Professional Documents

Culture Documents

JSO Cable Drum (02 Sept.'07)

JSO Cable Drum (02 Sept.'07)

Uploaded by

Francis Enriquez TanCopyright:

Available Formats

You might also like

- Risk Assessment For External Façade & Canopies CleaningDocument8 pagesRisk Assessment For External Façade & Canopies CleaningFrancis Enriquez Tan100% (2)

- Ms For Tele Tower ErectionDocument12 pagesMs For Tele Tower ErectionSahabzada AamirNo ratings yet

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSDocument2 pagesProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohn100% (1)

- Trestles and StagingDocument2 pagesTrestles and Stagingdak comeiNo ratings yet

- 675Document2 pages675Rameese MuhammedNo ratings yet

- JAPL-F-HE-001-Weekly Grader Inspection ChecklistDocument2 pagesJAPL-F-HE-001-Weekly Grader Inspection ChecklistAli Hassan100% (1)

- Risk - Assessment - TelehandlerDocument11 pagesRisk - Assessment - TelehandlerCiaraNo ratings yet

- Risk Assessment: Project Name: Se-57, Construction of 10 Villas at Giardino VillageDocument5 pagesRisk Assessment: Project Name: Se-57, Construction of 10 Villas at Giardino VillageFrancis Enriquez Tan100% (4)

- Duke XC SL Race ServiceDocument10 pagesDuke XC SL Race ServicesilverapeNo ratings yet

- JSO Slip, Trips & Fall (27 Aug.'07)Document1 pageJSO Slip, Trips & Fall (27 Aug.'07)Francis Enriquez TanNo ratings yet

- Water Proofing JSADocument9 pagesWater Proofing JSARamNo ratings yet

- Storage of Chemical Risk AssessmentsDocument1 pageStorage of Chemical Risk AssessmentsMohammed Amer PashaNo ratings yet

- CamScanner 03-22-2023 07.44Document2 pagesCamScanner 03-22-2023 07.44Umar AliNo ratings yet

- Pha ExcavationDocument13 pagesPha ExcavationirshadNo ratings yet

- Excavation and Trenching Emergency Response PlanDocument9 pagesExcavation and Trenching Emergency Response PlanShannon Moore100% (1)

- JSA Gate Installation - 1 ProjectDocument4 pagesJSA Gate Installation - 1 ProjectMuhammad Umar GondalNo ratings yet

- Contractor Safety Induction Attendance SheetDocument2 pagesContractor Safety Induction Attendance SheetBalogun Isaac100% (1)

- Asm Risk Assesment fv2 PDFDocument3 pagesAsm Risk Assesment fv2 PDFshijadNo ratings yet

- SampleAHA - Core Drilling - SawCutting - Concrete - Asphalt - Wet MethodDocument1 pageSampleAHA - Core Drilling - SawCutting - Concrete - Asphalt - Wet MethodJaycee Bareng PagadorNo ratings yet

- Work Method Statement: Maxworks LTD Montebello, Pailles Mr. Georges Yueng Wye Kong 2086463Document15 pagesWork Method Statement: Maxworks LTD Montebello, Pailles Mr. Georges Yueng Wye Kong 2086463Vinaye GopaulNo ratings yet

- Incident Report: Proj. N. Unit Document Code Serial NDocument1 pageIncident Report: Proj. N. Unit Document Code Serial NSyed Ali HassanNo ratings yet

- 7-Block Work Risk Assessment ReportDocument7 pages7-Block Work Risk Assessment ReportSyed Ali Hassan100% (4)

- Al-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetDocument3 pagesAl-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetMustafa hse JafferNo ratings yet

- SOP SOP0022 Concrete Core DrillDocument3 pagesSOP SOP0022 Concrete Core Drillkristian08No ratings yet

- Completed Example of A Risk Assessment - Example 1Document3 pagesCompleted Example of A Risk Assessment - Example 1Rahil Tasawar0% (1)

- Environmental, Health and Safety Risks AnalysisDocument2 pagesEnvironmental, Health and Safety Risks AnalysisKrishna Patil100% (1)

- Job Hazard Analysis (Earth Mounted Tank)Document8 pagesJob Hazard Analysis (Earth Mounted Tank)jay RNo ratings yet

- Activity Hazard AnalysisDocument4 pagesActivity Hazard AnalysisGerrard Singh100% (1)

- Safety Data Sheet: ARDROX 907PB AerosolDocument11 pagesSafety Data Sheet: ARDROX 907PB Aerosolabdulbaset alselwi100% (1)

- Young Persons Risk Assessment V2.0 October 2021Document2 pagesYoung Persons Risk Assessment V2.0 October 2021Lucas SantosNo ratings yet

- RA Templates ElectricalDocument17 pagesRA Templates ElectricalAbid MujtabaNo ratings yet

- Confined Space Entry Program 11 2021Document16 pagesConfined Space Entry Program 11 2021zaka ullahNo ratings yet

- Job Hazard Safety & Environment Analysis (JHSEA) Worksheet: Operation/QYPXDocument2 pagesJob Hazard Safety & Environment Analysis (JHSEA) Worksheet: Operation/QYPXJb TiscubNo ratings yet

- Excavation and Trenching Procedure PDFDocument38 pagesExcavation and Trenching Procedure PDFjohn michael medinaNo ratings yet

- Working at Height Op (Eration Scaffolding Work Risk AssessmentDocument22 pagesWorking at Height Op (Eration Scaffolding Work Risk AssessmentAhmed Farman Alqaysi100% (1)

- MEPI - TBT Dated On 18.10.2020Document1 pageMEPI - TBT Dated On 18.10.2020Venkadesh PeriathambiNo ratings yet

- Qcs 2010 Section 11 Part 1.7 Regulatory Document - FIRE and FLAMMABLEDocument75 pagesQcs 2010 Section 11 Part 1.7 Regulatory Document - FIRE and FLAMMABLEbryanpastor106100% (1)

- Fan InstallationDocument2 pagesFan InstallationKrishna PatilNo ratings yet

- Trial Pit During ExcavationDocument3 pagesTrial Pit During Excavationmujahid1137No ratings yet

- SF20 - OKL04 Risk Assessment WeldingDocument2 pagesSF20 - OKL04 Risk Assessment WeldingMike BoyesNo ratings yet

- HIRA AssessmentDocument25 pagesHIRA AssessmentPanchdev KumarNo ratings yet

- Gsa Generic Office Risk Assessment Health and Safety OfficeDocument7 pagesGsa Generic Office Risk Assessment Health and Safety Officetest fypNo ratings yet

- Cutting WorkDocument1 pageCutting WorkGudduNo ratings yet

- Safe Work Method Statement: One World Place Manila, 32nd ST, Taguig, Metro ManilaDocument6 pagesSafe Work Method Statement: One World Place Manila, 32nd ST, Taguig, Metro Manilanani ferrerNo ratings yet

- SDS - Fenomastic Enamel Semigloss - English (Uk) - DubaiDocument5 pagesSDS - Fenomastic Enamel Semigloss - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- Instructions For Use: Hse-Pro-006A Asbestos Management - Minor Works SwmsDocument21 pagesInstructions For Use: Hse-Pro-006A Asbestos Management - Minor Works SwmsWinstone AudiNo ratings yet

- Operation: Electrical Installation Risk Assessment Assessor: DateDocument4 pagesOperation: Electrical Installation Risk Assessment Assessor: Dateم.عبدالرحيم سلمان100% (1)

- Job Hazard Analysis (Jha) Worksheet: Perform Forwork, Rebar and Concrete WorkDocument6 pagesJob Hazard Analysis (Jha) Worksheet: Perform Forwork, Rebar and Concrete WorkAbdul Khairul RiduanNo ratings yet

- Permit To Work Shafts and Elevators: Compliance ChecklistDocument1 pagePermit To Work Shafts and Elevators: Compliance ChecklistNeil Buyco VillamorNo ratings yet

- Risk Assessment/Management Form: Section / Dept: ActivityDocument2 pagesRisk Assessment/Management Form: Section / Dept: ActivityJack PNo ratings yet

- Absolute Rules DeclarationDocument1 pageAbsolute Rules DeclarationThandabantu MagengeleleNo ratings yet

- Jha Clarke Engine PumpDocument4 pagesJha Clarke Engine Pumpperquino oasanNo ratings yet

- PTW JHA Prayer Garment Hanging Rack InstallationDocument2 pagesPTW JHA Prayer Garment Hanging Rack InstallationPHH9834No ratings yet

- Anchor Bolt Setting - Rev 01Document26 pagesAnchor Bolt Setting - Rev 01Geherson AbustanNo ratings yet

- Compliance Record Folder Checklist For Consultants/ ContractorsDocument1 pageCompliance Record Folder Checklist For Consultants/ ContractorsNijasNo ratings yet

- Working at Heights Translab and PBDocument1 pageWorking at Heights Translab and PBCIDI Avida Towers VergeNo ratings yet

- Risk Asses 53-GPR Fitting AssemblyDocument6 pagesRisk Asses 53-GPR Fitting AssemblyRochdi BahiriNo ratings yet

- PlasteringDocument1 pagePlasteringAnna Marie Aranaydo100% (1)

- Jsa PolypipeDocument2 pagesJsa PolypipeHow Chin Engineering Sdn BhdNo ratings yet

- JSO 30° Radius (26 Aug.'07)Document1 pageJSO 30° Radius (26 Aug.'07)Francis Enriquez TanNo ratings yet

- Risk Assessment - 1059Document3 pagesRisk Assessment - 1059Francis Enriquez TanNo ratings yet

- 2021-10-02 - Ddab-Hse-Dor-Contraco - RBLDocument3 pages2021-10-02 - Ddab-Hse-Dor-Contraco - RBLFrancis Enriquez TanNo ratings yet

- Risk Assessment - 1106Document2 pagesRisk Assessment - 1106Francis Enriquez TanNo ratings yet

- Oct-Nov-WSO Newsletter-2022Document18 pagesOct-Nov-WSO Newsletter-2022Francis Enriquez TanNo ratings yet

- Method Statement For Scaffolding WorksDocument17 pagesMethod Statement For Scaffolding WorksFrancis Enriquez TanNo ratings yet

- 2021 - 10 - 04 - Ddab-Hse-Dor-Contraco - JJJDocument3 pages2021 - 10 - 04 - Ddab-Hse-Dor-Contraco - JJJFrancis Enriquez TanNo ratings yet

- Defensive DrivingDocument54 pagesDefensive DrivingFrancis Enriquez TanNo ratings yet

- Cleaning Window Risk AssessmentDocument3 pagesCleaning Window Risk AssessmentFrancis Enriquez TanNo ratings yet

- Daily Observation Report: Health, Safety & EnvironmentDocument3 pagesDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNo ratings yet

- Daily Observation Report: Health, Safety & EnvironmentDocument3 pagesDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNo ratings yet

- Daily Observation Report: Health, Safety & EnvironmentDocument3 pagesDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNo ratings yet

- 2021.10.2 - Ddab-Hse-Dor-Contraco - MDDocument2 pages2021.10.2 - Ddab-Hse-Dor-Contraco - MDFrancis Enriquez Tan100% (1)

- Daily Observation Report: Health, Safety & EnvironmentDocument3 pagesDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNo ratings yet

- 2021.10.2 - Ddab-Hse-Dor-Contraco - JJJDocument3 pages2021.10.2 - Ddab-Hse-Dor-Contraco - JJJFrancis Enriquez TanNo ratings yet

- 2021.10.02 - Ddab-Hse-Dor-Contraco - MNLDocument3 pages2021.10.02 - Ddab-Hse-Dor-Contraco - MNLFrancis Enriquez TanNo ratings yet

- 2021.10.02 - Ddab-Hse-Dor-Contraco - RFMDocument2 pages2021.10.02 - Ddab-Hse-Dor-Contraco - RFMFrancis Enriquez TanNo ratings yet

- Additional Guidance Unit 1Document5 pagesAdditional Guidance Unit 1Francis Enriquez TanNo ratings yet

- Ev05 - Safety Task Analysis Reduction - Star Card in Different LanguageDocument3 pagesEv05 - Safety Task Analysis Reduction - Star Card in Different LanguageFrancis Enriquez TanNo ratings yet

- Daily Observation Report: Health, Safety & EnvironmentDocument3 pagesDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNo ratings yet

- Ev04 - Behavioral Based Safety Training SlidesDocument21 pagesEv04 - Behavioral Based Safety Training SlidesFrancis Enriquez TanNo ratings yet

- Ev02 - Brief Program For New Work at Height CampaignDocument2 pagesEv02 - Brief Program For New Work at Height CampaignFrancis Enriquez TanNo ratings yet

- Risk Assessment: Project Name: Se-57, Construction of 10 Villas at Giardino VillageDocument11 pagesRisk Assessment: Project Name: Se-57, Construction of 10 Villas at Giardino VillageFrancis Enriquez TanNo ratings yet

- Assignment Nos. 3 - Scaffolding Risk AssessmentDocument11 pagesAssignment Nos. 3 - Scaffolding Risk AssessmentFrancis Enriquez Tan100% (2)

- RA For Block Works For 10 VillasDocument5 pagesRA For Block Works For 10 VillasFrancis Enriquez TanNo ratings yet

- Ev01 - Hse Induction Attendance SheetDocument5 pagesEv01 - Hse Induction Attendance SheetFrancis Enriquez TanNo ratings yet

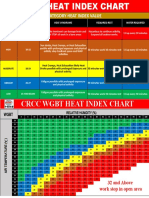

- Table 2 WGBTDocument3 pagesTable 2 WGBTFrancis Enriquez TanNo ratings yet

- Heat IndexDocument2 pagesHeat IndexFrancis Enriquez TanNo ratings yet

- JSO Slip, Trips & Fall (27 Aug.'07)Document1 pageJSO Slip, Trips & Fall (27 Aug.'07)Francis Enriquez TanNo ratings yet

- Pistons To JetsDocument41 pagesPistons To JetsRon Downey100% (2)

- 0 Theme 2 Stalin SOWDocument14 pages0 Theme 2 Stalin SOWEl DeNo ratings yet

- Earth SpecificationDocument20 pagesEarth SpecificationMohammad Hafiz MahadzirNo ratings yet

- Worksheet in Deloittes System Design DocumentDocument32 pagesWorksheet in Deloittes System Design Documentascentcommerce100% (1)

- 03 Molar Volume of A Gas Long ReportDocument5 pages03 Molar Volume of A Gas Long ReportHoomehr TayariyanNo ratings yet

- Geostr C: Engineering and Testing ServicesDocument2 pagesGeostr C: Engineering and Testing ServicesTechnical Priyanka GroupNo ratings yet

- Volume AdministrationDocument264 pagesVolume AdministrationeviyipyipNo ratings yet

- The Dino GameDocument1 pageThe Dino Game296 004 Aditya ChaudhariNo ratings yet

- On Arushi Murder CaseDocument8 pagesOn Arushi Murder Case0000No ratings yet

- Total DataDocument984 pagesTotal DataajayNo ratings yet

- Nepal National Building Code: Draft Final NBC 205: 2012Document52 pagesNepal National Building Code: Draft Final NBC 205: 2012Sudan ShresthaNo ratings yet

- Module 5 in Eed 114: ReviewDocument6 pagesModule 5 in Eed 114: ReviewYvi BenrayNo ratings yet

- SafeGrid Tutorial How To Perform A Simple Earthing DesignDocument10 pagesSafeGrid Tutorial How To Perform A Simple Earthing DesignAnwesh Kumar MaddikuntaNo ratings yet

- ThevoidsummaryDocument6 pagesThevoidsummaryVaibhav Mishra80% (5)

- Anullment CATHOLIC TRIBUNALDocument20 pagesAnullment CATHOLIC TRIBUNALMons Jr BaturianoNo ratings yet

- Item Wise Rate TenderDocument5 pagesItem Wise Rate TenderB-05 ISHA PATELNo ratings yet

- Simultaneous Equations O/LDocument13 pagesSimultaneous Equations O/LVenuja De SilvaNo ratings yet

- International Strategic Alliances 1Document21 pagesInternational Strategic Alliances 1mukesh93567No ratings yet

- LISI AEROSPACE - PULL-STEM™ and PULL-IN™ PinsDocument6 pagesLISI AEROSPACE - PULL-STEM™ and PULL-IN™ PinsLeandro González De CeccoNo ratings yet

- Quest Test 6 Wave Phenomena KEYDocument7 pagesQuest Test 6 Wave Phenomena KEYHa ViNo ratings yet

- Lecture 1 Part 1Document13 pagesLecture 1 Part 1Marianna KlosNo ratings yet

- TL Files Struktol Content Maerkte-Produkte Kautschuk-Additive en Technische-Merkblaetter 01032 WB16FLAKES GB TECHDocument2 pagesTL Files Struktol Content Maerkte-Produkte Kautschuk-Additive en Technische-Merkblaetter 01032 WB16FLAKES GB TECHJoban AroraNo ratings yet

- Resume of Noah C.D. HillDocument3 pagesResume of Noah C.D. HillNoah (AmericanGuy)No ratings yet

- Adam Izdebski & Michael Mulryan - Environment and Society in The Long LateDocument7 pagesAdam Izdebski & Michael Mulryan - Environment and Society in The Long Latecarlos murciaNo ratings yet

- G23002.18 - 04-Bus TieDocument30 pagesG23002.18 - 04-Bus TiemaxvanmaxNo ratings yet

- Refrigerant Changeover Guidelines CFC-12 To R-401ADocument7 pagesRefrigerant Changeover Guidelines CFC-12 To R-401AMaria DazaNo ratings yet

- Business Freedom: An Animated Powerpoint TemplateDocument19 pagesBusiness Freedom: An Animated Powerpoint TemplateKevin LpsNo ratings yet

- Product Description: Mark II Electric Fire Pump ControllersDocument2 pagesProduct Description: Mark II Electric Fire Pump ControllersBill Kerwin Nava JimenezNo ratings yet

JSO Cable Drum (02 Sept.'07)

JSO Cable Drum (02 Sept.'07)

Uploaded by

Francis Enriquez TanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSO Cable Drum (02 Sept.'07)

JSO Cable Drum (02 Sept.'07)

Uploaded by

Francis Enriquez TanCopyright:

Available Formats

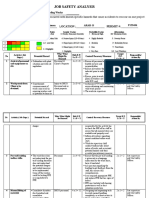

Instrument, Installation & Maintenance Co.

Job Safety Observation Report No: IMCO_JSO_27

P. O. Box 22803, Doha, Qatar

Tel no. 0974-466-79-10/23/24 REPORT Project Title: EPIC FOR POWER

SUPPLY TO DSSA & NWDH

Describe in detail the Job Safety Observation: (including scenarios and recommendations)

_________________________________________________________________________________________________

Date of Job Safety Observation: 02 Sept.’ 07 Time of JSO: 08:00 pm

Person Involved: Not Applicable Company Name: Inter Continental

Nationality: Not Applicable Badge Number: Sub Contractor

Location of Incident: Near Kahramaa substation IMCO Worksite Supervisor: Jojo Macasa & Ayan

Brief Description of incident:

At around 8:00 am during cable pulling and laying, I found out the unsafe condition of the cable drums loading

in the cable stand with stud shaft which is in improper position in the inclined area near kahramaa s/s while

they are pulling the cable, the rotation of the drum in the stud shaft is very fast and possible cause of hazards

if a drum comes drop to the ground and rolled down which is possible to injury to the workers or damage to

property.

Attach separate sheets if insufficient space; NOTE IMCO_FO_JSO_019a

Action Taken:

Immediately stop the job task and given instruction to minimized the speed of the pulling machine control to

prevent possible hazards which is causing to personnel injury or damage to property.

State actions taken to correct and prevent such occurrence: If closed what evidence have you to verify:

If still OPEN state measures for closure:

Recommendation;

1) Ensure that the work In-Charge in the site shall correct the unsafe act or unsafe condition noticed by an individual

and take measure to reduce the risk.

2) Prepare toolbox talks before start to job task and discuss the possible hazards in cable pulling using a machine.

3) Assign appropriate signalman in uneven distant location to prevent injury or damage to property.

4) Ensure to minimize the speed limit of pulling machine control.

5) If any unsafe acts of unsafe condition exist due to ignorance, explain the applicable Safety Rules and Regulation to

the workers involved and make him/them aware to the hazards.

6) Ensure that the Safety Rules and Regulation are adhered to and that relevant Safety Precaution is taken.

Confirm if Job Safety Observation is Open or Closed

OPEN CLOSED

If closed sign: Safety Officer: I hereby confirm that the Job Safety Observation has been closed and corrective preventive

methods applied

Signature: Roger P. Drillon Date open: Date closed:

Reported By: Reviewed and Checked by HSE In-Charge ONLY:

Name: Roger P. Drillon Name: Francis E. Tan

Signature: Date: Signature: Date:

Designation: Safety Officer Confirm closure if applicable

Are their attachments

YES NO Closed: YES NO

Form Created: 16_January_07 IMCO_FO_JSO_019

Form revision # : 0

Instrument, Installation & Maintenance Co. Job Safety Observation Report No: IMCO_JSO_27

P. O. Box 22803, Doha, Qatar

Tel no. 0974-466-79-10/23/24 REPORT Project Title: EPIC FOR POWER

SUPPLY TO DSSA & NWDH

Note: Form must be completed in all sections where possible; clear precise legible reporting must be made, ensure that any

attachments are correctly filled out and stabled or adequately clipped

Form Created: 16_January_07 IMCO_FO_JSO_019

Form revision # : 0

You might also like

- Risk Assessment For External Façade & Canopies CleaningDocument8 pagesRisk Assessment For External Façade & Canopies CleaningFrancis Enriquez Tan100% (2)

- Ms For Tele Tower ErectionDocument12 pagesMs For Tele Tower ErectionSahabzada AamirNo ratings yet

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSDocument2 pagesProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohn100% (1)

- Trestles and StagingDocument2 pagesTrestles and Stagingdak comeiNo ratings yet

- 675Document2 pages675Rameese MuhammedNo ratings yet

- JAPL-F-HE-001-Weekly Grader Inspection ChecklistDocument2 pagesJAPL-F-HE-001-Weekly Grader Inspection ChecklistAli Hassan100% (1)

- Risk - Assessment - TelehandlerDocument11 pagesRisk - Assessment - TelehandlerCiaraNo ratings yet

- Risk Assessment: Project Name: Se-57, Construction of 10 Villas at Giardino VillageDocument5 pagesRisk Assessment: Project Name: Se-57, Construction of 10 Villas at Giardino VillageFrancis Enriquez Tan100% (4)

- Duke XC SL Race ServiceDocument10 pagesDuke XC SL Race ServicesilverapeNo ratings yet

- JSO Slip, Trips & Fall (27 Aug.'07)Document1 pageJSO Slip, Trips & Fall (27 Aug.'07)Francis Enriquez TanNo ratings yet

- Water Proofing JSADocument9 pagesWater Proofing JSARamNo ratings yet

- Storage of Chemical Risk AssessmentsDocument1 pageStorage of Chemical Risk AssessmentsMohammed Amer PashaNo ratings yet

- CamScanner 03-22-2023 07.44Document2 pagesCamScanner 03-22-2023 07.44Umar AliNo ratings yet

- Pha ExcavationDocument13 pagesPha ExcavationirshadNo ratings yet

- Excavation and Trenching Emergency Response PlanDocument9 pagesExcavation and Trenching Emergency Response PlanShannon Moore100% (1)

- JSA Gate Installation - 1 ProjectDocument4 pagesJSA Gate Installation - 1 ProjectMuhammad Umar GondalNo ratings yet

- Contractor Safety Induction Attendance SheetDocument2 pagesContractor Safety Induction Attendance SheetBalogun Isaac100% (1)

- Asm Risk Assesment fv2 PDFDocument3 pagesAsm Risk Assesment fv2 PDFshijadNo ratings yet

- SampleAHA - Core Drilling - SawCutting - Concrete - Asphalt - Wet MethodDocument1 pageSampleAHA - Core Drilling - SawCutting - Concrete - Asphalt - Wet MethodJaycee Bareng PagadorNo ratings yet

- Work Method Statement: Maxworks LTD Montebello, Pailles Mr. Georges Yueng Wye Kong 2086463Document15 pagesWork Method Statement: Maxworks LTD Montebello, Pailles Mr. Georges Yueng Wye Kong 2086463Vinaye GopaulNo ratings yet

- Incident Report: Proj. N. Unit Document Code Serial NDocument1 pageIncident Report: Proj. N. Unit Document Code Serial NSyed Ali HassanNo ratings yet

- 7-Block Work Risk Assessment ReportDocument7 pages7-Block Work Risk Assessment ReportSyed Ali Hassan100% (4)

- Al-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetDocument3 pagesAl-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetMustafa hse JafferNo ratings yet

- SOP SOP0022 Concrete Core DrillDocument3 pagesSOP SOP0022 Concrete Core Drillkristian08No ratings yet

- Completed Example of A Risk Assessment - Example 1Document3 pagesCompleted Example of A Risk Assessment - Example 1Rahil Tasawar0% (1)

- Environmental, Health and Safety Risks AnalysisDocument2 pagesEnvironmental, Health and Safety Risks AnalysisKrishna Patil100% (1)

- Job Hazard Analysis (Earth Mounted Tank)Document8 pagesJob Hazard Analysis (Earth Mounted Tank)jay RNo ratings yet

- Activity Hazard AnalysisDocument4 pagesActivity Hazard AnalysisGerrard Singh100% (1)

- Safety Data Sheet: ARDROX 907PB AerosolDocument11 pagesSafety Data Sheet: ARDROX 907PB Aerosolabdulbaset alselwi100% (1)

- Young Persons Risk Assessment V2.0 October 2021Document2 pagesYoung Persons Risk Assessment V2.0 October 2021Lucas SantosNo ratings yet

- RA Templates ElectricalDocument17 pagesRA Templates ElectricalAbid MujtabaNo ratings yet

- Confined Space Entry Program 11 2021Document16 pagesConfined Space Entry Program 11 2021zaka ullahNo ratings yet

- Job Hazard Safety & Environment Analysis (JHSEA) Worksheet: Operation/QYPXDocument2 pagesJob Hazard Safety & Environment Analysis (JHSEA) Worksheet: Operation/QYPXJb TiscubNo ratings yet

- Excavation and Trenching Procedure PDFDocument38 pagesExcavation and Trenching Procedure PDFjohn michael medinaNo ratings yet

- Working at Height Op (Eration Scaffolding Work Risk AssessmentDocument22 pagesWorking at Height Op (Eration Scaffolding Work Risk AssessmentAhmed Farman Alqaysi100% (1)

- MEPI - TBT Dated On 18.10.2020Document1 pageMEPI - TBT Dated On 18.10.2020Venkadesh PeriathambiNo ratings yet

- Qcs 2010 Section 11 Part 1.7 Regulatory Document - FIRE and FLAMMABLEDocument75 pagesQcs 2010 Section 11 Part 1.7 Regulatory Document - FIRE and FLAMMABLEbryanpastor106100% (1)

- Fan InstallationDocument2 pagesFan InstallationKrishna PatilNo ratings yet

- Trial Pit During ExcavationDocument3 pagesTrial Pit During Excavationmujahid1137No ratings yet

- SF20 - OKL04 Risk Assessment WeldingDocument2 pagesSF20 - OKL04 Risk Assessment WeldingMike BoyesNo ratings yet

- HIRA AssessmentDocument25 pagesHIRA AssessmentPanchdev KumarNo ratings yet

- Gsa Generic Office Risk Assessment Health and Safety OfficeDocument7 pagesGsa Generic Office Risk Assessment Health and Safety Officetest fypNo ratings yet

- Cutting WorkDocument1 pageCutting WorkGudduNo ratings yet

- Safe Work Method Statement: One World Place Manila, 32nd ST, Taguig, Metro ManilaDocument6 pagesSafe Work Method Statement: One World Place Manila, 32nd ST, Taguig, Metro Manilanani ferrerNo ratings yet

- SDS - Fenomastic Enamel Semigloss - English (Uk) - DubaiDocument5 pagesSDS - Fenomastic Enamel Semigloss - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- Instructions For Use: Hse-Pro-006A Asbestos Management - Minor Works SwmsDocument21 pagesInstructions For Use: Hse-Pro-006A Asbestos Management - Minor Works SwmsWinstone AudiNo ratings yet

- Operation: Electrical Installation Risk Assessment Assessor: DateDocument4 pagesOperation: Electrical Installation Risk Assessment Assessor: Dateم.عبدالرحيم سلمان100% (1)

- Job Hazard Analysis (Jha) Worksheet: Perform Forwork, Rebar and Concrete WorkDocument6 pagesJob Hazard Analysis (Jha) Worksheet: Perform Forwork, Rebar and Concrete WorkAbdul Khairul RiduanNo ratings yet

- Permit To Work Shafts and Elevators: Compliance ChecklistDocument1 pagePermit To Work Shafts and Elevators: Compliance ChecklistNeil Buyco VillamorNo ratings yet

- Risk Assessment/Management Form: Section / Dept: ActivityDocument2 pagesRisk Assessment/Management Form: Section / Dept: ActivityJack PNo ratings yet

- Absolute Rules DeclarationDocument1 pageAbsolute Rules DeclarationThandabantu MagengeleleNo ratings yet

- Jha Clarke Engine PumpDocument4 pagesJha Clarke Engine Pumpperquino oasanNo ratings yet

- PTW JHA Prayer Garment Hanging Rack InstallationDocument2 pagesPTW JHA Prayer Garment Hanging Rack InstallationPHH9834No ratings yet

- Anchor Bolt Setting - Rev 01Document26 pagesAnchor Bolt Setting - Rev 01Geherson AbustanNo ratings yet

- Compliance Record Folder Checklist For Consultants/ ContractorsDocument1 pageCompliance Record Folder Checklist For Consultants/ ContractorsNijasNo ratings yet

- Working at Heights Translab and PBDocument1 pageWorking at Heights Translab and PBCIDI Avida Towers VergeNo ratings yet

- Risk Asses 53-GPR Fitting AssemblyDocument6 pagesRisk Asses 53-GPR Fitting AssemblyRochdi BahiriNo ratings yet

- PlasteringDocument1 pagePlasteringAnna Marie Aranaydo100% (1)

- Jsa PolypipeDocument2 pagesJsa PolypipeHow Chin Engineering Sdn BhdNo ratings yet

- JSO 30° Radius (26 Aug.'07)Document1 pageJSO 30° Radius (26 Aug.'07)Francis Enriquez TanNo ratings yet

- Risk Assessment - 1059Document3 pagesRisk Assessment - 1059Francis Enriquez TanNo ratings yet

- 2021-10-02 - Ddab-Hse-Dor-Contraco - RBLDocument3 pages2021-10-02 - Ddab-Hse-Dor-Contraco - RBLFrancis Enriquez TanNo ratings yet

- Risk Assessment - 1106Document2 pagesRisk Assessment - 1106Francis Enriquez TanNo ratings yet

- Oct-Nov-WSO Newsletter-2022Document18 pagesOct-Nov-WSO Newsletter-2022Francis Enriquez TanNo ratings yet

- Method Statement For Scaffolding WorksDocument17 pagesMethod Statement For Scaffolding WorksFrancis Enriquez TanNo ratings yet

- 2021 - 10 - 04 - Ddab-Hse-Dor-Contraco - JJJDocument3 pages2021 - 10 - 04 - Ddab-Hse-Dor-Contraco - JJJFrancis Enriquez TanNo ratings yet

- Defensive DrivingDocument54 pagesDefensive DrivingFrancis Enriquez TanNo ratings yet

- Cleaning Window Risk AssessmentDocument3 pagesCleaning Window Risk AssessmentFrancis Enriquez TanNo ratings yet

- Daily Observation Report: Health, Safety & EnvironmentDocument3 pagesDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNo ratings yet

- Daily Observation Report: Health, Safety & EnvironmentDocument3 pagesDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNo ratings yet

- Daily Observation Report: Health, Safety & EnvironmentDocument3 pagesDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNo ratings yet

- 2021.10.2 - Ddab-Hse-Dor-Contraco - MDDocument2 pages2021.10.2 - Ddab-Hse-Dor-Contraco - MDFrancis Enriquez Tan100% (1)

- Daily Observation Report: Health, Safety & EnvironmentDocument3 pagesDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNo ratings yet

- 2021.10.2 - Ddab-Hse-Dor-Contraco - JJJDocument3 pages2021.10.2 - Ddab-Hse-Dor-Contraco - JJJFrancis Enriquez TanNo ratings yet

- 2021.10.02 - Ddab-Hse-Dor-Contraco - MNLDocument3 pages2021.10.02 - Ddab-Hse-Dor-Contraco - MNLFrancis Enriquez TanNo ratings yet

- 2021.10.02 - Ddab-Hse-Dor-Contraco - RFMDocument2 pages2021.10.02 - Ddab-Hse-Dor-Contraco - RFMFrancis Enriquez TanNo ratings yet

- Additional Guidance Unit 1Document5 pagesAdditional Guidance Unit 1Francis Enriquez TanNo ratings yet

- Ev05 - Safety Task Analysis Reduction - Star Card in Different LanguageDocument3 pagesEv05 - Safety Task Analysis Reduction - Star Card in Different LanguageFrancis Enriquez TanNo ratings yet

- Daily Observation Report: Health, Safety & EnvironmentDocument3 pagesDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNo ratings yet

- Ev04 - Behavioral Based Safety Training SlidesDocument21 pagesEv04 - Behavioral Based Safety Training SlidesFrancis Enriquez TanNo ratings yet

- Ev02 - Brief Program For New Work at Height CampaignDocument2 pagesEv02 - Brief Program For New Work at Height CampaignFrancis Enriquez TanNo ratings yet

- Risk Assessment: Project Name: Se-57, Construction of 10 Villas at Giardino VillageDocument11 pagesRisk Assessment: Project Name: Se-57, Construction of 10 Villas at Giardino VillageFrancis Enriquez TanNo ratings yet

- Assignment Nos. 3 - Scaffolding Risk AssessmentDocument11 pagesAssignment Nos. 3 - Scaffolding Risk AssessmentFrancis Enriquez Tan100% (2)

- RA For Block Works For 10 VillasDocument5 pagesRA For Block Works For 10 VillasFrancis Enriquez TanNo ratings yet

- Ev01 - Hse Induction Attendance SheetDocument5 pagesEv01 - Hse Induction Attendance SheetFrancis Enriquez TanNo ratings yet

- Table 2 WGBTDocument3 pagesTable 2 WGBTFrancis Enriquez TanNo ratings yet

- Heat IndexDocument2 pagesHeat IndexFrancis Enriquez TanNo ratings yet

- JSO Slip, Trips & Fall (27 Aug.'07)Document1 pageJSO Slip, Trips & Fall (27 Aug.'07)Francis Enriquez TanNo ratings yet

- Pistons To JetsDocument41 pagesPistons To JetsRon Downey100% (2)

- 0 Theme 2 Stalin SOWDocument14 pages0 Theme 2 Stalin SOWEl DeNo ratings yet

- Earth SpecificationDocument20 pagesEarth SpecificationMohammad Hafiz MahadzirNo ratings yet

- Worksheet in Deloittes System Design DocumentDocument32 pagesWorksheet in Deloittes System Design Documentascentcommerce100% (1)

- 03 Molar Volume of A Gas Long ReportDocument5 pages03 Molar Volume of A Gas Long ReportHoomehr TayariyanNo ratings yet

- Geostr C: Engineering and Testing ServicesDocument2 pagesGeostr C: Engineering and Testing ServicesTechnical Priyanka GroupNo ratings yet

- Volume AdministrationDocument264 pagesVolume AdministrationeviyipyipNo ratings yet

- The Dino GameDocument1 pageThe Dino Game296 004 Aditya ChaudhariNo ratings yet

- On Arushi Murder CaseDocument8 pagesOn Arushi Murder Case0000No ratings yet

- Total DataDocument984 pagesTotal DataajayNo ratings yet

- Nepal National Building Code: Draft Final NBC 205: 2012Document52 pagesNepal National Building Code: Draft Final NBC 205: 2012Sudan ShresthaNo ratings yet

- Module 5 in Eed 114: ReviewDocument6 pagesModule 5 in Eed 114: ReviewYvi BenrayNo ratings yet

- SafeGrid Tutorial How To Perform A Simple Earthing DesignDocument10 pagesSafeGrid Tutorial How To Perform A Simple Earthing DesignAnwesh Kumar MaddikuntaNo ratings yet

- ThevoidsummaryDocument6 pagesThevoidsummaryVaibhav Mishra80% (5)

- Anullment CATHOLIC TRIBUNALDocument20 pagesAnullment CATHOLIC TRIBUNALMons Jr BaturianoNo ratings yet

- Item Wise Rate TenderDocument5 pagesItem Wise Rate TenderB-05 ISHA PATELNo ratings yet

- Simultaneous Equations O/LDocument13 pagesSimultaneous Equations O/LVenuja De SilvaNo ratings yet

- International Strategic Alliances 1Document21 pagesInternational Strategic Alliances 1mukesh93567No ratings yet

- LISI AEROSPACE - PULL-STEM™ and PULL-IN™ PinsDocument6 pagesLISI AEROSPACE - PULL-STEM™ and PULL-IN™ PinsLeandro González De CeccoNo ratings yet

- Quest Test 6 Wave Phenomena KEYDocument7 pagesQuest Test 6 Wave Phenomena KEYHa ViNo ratings yet

- Lecture 1 Part 1Document13 pagesLecture 1 Part 1Marianna KlosNo ratings yet

- TL Files Struktol Content Maerkte-Produkte Kautschuk-Additive en Technische-Merkblaetter 01032 WB16FLAKES GB TECHDocument2 pagesTL Files Struktol Content Maerkte-Produkte Kautschuk-Additive en Technische-Merkblaetter 01032 WB16FLAKES GB TECHJoban AroraNo ratings yet

- Resume of Noah C.D. HillDocument3 pagesResume of Noah C.D. HillNoah (AmericanGuy)No ratings yet

- Adam Izdebski & Michael Mulryan - Environment and Society in The Long LateDocument7 pagesAdam Izdebski & Michael Mulryan - Environment and Society in The Long Latecarlos murciaNo ratings yet

- G23002.18 - 04-Bus TieDocument30 pagesG23002.18 - 04-Bus TiemaxvanmaxNo ratings yet

- Refrigerant Changeover Guidelines CFC-12 To R-401ADocument7 pagesRefrigerant Changeover Guidelines CFC-12 To R-401AMaria DazaNo ratings yet

- Business Freedom: An Animated Powerpoint TemplateDocument19 pagesBusiness Freedom: An Animated Powerpoint TemplateKevin LpsNo ratings yet

- Product Description: Mark II Electric Fire Pump ControllersDocument2 pagesProduct Description: Mark II Electric Fire Pump ControllersBill Kerwin Nava JimenezNo ratings yet