Professional Documents

Culture Documents

Masterseal HLM 5000 India v2 PDF

Masterseal HLM 5000 India v2 PDF

Uploaded by

shashiCopyright:

Available Formats

You might also like

- MasterProtect 300Document3 pagesMasterProtect 300Gavriel NgNo ratings yet

- FRP Piping Design Manual - Sep-06Document27 pagesFRP Piping Design Manual - Sep-06Sabir Nasim100% (3)

- Truck Lay Bye Toilet Block - 04 PDFDocument1 pageTruck Lay Bye Toilet Block - 04 PDFSanjeev KumarNo ratings yet

- Herget, G. Stresses in Rock PDFDocument4 pagesHerget, G. Stresses in Rock PDFAna Julia Becerra HernandezNo ratings yet

- Masterseal HLM 5000 India v2Document2 pagesMasterseal HLM 5000 India v2SUCHARITNo ratings yet

- 5000 Tds (1) 1Document6 pages5000 Tds (1) 1Abigail Myrra Magpayo DiazNo ratings yet

- Masterseal HLM 5000 R: Liquid Cold-Applied Waterproofing Membrane SystemDocument2 pagesMasterseal HLM 5000 R: Liquid Cold-Applied Waterproofing Membrane SystemLemark R.No ratings yet

- Masterseal hlm5000r TdsDocument3 pagesMasterseal hlm5000r TdsHabib ArifnurNo ratings yet

- Masterseal HLM 5000 R: Liquid Cold-Applied Elastomeric Waterproofing Membrane SystemDocument5 pagesMasterseal HLM 5000 R: Liquid Cold-Applied Elastomeric Waterproofing Membrane SystemshashiNo ratings yet

- Basf Masterseal m200 TdsDocument2 pagesBasf Masterseal m200 Tdsangelito bernalNo ratings yet

- Ex Pan Proof 600Document4 pagesEx Pan Proof 600Amar WadoodNo ratings yet

- 6 2 1 6 1 Polyflex PDFDocument2 pages6 2 1 6 1 Polyflex PDFFourier MakambioNo ratings yet

- Basf Masterseal 640 TdsDocument2 pagesBasf Masterseal 640 TdsJassi Singh0% (1)

- Basf Masterseal m200 TdsDocument2 pagesBasf Masterseal m200 Tdsjuli_radNo ratings yet

- Basf Masterseal 725hc TdsDocument2 pagesBasf Masterseal 725hc TdsshashiNo ratings yet

- AQUASHIELD PU PLUS December 2018Document2 pagesAQUASHIELD PU PLUS December 2018Anoop ShankarNo ratings yet

- NITOPROOFDocument4 pagesNITOPROOFTejinder KumarNo ratings yet

- Aquaarm Wpu 1K (E) Aquaarm Wpu 1K (E) Aquaarm Wpu 1K (E)Document3 pagesAquaarm Wpu 1K (E) Aquaarm Wpu 1K (E) Aquaarm Wpu 1K (E)PANDU RANGARAO A N VNo ratings yet

- Ikote CM 50X TDS (02-April-2024) V1.3Document2 pagesIkote CM 50X TDS (02-April-2024) V1.3nguyen hoang AnhNo ratings yet

- MasterProtect 300 Asean v3-0415Document2 pagesMasterProtect 300 Asean v3-0415Muhammad Fadhil ImansyahNo ratings yet

- ShaliUrethane WPUDocument3 pagesShaliUrethane WPURana MahatoNo ratings yet

- El Hyperdesmo-ClassicDocument4 pagesEl Hyperdesmo-ClassicΙοαννης ΡενκοNo ratings yet

- MR. DRY 805-v4Document2 pagesMR. DRY 805-v4Ankita Baban GavadeNo ratings yet

- AquaArm SBS 3000X Ver 2 1 PDFDocument3 pagesAquaArm SBS 3000X Ver 2 1 PDFNovember RainNo ratings yet

- Polytherm Ac: Highly Efficient, Energy-Saving Flexible CoatingDocument2 pagesPolytherm Ac: Highly Efficient, Energy-Saving Flexible CoatingVaittianathan MahavapillaiNo ratings yet

- Nitoproof 600: Liquid Applied Single Component Elastomeric Waterproofi NG MembraneDocument4 pagesNitoproof 600: Liquid Applied Single Component Elastomeric Waterproofi NG MembraneKunal MandalaywalaNo ratings yet

- Superthermolay 7: DescriptionDocument3 pagesSuperthermolay 7: DescriptioncsudhaNo ratings yet

- Masterpren Masterpren Masterpren Masterpren 1000 1000 1000 1000Document2 pagesMasterpren Masterpren Masterpren Masterpren 1000 1000 1000 1000Lemark R.No ratings yet

- Masterseal M 811 TdsDocument4 pagesMasterseal M 811 TdsAdityaVikramVermaNo ratings yet

- 2.AquaArm SBS 3000XDocument3 pages2.AquaArm SBS 3000XBijaya RaulaNo ratings yet

- Tds-Unichem AlumcoatDocument3 pagesTds-Unichem AlumcoatAnvesh BondugulaNo ratings yet

- Techothane-Pu: High Build Elastomeric Bituminous Polyurethane Based Waterproofing MembraneDocument5 pagesTechothane-Pu: High Build Elastomeric Bituminous Polyurethane Based Waterproofing Membraneannayya.chandrashekar Civil EngineerNo ratings yet

- Nitoproof 600 UAEDocument4 pagesNitoproof 600 UAECharles FernandesNo ratings yet

- Basf Masterflow 980 TdsDocument4 pagesBasf Masterflow 980 Tdschopdekar1969_890124No ratings yet

- Cemtec A1 Black PUDocument2 pagesCemtec A1 Black PUAhmad ElghazolyNo ratings yet

- X-Shield AcrylCoatDocument2 pagesX-Shield AcrylCoatEGO AnimationNo ratings yet

- Basf MasterEmaco S 488Document3 pagesBasf MasterEmaco S 488abdul majeedNo ratings yet

- MasterSeal 726 - TDSDocument2 pagesMasterSeal 726 - TDSKhin Sandi KoNo ratings yet

- BASF - MasterEmaco S5300CI - TDSDocument3 pagesBASF - MasterEmaco S5300CI - TDSKelvinNo ratings yet

- BM SELF HD 150 - 1 (2 Files Merged)Document4 pagesBM SELF HD 150 - 1 (2 Files Merged)vinoth kumar SanthanamNo ratings yet

- 1 - Masterseal-M-262-TdsDocument2 pages1 - Masterseal-M-262-TdsPaul ManiquisNo ratings yet

- Hyperdesmo 815Document5 pagesHyperdesmo 815Roger DaoudNo ratings yet

- Terrace Water ProofingDocument3 pagesTerrace Water ProofingKvrd PrasadNo ratings yet

- MasterProtect 300 v2Document2 pagesMasterProtect 300 v2Zainal AbidhynNo ratings yet

- Flexcrete 500: Epoxy Polysulfide Waterproofing CoatingDocument2 pagesFlexcrete 500: Epoxy Polysulfide Waterproofing CoatingSuresh YadavNo ratings yet

- STP Super Thermolay 3 MMDocument3 pagesSTP Super Thermolay 3 MMmanasmech002No ratings yet

- MasterBrace LAM - Updated.1 2Document2 pagesMasterBrace LAM - Updated.1 2Obrobb 92No ratings yet

- Rooftite AC5Document2 pagesRooftite AC5Anas SalamaNo ratings yet

- Hyperdesmo: (Classic Version) Polyurethane Liquid Membrane For Waterproofing & Protection, Easy ApplicationDocument4 pagesHyperdesmo: (Classic Version) Polyurethane Liquid Membrane For Waterproofing & Protection, Easy ApplicationGİZEM DEMİRNo ratings yet

- TamSeal 1500 V1SG 14Document2 pagesTamSeal 1500 V1SG 14Eagle RyonNo ratings yet

- TDS-Conbextra-HR-India5 6Document3 pagesTDS-Conbextra-HR-India5 6onshore purchaseNo ratings yet

- Mastertop 1205: Two Component Solvent Free High Build Epoxy Floor CoatingDocument3 pagesMastertop 1205: Two Component Solvent Free High Build Epoxy Floor CoatingFrancois-No ratings yet

- Basf Masterprotect 300 TdsDocument3 pagesBasf Masterprotect 300 TdsEngTamerNo ratings yet

- Aquashield: DescriptionDocument3 pagesAquashield: DescriptionRana MahatoNo ratings yet

- Ex Pan Proof 100Document3 pagesEx Pan Proof 100Amar WadoodNo ratings yet

- Cemtec A1 Black PUDocument2 pagesCemtec A1 Black PUPageduesca RouelNo ratings yet

- Hydroblocker Superelastic: Liquid MembraneDocument2 pagesHydroblocker Superelastic: Liquid MembraneSemir SpahicNo ratings yet

- Hyperdesmo Haa v2.1 - 0Document4 pagesHyperdesmo Haa v2.1 - 0Pro MNNo ratings yet

- Technical Data Sheet: Lasteek Rwe500Document2 pagesTechnical Data Sheet: Lasteek Rwe500Engr KamalNo ratings yet

- BASF MasterTop 1205 Data SheetDocument3 pagesBASF MasterTop 1205 Data SheetAhmed AssafNo ratings yet

- Basf Masterflow 950 TdsDocument3 pagesBasf Masterflow 950 TdsplmoNo ratings yet

- Masterflow 980 Tds PDFDocument4 pagesMasterflow 980 Tds PDFAdamo Absalome MulocheNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Sujok Therapy BooksDocument3 pagesSujok Therapy Booksshashi60% (5)

- Masterseal HLM 5000 R: Liquid Cold-Applied Elastomeric Waterproofing Membrane SystemDocument5 pagesMasterseal HLM 5000 R: Liquid Cold-Applied Elastomeric Waterproofing Membrane SystemshashiNo ratings yet

- Drfixit Torchshield PDFDocument4 pagesDrfixit Torchshield PDFshashiNo ratings yet

- Description Dr. Fixit Pidifin 2KDocument4 pagesDescription Dr. Fixit Pidifin 2KshashiNo ratings yet

- Basf Masterseal 725hc TdsDocument2 pagesBasf Masterseal 725hc TdsshashiNo ratings yet

- Masterseal 555S: Flexible, Polymer Cement Waterproofing SlurryDocument2 pagesMasterseal 555S: Flexible, Polymer Cement Waterproofing SlurryshashiNo ratings yet

- Topographic Map of OlneyDocument1 pageTopographic Map of OlneyHistoricalMapsNo ratings yet

- Accomplishment Report # 4Document2 pagesAccomplishment Report # 4Arnel FreoNo ratings yet

- Ch3 Fluids in Motion BerEqnDocument23 pagesCh3 Fluids in Motion BerEqnÄbðül BäşıţNo ratings yet

- CES522 A 04 - Topic 2b - 1. RC Beam Design - NotesDocument13 pagesCES522 A 04 - Topic 2b - 1. RC Beam Design - NotesAizuddinNo ratings yet

- FinalDocument19 pagesFinalADITYA BANERJEENo ratings yet

- Slope Stabilization MethodsDocument155 pagesSlope Stabilization MethodsJOE G PHILIP CENo ratings yet

- Thermowell Vibration Investigation and AnalysisDocument6 pagesThermowell Vibration Investigation and AnalysissheenNo ratings yet

- Material Tech Questions Solved BitsDocument22 pagesMaterial Tech Questions Solved BitsBalakumarNo ratings yet

- Awwa Hdpe PDFDocument37 pagesAwwa Hdpe PDFRaphael LinoNo ratings yet

- Fluid Mechanics Concept & Centrifugal Pump DesignDocument84 pagesFluid Mechanics Concept & Centrifugal Pump DesignRIMEL ASMANo ratings yet

- Archived CAITM Part B May 2010Document232 pagesArchived CAITM Part B May 2010binsuniNo ratings yet

- Air Conditioning and Heater System Air Conditioning and Heater SystemDocument2 pagesAir Conditioning and Heater System Air Conditioning and Heater SystemMichael DavenportNo ratings yet

- PWA IAN 021 Rev A1 - Cycleways and Footways Pavement Design GuidelinesDocument31 pagesPWA IAN 021 Rev A1 - Cycleways and Footways Pavement Design GuidelinesHenry TuganoNo ratings yet

- Manar Steel Waler SystemDocument56 pagesManar Steel Waler Systemtarek.fileNo ratings yet

- Schedules A B C D H Nalagampalli To KNT Border PDFDocument46 pagesSchedules A B C D H Nalagampalli To KNT Border PDFsankarrao333No ratings yet

- Tadepally GudamDocument469 pagesTadepally Gudamkiran raghukiranNo ratings yet

- References: ProblemsDocument14 pagesReferences: ProblemsDiego AlejandroNo ratings yet

- VRF System Vs Chiller SystemDocument14 pagesVRF System Vs Chiller Systemgowrish80_bmsNo ratings yet

- Thermax Mr.R.kulkarniDocument26 pagesThermax Mr.R.kulkarniPhani Kumar100% (1)

- Experiment No. 7: Mechanics of FluidsDocument7 pagesExperiment No. 7: Mechanics of FluidsJohn Patrick GoNo ratings yet

- Truss Analysis and DesignDocument14 pagesTruss Analysis and Designraymund baylonNo ratings yet

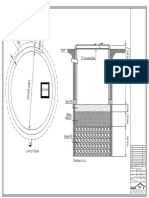

- Soakage WellDocument1 pageSoakage WellZayn ZahidNo ratings yet

- Design and Operations of Leach Pads PDFDocument42 pagesDesign and Operations of Leach Pads PDFEvan Buntoro100% (5)

- Numerical Modeling of The Annular Failure Pressure During HDD in Noncohesive SoilsDocument8 pagesNumerical Modeling of The Annular Failure Pressure During HDD in Noncohesive SoilsMD Anan MorshedNo ratings yet

- DPR Rate EstimateDocument2 pagesDPR Rate EstimateRajdeep BhadraNo ratings yet

- International Society For Soil Mechanics and Geotechnical EngineeringDocument6 pagesInternational Society For Soil Mechanics and Geotechnical EngineeringmaizansofiaNo ratings yet

- Plate No. 1 Reinforced Concrete DesignDocument3 pagesPlate No. 1 Reinforced Concrete DesignWilkenn TuazonNo ratings yet

Masterseal HLM 5000 India v2 PDF

Masterseal HLM 5000 India v2 PDF

Uploaded by

shashiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Masterseal HLM 5000 India v2 PDF

Masterseal HLM 5000 India v2 PDF

Uploaded by

shashiCopyright:

Available Formats

MasterSeal HLM 5000

(formerly known as Sonoshield HLM 5000)

Liquid cold-applied waterproofing membrane system

DESCRIPTION Supply form Liquid

MasterSeal HLM 5000 is a single component, Colour Black

bitumen modified, polyurethane based

Viscosity in poise of Self Level – 125,

waterproofing membrane that cures by reaction

various grades, Spray – 450, Roller –

with atmospheric moisture to form a tough

Brookfield 800,

membrane. MasterSeal HLM 5000 protects

structures from water penetration while remaining Application temperature 5°C to 35°C

flexible to handle the nominal expansion and

Minimum recovery 90%

contraction of substrates.

Swelling in water Nil

RECOMMENDED USES

Service temp, range -40°C to 50°C

Waterproofing exterior, below grade concrete and

between concrete slab applications. Self level-183 g/L

FEATURES AND BENEFITS VOC Content Spray- 190 g/L

Roller-180 g/L

• Waterproof - Protects structure from water

penetration % Solids 85%

• Elastomeric - Permits nominal expansion

and contraction of the structure Specific gravity 1.24

• Inert when cured - Resists bacterial attack

and salts found in ground waters

• Monolithic Single pack and one coat finish STANDARDS

liquid-applied - Eliminates lapping, seaming, • ASTM C 836

and precutting

• National standard of Canada 37.58-M86

• Single pack and one coat finish developed by CGSB

• Tough and durable - Long-term protection

APPLICATION

Surface Preparation

PROPERTIES

For best results, all concrete deck surfaces should

be lightly steel troweled to a flat, uniform surface.

A light broom finish is acceptable. New concrete

must be properly water cured at least 14 days.

Membrane curing compounds must be

mechanically removed.

Property Results Test For extremely porous block: Prime with a coat of

Method MasterSeal HLM 5000 diluted up to 25% with

ASTM C xylene.

Shore OO hardness 85 836 Remove dust, dirt and other contaminants just

ASTM D before or during application. Surfaces must be dry

Tensile strength – MPa 1.0 412 at the time of application. Air-void pockmarks or

ASTM D honeycombs must be opened up to allow

Average elongation % 600 412 MasterSeal HLM 5000 to fill the cavities

ASTM D completely.

100% modulus - MPa 0.6 412 Pre-striping

Moisture vapor ASTM E Before applying the final membrane, all joints,

permeability, dry perms 0.1 96

cracks and openings around protrusions must be

Crack bridging test, sealed by caulking or pre-striping (a preliminary

Passed ASTM C

cycled 10 times per 24 coating of MasterSeal HLM 5000 applied with a

@1.5mm 836

hours at –9°C trowel or stiff-bristled brush). Allow to dry overnight

Extensibility after heat No ASTM C before applying final membrane.

ageing cracking 836

ASTM C When the final membrane is applied, the overall

Weight loss (20% max) 16% 836 thickness over joints and cracks, at coves and

around penetrations should be approximately 2.5

mm on the standard system.

MasterSeal HLM 5000

®

(formerly known as Sonoshield HLM 5000)

Static Joints and Cracks Curing

Joints and cracks less than 1.6 mm should be filled Appreciable properties develop within 24–48 hours

by pre-striping. Apply material so it both fills and at 24°C and 50% relative humidity. Protect

overlaps the joint or crack to a width of 100 mm on MasterSeal HLM 5000 from traffic during curing.

each side. Drainage and Protection

For protection during backfill and where

Working or Expansion Joints hydrostatic pressure is anticipated, use a suitable

All joints over 3 mm must be sealed with a Master geotextile to divert the water.

Builders Solutions urethane sealant. Any working For protection during backfill only, install

joint less than 3 mm should be routed to a protection board as soon as possible following

minimum of 6 mm and filled with a sealant. cure of MasterSeal HLM 5000.

Prevent the waterproofing membrane from

adhering to the joint sealant by applying a coat of ESTIMATING DATA

wax or bond breaker tape over the cured sealant Wet Film Thickness @ 1.65mm = 0.6m2/litre

and then pre-striping. Coverage per 18.93 litres is approximately 11.6m²

Uncoated Metal Surfaces PACKAGING

Remove dust, debris, and any other contaminants

MasterSeal HLM 5000 comes in a variety of

from vent, drain pipe and post penetrations, reglets

grades for different applications, dependent on

and other metal surfaces. Clean surfaces to near

surface profile, texture and horizontal or vertical.

white to SAE2.5 and prime immediately with

• MasterSeal HLM 5000SL (self-leveling) is

MasterSeal P 691.

formulated for application by squeegee or

Provide appropriate cant with MasterSeal sealant

trowel to horizontal areas.

to eliminate 90° angles.

• MasterSeal HLM 5000S (spray or roller) is a

Application versatile formulated version for spray

A test application is always recommended before application and or rolled onto horizontal or

proceeding with entire application. vertical surfaces.

Standard System All grades are available in 18.93 litre pails.

Select the grade of MasterSeal HLM 5000 that

SHELF LIFE

best meets individual job requirements

For horizontal applications, empty contents of pail MasterSeal HLM 5000 has a shelf life of 12

and spread immediately to ensure workability. Best months. Store out of direct sunlight, clear of the

results are obtained by marking off 11.6 m2 areas ground on pallets protected from rainfall.

and evenly spreading the contents of a 18.93 L PRECAUTIONS

unit with a rubber-edged notched squeegee.

For vertical applications, apply by trowel, roller or For the full health and safety hazard information

spray at the rate of 0.6 m2/L. and how to safely handle and use this product,

Verify the applied thickness with a wet film gauge please make sure that you obtain a copy of the

as the work progresses. BASF Material Safety Data Sheet (MSDS) from

our office or our website.

® = registered trademark of BASF group in many countries MasterSeal HLM _5000 india-v2-1119

The technical information and application advice given in this BASF publication are based on the present state of

STATEMENT OF our best scientific and practical knowledge. As the information herein is of a general nature, no assumption can be

RESPONSIBILITY made as to a product's suitability for a particular use or application and no warranty as to its accuracy, reliability or

completeness either expressed or implied is given other than those required by law. The user is responsible for

checking the suitability of products for their intended use.

Field service where provided does not constitute supervisory responsibility. Suggestions made by BASF

NOTE Construction Chemicals either orally or in writing may be followed, modified or rejected by the owner, engineer or

contractor since they, and not BASF Construction Chemicals, are responsible for carrying out procedures

appropriate to a specific application.

BASF India Limited

Construction Chemicals Division

Plot.No.12,TTC Area

Thane Belapur Road,Turbhe

Navi Mumbai - 400705,India

Tel: +91 22 67127600, Fax: +91 22 67917358

E-mail: construction-india@basf.com , www.master-builders-solutions.basf.in

You might also like

- MasterProtect 300Document3 pagesMasterProtect 300Gavriel NgNo ratings yet

- FRP Piping Design Manual - Sep-06Document27 pagesFRP Piping Design Manual - Sep-06Sabir Nasim100% (3)

- Truck Lay Bye Toilet Block - 04 PDFDocument1 pageTruck Lay Bye Toilet Block - 04 PDFSanjeev KumarNo ratings yet

- Herget, G. Stresses in Rock PDFDocument4 pagesHerget, G. Stresses in Rock PDFAna Julia Becerra HernandezNo ratings yet

- Masterseal HLM 5000 India v2Document2 pagesMasterseal HLM 5000 India v2SUCHARITNo ratings yet

- 5000 Tds (1) 1Document6 pages5000 Tds (1) 1Abigail Myrra Magpayo DiazNo ratings yet

- Masterseal HLM 5000 R: Liquid Cold-Applied Waterproofing Membrane SystemDocument2 pagesMasterseal HLM 5000 R: Liquid Cold-Applied Waterproofing Membrane SystemLemark R.No ratings yet

- Masterseal hlm5000r TdsDocument3 pagesMasterseal hlm5000r TdsHabib ArifnurNo ratings yet

- Masterseal HLM 5000 R: Liquid Cold-Applied Elastomeric Waterproofing Membrane SystemDocument5 pagesMasterseal HLM 5000 R: Liquid Cold-Applied Elastomeric Waterproofing Membrane SystemshashiNo ratings yet

- Basf Masterseal m200 TdsDocument2 pagesBasf Masterseal m200 Tdsangelito bernalNo ratings yet

- Ex Pan Proof 600Document4 pagesEx Pan Proof 600Amar WadoodNo ratings yet

- 6 2 1 6 1 Polyflex PDFDocument2 pages6 2 1 6 1 Polyflex PDFFourier MakambioNo ratings yet

- Basf Masterseal 640 TdsDocument2 pagesBasf Masterseal 640 TdsJassi Singh0% (1)

- Basf Masterseal m200 TdsDocument2 pagesBasf Masterseal m200 Tdsjuli_radNo ratings yet

- Basf Masterseal 725hc TdsDocument2 pagesBasf Masterseal 725hc TdsshashiNo ratings yet

- AQUASHIELD PU PLUS December 2018Document2 pagesAQUASHIELD PU PLUS December 2018Anoop ShankarNo ratings yet

- NITOPROOFDocument4 pagesNITOPROOFTejinder KumarNo ratings yet

- Aquaarm Wpu 1K (E) Aquaarm Wpu 1K (E) Aquaarm Wpu 1K (E)Document3 pagesAquaarm Wpu 1K (E) Aquaarm Wpu 1K (E) Aquaarm Wpu 1K (E)PANDU RANGARAO A N VNo ratings yet

- Ikote CM 50X TDS (02-April-2024) V1.3Document2 pagesIkote CM 50X TDS (02-April-2024) V1.3nguyen hoang AnhNo ratings yet

- MasterProtect 300 Asean v3-0415Document2 pagesMasterProtect 300 Asean v3-0415Muhammad Fadhil ImansyahNo ratings yet

- ShaliUrethane WPUDocument3 pagesShaliUrethane WPURana MahatoNo ratings yet

- El Hyperdesmo-ClassicDocument4 pagesEl Hyperdesmo-ClassicΙοαννης ΡενκοNo ratings yet

- MR. DRY 805-v4Document2 pagesMR. DRY 805-v4Ankita Baban GavadeNo ratings yet

- AquaArm SBS 3000X Ver 2 1 PDFDocument3 pagesAquaArm SBS 3000X Ver 2 1 PDFNovember RainNo ratings yet

- Polytherm Ac: Highly Efficient, Energy-Saving Flexible CoatingDocument2 pagesPolytherm Ac: Highly Efficient, Energy-Saving Flexible CoatingVaittianathan MahavapillaiNo ratings yet

- Nitoproof 600: Liquid Applied Single Component Elastomeric Waterproofi NG MembraneDocument4 pagesNitoproof 600: Liquid Applied Single Component Elastomeric Waterproofi NG MembraneKunal MandalaywalaNo ratings yet

- Superthermolay 7: DescriptionDocument3 pagesSuperthermolay 7: DescriptioncsudhaNo ratings yet

- Masterpren Masterpren Masterpren Masterpren 1000 1000 1000 1000Document2 pagesMasterpren Masterpren Masterpren Masterpren 1000 1000 1000 1000Lemark R.No ratings yet

- Masterseal M 811 TdsDocument4 pagesMasterseal M 811 TdsAdityaVikramVermaNo ratings yet

- 2.AquaArm SBS 3000XDocument3 pages2.AquaArm SBS 3000XBijaya RaulaNo ratings yet

- Tds-Unichem AlumcoatDocument3 pagesTds-Unichem AlumcoatAnvesh BondugulaNo ratings yet

- Techothane-Pu: High Build Elastomeric Bituminous Polyurethane Based Waterproofing MembraneDocument5 pagesTechothane-Pu: High Build Elastomeric Bituminous Polyurethane Based Waterproofing Membraneannayya.chandrashekar Civil EngineerNo ratings yet

- Nitoproof 600 UAEDocument4 pagesNitoproof 600 UAECharles FernandesNo ratings yet

- Basf Masterflow 980 TdsDocument4 pagesBasf Masterflow 980 Tdschopdekar1969_890124No ratings yet

- Cemtec A1 Black PUDocument2 pagesCemtec A1 Black PUAhmad ElghazolyNo ratings yet

- X-Shield AcrylCoatDocument2 pagesX-Shield AcrylCoatEGO AnimationNo ratings yet

- Basf MasterEmaco S 488Document3 pagesBasf MasterEmaco S 488abdul majeedNo ratings yet

- MasterSeal 726 - TDSDocument2 pagesMasterSeal 726 - TDSKhin Sandi KoNo ratings yet

- BASF - MasterEmaco S5300CI - TDSDocument3 pagesBASF - MasterEmaco S5300CI - TDSKelvinNo ratings yet

- BM SELF HD 150 - 1 (2 Files Merged)Document4 pagesBM SELF HD 150 - 1 (2 Files Merged)vinoth kumar SanthanamNo ratings yet

- 1 - Masterseal-M-262-TdsDocument2 pages1 - Masterseal-M-262-TdsPaul ManiquisNo ratings yet

- Hyperdesmo 815Document5 pagesHyperdesmo 815Roger DaoudNo ratings yet

- Terrace Water ProofingDocument3 pagesTerrace Water ProofingKvrd PrasadNo ratings yet

- MasterProtect 300 v2Document2 pagesMasterProtect 300 v2Zainal AbidhynNo ratings yet

- Flexcrete 500: Epoxy Polysulfide Waterproofing CoatingDocument2 pagesFlexcrete 500: Epoxy Polysulfide Waterproofing CoatingSuresh YadavNo ratings yet

- STP Super Thermolay 3 MMDocument3 pagesSTP Super Thermolay 3 MMmanasmech002No ratings yet

- MasterBrace LAM - Updated.1 2Document2 pagesMasterBrace LAM - Updated.1 2Obrobb 92No ratings yet

- Rooftite AC5Document2 pagesRooftite AC5Anas SalamaNo ratings yet

- Hyperdesmo: (Classic Version) Polyurethane Liquid Membrane For Waterproofing & Protection, Easy ApplicationDocument4 pagesHyperdesmo: (Classic Version) Polyurethane Liquid Membrane For Waterproofing & Protection, Easy ApplicationGİZEM DEMİRNo ratings yet

- TamSeal 1500 V1SG 14Document2 pagesTamSeal 1500 V1SG 14Eagle RyonNo ratings yet

- TDS-Conbextra-HR-India5 6Document3 pagesTDS-Conbextra-HR-India5 6onshore purchaseNo ratings yet

- Mastertop 1205: Two Component Solvent Free High Build Epoxy Floor CoatingDocument3 pagesMastertop 1205: Two Component Solvent Free High Build Epoxy Floor CoatingFrancois-No ratings yet

- Basf Masterprotect 300 TdsDocument3 pagesBasf Masterprotect 300 TdsEngTamerNo ratings yet

- Aquashield: DescriptionDocument3 pagesAquashield: DescriptionRana MahatoNo ratings yet

- Ex Pan Proof 100Document3 pagesEx Pan Proof 100Amar WadoodNo ratings yet

- Cemtec A1 Black PUDocument2 pagesCemtec A1 Black PUPageduesca RouelNo ratings yet

- Hydroblocker Superelastic: Liquid MembraneDocument2 pagesHydroblocker Superelastic: Liquid MembraneSemir SpahicNo ratings yet

- Hyperdesmo Haa v2.1 - 0Document4 pagesHyperdesmo Haa v2.1 - 0Pro MNNo ratings yet

- Technical Data Sheet: Lasteek Rwe500Document2 pagesTechnical Data Sheet: Lasteek Rwe500Engr KamalNo ratings yet

- BASF MasterTop 1205 Data SheetDocument3 pagesBASF MasterTop 1205 Data SheetAhmed AssafNo ratings yet

- Basf Masterflow 950 TdsDocument3 pagesBasf Masterflow 950 TdsplmoNo ratings yet

- Masterflow 980 Tds PDFDocument4 pagesMasterflow 980 Tds PDFAdamo Absalome MulocheNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Sujok Therapy BooksDocument3 pagesSujok Therapy Booksshashi60% (5)

- Masterseal HLM 5000 R: Liquid Cold-Applied Elastomeric Waterproofing Membrane SystemDocument5 pagesMasterseal HLM 5000 R: Liquid Cold-Applied Elastomeric Waterproofing Membrane SystemshashiNo ratings yet

- Drfixit Torchshield PDFDocument4 pagesDrfixit Torchshield PDFshashiNo ratings yet

- Description Dr. Fixit Pidifin 2KDocument4 pagesDescription Dr. Fixit Pidifin 2KshashiNo ratings yet

- Basf Masterseal 725hc TdsDocument2 pagesBasf Masterseal 725hc TdsshashiNo ratings yet

- Masterseal 555S: Flexible, Polymer Cement Waterproofing SlurryDocument2 pagesMasterseal 555S: Flexible, Polymer Cement Waterproofing SlurryshashiNo ratings yet

- Topographic Map of OlneyDocument1 pageTopographic Map of OlneyHistoricalMapsNo ratings yet

- Accomplishment Report # 4Document2 pagesAccomplishment Report # 4Arnel FreoNo ratings yet

- Ch3 Fluids in Motion BerEqnDocument23 pagesCh3 Fluids in Motion BerEqnÄbðül BäşıţNo ratings yet

- CES522 A 04 - Topic 2b - 1. RC Beam Design - NotesDocument13 pagesCES522 A 04 - Topic 2b - 1. RC Beam Design - NotesAizuddinNo ratings yet

- FinalDocument19 pagesFinalADITYA BANERJEENo ratings yet

- Slope Stabilization MethodsDocument155 pagesSlope Stabilization MethodsJOE G PHILIP CENo ratings yet

- Thermowell Vibration Investigation and AnalysisDocument6 pagesThermowell Vibration Investigation and AnalysissheenNo ratings yet

- Material Tech Questions Solved BitsDocument22 pagesMaterial Tech Questions Solved BitsBalakumarNo ratings yet

- Awwa Hdpe PDFDocument37 pagesAwwa Hdpe PDFRaphael LinoNo ratings yet

- Fluid Mechanics Concept & Centrifugal Pump DesignDocument84 pagesFluid Mechanics Concept & Centrifugal Pump DesignRIMEL ASMANo ratings yet

- Archived CAITM Part B May 2010Document232 pagesArchived CAITM Part B May 2010binsuniNo ratings yet

- Air Conditioning and Heater System Air Conditioning and Heater SystemDocument2 pagesAir Conditioning and Heater System Air Conditioning and Heater SystemMichael DavenportNo ratings yet

- PWA IAN 021 Rev A1 - Cycleways and Footways Pavement Design GuidelinesDocument31 pagesPWA IAN 021 Rev A1 - Cycleways and Footways Pavement Design GuidelinesHenry TuganoNo ratings yet

- Manar Steel Waler SystemDocument56 pagesManar Steel Waler Systemtarek.fileNo ratings yet

- Schedules A B C D H Nalagampalli To KNT Border PDFDocument46 pagesSchedules A B C D H Nalagampalli To KNT Border PDFsankarrao333No ratings yet

- Tadepally GudamDocument469 pagesTadepally Gudamkiran raghukiranNo ratings yet

- References: ProblemsDocument14 pagesReferences: ProblemsDiego AlejandroNo ratings yet

- VRF System Vs Chiller SystemDocument14 pagesVRF System Vs Chiller Systemgowrish80_bmsNo ratings yet

- Thermax Mr.R.kulkarniDocument26 pagesThermax Mr.R.kulkarniPhani Kumar100% (1)

- Experiment No. 7: Mechanics of FluidsDocument7 pagesExperiment No. 7: Mechanics of FluidsJohn Patrick GoNo ratings yet

- Truss Analysis and DesignDocument14 pagesTruss Analysis and Designraymund baylonNo ratings yet

- Soakage WellDocument1 pageSoakage WellZayn ZahidNo ratings yet

- Design and Operations of Leach Pads PDFDocument42 pagesDesign and Operations of Leach Pads PDFEvan Buntoro100% (5)

- Numerical Modeling of The Annular Failure Pressure During HDD in Noncohesive SoilsDocument8 pagesNumerical Modeling of The Annular Failure Pressure During HDD in Noncohesive SoilsMD Anan MorshedNo ratings yet

- DPR Rate EstimateDocument2 pagesDPR Rate EstimateRajdeep BhadraNo ratings yet

- International Society For Soil Mechanics and Geotechnical EngineeringDocument6 pagesInternational Society For Soil Mechanics and Geotechnical EngineeringmaizansofiaNo ratings yet

- Plate No. 1 Reinforced Concrete DesignDocument3 pagesPlate No. 1 Reinforced Concrete DesignWilkenn TuazonNo ratings yet