Professional Documents

Culture Documents

System QSB First Step Fast Response PDF

System QSB First Step Fast Response PDF

Uploaded by

Prabagarane RamachandranOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

System QSB First Step Fast Response PDF

System QSB First Step Fast Response PDF

Uploaded by

Prabagarane RamachandranCopyright:

Available Formats

FAST RESPONSE

FAST RESPONSE PROCESS KEY STEPS

Quality gathers significant issues from the past 24 hours.

Daily Fast Response Meeting assigns owner to each issue.

Outside the meeting the owner utilizes the Problem Solving

process to correct and prevent recurrence.

Issues are tracked on the Fast Response Tracking Board.

Owners are required to give periodic updates at Fast

Response meeting.

Owner responsible for completion of all exit criteria including

Lessons Learned. Results of Problem Solving process

communicated. Fast Response Tracking Board indicates exit

criteria is green.

Global Purchasing and Supply

1

Chain

FAST RESPONSE

Fast Response is a system which:

• Standardizes reaction to significant External/Internal Quality failures.

• Instills problem solving discipline through use of a standard documented

format for all problems.

• Promotes communication and a sharing of knowledge through daily meetings.

• Utilizes a visual method of displaying important information to drive closure.

• Moves problem identification upstream from the customer to

addressing internal issues sooner.

Global Purchasing and Supply

2

Chain

FAST RESPONSE

Global Purchasing and Supply

3

Chain

FAST RESPONSE TRACKING BOARD (Example)

To optimize visual management, this form is displayed in the meeting

area (ex.: 4’ x 8’ dry erase board, laminated poster, etc…).

EXIT CRITERIA

Standardized Work

(Institutionalized)

Corrective Action

Corrective Action

Lessons Learned

Layered Process

Proof/Detection

Next

Implemented

Overall Status

Containment

Date (of

PFMEA / CP

Date Closed

Root Cause

Owner

Operator

Analysis

Updated

Verified

Report

Audits

Error

Issue Issue Date out to

Number Description Opened Unit I.D. # Owner Staff)

Material

Y 1 1/10/2005 333933 McGrath 4/29/2005 G G G G G G Y G Y Open

Contam inated

G 2 Burrs 2/15/2005 98002222 Adam s CLOSED G G G G G G G G G 4/23/05

Parts

R 3 m islocated on 3/21/2005 9950560607 McIntosh 4/29/2005 G G G R R R N/A G N/A Open

assem bly

R 4 Mixed Parts 3/22/2005 34523339 McGrath 4/29/2005 G G G G R G G Y G Open

Paint dots

found on loose

R 5 3/28/2005 98002222 McGrath 5/11/2005 G G G G G N/A N/A R R Open

& m is-built

parts

Loose 7m m

R 6 bolt on front 3/28/2005 98002222 McGrath 5/23/2005 R R R R R R R N/A R Open

cover

EXIT CRITERIA STATUS KEY

R Required but

not initiated

For Red or Yellow Status Points to Review:

Ownership

Y Initiated but not

com plete

– Include Target Date Exit Criteria

G Com plete Overall Status

N/A Not Applicable

FAST RESPONSE

Problem Identification:

In preparation for the Fast Response meeting, at the start of the day, Quality shall

identify significant quality concerns from the past 24 hours which include:

• External Concerns:

– Customer concerns (PRR’s, Liaison Issues, Customer Calls, Warranty)

– Supplier concerns (Suppliers should be notified in advance when they

are to report out at the meeting).

• Internal Concerns:

– Verification Station Findings

– Layered Process Audit Systemic issues

– Line stops and Teardown issues

– Other internal Quality concerns (Dock Audits, containment activity)

– Error Proof device failures

Global Purchasing and Supply

5

Chain

FAST RESPONSE

Structure:

Cross functional meeting typically owned by manufacturing

Daily review of significant concerns

Communications meeting, not a problem solving meeting.

Short sharp meeting typically held on the shop floor.

Each issue documented & reviewed at the meeting to provide structure for the

report out

Global Purchasing and Supply

6

Chain

FAST RESPONSE

Responsibilities:

New issues updated on the Fast Response board

Owner shall report progress to the team

Plant Manager or designated manufacturing lead ensures Fast Response process is

effective.

At the Fast Response meeting, site leadership shall:

• Designate a leader (natural owner) for each concern/issue

• Identify action required and owner for items statused as RED.

• Establish the next report out date for the issue if it is not closed.

Global Purchasing and Supply

7

Chain

FAST RESPONSE TRACKING BOARD EXAMPLE

Board can be different but must meet INTENT

Global Purchasing and Supply

8

Chain

FAST RESPONSE

Exit Criteria, Statusing:

Typical Exit Criteria

Timing for each of the exit criteria

shall be established in order to EXIT CRITERIA

properly status each item Target Timing, Status, & Date Green

24 H 7D 14 D 34 D 35 D 40 D

Containment - Breakpoint

Layered Process Audits

Standard Work Operator

PFMEA / CP Updated

Root Cause Identified

Error Proof/Detection

Exit criteria shall be established for

Lessons Learned

Corrective Action

Corrective Action

(Institutionalized)

Implemented

each key step in the problem solving

Instructions

Validated

process.

The default when a problem is first

opened is Yellow G G G G G G G Y Y

1/11 1/18 1/24 1/24 1/25 2/13 2/15 2/20 2/20

Evidence of each criteria should be

reviewed by the Owner at the Fast

Response Meeting.

Global Purchasing and Supply

9

Chain

FAST RESPONSE

Performance Metrics:

How do you know the Fast Response process is

working?

Any type of visual management can be used

A Picture from Zaragoza Plant Q?

Global Purchasing and Supply

10

Chain

FAST RESPONSE

Step 1-DEFINE THE PROBLEM:

Standard

Discrepancy

Actual

TIME

Process 3 Is the Point of Cause!

Global Purchasing and Supply

11

Chain

FAST RESPONSE

Step 2-CONTAIN THE PROBLEM:

Need to determine

• The best method to contain the defect.

• How long has this been happening?

– Review data for last known good part

– Engage operators regarding changes or abnormal conditions and

timing.

– Initiate a containment work sheet

• Whether other areas or customers are impacted by the problem and to what

extent.

Global Purchasing and Supply

12

Chain

FAST RESPONSE

Step 3 – Identify the Root Cause:

Cause Effect

Global Purchasing and Supply

13

Chain

FAST RESPONSE

Step 4– Implement Corrective Action:

Brainstorm possible solutions and select

the most effective

Determine if a trial run is needed to

confirm the solution is effective .

Determine implemention and timing.

Identify the breakpoint and communicate

to all key stake holders.

Global Purchasing and Supply

14

Chain

FAST RESPONSE

Step 5 – Verify Effectiveness of Actions:

• Use Layered Process Audits to verify actions working as intended.

• Verify effectiveness through measurement and data.

• Establish a verification period.

• Determine who will follow up. MARCH

• Create a standardized process or method.

Global Purchasing and Supply

15

Chain

FAST RESPONSE

Step 6 - Institutionalize:

Identify similar products and processes which potentially have or may produce the

same failure mode.

Implement the solution across the organization.

Update remaining necessary documentation:

– PFMEA

– Control Plan

– Error Proofing Verification

– Standardized Work

– Operator Instructions

Perform Lessons Learned

Global Purchasing and Supply

16

Chain

FAST RESPONSE

Lessons Learned

A Lessons Learned system:

• Is a process for capturing information to support continuous improvement and

prevents repeated mistakes

• Applies to the entire organization, all functions should participate.

• Lessons Learned may be identified by anyone

• Must be documented (e.g. Master PFMEA, APQP Checklist e.t.c

• Leadership shall review the process to assure implementation.

Global Purchasing and Supply

17

Chain

FAST RESPONSE – Lessons Learned Example

Global Purchasing and Supply

18

Chain

FAST RESPONSE SUMMARY

Organizations shall…

Identify significant concerns from the past 24 hours

Hold a daily Fast Response meeting.

Utilize a format such as the Fast Response Tracking Board to identify:

Overall status of the significant concerns.

Ownership of each concern.

Exit criteria required to close a concern.

Owners shall:

Use a standard problem solving form for all Fast Response issues.

Report out to each of the problem steps.

Ensure all Exit Criteria are completed.

Global Purchasing and Supply

19

Chain

You might also like

- 6-New APQP Manual 3rd Edition - Advanced Product Quality Planning 2024Document7 pages6-New APQP Manual 3rd Edition - Advanced Product Quality Planning 2024Wilson Ang100% (1)

- ANPQP Version 3.2 RevisionDocument33 pagesANPQP Version 3.2 RevisionFaby Mendoza50% (2)

- AIAG Quality ManualsDocument2 pagesAIAG Quality Manualsquality japtechNo ratings yet

- The 7QB of Production: FAS Training PresentationDocument50 pagesThe 7QB of Production: FAS Training Presentationcong da100% (1)

- BIQS 2017 Slide ShowDocument202 pagesBIQS 2017 Slide Showismael cantuNo ratings yet

- VCC Phased PPAP Requirements Handbook - V2Document14 pagesVCC Phased PPAP Requirements Handbook - V2medi38No ratings yet

- Customer Complaints or Problems - Fast Response Tracking BoardDocument1 pageCustomer Complaints or Problems - Fast Response Tracking Boardsrinivigna100% (3)

- Customer Specific Requirment - 2021-22 - TML CSR Rev04Document5 pagesCustomer Specific Requirment - 2021-22 - TML CSR Rev04Ali MujawarNo ratings yet

- HF-0467 - Product Audit Report - C - 2015-08-06Document44 pagesHF-0467 - Product Audit Report - C - 2015-08-06Enis SirbegovicNo ratings yet

- Daimler-Chrysler Layered Process AuditsDocument27 pagesDaimler-Chrysler Layered Process AuditsR JNo ratings yet

- GM 1927-36 SzkoleniaDocument262 pagesGM 1927-36 Szkoleniazzza100% (2)

- 01 - APQP Training Material PDFDocument62 pages01 - APQP Training Material PDFMohit SinghNo ratings yet

- P!. GM 1927-30 - BIQS Audit v.7.0 2017-04-05Document14 pagesP!. GM 1927-30 - BIQS Audit v.7.0 2017-04-05Duho ConsultoresNo ratings yet

- Advanced Product Quality Planning and Control Plan: Second EditionDocument8 pagesAdvanced Product Quality Planning and Control Plan: Second EditionAnil AhirNo ratings yet

- 5.1.1.2 - Process Effectiveness EfficiencyDocument1 page5.1.1.2 - Process Effectiveness EfficiencyPrakash kumarTripathiNo ratings yet

- CSR Matrix For RefDocument6 pagesCSR Matrix For RefBard Z8No ratings yet

- MSIL Audit Cheklist 16Document22 pagesMSIL Audit Cheklist 16Pravin Balasaheb GunjalNo ratings yet

- Reverse PFMEA Training MaterialDocument11 pagesReverse PFMEA Training MaterialThe PhongNo ratings yet

- Supplier APQP TrainingDocument29 pagesSupplier APQP Trainingfdsa01No ratings yet

- PPAP Webinar Core Tools PDFDocument62 pagesPPAP Webinar Core Tools PDFSirius100% (1)

- IATF 16949 Frequently Asked Questions October 2017Document12 pagesIATF 16949 Frequently Asked Questions October 2017Armando FloresNo ratings yet

- GR&R Training DraftDocument53 pagesGR&R Training DraftLOGANATHAN VNo ratings yet

- GM SQD Bulletin 1927 36 2018Document3 pagesGM SQD Bulletin 1927 36 2018Oscar DiazNo ratings yet

- Requirements Comparison TS16949 VDA61Document22 pagesRequirements Comparison TS16949 VDA61TarunaiNo ratings yet

- ISO9 - IATF16 - Combo - GAP - March - 2017 - 1Document100 pagesISO9 - IATF16 - Combo - GAP - March - 2017 - 1Bruce GilchristNo ratings yet

- APQP Phases and ActivitiesDocument1 pageAPQP Phases and Activitiesaorto3919No ratings yet

- Iatf TrainingDocument10 pagesIatf TrainingAniket JadhavNo ratings yet

- GM 1927 36 Group C Elements BIQSDocument52 pagesGM 1927 36 Group C Elements BIQSVanessa GurrolaNo ratings yet

- PFMEA AIAG VDA Heading Hints PDFDocument1 pagePFMEA AIAG VDA Heading Hints PDFRamdas PaithankarNo ratings yet

- New Supplier Quality Manual Training ModuleDocument119 pagesNew Supplier Quality Manual Training ModuleMohit Singh100% (1)

- Coherence PlanDocument2 pagesCoherence PlanAman JasujaNo ratings yet

- Layered Audit ChecklistDocument4 pagesLayered Audit ChecklistNavnath TamhaneNo ratings yet

- Attribute MSA TrainingDocument21 pagesAttribute MSA TrainingDisha ShahNo ratings yet

- FMEA Errata Sheet ENG AIAG VDA FMEA Handbook 202000602 PDFDocument10 pagesFMEA Errata Sheet ENG AIAG VDA FMEA Handbook 202000602 PDFBonny BonitoNo ratings yet

- PPAP 4th. EditionDocument75 pagesPPAP 4th. EditionGilberto FloresNo ratings yet

- Q1 Rules Ref CardDocument10 pagesQ1 Rules Ref Cardparigomo2No ratings yet

- AIAG-VDA PFMEA Template For Activity - (Delegate)Document38 pagesAIAG-VDA PFMEA Template For Activity - (Delegate)nadia_naaz90No ratings yet

- GP-12 Check SheetsDocument2 pagesGP-12 Check SheetsLam Nguyen100% (4)

- Training Module Aiag Cqi Licensed Training Partner Topqm Systems Overview enDocument3 pagesTraining Module Aiag Cqi Licensed Training Partner Topqm Systems Overview enjpaulNo ratings yet

- PFMEA AIAG VDA Filled Example Assly PDFDocument1 pagePFMEA AIAG VDA Filled Example Assly PDFRamdas PaithankarNo ratings yet

- Project Checklist For IATF 16949:2016 Implementation: Implementation Phases Tasks DoneDocument2 pagesProject Checklist For IATF 16949:2016 Implementation: Implementation Phases Tasks DoneNikita Fatah EntingNo ratings yet

- Apqp VolvoDocument7 pagesApqp Volvofdsa01No ratings yet

- Iatf Process Audit Check Sheet FormatDocument14 pagesIatf Process Audit Check Sheet FormatPuspavathi S Rama NaiduNo ratings yet

- Iso and Iatf 16949.2016 ManualDocument48 pagesIso and Iatf 16949.2016 Manualsanjay sharma100% (1)

- Supplier Incident Analysis: Claim NoDocument10 pagesSupplier Incident Analysis: Claim Nonitin pendharkarNo ratings yet

- Ii. Structure Analysis Iii. Function Analysis: Company NameDocument6 pagesIi. Structure Analysis Iii. Function Analysis: Company NameJohn OoNo ratings yet

- Iatf 16949 PPT Training Awareness - PDF - Quality Management System - Iso 9000Document51 pagesIatf 16949 PPT Training Awareness - PDF - Quality Management System - Iso 9000wadot43402No ratings yet

- PPAP - 4th Edition - Course MaterialDocument18 pagesPPAP - 4th Edition - Course MaterialMy Dad My WorldNo ratings yet

- MACE - Formats - 015 - APQP Matrix Sign OffDocument3 pagesMACE - Formats - 015 - APQP Matrix Sign OffMohit KaushikNo ratings yet

- GM 1927-30 QSB AuditDocument38 pagesGM 1927-30 QSB Auditmanune01No ratings yet

- VDA6.3 - Engl06 04 04 PDFDocument26 pagesVDA6.3 - Engl06 04 04 PDFjpenjerryNo ratings yet

- IATF Audit Observation 21.06.2021-23.06.2021Document6 pagesIATF Audit Observation 21.06.2021-23.06.2021Karan Malhi100% (1)

- Detection Table - AIAG-VDA Process FMEADocument1 pageDetection Table - AIAG-VDA Process FMEARaajha MunibathiranNo ratings yet

- KMM Suplier Quality Manual 2018Document23 pagesKMM Suplier Quality Manual 2018Jesus Cardona RezaNo ratings yet

- Production Part Approval ProcessDocument6 pagesProduction Part Approval ProcessleonardoNo ratings yet

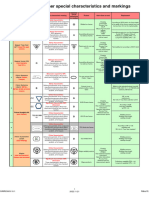

- Customer Special CharacteristicsDocument1 pageCustomer Special Characteristicspundhir12898No ratings yet

- GM CSR TrainingDocument9 pagesGM CSR TrainingVanessa GurrolaNo ratings yet

- Worldwide Fastener Standard: Printed Copies Are UncontrolledDocument2 pagesWorldwide Fastener Standard: Printed Copies Are UncontrolledPrabagarane RamachandranNo ratings yet

- Defects, Root Causes in Casting Process and Their Remedies: ReviewDocument9 pagesDefects, Root Causes in Casting Process and Their Remedies: ReviewPrabagarane RamachandranNo ratings yet

- Traceability Implementation and ApplicationDocument23 pagesTraceability Implementation and ApplicationPrabagarane RamachandranNo ratings yet

- Die Casting Design PDFDocument38 pagesDie Casting Design PDFPrabagarane Ramachandran100% (2)

- Sri Lanka: Economy ProfileDocument67 pagesSri Lanka: Economy Profileantoine stollNo ratings yet

- API Documentation Alpha VantageDocument55 pagesAPI Documentation Alpha VantageFun WorldNo ratings yet

- sc1 PDFDocument7 pagessc1 PDFGajadhur AmishaNo ratings yet

- Local Content ComplianceDocument2 pagesLocal Content ComplianceAnonymous VAyE02PNo ratings yet

- Del Castillo v. RichmondDocument2 pagesDel Castillo v. RichmondRaymond ChengNo ratings yet

- S96029 HIRARC Formwork-Rev02 27-8-22Document3 pagesS96029 HIRARC Formwork-Rev02 27-8-22Azman OyobNo ratings yet

- Corpus Vs GrospeDocument2 pagesCorpus Vs GrospeMary Anne Guanzon VitugNo ratings yet

- Introduction To Commercial Duck Farming PDFDocument6 pagesIntroduction To Commercial Duck Farming PDFMattos CorreiaNo ratings yet

- Public Sector AccountingDocument1 pagePublic Sector AccountingKansaanah Tierong JaphethNo ratings yet

- Christian Paul D. Legaspi Easy Problem 1, CCEDocument16 pagesChristian Paul D. Legaspi Easy Problem 1, CCELyca Mae CubangbangNo ratings yet

- Virtual University Presents: Slide 1 / 69Document69 pagesVirtual University Presents: Slide 1 / 69mba departmentNo ratings yet

- Enterprise ValueDocument3 pagesEnterprise Valuezairulp1No ratings yet

- MARKET STUDY of A Feasibility StudyDocument19 pagesMARKET STUDY of A Feasibility StudySheena Doria de VeraNo ratings yet

- A Presentation On GATTDocument34 pagesA Presentation On GATTVinod Menon100% (2)

- 1 D Ifrs 16 Example Lease Modification Scope Increase and Decrease 02Document7 pages1 D Ifrs 16 Example Lease Modification Scope Increase and Decrease 02Imelda FebriputriNo ratings yet

- Kuenzle & Streiff, Inc., Petitioner, V. The Commissioner of Internal Revenue, Respondent. (G.R. No. L-18840. May 29, 1969.)Document7 pagesKuenzle & Streiff, Inc., Petitioner, V. The Commissioner of Internal Revenue, Respondent. (G.R. No. L-18840. May 29, 1969.)Samantha BaricauaNo ratings yet

- T13014 - KunalDocument3 pagesT13014 - KunalKunal AgrawalNo ratings yet

- Anylogistix ALX TrainingDocument273 pagesAnylogistix ALX Trainingdesp100% (1)

- ..Se'curities'and Exchange Commission.: T. Leonardo C. Santos Associates Law FirmDocument3 pages..Se'curities'and Exchange Commission.: T. Leonardo C. Santos Associates Law FirmJustin Mark ChanNo ratings yet

- Process Flow Diagram (PFD) - How To & ExamplesDocument43 pagesProcess Flow Diagram (PFD) - How To & ExamplesKu Kema100% (1)

- Module 6 Qualitites of Filipino EntrepreneirDocument21 pagesModule 6 Qualitites of Filipino EntrepreneirNick Allan PiojoNo ratings yet

- Wheeling ChargeDocument6 pagesWheeling Chargegopal sapkotaNo ratings yet

- Five Interdisciplinary Dimensions of Consumer Behaviour 1. EconomicDocument13 pagesFive Interdisciplinary Dimensions of Consumer Behaviour 1. EconomicRima Parekh100% (3)

- Mgt101 Final Term Solved 14 PapersDocument161 pagesMgt101 Final Term Solved 14 Paperssalman khanNo ratings yet

- Lab 10 97Document2 pagesLab 10 97Phạm Tiến ĐạtNo ratings yet

- Kickstart Career As Data AnalystDocument44 pagesKickstart Career As Data Analystajank shadowNo ratings yet

- Manipal Hackathon 2023 BrochureDocument12 pagesManipal Hackathon 2023 BrochureJesse PinkmanNo ratings yet

- Proposal For Project Management PlanDocument25 pagesProposal For Project Management Plansellitt ngNo ratings yet

- Kumpulan Serial Number Windows XPDocument4 pagesKumpulan Serial Number Windows XPspsc66No ratings yet

- Unit 3: Product ManagementDocument60 pagesUnit 3: Product ManagementSumit KumarNo ratings yet