Professional Documents

Culture Documents

Nma App B PDF

Nma App B PDF

Uploaded by

Jesus Gabrielw Blanco GhostbustersIzOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nma App B PDF

Nma App B PDF

Uploaded by

Jesus Gabrielw Blanco GhostbustersIzCopyright:

Available Formats

APPENDIX B — NONMANDATORY

WELDING AND BRAZING FORMS

B-100 FORMS Form QW-484 is a suggested format for Welder /

Welding Operator /Performance Qualification (WPQ) for

This Nonmandatory Appendix illustrates sample for-

groove or fillet welds.

mats for Welding and Brazing Procedure Specifications,

Form QW-485 is a suggested format for Demonstra-

Procedure Qualification Records, and Performance Qual-

tion of Standard Welding Procedure Specifications.

ification.

B-102 Brazing

B-101 Welding

Form QB-482 is a suggested format for Brazing

Form QW-482 is a suggested format for Welding Procedure Specifications (BPS); Form QB-483 is a

Procedure Specifications (WPS); Form QW-483 is a suggested format for Procedure Qualifications Records

suggested format for Procedure Qualification Records (PQR). These forms are for torch brazing (TB), furnace

(PQR). These forms are for the shielded metal-arc brazing (FB), induction brazing (IB, resistance brazing

(SMAW), submerged-arc (SAW), gas metal-arc (RB), and dip brazing (DB) processes.

(GMAW), and gas tungsten-arc (GTAW) welding pro- Forms for other welding processes may follow the

cesses, or a combination of these processes. general format of Forms QW-482 and QW-483, as

Forms for other welding processes may follow the applicable.

general format of Forms QW-482 and QW-483, as Form QB-484 is a suggested format for Brazer /

applicable. Brazing Operator /Performance Qualification (BPQ).

241

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QW-482 2001 SECTION IX

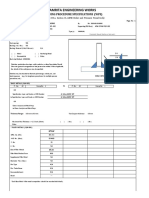

QW-482 SUGGESTED FORMAT FOR WELDING PROCEDURE SPECIFICATIONS (WPS)

(See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)

Company Name By:

Welding Procedure Specification No. Date Supporting PQR No.(s)

Revision No. Date

Welding Process(es) Type(s)

(Automatic, Manual, Machine, or Semi-Auto.)

JOINTS (QW-402) Details

Joint Design

Backing (Yes) (No)

Backing Material (Type)

(Refer to both backing and retainers.)

䊐 Metal 䊐 Nonfusing Metal

䊐 Nonmetallic 䊐 Other

Sketches, Production Drawings, Weld Symbols or Written Description

should show the general arrangement of the parts to be welded. Where

applicable, the root spacing and the details of weld groove may be

E

specified.

(At the option of the Mfgr., sketches may be attached to illustrate joint

design, weld layers and bead sequence, e.g., for notch toughness proce-

dures, for multiple process procedures, etc.)

PL

*BASE METALS (QW-403)

P-No. Group No. to P-No. Group No.

M

OR

Specification type and grade

to Specification type and grade

OR

SA

Chem. Analysis and Mech. Prop.

to Chem. Analysis and Mech. Prop.

Thickness Range:

Base Metal: Groove Fillet

Other

*FILLER METALS (QW-404)

Spec. No. (SFA)

AWS No. (Class)

F-No.

A-No.

Size of Filler Metals

Weld Metal

Thickness Range:

Groove

Fillet

Electrode-Flux (Class)

Flux Trade Name

Consumable Insert

Other

*Each base metal-filler metal combination should be recorded individually.

(7/00) This form (E00006) may be obtained from the Order Dept., ASME, 22 Law Drive, Box 2300, Fairfield, NJ 07007-2300

242

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

NONMANDATORY APPENDIX B QW-482

243

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QW-483 2001 SECTION IX

244

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

NONMANDATORY APPENDIX B QW-483

245

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QW-484A 2001 SECTION IX

01

QW-484A SUGGESTED FORMAT A FOR WELDER PERFORMANCE QUALIFICATIONS (WPQ)

(See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)

Welder’s name Identification no.

Test Description

Identification of WPS followed ( Test coupon ( Production weld

Specification of base metal(s) Thickness

Testing Conditions and Qualification Limits

Welding Variables (QW-350) Actual Values Range Qualified

Welding process(es)

Type (ie: manual, semi-auto) used

Backing (metal, weld metal, double-welded, etc.)

( Plate ( Pipe (enter diameter if pipe or tube)

Base metal P or S-Number to P- or S-Number

Filler metal or electrode specification(s) (SFA) (info only)

Filler metal or electrode classification(s) (info only)

Filler metal F-Number(s)

Consumable insert (GTAW or PAW)

E

Filler type (solid/metal or flux cored/powder) (GTAW or PAW)

Deposit thickness for each process

Position qualified (2G, 6G, 3F, etc.)

PL

Vertical progression (uphill or downhill)

Type of fuel gas (OFW)

Inert gas backing (GTAW, PAW, GMAW)

Transfer mode (spray/globular or pulse to short circuit-GMAW)

M

GTAW current type/polarity (AC, DCEP, DCEN)

RESULTS

Visual Examination of Completed Weld (QW-302.4)

SA

( Bend test; ( Transverse root and face [QW-462.3(a)]; ( Longitudinal root and face [QW-462.3(b)]; ( Side (QW-462.2);

( Pipe bend specimen, corrosion-resistant overlay [QW-462.5(c)]; ( Plate bend specimen, corrosion-resistant overlay [QW-462.5(d)];

( Macro test for fusion [QW-462.5(b)]; ( Macro test for fusion [QW-462.5(e)]

Type Result Type Result Type Result

Alternative radiographic examination results (QW-191)

Fillet weld — fracture test (QW-180) Length and percent of defects

Macro examination (QW-184) Fillet size (in.) × Concavity/convexity (in.)

Other tests

Film or specimens evaluated by Company

Mechanical tests conducted by Laboratory test no.

Welding supervised by

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and tested in accordance with the

requirements of Section IX of the ASME Code.

Organization

Date By

This form (E0008A) may be obtained from the Order Dept., ASME, 22 Law Drive, Box 2300, Fairfield, NJ 07007-2300.

246

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

NONMANDATORY APPENDIX B QW-484B

01

QW-484B SUGGESTED FORMAT B FOR WELDING OPERATOR PERFORMANCE QUALIFICATIONS (WOPQ)

(See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)

Welder’s name Identification no.

Test Description (Information Only)

Identification of WPS followed ( Test coupon ( Production weld

Specification of base metal(s) Thickness

Base metal P or S-Number to P or S-Number Position (2G, 6G, 3F, etc.)

( Plate ( Pipe (enter diameter if pipe or tube):

Filler metal (SFA) specification Filler metal or electrode classification

Testing Conditions and Qualification Limits When Using Automatic Welding Equipment

Welding Variables (QW-361.1) Actual Values Range Qualified

Type of welding (Automatic)

Welding process

Filler metal (EBW or LBW)

Type of laser for LBW (CO2 to YAG, etc.)

Continuous drive or inertia welding (FW)

Vacuum or out of vacuum (EBW)

Testing Conditions and Qualification Limits When Using Machine Welding Equipment

E

Welding Variables (QW-361.2) Actual Values Range Qualified

Type of welding (machine)

Welding process

Direct or remote visual control

PL

Automatic arc voltage control (GTAW)

Automatic joint tracking

Position qualified (2G, 6G, 3F, etc.)

M

Consumable inserts (GTAW or PAW)

Backing (metal, weld metal, etc.)

Single or multiple passes per side

SA

RESULTS

Visual Examination of Completed Weld (QW-302.4)

( Bend test; ( Transverse root and face [QW-462.3(a)]; ( Longitudinal root and face [QW-462.3(b)]; ( Side (QW-462.2);

( Pipe bend specimen, corrosion-resistant overlay [QW-462.5(c)]; ( Plate bend specimen, corrosion-resistant overlay [QW-462.5(d)];

( Macro test for fusion [QW-462.5(b)]; ( Macro test for fusion [QW-462.5(e)]

Type Result Type Result Type Result

Alternative radiographic examination results (QW-191)

Fillet weld — fracture test (QW-180) Length and percent of defects

Macro examination (QW-184) Fillet size (in.) × Concavity/convexity (in.)

Other tests

Film or specimens evaluated by Company

Mechanical tests conducted by Laboratory test no.

Welding supervised by

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and tested in accordance with the

requirements of Section IX of the ASME Code.

Organization

Date By

This form (E0008B) may be obtained from the Order Dept., ASME, 22 Law Drive, Box 2300, Fairfield, NJ 07007-2300.

247

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QW-485 2001 SECTION IX

QW-485 SUGGESTED FORMAT FOR DEMONSTRATION OF STANDARD WELDING

PROCEDURE SPECIFICATIONS (WPS)

(See Article V)

Identification of Standard Welding Procedure Specification Demonstrated:

Demonstration Welding Conditions

Specification, Type, and Grade of Base Metal(s):

To Specification, Type, and Grade of Base Metal(s):

Base Metal P- or S-Number to Base Metal P- or S-Number Thickness:

Welding Process(es) used:

䊐 Plate 䊐 Pipe (Enter Diameter of Pipe or Tube):

Groove Type (Single V, Double V, Single U, etc.):

Initial Cleaning Method:

Backing (Metal, Weld Metal, Backwelded, etc.):

E

Filler Metal (SFA) Specification:

Filler Metal or Electrode Classification:

Filler Metal or Electrode Trade Name:

Tungsten Electrode Type and Size for GTAW:

Consumable Insert Class and Size for GTAW or PAW:

Backing Gas Composition and Flow Rate for GTAW, PAW, GMAW:

PL

Preheat Temperature (°F):

Position (F, V, OH, H) of Weld:

M

Progression (Uphill or Downhill):

Interpass Cleaning Method:

Measured Interpass Temperature (°F):

Approximate Deposit Thickness for Each Filler Metal or Electrode Type (in.):

SA

Current Type/Polarity (AC, DCEP, DCEN):

Postweld Heat Treatment Time and Temperature:

Visual Examination of Completed Weld: Date of Test:

Bend Test 䊐 Transverse Root and Face [QW-462.3(a)] 䊐 Side (QW-462.2)

Type Result Type Result Type Result

Alternative Radiographic Examination Results:

Specimens Evaluated By: Title: Company:

Welding Supervised By: Title: Company:

Welder’s Name: Stamp No.

We certify that the statements in this record are correct and that the weld described above was prepared, welded, and tested in accordance with

the requirements of Section IX of the ASME Code.

Manufacturer or Contractor:

By: Date: Demonstration Number:

This form (E00136) may be obtained from the Order Dept., ASME, 22 Law Drive, Box 2300, Fairfield, NJ 07007-2300.

248

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

NONMANDATORY APPENDIX B QB-482

QB-482 SUGGESTED FORMAT FOR BRAZING PROCEDURE SPECIFICATIONS (BPS)

(See QB-200.1, Section IX, ASME Boiler and Pressure Vessel Code)

Company Name

BPS No. Date Supporting PQR No.

Revisions

Brazing Process(es) Type(s)

(Manual, mechanical torch, etc.)

JOINTS (QB-408)

Type of Joint(s)

Joint Clearance Range

Lap Length Range

Sketches, production drawings, symbols,

or written description should show the

general arrangement of the parts to be

E

joined.

(At the option of the Mfgr., sketches

may be attached to illustrate joint design.)

BASE METALS (QB-402)

P-No.

Spec. type and grade

to P-No.

PL BRAZING FLUX OR ATMOSPHERE (QB-406)

Flux Trade Name or Composition

Atmosphere for Furnace Brazing

M

to spec. type and grade [name or trade designation of the fuel used or

OR the name or trade designation of the gas compressing the atmosphere

Chem. analysis and mech. prop (hydrogen, Ammo-Gas, etc.) and a statement regarding the designed

to chem. analysis and mech. prop. character of the furnace atmosphere, e.g., whether it is reducing, de-

SA

Thickness Range carburizing, inert, etc.]

Other

FLOW POSITION (QB-407)

FILLER METALS (QB-403) Flow Position(s)

F-No. Other Method of Applying Filler (Metal

ASME Spec. No. Other (face feeding, preplaced rings, shims, spray de-

AWS Class No. Other posit, cladding, etc.)

Size or Shape of Filler Metal Other

Other

POSTBRAZE HEAT TREATMENT (QB-409)

BRAZING TEMPERATURE (QB-404) Type and temperature of aging or stabilizing thermal treatment after

Temperature Range* brazing

Other

*Not applicable for torch brazing

TECHNIQUE (QB-410)

Method of Precleaning

Method of Postbrazing Cleaning

Type of Flame

Torch Tip Size

Other

This form (E00031) may be obtained from the Order Dept., ASME, 22 Law Drive, Box 2300, Fairfield, NJ 07007-2300.

249

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QB-483 2001 SECTION IX

250

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

NONMANDATORY APPENDIX B QB-483

251

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

You might also like

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 4 out of 5 stars4/5 (9)

- QW-482 201.1Document2 pagesQW-482 201.1Barwin CruzNo ratings yet

- WPS14-1 A106 B SmawDocument4 pagesWPS14-1 A106 B SmawRahul MoottolikandyNo ratings yet

- QW-482 WPS FormatDocument2 pagesQW-482 WPS FormatMardeOpamen100% (1)

- Gym SharkDocument2 pagesGym SharkrohitNo ratings yet

- JT3D (TF33) S3P2Document16 pagesJT3D (TF33) S3P2junmech-1No ratings yet

- QW 482 Suggested Format For Welding ProcedureDocument1 pageQW 482 Suggested Format For Welding ProcedureNisarg PandyaNo ratings yet

- Wps PQR FormDocument8 pagesWps PQR Formmayank0738No ratings yet

- Format For Manufacturer Record of Welding Operator QualificationDocument1 pageFormat For Manufacturer Record of Welding Operator QualificationRajeev KumarNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)pradeep4545No ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Balkishan DyavanapellyNo ratings yet

- QW-482 (WPS) GTAW 4MM FilletDocument4 pagesQW-482 (WPS) GTAW 4MM FilletBalkishan DyavanapellyNo ratings yet

- WPS&PQR FormsDocument4 pagesWPS&PQR FormsArab WeldersNo ratings yet

- QW 482Document4 pagesQW 482Jesus Silva HenaoNo ratings yet

- WPS-PQR Pengelasan (AA)Document12 pagesWPS-PQR Pengelasan (AA)Abrianto AkuanNo ratings yet

- H 99 Sec 9 AppbDocument4 pagesH 99 Sec 9 AppbAxel MalusaNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)mohammadNo ratings yet

- Qw-484B Format For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document7 pagesQw-484B Format For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Gerardo Arispe AramayoNo ratings yet

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Co D E)Document2 pagesQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Co D E)Vaibhav GuptaNo ratings yet

- WPQ Format Sec IxDocument2 pagesWPQ Format Sec IxParminder SinghNo ratings yet

- Qw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)linaNo ratings yet

- QW 406 Asme CodeDocument3 pagesQW 406 Asme CodeMardeOpamenNo ratings yet

- 3 BodyPart Edcb3a5f Eede 445f A423 Ea2f5809c15eDocument6 pages3 BodyPart Edcb3a5f Eede 445f A423 Ea2f5809c15emayank0738No ratings yet

- Smaw Manual See Permitted Figures (Right) or Per Constr. DWG Butt JointDocument3 pagesSmaw Manual See Permitted Figures (Right) or Per Constr. DWG Butt JointNirmala DeshaNo ratings yet

- Asme IxDocument132 pagesAsme IxAhmed Shaban Kotb100% (1)

- Welding Procedure SpecificationDocument12 pagesWelding Procedure Specificationsanjay sharmaNo ratings yet

- Qw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesQw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)linaNo ratings yet

- QW 482Document2 pagesQW 482Ramu NallathambiNo ratings yet

- QW 482Document2 pagesQW 482Khaled bouhlelNo ratings yet

- ASME WPS-PQR-WQT CombinedDocument6 pagesASME WPS-PQR-WQT CombinedStan HonNo ratings yet

- Form Qw-485 Suggested Format For Demonstration of Standard Welding Procedure Specifications (SWPS) (See Article V)Document1 pageForm Qw-485 Suggested Format For Demonstration of Standard Welding Procedure Specifications (SWPS) (See Article V)Emma DNo ratings yet

- Welding ProceduresDocument29 pagesWelding ProceduresLaith Salman100% (1)

- Formas Soldadura ASME IX 2017Document7 pagesFormas Soldadura ASME IX 2017Ulises GómezNo ratings yet

- Qw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Jose Elian Cuellar PinzónNo ratings yet

- WPQ PDFDocument1 pageWPQ PDFJose Elian Cuellar PinzónNo ratings yet

- WA-AEI-001 Some Comments AddressedDocument2 pagesWA-AEI-001 Some Comments AddressedMulPXNo ratings yet

- ASME BPVC IX - 2017 Welding and Brazing Qualification 367Document1 pageASME BPVC IX - 2017 Welding and Brazing Qualification 367jiao longNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad MunadiNo ratings yet

- WPS Uide PDFDocument32 pagesWPS Uide PDFmuthuswamy77No ratings yet

- WPS Format PDFDocument2 pagesWPS Format PDFHimansu Sekhar JenaNo ratings yet

- 1108-DES-005 Rev02Document1 page1108-DES-005 Rev02Omar TocmoNo ratings yet

- Qw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Alesol EquipmentNo ratings yet

- Welders Performance Qualification Record (WPQ) : Welder Name Identification No. Test DescriptionDocument8 pagesWelders Performance Qualification Record (WPQ) : Welder Name Identification No. Test DescriptionGerardo Arispe AramayoNo ratings yet

- ASME BPVC Sec IX 2023 - Demonstration FormDocument1 pageASME BPVC Sec IX 2023 - Demonstration Formmr.bakhtiari.mahmoudNo ratings yet

- Experiment No.: - Welding Procedure Specification (WPS) & Welder Performance Qualification (WPQ)Document12 pagesExperiment No.: - Welding Procedure Specification (WPS) & Welder Performance Qualification (WPQ)Vandan GundaleNo ratings yet

- Suggested Wps Forms ASME - IX 2010Document5 pagesSuggested Wps Forms ASME - IX 2010Ajay ChodankarNo ratings yet

- PQR Sample PrintoutDocument2 pagesPQR Sample PrintoutDhewo Rachmad Yansyah100% (3)

- WQT 1236Document1 pageWQT 1236mir31721No ratings yet

- Form Qw-484B Suggested Format B For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageForm Qw-484B Suggested Format B For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)KautiilaNo ratings yet

- QW 482Document2 pagesQW 482Ali MoghiNo ratings yet

- Record of Welder or Welding Operator Qualification Test: Welders's Name: Stamp No.: WQT No.Document1 pageRecord of Welder or Welding Operator Qualification Test: Welders's Name: Stamp No.: WQT No.Weld Bro SandeepNo ratings yet

- WPS PQRDocument4 pagesWPS PQRGuillermo ZaragozaNo ratings yet

- BPVC Ix QW-482Document2 pagesBPVC Ix QW-482ganesh82No ratings yet

- QW484Document1 pageQW484Anonymous 4e7GNjzGWNo ratings yet

- Wps Asme Ix-2019 TemplateDocument2 pagesWps Asme Ix-2019 TemplateAlmasrizal AlmasrizalNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Advanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactFrom EverandAdvanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactNo ratings yet

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- SPD Module 1Document15 pagesSPD Module 1Daniel ReyesNo ratings yet

- Demand ForecastingDocument20 pagesDemand ForecastingShahbaz Ahmed AfsarNo ratings yet

- Vip in MathematicsDocument170 pagesVip in MathematicsJerome Jeremias100% (1)

- 02 - Property Tables and ChartsDocument2 pages02 - Property Tables and ChartsjhamilcarNo ratings yet

- Soal UAS Nov 2021 X LM BIG 3.2Document6 pagesSoal UAS Nov 2021 X LM BIG 3.2Alys AnastasyaNo ratings yet

- Queueing Problems Solutions 2021 SztrikDocument403 pagesQueueing Problems Solutions 2021 Sztrikjasleensaggu9417No ratings yet

- Equipo Ultrasonido TUD300 PDFDocument2 pagesEquipo Ultrasonido TUD300 PDFjoseperezoso100% (1)

- AerosolsDocument29 pagesAerosolsKulbhushan SharmaNo ratings yet

- Ai in EduDocument14 pagesAi in EduKang YihyunNo ratings yet

- Me 8951Document49 pagesMe 8951JHONNATHANCOLMENARESNo ratings yet

- ISO 10893-2-2011 Amd1-2020Document6 pagesISO 10893-2-2011 Amd1-2020Gennady FahmiNo ratings yet

- Matrix Korelasi ISO IntergrasiDocument3 pagesMatrix Korelasi ISO IntergrasiAgungMahendraNo ratings yet

- React JS: Notes For ProfessionalsDocument110 pagesReact JS: Notes For ProfessionalsudNo ratings yet

- Made Easy-ECDocument33 pagesMade Easy-ECb prashanthNo ratings yet

- Re - (Repeater-Builder) Midland Vehicular Repeater InfoDocument3 pagesRe - (Repeater-Builder) Midland Vehicular Repeater InfobbarinkNo ratings yet

- Faktor-Faktor Yang Berhubungan Dengan Kejadian Luka Dekubitus Akibat Penggunaan Alat Medis Di Ruang PicuDocument11 pagesFaktor-Faktor Yang Berhubungan Dengan Kejadian Luka Dekubitus Akibat Penggunaan Alat Medis Di Ruang PicuChensya SouisaNo ratings yet

- 013 Ching Vs CA 181 Scra 9 1990Document2 pages013 Ching Vs CA 181 Scra 9 1990frank japos100% (1)

- Reso SympathyDocument2 pagesReso SympathysangguniangNo ratings yet

- Example For Decision Making CriteriaDocument5 pagesExample For Decision Making CriteriaArly Kurt TorresNo ratings yet

- Assignment AnsDocument6 pagesAssignment AnsVAIGESWARI A/P MANIAM STUDENTNo ratings yet

- Coco Fire Indonesa - Anu 2021Document20 pagesCoco Fire Indonesa - Anu 2021Abizard Niaga UtamaNo ratings yet

- Лаб №9Document21 pagesЛаб №9tbzlover0115No ratings yet

- Canvasing Sekolah 2023Document12 pagesCanvasing Sekolah 2023yovithaithaNo ratings yet

- 2.1.2.3 Packet Tracer - Blinking An LED Using BlocklyDocument11 pages2.1.2.3 Packet Tracer - Blinking An LED Using BlocklyDenisa ZahariaNo ratings yet

- Online QuizDocument9 pagesOnline QuizKen LeNo ratings yet

- 2019 DLSU Research CongressDocument189 pages2019 DLSU Research CongressVoltaire MistadesNo ratings yet

- Install NetDocument2 pagesInstall Netmarcos edinson machado monteroNo ratings yet

- Resume Stephen SouthernDocument2 pagesResume Stephen SouthernstevesouthernNo ratings yet