Professional Documents

Culture Documents

Energy Efficient Appliances in A Residential Building

Energy Efficient Appliances in A Residential Building

Uploaded by

kannanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Energy Efficient Appliances in A Residential Building

Energy Efficient Appliances in A Residential Building

Uploaded by

kannanCopyright:

Available Formats

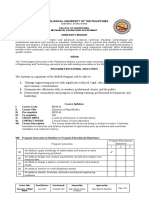

Energy Efficient Appliances in a Residential Building

D Kamalakannan, V Mariappan, V Narayanan and N S Ramanathan

Advanced engineering,

Lucas TVS Ltd,

Chennai, India.

kamalakannan.engg@lucastvs.co.in

Abstract— This paper compares various electrical motors being has been proposed by Indian Institute of Technology Madras to

used in a residential electrical appliances. Most of those motors address the issues of black out [1]. This project is actively

are induction/DC/universal motors and their efficiency levels are implemented in many parts of India. The various motors used

very low. It is an urge to develop a motor with higher operating in a residential building for both AC as well as DC bus systems

efficiency. With the recent development in the field of power are discussed in the following chapters [2].

electronics and magnet technologies, it would be possible to meet

the above requirements with brushless direct current motor. II. CURRENT HOUSEHOLD APPLIANCE MOTORS

Nowadays brushless direct current motors (BLDC) are used in

Electric motors are widely used in many appliances for

many applications due to their advantage of high efficiency,

compact size and easy control. In this paper, performance,

converting electrical energy to mechanical energy. Many

efficiency and other features of various household appliance applications such as ceiling fan, refrigerator, air conditioner,

motors such as motors in refrigerator compressor, ceiling fan, air water purifier, mixer – grinder and washing machine use either

conditioner, washing machine, water purifier, mixer-grinder and one of induction, DC and universal motor. The typical power

air cooler are all compared with those of BLDC motors. consumption of these appliances, range between 30W to

1500W.

A. Induction motor

buildings

Single and three phase induction motors are used in many

I. INTRODUCTION applications due to their simple design, low cost and long life

The energy consumption of industrial and residential sector [3]. It works based on the electromagnetic induction principle.

increases day by day due to the population growth. An When an induction motor is energized, a rotating magnetic

additional power generation is needed to meet the increased field is produced which links the rotor thereby producing a

demand. As the load demand is not met with the generation current in the same. This rotor current produces an opposite

capacity, power shortage is managed by load shedding. Even polarity of magnetic field to that of the stator. The integration

during the power availability, due to peak demand, the quality of the stator and rotor magnetic field produces a torque in the

of power is not good. Interrupted power supply leads to a poor rotor. For low power applications, single phase motors are

performance or permanent failure in the operating appliances. used. Based on the mechanism used to generate the rotating

In recent days the concept of micro or smart grid is popular to magnetic field, induction motors are classified into shaded

address this issue of power shortage. The power demand is met pole, resistance start induction run (RSIR), capacitor start

with solar, wind, diesel- generation and conventional grid induction run (CSIR), permanent split capacitor (PSC) and

individually or a suitable combination of generation sources. capacitor split capacitor run (CSCR). Each type of motor has

This system not only reduces transmission and distribution different peak efficiency, starting torque and cost implications.

losses also, it enables the user to manage the generation and B. DC motor

load demand by a proper energy management system. Due to

their limited availability and higher investment costs, it is high Direct current motors consist of a magnetic field (main

time we use the renewable and non renewable sources field) producing winding in their stator and armature winding

effectively. in the rotor. The power supply is given through a brush and

commutator arrangement. DC motors are grouped into shunt

In recent days many appliances use BLDC motors because and series motors based on the connection of field winding

of their compact size, high efficiency and easy controllability. with armature winding . Main field can be generated either by

Since, BLDC motors require DC power input it would be electromagnet or permanent magnet. The machine

possible to operate these motors with a battery or with a construction and speed control is simple as compared to other

common DC bus system. A separate DC bus electrical output motors. However, this motor faces the drawback of limited

power is derived from any of the inputs such as renewable life span, poor efficiecy and also requires frequent

sources of energy like solar, wind, tidal or from the AC grid. maintenance.

BLDC motors to be used in all the appliances can draw power

from this above DC bus electrical power thereby reducing the C. Universal motor

number of components of conversion as well as associated Universal motor are series wound commutator motor. In

losses. As mentioned earlier, a 48V DC bus Voltage system this arrangement, stator winding is connected in series with

rotor winding and is connected through a brush and

978-1-5090-3498-7/16/$31.00 ©2016 IEEE

You might also like

- Mitsubishi Electric Ecodan R32 Air To Water Heat Pumps Info 2020 ENG PDFDocument422 pagesMitsubishi Electric Ecodan R32 Air To Water Heat Pumps Info 2020 ENG PDFMarkoNo ratings yet

- Solidworks Tutorial - Alloy WheelDocument6 pagesSolidworks Tutorial - Alloy WheelAdam BillingtonNo ratings yet

- Energy Efficient Appliances in A Residential Building - IEEE - SGBC2016 - ConfDocument6 pagesEnergy Efficient Appliances in A Residential Building - IEEE - SGBC2016 - ConfkannanNo ratings yet

- Electric Motors of Use As Given at The W PDFDocument399 pagesElectric Motors of Use As Given at The W PDFjimNo ratings yet

- Ijetr022623 PDFDocument5 pagesIjetr022623 PDFerpublicationNo ratings yet

- ست خطوات العاكس لقيادة المحرك التعريفي ثلاث مراحلDocument113 pagesست خطوات العاكس لقيادة المحرك التعريفي ثلاث مراحلMOUHSSINE BEN HAMMOUNo ratings yet

- Comparison of Electric Motors For Electric Vehicle ApplicationDocument6 pagesComparison of Electric Motors For Electric Vehicle ApplicationMr. KhanNo ratings yet

- Speed Control of Brushless DC Motor Using Zeta ConverterDocument7 pagesSpeed Control of Brushless DC Motor Using Zeta ConverterRicard Alfredo PurbaNo ratings yet

- Electric MachinesDocument4 pagesElectric Machinesمحمد حسین فیض اللهیNo ratings yet

- Assessment of BLDC Motor For EV Application Considering Vehicle Design StrategyDocument7 pagesAssessment of BLDC Motor For EV Application Considering Vehicle Design StrategyPremier PublishersNo ratings yet

- What Is Electric Motor D1Document9 pagesWhat Is Electric Motor D1Shiv TonyNo ratings yet

- Ijarcce 16Document3 pagesIjarcce 16Black MambaNo ratings yet

- dc machine projectDocument20 pagesdc machine projectabrahamabate27No ratings yet

- DC MotorDocument45 pagesDC MotorRayz C.ONo ratings yet

- Mini Project BeeDocument13 pagesMini Project Bee237r1a66r0No ratings yet

- A Review On Control Techniques For Brushless DC (BLDC) MotorsDocument15 pagesA Review On Control Techniques For Brushless DC (BLDC) MotorsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- EE404 EE 2202 Group 3 Initial Laboratory ReportDocument30 pagesEE404 EE 2202 Group 3 Initial Laboratory ReportdenznirecodringNo ratings yet

- Model Predictive Control For DC Motors: Lafta E. J. Alkurawy Nisreen KhamasDocument6 pagesModel Predictive Control For DC Motors: Lafta E. J. Alkurawy Nisreen KhamasShubham ranjanNo ratings yet

- Term Paper: Subject: Ele 102Document20 pagesTerm Paper: Subject: Ele 102Rajesh VermaNo ratings yet

- Electrical DrivesDocument194 pagesElectrical DrivesKITSAO SAMUELNo ratings yet

- Advantages and Disadvantages of DC MotorDocument6 pagesAdvantages and Disadvantages of DC MotorMuhd Izwan Ikhmal RosliNo ratings yet

- Electrical DrivesDocument204 pagesElectrical DrivesRuchiNo ratings yet

- Development of Small Battery Powered Three Wheeler Using PM Hub Motor Prototype IDocument4 pagesDevelopment of Small Battery Powered Three Wheeler Using PM Hub Motor Prototype IKapish SharmaNo ratings yet

- What Is Electric MotorDocument9 pagesWhat Is Electric MotorElectrifying GuyNo ratings yet

- DC MotorDocument3 pagesDC MotorShubham AgrawalNo ratings yet

- Speed Control of 3-Ø Induction Motor by Using Vector Control Variable Frequency MethodDocument1 pageSpeed Control of 3-Ø Induction Motor by Using Vector Control Variable Frequency Methodvenky123456789No ratings yet

- .0 .0 Tensors - Fluid - Dynamics - CreteDocument8 pages.0 .0 Tensors - Fluid - Dynamics - CreteRabei RomulusNo ratings yet

- Classification of Electric Motors Electrical KnowhowDocument11 pagesClassification of Electric Motors Electrical Knowhowamanda christineNo ratings yet

- Electric Motor Cycle and ScooterDocument9 pagesElectric Motor Cycle and ScooterA A.DevanandhNo ratings yet

- PBL MotorDocument10 pagesPBL MotorAdam AriffNo ratings yet

- AC generators:AC Generators Are Known As Single-Phase Generators and Are Limited To 25kWDocument9 pagesAC generators:AC Generators Are Known As Single-Phase Generators and Are Limited To 25kWJera ObsinaNo ratings yet

- Electrical DrivesDocument191 pagesElectrical Drivesbangs34No ratings yet

- Definitions: DC Machines and EquipmentDocument20 pagesDefinitions: DC Machines and EquipmentChristian Angelo ButacNo ratings yet

- Lecture No 2Document25 pagesLecture No 2Walid salamaNo ratings yet

- Term Paper On DC MotorDocument4 pagesTerm Paper On DC Motorc5qfb5v5100% (1)

- DC MotorDocument6 pagesDC MotorUjjawal ParasarNo ratings yet

- Photovoltaic Based Brushless DC Motor Closed Loop Drive For Electric VehicleDocument7 pagesPhotovoltaic Based Brushless DC Motor Closed Loop Drive For Electric VehicleYasir KhanNo ratings yet

- AC and DC MotorDocument13 pagesAC and DC MotorrikechNo ratings yet

- AC MotorDocument3 pagesAC MotormadhumithaaNo ratings yet

- Ev Engine ResearchDocument15 pagesEv Engine ResearchAnshul YadavNo ratings yet

- Solid State Drives Digital NotesDocument195 pagesSolid State Drives Digital NotesShanmukh VegiNo ratings yet

- Utilization ReportDocument4 pagesUtilization Reportam4607647No ratings yet

- Chapter 1Document3 pagesChapter 1v9mhtc2qjzNo ratings yet

- Regenerative Hybrid Automobile ReportDocument67 pagesRegenerative Hybrid Automobile ReportRajat KapoorNo ratings yet

- Solar Based Multilevel Inverter F o R BLDC Motor DriveDocument8 pagesSolar Based Multilevel Inverter F o R BLDC Motor DriveInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Case StudyDocument3 pagesCase StudyRogelio AquinoNo ratings yet

- DC MotorDocument6 pagesDC Motordarshandarshana711No ratings yet

- Photovoltaic Based Brushless DC Motor Closed Loop Drive For Electric VehicleDocument7 pagesPhotovoltaic Based Brushless DC Motor Closed Loop Drive For Electric VehicleMani KandanNo ratings yet

- Technical College / Thi Qar: (Electrical Machines Class) Second YearDocument4 pagesTechnical College / Thi Qar: (Electrical Machines Class) Second YearReoo AlrikabyNo ratings yet

- Introduction To Electrical DrivesDocument11 pagesIntroduction To Electrical DrivesGaurav SrivastavaNo ratings yet

- PHILMOR ReportDocument3 pagesPHILMOR Reportpmor57409No ratings yet

- Module I DC Machines.pptxDocument175 pagesModule I DC Machines.pptxalanimmanuel80No ratings yet

- Basic Electrical MachinesDocument4 pagesBasic Electrical MachinesGedion AvatarNo ratings yet

- Types of MotorDocument5 pagesTypes of MotorMAHENDRAN DNo ratings yet

- Classification of Electric Motors: Electrical Motors Basic ComponentsDocument89 pagesClassification of Electric Motors: Electrical Motors Basic ComponentsSarada Sankar DasNo ratings yet

- DC MotorDocument14 pagesDC MotorMilanNo ratings yet

- Study Analysis of Conservation of Energy With VFDDocument9 pagesStudy Analysis of Conservation of Energy With VFDHashfi HamdaniNo ratings yet

- Electricity Power Generation Through Magnetic Couplings Index Sr. No. Content Page NoDocument72 pagesElectricity Power Generation Through Magnetic Couplings Index Sr. No. Content Page Noakshay jadhavNo ratings yet

- Low Voltage Non Motor Industrial Feeder Calculating Ampacity Ratings of Feeders Conductors Factors Affecting Ampacity RatingsDocument3 pagesLow Voltage Non Motor Industrial Feeder Calculating Ampacity Ratings of Feeders Conductors Factors Affecting Ampacity RatingsRance FloresNo ratings yet

- FinalpptDocument23 pagesFinalpptPoojaNo ratings yet

- Applications of DC Generators - Electrical4uDocument6 pagesApplications of DC Generators - Electrical4uM Kumar MarimuthuNo ratings yet

- 100 Kva Isb CPG Parts CatlugeDocument62 pages100 Kva Isb CPG Parts CatlugeNikkikumar MaisuriyaNo ratings yet

- Ansa Price ListDocument1 pageAnsa Price ListPrakash RajNo ratings yet

- Electrical Motors - Frame Sizes PDFDocument5 pagesElectrical Motors - Frame Sizes PDFGustavo CuatzoNo ratings yet

- Long Answer Questions - CHP 'Sound'Document4 pagesLong Answer Questions - CHP 'Sound'SaachiNo ratings yet

- SST LifeDocument3 pagesSST Liferaj_kr1078No ratings yet

- The GMSG Guideline For Determining The Bond Efficiency of Industrial Gri...Document18 pagesThe GMSG Guideline For Determining The Bond Efficiency of Industrial Gri...jlfyNo ratings yet

- Wolbers Solvent Gel Kit: Instructions For UseDocument3 pagesWolbers Solvent Gel Kit: Instructions For UseMaria SberaNo ratings yet

- Vib FileDocument3 pagesVib FileJohn Louie PimentelNo ratings yet

- Lab Report For Epoxy Resin Polymer Concrete by GroupbbbbbbbDocument23 pagesLab Report For Epoxy Resin Polymer Concrete by GroupbbbbbbbBetelhem KifleNo ratings yet

- 17 Calefactor Electrico de DuctosDocument6 pages17 Calefactor Electrico de DuctosRene Arenas EnecalNo ratings yet

- Gebrauchsanweisung 20 Kaltlicht-Fontäne D-LIGHT P Instruction Manual 20 Cold Light Fountain D-LIGHT P Manual de Instrucciones 20 Fuente de Luz Fría D-LIGHT PDocument68 pagesGebrauchsanweisung 20 Kaltlicht-Fontäne D-LIGHT P Instruction Manual 20 Cold Light Fountain D-LIGHT P Manual de Instrucciones 20 Fuente de Luz Fría D-LIGHT PersinNo ratings yet

- Rish Split Current TransformerDocument6 pagesRish Split Current TransformerluisNo ratings yet

- AC Axial Compact Fan: W2E200-HK86-01Document5 pagesAC Axial Compact Fan: W2E200-HK86-01dhanasekhar27No ratings yet

- Technological University of The Philippines: The Students As A Graduate of The BSME Program Will Be Able ToDocument4 pagesTechnological University of The Philippines: The Students As A Graduate of The BSME Program Will Be Able ToMarvin Sarmiento TalimonganNo ratings yet

- Exercise 6 Chaks Pure MathematicsDocument2 pagesExercise 6 Chaks Pure MathematicsDenzel WhataNo ratings yet

- LEDW UL2 UL1R 3AR Eng Rev22Document143 pagesLEDW UL2 UL1R 3AR Eng Rev22david1210712No ratings yet

- Chemistry Form 6 Organic Chemistry Chapter 8: AmineDocument52 pagesChemistry Form 6 Organic Chemistry Chapter 8: AmineChin Bao ErNo ratings yet

- Operation Manual MTC CryostatDocument21 pagesOperation Manual MTC CryostatNikolay PenevNo ratings yet

- Assignment 3 - Mechanical VibrationDocument4 pagesAssignment 3 - Mechanical VibrationMusadiq ChaudhryNo ratings yet

- Norma ASTM E208-95aDocument13 pagesNorma ASTM E208-95aCésar 11nnNo ratings yet

- 6SL3210-1PB13-0UL0 Datasheet enDocument2 pages6SL3210-1PB13-0UL0 Datasheet enCintexNo ratings yet

- YTS-09 (XI Maths Sample Paper - O.P. GUPTA)Document5 pagesYTS-09 (XI Maths Sample Paper - O.P. GUPTA)SahilNo ratings yet

- Aqu4518r1-Pdf Antena TribandaDocument3 pagesAqu4518r1-Pdf Antena TribandaJonathan Gonzalez.LNo ratings yet

- Communication System Basics PDFDocument2 pagesCommunication System Basics PDFJerryNo ratings yet

- Relay S-3PH From 30A To 40A: Power ControllerDocument4 pagesRelay S-3PH From 30A To 40A: Power ControllerPrecila CanobidaNo ratings yet

- D BlockDocument18 pagesD BlockRaju SinghNo ratings yet

- The Formation of Heavier Elements During Star Formation and EvolutionDocument8 pagesThe Formation of Heavier Elements During Star Formation and EvolutionJohn Nerlo DequiñaNo ratings yet

- Mee1003 Engineering-Thermodynamics TH 1.1 47 Mee1003 13Document2 pagesMee1003 Engineering-Thermodynamics TH 1.1 47 Mee1003 13سيد محمود بن مسرورNo ratings yet