MRC RailNo ratings yet

- TP Wanhua Clarnate A1227 Vs Lexan 243RDocument2 pagesTP Wanhua Clarnate A1227 Vs Lexan 243RMitja GorseNo ratings yet

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)hugo santiago chavez godoyNo ratings yet

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)DiegoTierradentroNo ratings yet

- Nominal Engineering Properties of Ryton R-4: Data SheetDocument4 pagesNominal Engineering Properties of Ryton R-4: Data SheetRakeshNo ratings yet

- Virgin PTFE Datasheet: Property Method Units ValuesDocument2 pagesVirgin PTFE Datasheet: Property Method Units ValuesMuhammad Ejaz QureshiNo ratings yet

- Lumiplas Ld7890: Description ApplicationDocument2 pagesLumiplas Ld7890: Description ApplicationLong HomaNo ratings yet

- Filament Specifications Unit ValueDocument4 pagesFilament Specifications Unit ValueRoberto Gonzalo PelazNo ratings yet

- Solef PVDF 6008Document2 pagesSolef PVDF 6008topteam123No ratings yet

- LUPOX TE5100: Description ApplicationDocument2 pagesLUPOX TE5100: Description Applicationhugo santiago chavez godoyNo ratings yet

- SABIC PC Resin - PC0703R - Technical - Data - SheetDocument3 pagesSABIC PC Resin - PC0703R - Technical - Data - SheetAryaNo ratings yet

- 7-2500 FbeDocument3 pages7-2500 FbejleonosNo ratings yet

- PolycarbonateDocument1 pagePolycarbonatezainudinNo ratings yet

- PBT Data SheetDocument2 pagesPBT Data Sheetabhishek chaudharyNo ratings yet

- LLDPE-218BJ EditDocument3 pagesLLDPE-218BJ EditChu ChuNo ratings yet

- Abs Xr409H: Description ApplicationDocument2 pagesAbs Xr409H: Description ApplicationPhuoc Thinh TruongNo ratings yet

- Injection Grade: GPPS (General Purpose Poly Styrene)Document2 pagesInjection Grade: GPPS (General Purpose Poly Styrene)Andy KayNo ratings yet

- Abs Af312A: Description ApplicationDocument2 pagesAbs Af312A: Description ApplicationAdonis BasilioNo ratings yet

- ABSaf 312 ADocument2 pagesABSaf 312 AAdonis BasilioNo ratings yet

- Abs PDFDocument2 pagesAbs PDFAdonis BasilioNo ratings yet

- Abs Af312A: Description ApplicationDocument2 pagesAbs Af312A: Description ApplicationAdonis BasilioNo ratings yet

- Abs PDFDocument2 pagesAbs PDFAdonis BasilioNo ratings yet

- TDS - Acrylic V045 - From TrinseoDocument3 pagesTDS - Acrylic V045 - From TrinseoVio AmarieiNo ratings yet

- CYCOLOY™ FR Resins - C2950HF - Americas - Technical - Data - SheetDocument2 pagesCYCOLOY™ FR Resins - C2950HF - Americas - Technical - Data - SheetLidiane RibeiroNo ratings yet

- Abs XR 404 LGDocument2 pagesAbs XR 404 LGLeandro LacerdaNo ratings yet

- Solvay Specialty Polymers Xydar G 930 Liquid Crystal Polymer LCP NbspUnverified DataDocument4 pagesSolvay Specialty Polymers Xydar G 930 Liquid Crystal Polymer LCP NbspUnverified DataFAUSANo ratings yet

- ASA LI970: Description ApplicationDocument4 pagesASA LI970: Description ApplicationRonal Deiby Cadavid PinzonNo ratings yet

- PA6, Unfilled, Cast Nylon (ASTM Data) : @frequency 1e+6 HZ @frequency 1e+6 HZDocument1 pagePA6, Unfilled, Cast Nylon (ASTM Data) : @frequency 1e+6 HZ @frequency 1e+6 HZroberto_perraciniNo ratings yet

- Bergquist Gap Pad Comparison TableDocument1 pageBergquist Gap Pad Comparison TableMaike SongNo ratings yet

- Polycarbonate-ABS Blend (PC-ABS) : Mechanical Properties Test Method Imperial MetricDocument1 pagePolycarbonate-ABS Blend (PC-ABS) : Mechanical Properties Test Method Imperial MetricIsabel Narloch CardosoNo ratings yet

- PPS Ryton R-4-230Document3 pagesPPS Ryton R-4-230thegeneral2040No ratings yet

- Metal BoqDocument1 pageMetal BoqsidsaleemNo ratings yet

- Tds TCC Ge75vDocument1 pageTds TCC Ge75vsidsaleemNo ratings yet

- White Master Batch TDS TCC-EH70MDocument1 pageWhite Master Batch TDS TCC-EH70MsidsaleemNo ratings yet

- FRP Louver Catalogue 1Document9 pagesFRP Louver Catalogue 1sidsaleemNo ratings yet

- Engineering Hut Pakistan - Company ProfileDocument14 pagesEngineering Hut Pakistan - Company ProfilesidsaleemNo ratings yet

- Uploads Media Document BAC Rigging-VXI RVXIv15ENDocument28 pagesUploads Media Document BAC Rigging-VXI RVXIv15ENsidsaleemNo ratings yet

- Epovia Optimum® KRF 1051: Technical Data SheetDocument1 pageEpovia Optimum® KRF 1051: Technical Data SheetsidsaleemNo ratings yet

- Lamination Plan and Lamination ThicknessDocument1 pageLamination Plan and Lamination ThicknesssidsaleemNo ratings yet

- Electrical ScopeDocument3 pagesElectrical ScopesidsaleemNo ratings yet

- Physical Science Module 5 Quarter 2Document13 pagesPhysical Science Module 5 Quarter 2John Lawrence Baniqued Abol100% (1)

- Salinometer - Requirements - Alfa LavalDocument5 pagesSalinometer - Requirements - Alfa LavalAlex AndrosNo ratings yet

- HDC SD1 PDFDocument77 pagesHDC SD1 PDFОлександр ВівчарчукNo ratings yet

- 12 Physics Prep QP 21Document14 pages12 Physics Prep QP 21alichaudaryNo ratings yet

- Teletronik Optical EquipmentDocument20 pagesTeletronik Optical EquipmentosamaokokNo ratings yet

- UntitledDocument18 pagesUntitledmarcinNo ratings yet

- CNC Machining Operations: Submitted By: Waqar Ahmad (22) Sibghat Ullah (20) Submitted To: Engr. Umer FarooqDocument51 pagesCNC Machining Operations: Submitted By: Waqar Ahmad (22) Sibghat Ullah (20) Submitted To: Engr. Umer FarooqEngr.shamiNo ratings yet

- Gcse Combined Science: Trilogy: Higher Tier Paper 6: Physics 2HDocument18 pagesGcse Combined Science: Trilogy: Higher Tier Paper 6: Physics 2HOmar AbdallaNo ratings yet

- Circulating Fluidized Bed BoilerDocument60 pagesCirculating Fluidized Bed Boilermeharrafaqatali123No ratings yet

- Atlanta Permaline 2021Document2 pagesAtlanta Permaline 2021Christopher VelascoNo ratings yet

- Magnetic Effect Galvanomter Into AmmterDocument3 pagesMagnetic Effect Galvanomter Into Ammterpraveen godaraNo ratings yet

- Solved - The State of Plane Stress Shown Is Expected in An Alu-I... PDFDocument3 pagesSolved - The State of Plane Stress Shown Is Expected in An Alu-I... PDFTafseer-e-QuranNo ratings yet

- Hashima HI-550P Instruction ManualDocument7 pagesHashima HI-550P Instruction ManualSergio Cayetano PalaciosNo ratings yet

- (SERVICE MANUAL) ) - CMP 200 Generator 200 XrayDocument371 pages(SERVICE MANUAL) ) - CMP 200 Generator 200 XrayGeorgiana Kokona100% (1)

- Procedure and Specifications FOR: Wind Load AnalysisDocument29 pagesProcedure and Specifications FOR: Wind Load Analysismatthew cometaNo ratings yet

- Module 4-ECE 1Document6 pagesModule 4-ECE 1Santy Enril Belardo Jr.No ratings yet

- Investigation On The Heating Performance of The Heat Pump Withwaste Heat Recovery For The Electric BusDocument14 pagesInvestigation On The Heating Performance of The Heat Pump Withwaste Heat Recovery For The Electric BusEmre EmlekNo ratings yet

- Thermo Scientific S2.GFS97 AAS SpecificationsDocument8 pagesThermo Scientific S2.GFS97 AAS SpecificationsYeisson MoraNo ratings yet

- FL G8 M07 Family+LetterDocument2 pagesFL G8 M07 Family+Letterahmed5030 ahmed5030No ratings yet

- EGYLUX Outdoor Lighting 2 - 2Document6 pagesEGYLUX Outdoor Lighting 2 - 2mowhead adelNo ratings yet

- Carrier 50ff PDFDocument96 pagesCarrier 50ff PDFfaraz siddiquiNo ratings yet

- Datasheet Vertex DE19R EU en 2023 BDocument2 pagesDatasheet Vertex DE19R EU en 2023 Bbehzad esNo ratings yet

- Endo 3 ManualDocument24 pagesEndo 3 Manualmimosart26No ratings yet

- JEE-Main-18-03-2021-Shift-1 (Memory Based) PhysicsDocument40 pagesJEE-Main-18-03-2021-Shift-1 (Memory Based) PhysicsRamacharyuluNo ratings yet

- Tu DelftDocument3 pagesTu DelftHimalaya GaurNo ratings yet

- Sierra02-0716y3 Data SheetDocument6 pagesSierra02-0716y3 Data SheetjonathanNo ratings yet

- PLC Programming For Conveyor MotorDocument4 pagesPLC Programming For Conveyor MotorInstrumentation ToolsNo ratings yet

- InductorsDocument4 pagesInductorssreekantha reddyNo ratings yet

- SOLAR THERMAL POWER PLANT RevanthDocument20 pagesSOLAR THERMAL POWER PLANT RevanthA AkashNo ratings yet

- 6-Pulse Controlled Rectifier Synchronisation MethodDocument6 pages6-Pulse Controlled Rectifier Synchronisation MethodOnur CanNo ratings yet

Properties of PVC & CPVC PIPE Fitting: Item Test Method SI Unit Unit PVC CPVC

Properties of PVC & CPVC PIPE Fitting: Item Test Method SI Unit Unit PVC CPVC

Uploaded by

sidsaleemOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Properties of PVC & CPVC PIPE Fitting: Item Test Method SI Unit Unit PVC CPVC

Properties of PVC & CPVC PIPE Fitting: Item Test Method SI Unit Unit PVC CPVC

Uploaded by

sidsaleemCopyright:

Available Formats

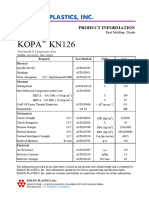

Properties of PVC & CPVC PIPE Fitting

SI unit

ITEM Test Method

unit PVC CPVC

GENERAL

Cell Classification ASTM D1784 12454 23447

Maximum Usable Temp. °C 60 93

Specific Gravity @ 73°F (23°C) ASTM D792 g/cc 1.42±0.02 1.55±0.02

10

Water Absorption % increase 24 hrs@ 73°F (23°C) ASTM D570 % 0.04 0.04

Eslon Sch80 PVC and CPVC Pipe and Fittings

Hardness, Rockwell ASTM D785 110 - 120 115-125

Poisson's Ratio @ 73°F (23°C) ASTM D638 0.38 0.36

MECHANICAL

Tensile Strength @ 73°F (23°C) ASTM D638 MPa 49.9 51.0

Tensile Strength @194 °F (90°C) MPa 20.7

Tensile Modulus of Elasticity @ 73°F (23°C) GPa 2.90 2.62

Tensile Modulus of Elasticity @ 194°F (90°C) GPa 1.38

Flexural Strength @ 73°F (23°C) ASTM D790 MPa 89.6 82.7

Flexural Modulus of Elasticity @ 73°F (23°C) GPa 2.90 2.76

Compressive Strength @ 73°F (23°C) ε =10% ASTM D695 MPa 69.0 103.4

Compressive Modulus of Elasticity @ 73°F(23°C) GPa 0.76 1.10

Izod Impact, notched @ 73°F (23°C) ASTM D256 J/m 66 162

THERMAL

Coefficient of Linear Expansion ASTM D696 m/m/°C 6.0-8.0x10 -5 7.0-8.0x10 -5

Coefficient of Thermal Conductivity ASTM C177 Watt/m/°K 0.16 0.13

Heat Deflection Temperature Under Load (264psi, annealed) ASTM D648 °C 80 102

Specific Heat ASTM D2766 J/°K/g 1.1 1.1

ELECTRICAL

Volume Resistivity ASTM D257 ohm/cm >1.0 x 10 15 >1.0 x 10 15

Dielectric Strength ASTM D149 volt/mm >1000 >1000

Dielectric Constant ASTM D150 3 3

Power Factor 〃 0.01-0.02 0.01-0.02

Electrical Conductivity Non Conductor Non Conductor

FIRE PERFORMANCE

Flammability Rating UL-94 V-0 V-0, 5VB, 5VA

Flame Spread Index 〃 <10 <10

Average Time of Burning ASTM D635 sec <5 <5

Average Extent of Burning mm <10 <10

Burning Rate mm/min Self Extinguishing Self Extinguishing

Limiting Oxygen Index (LOI) ASTM D2863 LOI 45 60

ESLON SCH80 PVC & CPVC Piping Sysyems

You might also like

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)DiegoTierradentroNo ratings yet

- Catalog E - SCH80PipeSystem 9 33Document25 pagesCatalog E - SCH80PipeSystem 9 33Eric Steven MargateNo ratings yet

- CPVC PipesDocument24 pagesCPVC Pipeschaudhary osamaNo ratings yet

- Physical Properties of PVC CPVC PipeDocument1 pagePhysical Properties of PVC CPVC PipeBimal DeyNo ratings yet

- Kocetal K700 Property DataDocument1 pageKocetal K700 Property DataRanjan GnanaoliNo ratings yet

- Lexan™ 8010 Uncoated Polished Film DatasheetDocument3 pagesLexan™ 8010 Uncoated Polished Film DatasheetTeng Yan ChanNo ratings yet

- LG Chem - TDS - PC1201-15 - EngDocument2 pagesLG Chem - TDS - PC1201-15 - EngMamdouhNo ratings yet

- Solvay - Halar 513 LCDocument3 pagesSolvay - Halar 513 LCRenan GadioliNo ratings yet

- Polycarbonate Sheets Technical DataDocument1 pagePolycarbonate Sheets Technical DataLee HuiNo ratings yet

- KOPA KN126 enDocument1 pageKOPA KN126 enJagadeesh WaranNo ratings yet

- Abs-Er460 EngDocument2 pagesAbs-Er460 Engjdstore99No ratings yet

- Kpic Yuhwa p600Document1 pageKpic Yuhwa p600quanghoang10986No ratings yet

- LUPOY EU5002W (Eng) - TDS (ASTM)Document3 pagesLUPOY EU5002W (Eng) - TDS (ASTM)erayNo ratings yet

- 2.2.Tds Astm-Abs Lgchem Hi121Document2 pages2.2.Tds Astm-Abs Lgchem Hi121Wilda Sania MtNo ratings yet

- LEXAN™ Resin - 141 - Americas - Technical - Data - SheetDocument2 pagesLEXAN™ Resin - 141 - Americas - Technical - Data - Sheetrichardhe528000No ratings yet

- Virgin Ptfe DatasheetDocument1 pageVirgin Ptfe DatasheetFelipe Zúñiga ParedesNo ratings yet

- ABS LG HI21H. Rev.01Document2 pagesABS LG HI21H. Rev.01Ivan TimarevNo ratings yet

- TDS ASTM LM915 Eng 210923Document2 pagesTDS ASTM LM915 Eng 210923PrashaNo ratings yet

- LEXAN™ Resin - 241R - Americas - Technical - Data - SheetDocument2 pagesLEXAN™ Resin - 241R - Americas - Technical - Data - Sheetr92g5478cxNo ratings yet

- Mitsubishi Chemical Advanced Materials Acetron ® Food Grade Blue 50 POM-C Copolymer Acetal, Extruded (ASTM Datasheet)Document2 pagesMitsubishi Chemical Advanced Materials Acetron ® Food Grade Blue 50 POM-C Copolymer Acetal, Extruded (ASTM Datasheet)jose lealNo ratings yet

- Mitsubishi Chemical Advanced Materials Nylatron ® GSM Nylon, Cast Mos2 Filled Type 6 (Astm Product Data Sheet)Document2 pagesMitsubishi Chemical Advanced Materials Nylatron ® GSM Nylon, Cast Mos2 Filled Type 6 (Astm Product Data Sheet)Irwan SaputraNo ratings yet

- Mitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedDocument2 pagesMitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedJuan Orlando Loaiza MurilloNo ratings yet

- LEXAN™ Resin - 141R - Asia - Technical - Data - SheetDocument2 pagesLEXAN™ Resin - 141R - Asia - Technical - Data - SheetTruc Thao NguyenNo ratings yet

- LG Abs Af365bDocument2 pagesLG Abs Af365bPhung LucNo ratings yet

- TDS Nylon101Document2 pagesTDS Nylon101wilderness_666No ratings yet

- CYCOLOY™ Resin - MC1300 - Americas - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - MC1300 - Americas - Technical - Data - SheetJoseNo ratings yet

- Pmma-Lg Pmma Ih 830a (Natural)Document1 pagePmma-Lg Pmma Ih 830a (Natural)AVLight AutomotivesNo ratings yet

- SABIC Innovative Plastics Lexan® 940 PC: Polymer, Thermoplastic, Polycarbonate (PC)Document3 pagesSABIC Innovative Plastics Lexan® 940 PC: Polymer, Thermoplastic, Polycarbonate (PC)MRC RailNo ratings yet

- TP Wanhua Clarnate A1227 Vs Lexan 243RDocument2 pagesTP Wanhua Clarnate A1227 Vs Lexan 243RMitja GorseNo ratings yet

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)hugo santiago chavez godoyNo ratings yet

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)DiegoTierradentroNo ratings yet

- Nominal Engineering Properties of Ryton R-4: Data SheetDocument4 pagesNominal Engineering Properties of Ryton R-4: Data SheetRakeshNo ratings yet

- Virgin PTFE Datasheet: Property Method Units ValuesDocument2 pagesVirgin PTFE Datasheet: Property Method Units ValuesMuhammad Ejaz QureshiNo ratings yet

- Lumiplas Ld7890: Description ApplicationDocument2 pagesLumiplas Ld7890: Description ApplicationLong HomaNo ratings yet

- Filament Specifications Unit ValueDocument4 pagesFilament Specifications Unit ValueRoberto Gonzalo PelazNo ratings yet

- Solef PVDF 6008Document2 pagesSolef PVDF 6008topteam123No ratings yet

- LUPOX TE5100: Description ApplicationDocument2 pagesLUPOX TE5100: Description Applicationhugo santiago chavez godoyNo ratings yet

- SABIC PC Resin - PC0703R - Technical - Data - SheetDocument3 pagesSABIC PC Resin - PC0703R - Technical - Data - SheetAryaNo ratings yet

- 7-2500 FbeDocument3 pages7-2500 FbejleonosNo ratings yet

- PolycarbonateDocument1 pagePolycarbonatezainudinNo ratings yet

- PBT Data SheetDocument2 pagesPBT Data Sheetabhishek chaudharyNo ratings yet

- LLDPE-218BJ EditDocument3 pagesLLDPE-218BJ EditChu ChuNo ratings yet

- Abs Xr409H: Description ApplicationDocument2 pagesAbs Xr409H: Description ApplicationPhuoc Thinh TruongNo ratings yet

- Injection Grade: GPPS (General Purpose Poly Styrene)Document2 pagesInjection Grade: GPPS (General Purpose Poly Styrene)Andy KayNo ratings yet

- Abs Af312A: Description ApplicationDocument2 pagesAbs Af312A: Description ApplicationAdonis BasilioNo ratings yet

- ABSaf 312 ADocument2 pagesABSaf 312 AAdonis BasilioNo ratings yet

- Abs PDFDocument2 pagesAbs PDFAdonis BasilioNo ratings yet

- Abs Af312A: Description ApplicationDocument2 pagesAbs Af312A: Description ApplicationAdonis BasilioNo ratings yet

- Abs PDFDocument2 pagesAbs PDFAdonis BasilioNo ratings yet

- TDS - Acrylic V045 - From TrinseoDocument3 pagesTDS - Acrylic V045 - From TrinseoVio AmarieiNo ratings yet

- CYCOLOY™ FR Resins - C2950HF - Americas - Technical - Data - SheetDocument2 pagesCYCOLOY™ FR Resins - C2950HF - Americas - Technical - Data - SheetLidiane RibeiroNo ratings yet

- Abs XR 404 LGDocument2 pagesAbs XR 404 LGLeandro LacerdaNo ratings yet

- Solvay Specialty Polymers Xydar G 930 Liquid Crystal Polymer LCP NbspUnverified DataDocument4 pagesSolvay Specialty Polymers Xydar G 930 Liquid Crystal Polymer LCP NbspUnverified DataFAUSANo ratings yet

- ASA LI970: Description ApplicationDocument4 pagesASA LI970: Description ApplicationRonal Deiby Cadavid PinzonNo ratings yet

- PA6, Unfilled, Cast Nylon (ASTM Data) : @frequency 1e+6 HZ @frequency 1e+6 HZDocument1 pagePA6, Unfilled, Cast Nylon (ASTM Data) : @frequency 1e+6 HZ @frequency 1e+6 HZroberto_perraciniNo ratings yet

- Bergquist Gap Pad Comparison TableDocument1 pageBergquist Gap Pad Comparison TableMaike SongNo ratings yet

- Polycarbonate-ABS Blend (PC-ABS) : Mechanical Properties Test Method Imperial MetricDocument1 pagePolycarbonate-ABS Blend (PC-ABS) : Mechanical Properties Test Method Imperial MetricIsabel Narloch CardosoNo ratings yet

- PPS Ryton R-4-230Document3 pagesPPS Ryton R-4-230thegeneral2040No ratings yet

- Metal BoqDocument1 pageMetal BoqsidsaleemNo ratings yet

- Tds TCC Ge75vDocument1 pageTds TCC Ge75vsidsaleemNo ratings yet

- White Master Batch TDS TCC-EH70MDocument1 pageWhite Master Batch TDS TCC-EH70MsidsaleemNo ratings yet

- FRP Louver Catalogue 1Document9 pagesFRP Louver Catalogue 1sidsaleemNo ratings yet

- Engineering Hut Pakistan - Company ProfileDocument14 pagesEngineering Hut Pakistan - Company ProfilesidsaleemNo ratings yet

- Uploads Media Document BAC Rigging-VXI RVXIv15ENDocument28 pagesUploads Media Document BAC Rigging-VXI RVXIv15ENsidsaleemNo ratings yet

- Epovia Optimum® KRF 1051: Technical Data SheetDocument1 pageEpovia Optimum® KRF 1051: Technical Data SheetsidsaleemNo ratings yet

- Lamination Plan and Lamination ThicknessDocument1 pageLamination Plan and Lamination ThicknesssidsaleemNo ratings yet

- Electrical ScopeDocument3 pagesElectrical ScopesidsaleemNo ratings yet

- Physical Science Module 5 Quarter 2Document13 pagesPhysical Science Module 5 Quarter 2John Lawrence Baniqued Abol100% (1)

- Salinometer - Requirements - Alfa LavalDocument5 pagesSalinometer - Requirements - Alfa LavalAlex AndrosNo ratings yet

- HDC SD1 PDFDocument77 pagesHDC SD1 PDFОлександр ВівчарчукNo ratings yet

- 12 Physics Prep QP 21Document14 pages12 Physics Prep QP 21alichaudaryNo ratings yet

- Teletronik Optical EquipmentDocument20 pagesTeletronik Optical EquipmentosamaokokNo ratings yet

- UntitledDocument18 pagesUntitledmarcinNo ratings yet

- CNC Machining Operations: Submitted By: Waqar Ahmad (22) Sibghat Ullah (20) Submitted To: Engr. Umer FarooqDocument51 pagesCNC Machining Operations: Submitted By: Waqar Ahmad (22) Sibghat Ullah (20) Submitted To: Engr. Umer FarooqEngr.shamiNo ratings yet

- Gcse Combined Science: Trilogy: Higher Tier Paper 6: Physics 2HDocument18 pagesGcse Combined Science: Trilogy: Higher Tier Paper 6: Physics 2HOmar AbdallaNo ratings yet

- Circulating Fluidized Bed BoilerDocument60 pagesCirculating Fluidized Bed Boilermeharrafaqatali123No ratings yet

- Atlanta Permaline 2021Document2 pagesAtlanta Permaline 2021Christopher VelascoNo ratings yet

- Magnetic Effect Galvanomter Into AmmterDocument3 pagesMagnetic Effect Galvanomter Into Ammterpraveen godaraNo ratings yet

- Solved - The State of Plane Stress Shown Is Expected in An Alu-I... PDFDocument3 pagesSolved - The State of Plane Stress Shown Is Expected in An Alu-I... PDFTafseer-e-QuranNo ratings yet

- Hashima HI-550P Instruction ManualDocument7 pagesHashima HI-550P Instruction ManualSergio Cayetano PalaciosNo ratings yet

- (SERVICE MANUAL) ) - CMP 200 Generator 200 XrayDocument371 pages(SERVICE MANUAL) ) - CMP 200 Generator 200 XrayGeorgiana Kokona100% (1)

- Procedure and Specifications FOR: Wind Load AnalysisDocument29 pagesProcedure and Specifications FOR: Wind Load Analysismatthew cometaNo ratings yet

- Module 4-ECE 1Document6 pagesModule 4-ECE 1Santy Enril Belardo Jr.No ratings yet

- Investigation On The Heating Performance of The Heat Pump Withwaste Heat Recovery For The Electric BusDocument14 pagesInvestigation On The Heating Performance of The Heat Pump Withwaste Heat Recovery For The Electric BusEmre EmlekNo ratings yet

- Thermo Scientific S2.GFS97 AAS SpecificationsDocument8 pagesThermo Scientific S2.GFS97 AAS SpecificationsYeisson MoraNo ratings yet

- FL G8 M07 Family+LetterDocument2 pagesFL G8 M07 Family+Letterahmed5030 ahmed5030No ratings yet

- EGYLUX Outdoor Lighting 2 - 2Document6 pagesEGYLUX Outdoor Lighting 2 - 2mowhead adelNo ratings yet

- Carrier 50ff PDFDocument96 pagesCarrier 50ff PDFfaraz siddiquiNo ratings yet

- Datasheet Vertex DE19R EU en 2023 BDocument2 pagesDatasheet Vertex DE19R EU en 2023 Bbehzad esNo ratings yet

- Endo 3 ManualDocument24 pagesEndo 3 Manualmimosart26No ratings yet

- JEE-Main-18-03-2021-Shift-1 (Memory Based) PhysicsDocument40 pagesJEE-Main-18-03-2021-Shift-1 (Memory Based) PhysicsRamacharyuluNo ratings yet

- Tu DelftDocument3 pagesTu DelftHimalaya GaurNo ratings yet

- Sierra02-0716y3 Data SheetDocument6 pagesSierra02-0716y3 Data SheetjonathanNo ratings yet

- PLC Programming For Conveyor MotorDocument4 pagesPLC Programming For Conveyor MotorInstrumentation ToolsNo ratings yet

- InductorsDocument4 pagesInductorssreekantha reddyNo ratings yet

- SOLAR THERMAL POWER PLANT RevanthDocument20 pagesSOLAR THERMAL POWER PLANT RevanthA AkashNo ratings yet

- 6-Pulse Controlled Rectifier Synchronisation MethodDocument6 pages6-Pulse Controlled Rectifier Synchronisation MethodOnur CanNo ratings yet