Professional Documents

Culture Documents

User Manual THC3T 02 - V103

User Manual THC3T 02 - V103

Uploaded by

tarom nasteknikaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

User Manual THC3T 02 - V103

User Manual THC3T 02 - V103

Uploaded by

tarom nasteknikaCopyright:

Available Formats

ROBOT3T

THC3T-02 UP/DOWN OPERATION MANUAL

sf

Version 1.0.3

Copyright 2018 by Robot3T

Table of Contents

1. Device information ........................................................................................................ 3

1.1 Introduction ................................................................................................................ 3

1.2 Specifications ............................................................................................................. 4

1.3 Mainboard .................................................................................................................. 5

1.4 Divider board ............................................................................................................. 6

2. Setup parameters ........................................................................................................... 7

3. Signals summary of THC3T-02 .................................................................................... 8

3.1 Power supply .............................................................................................................. 8

3.2 Arc-voltage ................................................................................................................. 8

3.3 Potentiometer ........................................................................................................... 11

3.4 Output ACR_OK, THC_UP & THC_DOWN (OPTO) ........................................... 12

4. Fast connect .................................................................................................................. 13

5. Fault processing ........................................................................................................... 16

6. Example for MACH3 configuration: ......................................................................... 17

7. Warranty Period and Coverage ................................................................................. 19

7.1 Warranty Period ....................................................................................................... 19

7.2 Warranty coverage ................................................................................................... 19

7.3 Notes on safety ......................................................................................................... 19

ROBOT3T- 3C MACHINERY CO., LTD

6/4, 328 Cao Lo Street, Ward 4, District 8, Hochiminh City, Vietnam

Email: sales@robot3t.com

(+84) 97-490-8615

1. Device information

1.1 Introduction

Compact THC3T-02 with up/down output uses arc voltage to maintain a consistent

distance from the plate while the torch is cutting. This allows the system to maintain proper

torch height regardless of variations in the material, of flatness of the cutting bed.

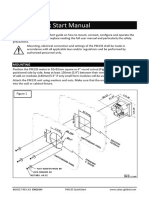

Simplified block diagram:

Fig1. Block diagram

The THC3T-02 package includes:

- 1 main board;

- 1 divider board;

- 1 potentiometer + cables.

USER MANUAL THC3T-02 UP/DOWN Page 3 | 20

ROBOT3T- 3C MACHINERY CO., LTD

6/4, 328 Cao Lo Street, Ward 4, District 8, Hochiminh City, Vietnam

Email: sales@robot3t.com

(+84) 97-490-8615

1.2 Specifications

- Using the potentiometer to set height’s torch

- Voltage divider and noise to obtain the raw signal from the plasma cutting

- Using signal processing an algorithms to derive the voltage stability of the plasma

- Apply an algorithm to support smooth motion.

- Auto calib the arc voltage with any plasma cutter

- Auto detect ARC OK

- Easy to connection, just three outputs: UP, DOWN, ARC OK

- Integrated voltage divider 1:50.

- This version is specify to integrated with Mach3 and LinuxCNC software.

Fig2. Connection diagram

USER MANUAL THC3T-02 UP/DOWN Page 4 | 20

ROBOT3T- 3C MACHINERY CO., LTD

6/4, 328 Cao Lo Street, Ward 4, District 8, Hochiminh City, Vietnam

Email: sales@robot3t.com

(+84) 97-490-8615

1.3 Mainboard

LEDs Status:

- Power red LED; Run yellow LED (THC ready); Height

green LED (Torch height OK);

- LED1 display “Up”, “Down”, “Height” status of Z-axis;

- LED2 is arc-voltage value from plasma cutter.

LED

LED2

1

Buttons:

- Menu: To change mode

- Up, Down: To change the

display or data in each mode.

Fig3. Main board

USER MANUAL THC3T-02 UP/DOWN Page 5 | 20

ROBOT3T- 3C MACHINERY CO., LTD

6/4, 328 Cao Lo Street, Ward 4, District 8, Hochiminh City, Vietnam

Email: sales@robot3t.com

(+84) 97-490-8615

The main parameters of the master board:

Table1. Main parameter

Parameter name Acceptable

Supply voltage 24 - 36V DC/2A

Maximum arc-voltage 660VDC

Maximum input voltage of 1:50 divider 6.6VDC

Maximum current of output relays 150mA/100VDC

Weight 300g

External Dimensions (L * W * H) 95x110x45[mm]

1.4 Divider board

Fig4. Divider board

SW MODE

DIVIDER SW 1 SW 2 Description

100:1 ON ON Voltage divide ratio 1:100

OFF ON

50:1 Voltage divide ratio 1:50

ON OFF

EXT- Voltage input of 1:50

OFF OFF

50:1 divider EXT(extension)

USER MANUAL THC3T-02 UP/DOWN Page 6 | 20

ROBOT3T- 3C MACHINERY CO., LTD

6/4, 328 Cao Lo Street, Ward 4, District 8, Hochiminh City, Vietnam

Email: sales@robot3t.com

(+84) 97-490-8615

2 Setup parameters

Press the “menu” button to choice mode need to set:

Table2. Parameters on LED display

No Mode Value Description

1 U Set-height To set height from torch to material in

U10 to U300 auto mode by the potentiometer.

2 A Area for control Device will change to auto mode when

A001 to A050 the arc voltage from:

[Voltage Set - Area for control] to

[Voltage Set + Area for control]

3 S Sensitive This parameter determines the value

S100 to S800 respond of Z axis motion.

4 P Arc-voltage Display the arc voltage value from

P000 to P300 plasma cutter.

5 d Delay time The delay time to send ARC_OK from

d001 to d099 0.1 to 10s: THC will sent ARC_OK

signal after this delay, the main purpose

is Z axis not move down at the first time

of cutting.

6 v Run speed Change speed of motor from 0 to 100%

v001 to v099 of max speed. This parameter only affect

in STEP/DIR version.

7 SW1 ON or OFF Change the direction of Z motor.

USER MANUAL THC3T-02 UP/DOWN Page 7 | 20

ROBOT3T- 3C MACHINERY CO., LTD

6/4, 328 Cao Lo Street, Ward 4, District 8, Hochiminh City, Vietnam

Email: sales@robot3t.com

(+84) 97-490-8615

3 Signals summary of THC3T-02

3.1 Power supply

24-36V DC

GND

Fig5. Power Supply

3.2 Arc-voltage

When connecting directly, use the shortest possible cables for connecting the plasma

cutter with THC controller - it is recommended the THC controller to be mounted directly

at the plasma cutter.

USER MANUAL THC3T-02 UP/DOWN Page 8 | 20

ROBOT3T- 3C MACHINERY CO., LTD

6/4, 328 Cao Lo Street, Ward 4, District 8, Hochiminh City, Vietnam

Email: sales@robot3t.com

(+84) 97-490-8615

Fig 6. Connect ARC-voltage from divider board

USER MANUAL THC3T-02 UP/DOWN Page 9 | 20

ROBOT3T- 3C MACHINERY CO., LTD

6/4, 328 Cao Lo Street, Ward 4, District 8, Hochiminh City, Vietnam

Email: sales@robot3t.com

(+84) 97-490-8615

Fig 7: Connecting the plasma source with DIVIDER

While being a universal THC, accepting full raw arc voltage for most any

plasma cutter on the market, an exciting new standard feature of this unit is the

addition of a 1:50 divider for an extremely fast, simple installation on most major

brands. There will most likely be a direct connection for this on the outside of the

plasma cutter's unit. Please refer to your plasma cutter owner's manual.

An example of how to connect the THC controller's measurement input with

the output of the very popular Hypertherm Powermax45® - The THC comes

USER MANUAL THC3T-02 UP/DOWN Page 10 | 20

ROBOT3T- 3C MACHINERY CO., LTD

6/4, 328 Cao Lo Street, Ward 4, District 8, Hochiminh City, Vietnam

Email: sales@robot3t.com

(+84) 97-490-8615

standard equipped with a low voltage output of 1:50 divider. This ratio is the

most commonly used division in most major brands and there will most likely be

a plug for this connection on the outside of the cutter's unit.

Fig8. Plasma cutter with voltage divider 1:50 output

3.3 Potentiometer

To set height from torch to material by the potentiometer. (U mode on LEDs display)

Fig9. Connect potentiometer

USER MANUAL THC3T-02 UP/DOWN Page 11 | 20

ROBOT3T- 3C MACHINERY CO., LTD

6/4, 328 Cao Lo Street, Ward 4, District 8, Hochiminh City, Vietnam

Email: sales@robot3t.com

(+84) 97-490-8615

3.4 Output ACR_OK, THC_UP & THC_DOWN (OPTO)

If the device operated at auto mode, ARC_OK signal is activated.

THC_DOWN

EXT_COM

ARC_OK

THC_UP

INPUT3

INPUT2

INPUT1

GND

BREAKOUT

BOARD

GND

Fig10. Arc_Ok, THC_UP & THC_DOWN outputs signal

USER MANUAL THC3T-02 UP/DOWN Page 12 | 20

ROBOT3T- 3C MACHINERY CO., LTD

6/4, 328 Cao Lo Street, Ward 4, District 8, Hochiminh City, Vietnam

Email: sales@robot3t.com

(+84) 97-490-8615

4. Fast connect

Step 1: Turn off the plasma cutter.

Step 2: Connect power supply.

24-36V DC

GND

Fig11. Power Supply

- After switching power on, red LED is turn on, the THC controller's display

shows "cthc" message, a flashing voltage value is presented for 2 seconds and

then run yellow LED blink Turn off THC power and go to Step 3.

- In case of, power LED, run LED or LED 4 digit 7 segment display not turn on

Error.1-page.16

Step 3: Arc_Ok, THC_DOWN & THC_UP output.

THC_DO

EXT_CO

ARC_OK

THC_UP

WN

M

INPUT

INPUT

INPUT

GND

Fig12. Arc_Ok, THC_UP

BREAKOUT

& THC_DOWN outputs signal

BOARD

USER MANUAL THC3T-02 UP/DOWN Page 13 | 20

ROBOT3T- 3C MACHINERY CO., LTD

6/4, 328 Cao Lo Street, Ward 4, District 8, Hochiminh City, Vietnam

Email: sales@robot3t.com

(+84) 97-490-8615

Step 4: Connect Arc-voltage (page.8&9)

- Turn on THC3T-02 and wait yellow LED blink. Press the“menu” button 4-

times to select “P” mode (fig.13-page.14).

Fig13. ARC-voltage parameter

- Turn on plasma cutter and read arc-voltage area on LED display (example:

Arc-voltage area from 110 to 120) Turn off the plasma cutter and go to

step 5.

- In case of, THC doesn’t have arc-voltage Error.3-page.16

Step 5: Press “menu” button to select “U” mode and using the potentiometer to set

“set-height” parameter value (fig.14-page.14)

- Example: If arc-voltage area on “P” mode from 145 to 155 then:

Set-height = (145+155)/2=150.

Fig14. Voltage set-point parameter

Step 6: Press “menu” button to select “A” mode (fig.15-page.15). This parameter

value set about 30. Device will change to auto mode when:

USER MANUAL THC3T-02 UP/DOWN Page 14 | 20

ROBOT3T- 3C MACHINERY CO., LTD

6/4, 328 Cao Lo Street, Ward 4, District 8, Hochiminh City, Vietnam

Email: sales@robot3t.com

(+84) 97-490-8615

[Set-height – Area for control] < Arc_voltage < [Set-height + Area for

control]

- Example: “U” mode: Set-height = 150;

“A” mode: Area for control = 30.

Device will change to auto mode and turn on relay ARC_OK when:

120 < Arc_volatge < 180.

Fig15. Area for control parameter

Arc_voltage = Set-height Height green LED turn on

Arc_voltage > Set-height THC_DOWN signal is activated

Arc_voltage < Set-height THC_UP signal is activated

Step 7: Press “menu” button to select work-screen (fig.16-page.15) and turn on the

plasma cutter to using.

Fig16. Area for control parameter

All parameters updated online during operation.

USER MANUAL THC3T-02 UP/DOWN Page 15 | 20

ROBOT3T- 3C MACHINERY CO., LTD

6/4, 328 Cao Lo Street, Ward 4, District 8, Hochiminh City, Vietnam

Email: sales@robot3t.com

(+84) 97-490-8615

5. Fault processing

No. Code Name Causes Countermeasures

-The THC is broken;

-Replace the THC;

-The power is not

Power -Connect the power supply;

1 Error.1 connected;

fault -Check that the power line is

-The line of power supply

wired correctly;

is broken

-Replace the power cable

-The power of the plasma -Connect the power supply;

cutter is not connected; -Check that the arc voltage

Arc-

-The line of arc-voltage line is wired correctly or

2 Error.2 voltage

from divider board to THC

fault replace;

is broken or not connected;

- The THC is broken; -Replace the THC.

-The signal is not

-Check that the relay line is

activated;

wired correctly or replace;

-Don’t have arc-voltage;

-Check that the arc voltage

Outputs -[Arc voltage > (set-

3 Error.3 line is wired correctly or

fault point)

replace;

+ (Area of control)] or

-Set parameters on “U” mode

[Arc-voltage < (set-point)

and “A” mode.

– (area of control)]

USER MANUAL THC3T-02 UP/DOWN Page 16 | 20

ROBOT3T- 3C MACHINERY CO., LTD

6/4, 328 Cao Lo Street, Ward 4, District 8, Hochiminh City, Vietnam

Email: sales@robot3t.com

(+84) 97-490-8615

6. Example for MACH3 configuration:

Fig17. Port setup and Axis selection

Fig18. Input signals

USER MANUAL THC3T-02 UP/DOWN Page 17 | 20

ROBOT3T- 3C MACHINERY CO., LTD

6/4, 328 Cao Lo Street, Ward 4, District 8, Hochiminh City, Vietnam

Email: sales@robot3t.com

(+84) 97-490-8615

Fig19. Mill options

Fig20. Motor turning Z axis

User need to config steps per, velocity and acceleration suitable to your system.

USER MANUAL THC3T-02 UP/DOWN Page 18 | 20

ROBOT3T- 3C MACHINERY CO., LTD

6/4, 328 Cao Lo Street, Ward 4, District 8, Hochiminh City, Vietnam

Email: sales@robot3t.com

(+84) 97-490-8615

7. Warranty Period and Coverage

7.1 Warranty Period

12 months after being shipped from our factory.

7.2 Warranty coverage

During the warranty period, we will repair without charge any problems on the

board that occurredwhile it was being used appropriately, and where the cause of

the problem is due to us.

However, the following cases will be not be covered by the warranty, even if the

warranty period has not expired.

- Problems caused by inappropriate handling or use.

- Problems caused by using parts not made or approved by us.

- Problems caused by modifications made to the board that was not authorized by

ROBOT3T.

- Problems caused by disasters, accidents, or fires.

We warranty only the product as delivered, and we do not accept responsibility for

any loss caused by a fault in our product. We will repair the board when the user

sends it to our plant

7.3 Notes on safety

Improper use or disregard of these warnings may result in the injury or death of

people.

Do not, in any manner, process, take apart, or make changes to this product.

When installing this product, we recommend that if technical knowledge

becomes necessary please consult a qualified mechanic.

Do not operate this product with wet hands, wet gloves, or any wet clothing.

Before turning the unit on, secure the safety of others, and read and

understand

all instructions. If you have any questions or concerns, do not continue.

USER MANUAL THC3T-02 UP/DOWN Page 19 | 20

ROBOT3T- 3C MACHINERY CO., LTD

6/4, 328 Cao Lo Street, Ward 4, District 8, Hochiminh City, Vietnam

Email: sales@robot3t.com

(+84) 97-490-8615

After assembly, secure protection of contact terminals from the operator's

touch.

For more information, please do not hesitate to contact us at:

E-mail: sales@robot3t.com

Website: www.robot3t.com

Thank you for purchasing ROBOT3T product.

Please read this manual carefully and keep it for future reference.

USER MANUAL THC3T-02 UP/DOWN Page 20 | 20

You might also like

- !user Manual SOCT Copernicus Ver. 4.2 Rev.0.01 PDFDocument108 pages!user Manual SOCT Copernicus Ver. 4.2 Rev.0.01 PDFchafic WEISS100% (2)

- Dell Optiplex 780 Arrowhead Ra03Document45 pagesDell Optiplex 780 Arrowhead Ra03okeinfoNo ratings yet

- Description Power Range: Analog Servo DriveDocument8 pagesDescription Power Range: Analog Servo DriveElectromateNo ratings yet

- 1/16 Din Microbased Controller: Operators ManualDocument69 pages1/16 Din Microbased Controller: Operators ManualJosue Camacho100% (2)

- EB Tester Software User Manual V1.8.5Document16 pagesEB Tester Software User Manual V1.8.5ORLANDO VERDUGO100% (1)

- Sel-487b-1 5aDocument2 pagesSel-487b-1 5aAbelardo Estebanez NietoNo ratings yet

- User Manual Thc3t-02 v104 UpdownDocument21 pagesUser Manual Thc3t-02 v104 UpdownCRISTIANE CARDOSO DA SILVANo ratings yet

- Description Power Range: Analog Servo DriveDocument9 pagesDescription Power Range: Analog Servo DriveElectromateNo ratings yet

- Capacitive Torch Height Controller CHC 200f For CNC Flame Cutting MachineDocument17 pagesCapacitive Torch Height Controller CHC 200f For CNC Flame Cutting MachineAlaa Abu KhurjNo ratings yet

- Description Power Range: Analog Servo DriveDocument9 pagesDescription Power Range: Analog Servo DriveElectromateNo ratings yet

- Description Power Range: Analog Servo DriveDocument8 pagesDescription Power Range: Analog Servo DriveElectromateNo ratings yet

- 3 Axis TB6560 CNC Driver Board Users ManualDocument13 pages3 Axis TB6560 CNC Driver Board Users ManualJoão Luis Paiva JuniorNo ratings yet

- Description Power Range: Analog Servo DriveDocument9 pagesDescription Power Range: Analog Servo DriveElectromateNo ratings yet

- 25 A 20Document9 pages25 A 20s_barriosNo ratings yet

- User Manual: Hat530 Ats ControllerDocument26 pagesUser Manual: Hat530 Ats Controllerrjcp01No ratings yet

- Advanced Motion Controls S100a20Document8 pagesAdvanced Motion Controls S100a20ElectromateNo ratings yet

- Hat530n en ManualDocument19 pagesHat530n en Manualdario sanchezNo ratings yet

- SF-H25G Plasma Height ControlDocument23 pagesSF-H25G Plasma Height ControlgabrielNo ratings yet

- Advanced Motion Controls S16a8Document8 pagesAdvanced Motion Controls S16a8ElectromateNo ratings yet

- PM135 QuickstartDocument4 pagesPM135 QuickstartNguyen Danh HuyNo ratings yet

- Description Power Range: Analog Servo DriveDocument8 pagesDescription Power Range: Analog Servo DriveElectromateNo ratings yet

- Analog Servo Drive: Description Power RangeDocument9 pagesAnalog Servo Drive: Description Power RangeElectromateNo ratings yet

- Emko ATS10 Eng Short v00 PDFDocument6 pagesEmko ATS10 Eng Short v00 PDFCarmen Serbanoiu33% (3)

- Analog Servo Drive: Description Power RangeDocument9 pagesAnalog Servo Drive: Description Power RangeElectromateNo ratings yet

- Amc 12a8 SpecsheetDocument9 pagesAmc 12a8 SpecsheetElectromateNo ratings yet

- CMXC 007 Service Manual 003038-9Document9 pagesCMXC 007 Service Manual 003038-9Siding BarroNo ratings yet

- ELS-DR-Dual Relay Tilt SwitchDocument5 pagesELS-DR-Dual Relay Tilt SwitchKrum KashavarovNo ratings yet

- Analog Servo Drive: Description Power RangeDocument9 pagesAnalog Servo Drive: Description Power RangeElectromateNo ratings yet

- Description Power Range: Analog Servo DriveDocument8 pagesDescription Power Range: Analog Servo DriveElectromateNo ratings yet

- Description Power Range: Analog Servo DriveDocument8 pagesDescription Power Range: Analog Servo DriveElectromateNo ratings yet

- PM135 Quick Start Manual: Win A Tablet!Document4 pagesPM135 Quick Start Manual: Win A Tablet!Vũ MinhNo ratings yet

- Azbh 12 A 8Document8 pagesAzbh 12 A 8ElectromateNo ratings yet

- Tps Can Ban Can San TPSSERI DHDocument18 pagesTps Can Ban Can San TPSSERI DHdaocongdablNo ratings yet

- Pz96l-3eh Manual PDFDocument15 pagesPz96l-3eh Manual PDFadrianomajoneNo ratings yet

- Instrucciones Variador de FrecuenciaDocument40 pagesInstrucciones Variador de FrecuenciahalfonsoNo ratings yet

- Description Power Range: Analog Servo DriveDocument8 pagesDescription Power Range: Analog Servo DriveElectromateNo ratings yet

- Analog Servo Drive: Description Power RangeDocument9 pagesAnalog Servo Drive: Description Power RangeElectromateNo ratings yet

- 87 - Ams4a062!63!64 Winch Operators Panel RevdDocument48 pages87 - Ams4a062!63!64 Winch Operators Panel RevdNickUS79No ratings yet

- Description Power Range: Analog Servo DriveDocument8 pagesDescription Power Range: Analog Servo DriveElectromateNo ratings yet

- Analog Servo Drive: Description Power RangeDocument9 pagesAnalog Servo Drive: Description Power RangeElectromateNo ratings yet

- Description Power Range: Analog Servo DriveDocument8 pagesDescription Power Range: Analog Servo DriveElectromateNo ratings yet

- Analog Servo Drive: Description Power RangeDocument8 pagesAnalog Servo Drive: Description Power RangeElectromateNo ratings yet

- SEA2M68 Stepper Motor Driver - Shenzhen Instar Electromechanical Technology Development Co., LTDDocument6 pagesSEA2M68 Stepper Motor Driver - Shenzhen Instar Electromechanical Technology Development Co., LTDKunal SupekarNo ratings yet

- Analog Servo Drive: Description Power RangeDocument9 pagesAnalog Servo Drive: Description Power RangeElectromateNo ratings yet

- Corona Treater: Operation and MainenanceDocument34 pagesCorona Treater: Operation and MainenanceJUAN RODRIGUEZNo ratings yet

- Huong Dan Cai Dat (OMT) CombaDocument12 pagesHuong Dan Cai Dat (OMT) Combahutech2000No ratings yet

- AQ3485Y ManualDocument15 pagesAQ3485Y ManualVu SonNo ratings yet

- User Manual: HGM6310D/6320D Auto Start ModuleDocument35 pagesUser Manual: HGM6310D/6320D Auto Start ModuleVaam Group sasNo ratings yet

- PAFM100W81 Rev5.2Document6 pagesPAFM100W81 Rev5.2Juan Enrique Castillo CanoNo ratings yet

- Ontime THC AVC118 ManualDocument27 pagesOntime THC AVC118 ManualNawres ArifNo ratings yet

- Pm1000 Quickstart Guide-SchneiderDocument8 pagesPm1000 Quickstart Guide-SchneiderTran Le100% (1)

- Smart Motor Devices: Programmable Step Motor Controller Smsd-4.2Lan and Smsd-8.0LanDocument12 pagesSmart Motor Devices: Programmable Step Motor Controller Smsd-4.2Lan and Smsd-8.0LanIvanNo ratings yet

- Amc B15a8 SpecsheetDocument8 pagesAmc B15a8 SpecsheetElectromateNo ratings yet

- RT-300 Industrial JoystickDocument13 pagesRT-300 Industrial JoystickRunnTechNo ratings yet

- Neuron Simplicity User ManualDocument45 pagesNeuron Simplicity User ManualShane MurrayNo ratings yet

- VFDL Frekvenciavalto ENGDocument16 pagesVFDL Frekvenciavalto ENGreghieNo ratings yet

- PM835 Panel Meter User ManualDocument24 pagesPM835 Panel Meter User ManualRENUS UPT MEDANNo ratings yet

- MDRC29 Rev 1Document5 pagesMDRC29 Rev 1haris_fikriNo ratings yet

- Analog Servo Drive: Description Power RangeDocument9 pagesAnalog Servo Drive: Description Power RangeElectromateNo ratings yet

- Checklist 3 Buoc Chua Diec Tieng AnhDocument16 pagesChecklist 3 Buoc Chua Diec Tieng AnhĐồng Nai CTNo ratings yet

- Description Power Range: Analog Servo DriveDocument8 pagesDescription Power Range: Analog Servo DriveElectromateNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Trex ManualDocument214 pagesTrex ManualOmar AlfaroNo ratings yet

- Product Description (V100R002 - 03)Document142 pagesProduct Description (V100R002 - 03)zerocreatividadNo ratings yet

- Denon AVR X4300H Service ManualDocument247 pagesDenon AVR X4300H Service ManualMichelNo ratings yet

- Inteligen NTC Basebox DatabladDocument4 pagesInteligen NTC Basebox DatabladWilliam Will Controle WoodwardNo ratings yet

- L1740PQDocument25 pagesL1740PQlpenialver1No ratings yet

- A Seminar Report ON "ZEN Technology" Mr. Ajay V. Zambad: Final Year (Master of Computer Management (M.C.M.)Document21 pagesA Seminar Report ON "ZEN Technology" Mr. Ajay V. Zambad: Final Year (Master of Computer Management (M.C.M.)api-3707156No ratings yet

- AssigmentDocument11 pagesAssigmentYonatan GizawNo ratings yet

- WINSEM2021-22 BECE101L TH VL2021220505625 Reference Material I 15-02-2022 Basic Electronics ECE101 Module-1Document33 pagesWINSEM2021-22 BECE101L TH VL2021220505625 Reference Material I 15-02-2022 Basic Electronics ECE101 Module-1Varun YadavNo ratings yet

- 2018 - Chapter 2 - KPI of Network Performance and Quality of Service - Sigit HaryadiDocument14 pages2018 - Chapter 2 - KPI of Network Performance and Quality of Service - Sigit HaryadirahmatNo ratings yet

- ARM Organization and Implementation: Aleksandar MilenkovicDocument37 pagesARM Organization and Implementation: Aleksandar Milenkovicarthicse100% (1)

- AVR Automatic Voltage RegulatorDocument2 pagesAVR Automatic Voltage RegulatorLithleuxay Philavong50% (2)

- Adl 5544Document20 pagesAdl 5544Durbha RaviNo ratings yet

- MC PLC Lab 2013Document37 pagesMC PLC Lab 2013sivaeeinfoNo ratings yet

- NCR 333 PDFDocument2 pagesNCR 333 PDFAicky IkrackNo ratings yet

- Omniscan X3: Phased Array Flaw DetectorDocument8 pagesOmniscan X3: Phased Array Flaw DetectorOmarNo ratings yet

- Philips CP90 SchematicsDocument11 pagesPhilips CP90 Schematicstechnical-manualsNo ratings yet

- JNTUK Question Paper April 2012Document4 pagesJNTUK Question Paper April 2012Atluri PriyankaNo ratings yet

- Dinamic BrakeDocument18 pagesDinamic BrakeSam eagle goodNo ratings yet

- 7 Series Product Selection GuideDocument12 pages7 Series Product Selection GuidematrixNo ratings yet

- Datasheet ACS2000 - FRAUSHERDocument2 pagesDatasheet ACS2000 - FRAUSHERMadhusudan RNo ratings yet

- Experiment 3 Series Resonance PDFDocument11 pagesExperiment 3 Series Resonance PDFSimon Christopher CerdeñaNo ratings yet

- JOtron tr-2500 PDFDocument77 pagesJOtron tr-2500 PDFMarco DelvalleNo ratings yet

- 9140 9260 Installation Instructions PDFDocument2 pages9140 9260 Installation Instructions PDFMd ShNo ratings yet

- TTP 244p Service Manual 2008-8-18 EDocument39 pagesTTP 244p Service Manual 2008-8-18 Esousuke30No ratings yet

- 2nd Generation IP Video Intercom System 2019H2 PDFDocument16 pages2nd Generation IP Video Intercom System 2019H2 PDFotorenikNo ratings yet

- Manual CRT 6900 ENGDocument22 pagesManual CRT 6900 ENGstrijker13No ratings yet