Professional Documents

Culture Documents

G-O-Vibration Compensator

G-O-Vibration Compensator

Uploaded by

vran77Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

G-O-Vibration Compensator

G-O-Vibration Compensator

Uploaded by

vran77Copyright:

Available Formats

G&O Vibration Compensator

ECO Design

– Eliminating the source of vibration

Electrically driven moment compensator

Gertsen & Olufsen Vibration Compensators are world leaders in eliminating

and reducing unwanted vibrations of ships and diesel power plants, before it is

transferred into other elements.

Guide force moments, unbalanced moments, axial thrust, hull beam and pro-

peller induced vibrations are well-known issues related to low speed two stroke

diesel engine. Vibrations often lead to limited engine performance, cracking,

reduced mechanical strengths, abnormal wear on rotating machinery or failure

of electronic components.

The servo driven moment compensator reduces or even eliminates the source

of vibration due to the unique technology that creates an exact opposite direc-

tion with a counterforce identical to the force induced by the engine. The imbal-

ance is neutralized and no stress or vibrations will be transferred into engine

foundations and neighbouring structures.

KEY FEATURES INCLUDES

2nd order vibration compensator

Size of force can be adjusted from 0-100%, to get exact counterforce

required. Adjustment range 1 kg.

Direction of force can be adjusted from 0 to 360º, to get precise direction

of force +/- 1°.

2nd Order (m2V) Confirmation test

Unique frequency controller enables a fast and precise phase

synchronization. 3000 pulses per engine rpm.

12

10 Recommended by leading classification societies, ship-owners,

Vibration velocity in mm/s.

engine- and shipbuilders worldwide.

8

6 ECO Design – leading excess and break energy back to the net.

0

64 66 68 70 72 74 76 78 80 82 84 86 88 90 92 94 96 98 100 102 104

Main engine rpm.

Navigator Bridge. Without Compensator. Navigator Bridge. With 2nd Order Compensator.

– Eliminating the source of vibration

Eliminating unwanted vibrations and

improving engine performance and comfort

COMPENSATOR FACTS

Improved engine performance and comfort. Whether a resonance is present, reduction of external moments and guide

force moments means better and smoother running engines. The vibration

Low energy consumption and a better fuel economy.

compensator can be used as a preventive maintenance tool reducing wear

Independent operations – use when needed. on most engine related equipment as well.

Easy adjustment of force and direction.

Easy installation, without operations interference. Installing the vibration compensator is a relatively simple project that does

not interfere with the operation of the vessel. Once installed, no further adjust-

Reduced maintenance costs.

ments or operational attendance are required.

No change to engine or engine room.

Navigation Bridge - HL

25

20

Vibration velocity in mm/s.

15

10

0

85 86 87 88 89 90 91 92 93 94

Main engine rpm.

Without Compensator. With Horizontal Compensator.

Horizontal vibration compensator

G&O COMPENSATOR RANGE

Type Version/Design Moment

C-125V1 ECO Design Vertical

C-200V1 ECO Design Vertical

C-600V1 ECO Design Vertical

C-10H1 Standard Design Horizontal

C-20H Standard Design Horizontal

C-40H Standard Design Horizontal

C-65H Standard Design Horizontal

C-90H Standard Design Horizontal

Simple and easy installation

where the compensator is needed

V V V

H

External 2nd order moment: A vertical External 2nd moment and H-moments: 2nd order Propeller induced vibrations: 2nd order

compensator is placed in the steering gear room. compensator in combination with horizontal compensator above the propeller.

compensator.

H H H

Guide force H-moments: A horizontal compensator Hull and propeller vibrations: A horizontal X-moment, guide force: 2 counter rotating

is placed directly on the engine gallery. compensator is placed in vessel structure. horizontal vibration compensator.

V H

Contact: info@g-o.dk | +45 45 76 36 00 | www.g-o.dk

You might also like

- Airxcel 48254C969 AC Manuals Install 1976307Document10 pagesAirxcel 48254C969 AC Manuals Install 1976307garyNo ratings yet

- EEE3091F Test 1 Questions - 2022Document3 pagesEEE3091F Test 1 Questions - 2022Student 80No ratings yet

- Panasonic+TH 32D430DXDocument51 pagesPanasonic+TH 32D430DXwinston mataNo ratings yet

- G005 Sinexcel BESS Micro Grid Solution-MyamarDocument2 pagesG005 Sinexcel BESS Micro Grid Solution-MyamarSyed Furqan RafiqueNo ratings yet

- LORENTZ - PSk2-7 - c-sj8-30 - Pi - en - Ver310183Document2 pagesLORENTZ - PSk2-7 - c-sj8-30 - Pi - en - Ver310183Muhammad JawadNo ratings yet

- Mini Comp Sony Cmt-A50 - Cmt-A70Document74 pagesMini Comp Sony Cmt-A50 - Cmt-A70ppstoneNo ratings yet

- SatspecsDocument1 pageSatspecsRgonz79100% (1)

- KVH M7 Gyrotrac ConfigDocument103 pagesKVH M7 Gyrotrac ConfigPalaKhartikeyanNo ratings yet

- EC Motors & Fan Applications: What Is An Ec Motor?Document5 pagesEC Motors & Fan Applications: What Is An Ec Motor?Arjun ReddyNo ratings yet

- Studer Quick Guide RCC v6.1 - en PDFDocument44 pagesStuder Quick Guide RCC v6.1 - en PDFakaNo ratings yet

- HCI534C/544C - Winding 311 Single Phase: Technical Data SheetDocument9 pagesHCI534C/544C - Winding 311 Single Phase: Technical Data SheetAhmed El-FayoumyNo ratings yet

- Dokumentation Energoutil 2015-35370 - enDocument37 pagesDokumentation Energoutil 2015-35370 - enbrctlnNo ratings yet

- Item 6 - CEC Installation ChecklistDocument3 pagesItem 6 - CEC Installation ChecklistShane LiebichNo ratings yet

- Product Specifications CUBO 2022 Sarangani Suite 09.09.21Document10 pagesProduct Specifications CUBO 2022 Sarangani Suite 09.09.21Arturo TJ PacificadorNo ratings yet

- TD Sigma Tracker enDocument2 pagesTD Sigma Tracker enMeel Electic GeneralNo ratings yet

- FIMER - MGS100-15 - Manual BookDocument98 pagesFIMER - MGS100-15 - Manual BookWinSajeewaNo ratings yet

- Te S Raychem Screened Elbow/Straight Separable Connectors Rses/RsssDocument2 pagesTe S Raychem Screened Elbow/Straight Separable Connectors Rses/RsssIrfan Pv50% (2)

- User Manual For AN97 SeriesDocument25 pagesUser Manual For AN97 SeriesMehmet Kürşad AlpNo ratings yet

- R.M.K. College of Engineering and TechnologyDocument7 pagesR.M.K. College of Engineering and TechnologyvlkumashankardeekshithNo ratings yet

- Kenwood TS-590SG Owners ManualDocument100 pagesKenwood TS-590SG Owners ManualdonsterthemonsterNo ratings yet

- Catalogo Tecnico Split Ducto Baja SiluetaDocument120 pagesCatalogo Tecnico Split Ducto Baja SiluetaPavlo Rodriguex100% (2)

- Cable Connectors To RMUDocument10 pagesCable Connectors To RMUSaqib RasoolNo ratings yet

- DR63L4Document2 pagesDR63L4Ramiro Sew EurodriveNo ratings yet

- Electus Distribution Reference Data Sheet: FUSEPRMR PDFDocument2 pagesElectus Distribution Reference Data Sheet: FUSEPRMR PDFFarshad yazdiNo ratings yet

- LC Sine Wave Filter Technical Specifications: SmisenDocument6 pagesLC Sine Wave Filter Technical Specifications: Smisenrajabharath12No ratings yet

- Brochure BPS-200 EnglishDocument8 pagesBrochure BPS-200 Englishpls509sNo ratings yet

- Nooro Iii Tower CSP Power Plant: Operation & Maintenance Manual of DC SystemDocument30 pagesNooro Iii Tower CSP Power Plant: Operation & Maintenance Manual of DC Systemscribd birdNo ratings yet

- Alone, FCG-Driven High Power Microwave SystemDocument5 pagesAlone, FCG-Driven High Power Microwave SystempauljansonNo ratings yet

- Rca Rlded4016a EnfrDocument49 pagesRca Rlded4016a EnfrWilliam WallaceNo ratings yet

- Reliance: LED Taxiway Centerline, Lead-on/Exit, Apron Lead-In, L-852C (L), L-852D (L), L-852K (L)Document7 pagesReliance: LED Taxiway Centerline, Lead-on/Exit, Apron Lead-In, L-852C (L), L-852D (L), L-852K (L)giant360No ratings yet

- BCS722 48xLED LXN WH 6Document5 pagesBCS722 48xLED LXN WH 6Lazna adresaNo ratings yet

- OKi Catalog 2010Document48 pagesOKi Catalog 2010dilipjraneNo ratings yet

- AR860 English ManualDocument10 pagesAR860 English ManualMARIO SALVATORE SANDOVAL PAIPAYNo ratings yet

- Navien NR-210A Op ManualDocument132 pagesNavien NR-210A Op ManualChris Allen100% (1)

- Samwha Capacitor Full CatalogDocument68 pagesSamwha Capacitor Full Catalograyyan2007No ratings yet

- Led Performance High Power Flood LightDocument12 pagesLed Performance High Power Flood LightRoudy J. MhawasNo ratings yet

- 2005-01-4130v001 Development Flexfuel Ford PDFDocument11 pages2005-01-4130v001 Development Flexfuel Ford PDFFabio GuedesNo ratings yet

- Inventor Service ManualDocument105 pagesInventor Service ManualMaurizio DumitracheNo ratings yet

- Unit-III Transmission SysytemDocument168 pagesUnit-III Transmission Sysytemriyaz ahmedNo ratings yet

- Conserv Meters Em3460Document65 pagesConserv Meters Em3460asrinivasareddy100% (1)

- Unit 5 Vibration and Strain MeasurementDocument12 pagesUnit 5 Vibration and Strain Measurement08 Dadarkar Mujtaba MEANo ratings yet

- Article Fitters Notes 4-Way Valve Part 12Document31 pagesArticle Fitters Notes 4-Way Valve Part 12osama alabsiNo ratings yet

- TS 590 User - ManualDocument92 pagesTS 590 User - ManualMauroNo ratings yet

- Ac 138 PDFDocument5 pagesAc 138 PDFPablo Gaspar D'Agostini AmengualNo ratings yet

- 18 - MonarchDocument1 page18 - MonarchBima MahendraNo ratings yet

- 60 kVA / 48 KW POWERED by Perkins: MPG-60 KVA-PK@50HzDocument4 pages60 kVA / 48 KW POWERED by Perkins: MPG-60 KVA-PK@50HzcafubodoNo ratings yet

- Unit 6 Miscllanious MeasurementDocument10 pagesUnit 6 Miscllanious Measurement08 Dadarkar Mujtaba MEANo ratings yet

- PBB UpgradeDocument36 pagesPBB Upgradeamerico100% (1)

- CM8340 Diagrama Fuente PDFDocument2 pagesCM8340 Diagrama Fuente PDFLorenzo100% (2)

- Design of Power Electronic Converters: Prof. Shabari NathDocument843 pagesDesign of Power Electronic Converters: Prof. Shabari NathDianeNo ratings yet

- Gashub - 2018Document23 pagesGashub - 2018Ricky PrasetyaNo ratings yet

- AristonDocument40 pagesAristonsivarajan eNo ratings yet

- Door Alarm Using Silicon Controlled RectifierDocument9 pagesDoor Alarm Using Silicon Controlled RectifierLucks Gonzales100% (1)

- 1 ISTrd0185v010 (IST7918) 20170523 PDFDocument60 pages1 ISTrd0185v010 (IST7918) 20170523 PDFsophieNo ratings yet

- 25510-A New Calculation For Designing Multilayer Planar Spiral Inductors PDF PDFDocument4 pages25510-A New Calculation For Designing Multilayer Planar Spiral Inductors PDF PDFAnonymous Kti5jq5EJINo ratings yet

- Visit at Gss Debari, Udaipur: Presented by Rajat RathoreDocument12 pagesVisit at Gss Debari, Udaipur: Presented by Rajat RathoreYatendra VarmaNo ratings yet

- IEC61727 IEC62116 IEC 61683 Certificate For SOFAR50000TL-60000TL-70000TL PDFDocument1 pageIEC61727 IEC62116 IEC 61683 Certificate For SOFAR50000TL-60000TL-70000TL PDFMateus AndradeNo ratings yet

- Review of Fundamental Two Pole Induction Motor Mechanics by Cletus A. CoreyDocument6 pagesReview of Fundamental Two Pole Induction Motor Mechanics by Cletus A. CoreyEswin Paico de la CruzNo ratings yet

- Technical Note - Foundation Design For High Voltage Induction Motors PDFDocument2 pagesTechnical Note - Foundation Design For High Voltage Induction Motors PDFMashudi FikriNo ratings yet

- Too Much Vibration PDFDocument8 pagesToo Much Vibration PDFThanh LuanNo ratings yet

- E Services 2Document3 pagesE Services 2vran77No ratings yet

- Sulphur 2020: From Contracting To Final CombustionDocument24 pagesSulphur 2020: From Contracting To Final Combustionvran77No ratings yet

- Steel Pipe PicklingDocument4 pagesSteel Pipe Picklingvran77No ratings yet

- The (Low-Carbon) Shipping ForecastDocument4 pagesThe (Low-Carbon) Shipping Forecastvran77No ratings yet

- COMPARISON Vs MEWIS DUCTDocument1 pageCOMPARISON Vs MEWIS DUCTvran77No ratings yet

- Steel Ships New Building Supervision Company ProfileDocument16 pagesSteel Ships New Building Supervision Company Profilevran77No ratings yet

- EPC-Shipyard EPC ProjectDocument7 pagesEPC-Shipyard EPC Projectvran77100% (1)

- MAN B&W Diesel A/S: Production RecommendationDocument3 pagesMAN B&W Diesel A/S: Production Recommendationvran77No ratings yet

- MAN B&W Diesel A/S: Production RecommendationDocument3 pagesMAN B&W Diesel A/S: Production Recommendationvran77No ratings yet

- Sulphur 2020: From Contracting To Final CombustionDocument24 pagesSulphur 2020: From Contracting To Final Combustionvran77No ratings yet

- Company Profile Sept 2019Document24 pagesCompany Profile Sept 2019vran77No ratings yet

- Lgip PDFDocument2 pagesLgip PDFvran77No ratings yet

- Ship Efficiency and Performance PDFDocument277 pagesShip Efficiency and Performance PDFvran77No ratings yet

- IMO Sulphur 2020Document24 pagesIMO Sulphur 2020vran77No ratings yet

- FG-18 Report of Sea Trial 200-215) PDFDocument16 pagesFG-18 Report of Sea Trial 200-215) PDFvran77No ratings yet

- LNG Tanker 5000 CBMDocument2 pagesLNG Tanker 5000 CBMvran77No ratings yet

- Freight Rates and The Price of Oil Part Company: Charles R. Weber Company TankerDocument23 pagesFreight Rates and The Price of Oil Part Company: Charles R. Weber Company Tankervran77No ratings yet

- WWII Liberty Cargo Ship HistoryDocument164 pagesWWII Liberty Cargo Ship HistoryCAP History Library100% (6)

- Lake Carriers' Association: The Greatest Ships On The Great LakesDocument14 pagesLake Carriers' Association: The Greatest Ships On The Great Lakesvran77No ratings yet

- Waste Heat Recovery SystemDocument32 pagesWaste Heat Recovery Systemvran77No ratings yet

- Variable Injection TimingDocument2 pagesVariable Injection Timingvran770% (1)

- TSHD UtrechtDocument1 pageTSHD UtrechtRida DesyaniNo ratings yet

- Pemilihan Propeller Dan As PropellerDocument14 pagesPemilihan Propeller Dan As Propellersupriadi90315No ratings yet

- 19 - Wartsila - Turbocharging 2 Stroke Engine - Existing & Future DemandsDocument18 pages19 - Wartsila - Turbocharging 2 Stroke Engine - Existing & Future DemandsCháu Bác HồNo ratings yet

- Yanmar-Datasheet 3JH5EDocument2 pagesYanmar-Datasheet 3JH5EFrederik CañabiNo ratings yet

- Honeywell IAS For LNG Carrier BrochureDocument6 pagesHoneywell IAS For LNG Carrier BrochuremariodalNo ratings yet

- Marines Team TurbinesDocument13 pagesMarines Team TurbinesNOOH EXPORTERNo ratings yet

- Rolls Royce Insights 2018 Issue 32Document48 pagesRolls Royce Insights 2018 Issue 32Vladimir V. HaltakovNo ratings yet

- ChiefMate Phase 2 II Question Papers Bank Till Feb19 DG SHIPPING INDIADocument189 pagesChiefMate Phase 2 II Question Papers Bank Till Feb19 DG SHIPPING INDIAGurjit Singh100% (6)

- 02.sea Service Letter 2NDDocument2 pages02.sea Service Letter 2NDSubham SamantarayNo ratings yet

- Vessel Equipment Guide Non Survey Class 2d 3d 4dDocument4 pagesVessel Equipment Guide Non Survey Class 2d 3d 4ddamian cabello vegaNo ratings yet

- Iinterview QuestionDocument5 pagesIinterview QuestionPaul Kenley Alcaraz MagallanoNo ratings yet

- Product: Marine Propulsion SystemsDocument5 pagesProduct: Marine Propulsion SystemsJuan EmirNo ratings yet

- Executive Summary Stan Pilot 1605 FRPDocument16 pagesExecutive Summary Stan Pilot 1605 FRPAstrid RdoNo ratings yet

- Ge ExperienceDocument24 pagesGe ExperienceFrankNo ratings yet

- Nasa R.U5 Pwas4M: N76-933 COWSUNPTION Final R Eport (Pratt Ani WhitneyDocument142 pagesNasa R.U5 Pwas4M: N76-933 COWSUNPTION Final R Eport (Pratt Ani WhitneyMark Evan SalutinNo ratings yet

- U.S. Merchant Marine DictionaryDocument769 pagesU.S. Merchant Marine DictionaryMarcelo MartinsNo ratings yet

- Dynapac Cc1300 Spare Parts CatalogueDocument20 pagesDynapac Cc1300 Spare Parts Catalogueaaron100% (56)

- OPT - Yuri Senkevich - Machinery Systems Manual PDFDocument352 pagesOPT - Yuri Senkevich - Machinery Systems Manual PDFpNo ratings yet

- MES Products Catalog.eDocument21 pagesMES Products Catalog.eSeanPark94100% (1)

- Marine Engines Running On LNG For Submission Ioannis BakasDocument28 pagesMarine Engines Running On LNG For Submission Ioannis Bakaswaleed yehiaNo ratings yet

- Manipal University Jaipur: CryocarDocument19 pagesManipal University Jaipur: CryocarHarshit SharmaNo ratings yet

- ME Bridge Manouvering System DMS2100i Manual NewDocument183 pagesME Bridge Manouvering System DMS2100i Manual NewRadoslaw PobierowskiNo ratings yet

- Pedoman D2 - Rev04Document26 pagesPedoman D2 - Rev04ullyNo ratings yet

- DF 2013-1 PDFDocument12 pagesDF 2013-1 PDFaminNo ratings yet

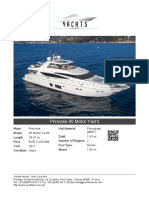

- 29.41m Princess 95 Motor YachtDocument17 pages29.41m Princess 95 Motor YachtAbrham B. GMNo ratings yet

- 37 Azimuth-2p-22 04 21 PDFDocument2 pages37 Azimuth-2p-22 04 21 PDFWataq MarwanNo ratings yet

- Yanmar Propulsion Medium Speed 0803Document20 pagesYanmar Propulsion Medium Speed 0803Mohsen MoghadamNo ratings yet

- Crude Oil Carrier ALBA - IMO 9297345 - Machinery Operating ManualDocument325 pagesCrude Oil Carrier ALBA - IMO 9297345 - Machinery Operating Manualseawolf50No ratings yet

- Accessories CatalogDocument96 pagesAccessories CatalogLucas OmenaNo ratings yet

- Pub Cat 15Document22 pagesPub Cat 15Flavio MoraesNo ratings yet