Professional Documents

Culture Documents

1639-U-008 R02 Data Sheet

1639-U-008 R02 Data Sheet

Uploaded by

HEMANTCopyright:

Available Formats

You might also like

- ELG2336 Lab 2 - Oscilloscope and Function GeneratorDocument7 pagesELG2336 Lab 2 - Oscilloscope and Function GeneratorJonathan Sergio100% (1)

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionFrom EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionRating: 4 out of 5 stars4/5 (1)

- 1639-U-008 R02 Data Sheet 16 Dec 18Document16 pages1639-U-008 R02 Data Sheet 16 Dec 18HEMANTNo ratings yet

- Sludge Screw Pump DatasheetDocument2 pagesSludge Screw Pump DatasheetVenkatesh SivaramanNo ratings yet

- Rating 460.8 m3h - 108m - CEP 150-630-250.0kW-1500rpm-380V-3Ph-50HzDocument3 pagesRating 460.8 m3h - 108m - CEP 150-630-250.0kW-1500rpm-380V-3Ph-50HzTrung TrịnhNo ratings yet

- Brochure LPDA, 50 HZDocument6 pagesBrochure LPDA, 50 HZTAUFIQ ARIEF NUGRAHANo ratings yet

- Bomba Centrifuga InoxDocument9 pagesBomba Centrifuga InoxGregorio Mata MartínezNo ratings yet

- C 15 EngineDocument2 pagesC 15 EngineAldo Cesar Mina SosaNo ratings yet

- PN11 - Deluge PumpDocument2 pagesPN11 - Deluge PumpFayez Al-ahmadiNo ratings yet

- Technical Specification Sheet For Auxiliaries Equipment OfJ - 420Document2 pagesTechnical Specification Sheet For Auxiliaries Equipment OfJ - 420Muhammad Mujtaba TariqNo ratings yet

- Annexure To Be AttachedDocument12 pagesAnnexure To Be AttachedAnonymous vspGaH8No ratings yet

- FACOR - TS 5.1 - Pumps - R1Document9 pagesFACOR - TS 5.1 - Pumps - R1Amit TiwariNo ratings yet

- TRHC 80-600-750Document5 pagesTRHC 80-600-750Sukron Nursalim100% (1)

- 5 KJ 4 e 75 YsabetrvrfDocument2 pages5 KJ 4 e 75 YsabetrvrfMohamed SelimNo ratings yet

- CNE 2AC - 341 m3ph @200 M (Sump Depth 2000m)Document3 pagesCNE 2AC - 341 m3ph @200 M (Sump Depth 2000m)Wibowo ArieNo ratings yet

- TDB FHA 50HZ Rev 2Document36 pagesTDB FHA 50HZ Rev 2quangsang1311No ratings yet

- Datasheet - PG G-Drive NEF45SM2X - 69kWDocument13 pagesDatasheet - PG G-Drive NEF45SM2X - 69kWcesar saavedra saavedraNo ratings yet

- CDL 20-14 3PH 50HZ Ci 15-0KWDocument2 pagesCDL 20-14 3PH 50HZ Ci 15-0KWthreephase electricNo ratings yet

- Technical Specification: General InformationDocument3 pagesTechnical Specification: General InformationAli BhaiNo ratings yet

- 4 Stroke Diesel Engine, Direct Injection: 126 X 155 MM 6 in Line 11.6 Litres 17/1 CCW 600 RPM 1200 KG Sae 1 SAE 14"Document2 pages4 Stroke Diesel Engine, Direct Injection: 126 X 155 MM 6 in Line 11.6 Litres 17/1 CCW 600 RPM 1200 KG Sae 1 SAE 14"NarcisaNo ratings yet

- Service Manual: Mjfcifss Diesel EnginesDocument16 pagesService Manual: Mjfcifss Diesel EnginesCiprian CojocaruNo ratings yet

- 2.6.4 Alimentación Al Sistema de Ultrafiltración (5450-PP-007 A-B)Document2 pages2.6.4 Alimentación Al Sistema de Ultrafiltración (5450-PP-007 A-B)Jennifer FigueroaNo ratings yet

- Perkins 650 KVADocument4 pagesPerkins 650 KVASulistiani ArlimNo ratings yet

- Technical Data Book Vertical In-Line Centrifugal Pump: Model Suction and Dicharge Size 100 200 MMDocument24 pagesTechnical Data Book Vertical In-Line Centrifugal Pump: Model Suction and Dicharge Size 100 200 MMpratikNo ratings yet

- Grundfos - CR 5 4 A A A E HQQE PDFDocument15 pagesGrundfos - CR 5 4 A A A E HQQE PDFabhe prasetyaNo ratings yet

- Mesin 1TR-FEDocument59 pagesMesin 1TR-FEkopler100% (1)

- 195 6lms3811 28084550Document6 pages195 6lms3811 28084550Mustafa FaisalNo ratings yet

- Grundfos CR 5 13 A FGJ A e HqqeDocument15 pagesGrundfos CR 5 13 A FGJ A e HqqeRadu-Stefan MusatNo ratings yet

- Amacan P 50 HZDocument52 pagesAmacan P 50 HZtejo murgiyantoNo ratings yet

- Parameter NSH-CGS1111-C22-320-C1Document2 pagesParameter NSH-CGS1111-C22-320-C1Didik SupriyantoNo ratings yet

- Qty. Description CR 5-13: Note! Product Picture May Differ From Actual ProductDocument2 pagesQty. Description CR 5-13: Note! Product Picture May Differ From Actual ProductMáy bơm Công nghiệpNo ratings yet

- Diesel Power 50Hz Open Type Generator SetDocument8 pagesDiesel Power 50Hz Open Type Generator Setchock channel 19No ratings yet

- Technical Specification: General InformationDocument3 pagesTechnical Specification: General InformationMuzaffar AliNo ratings yet

- Omega RDLDocument24 pagesOmega RDLOmar LamraniNo ratings yet

- CDL4 163ph50hzci30kwDocument2 pagesCDL4 163ph50hzci30kwthreephase electricNo ratings yet

- Cat® Engine SpecificationsDocument5 pagesCat® Engine SpecificationsadelabostatNo ratings yet

- SPECSHEET - CP150 - Perkins 1104Document3 pagesSPECSHEET - CP150 - Perkins 1104Abe BustomiNo ratings yet

- Deutz 30 KvaDocument4 pagesDeutz 30 Kvafirman harianjaNo ratings yet

- Etachrom NC Bomba 1700m011-m012-m013Document16 pagesEtachrom NC Bomba 1700m011-m012-m013Miguel Morales SandovalNo ratings yet

- Deutz Chin (s6K)Document1 pageDeutz Chin (s6K)ehsan alirezaeiNo ratings yet

- 195 6lms6006 28150403Document6 pages195 6lms6006 28150403Mustafa FaisalNo ratings yet

- Pump Duty Points - DesDocument8 pagesPump Duty Points - DesMaqsood NishatNo ratings yet

- CHLF4 603PH50HZSS 31611KWDocument2 pagesCHLF4 603PH50HZSS 31611KWKunal GadeNo ratings yet

- Offer No 9498 DTD 07.03.23Document1 pageOffer No 9498 DTD 07.03.23Shahab Z AhmedNo ratings yet

- Page 493 of 635Document30 pagesPage 493 of 635Sugadev SinghNo ratings yet

- Grundfos - CR 10 4 A FJ A E HQQEDocument15 pagesGrundfos - CR 10 4 A FJ A E HQQErosneyNo ratings yet

- C100 Service Training Manual: Engine Repair (2.4L DOHC)Document30 pagesC100 Service Training Manual: Engine Repair (2.4L DOHC)DangLuyenNo ratings yet

- Perkins 45 KVADocument4 pagesPerkins 45 KVASadiman SadimanNo ratings yet

- KAKFIREALARM04DESDocument3 pagesKAKFIREALARM04DESGilang ArdiNo ratings yet

- FW16 WP13 Engine Spec SheetDocument2 pagesFW16 WP13 Engine Spec Sheetwilmer andrade bustamanteNo ratings yet

- Amacan K: Submersible Motor Pump For Installation in Discharge Tubes With Channel-Type ImpellerDocument44 pagesAmacan K: Submersible Motor Pump For Installation in Discharge Tubes With Channel-Type Impellerst_calvoNo ratings yet

- Appl NT081 TDK FPS TDS 01 R0Document12 pagesAppl NT081 TDK FPS TDS 01 R0TILAK RAJ KambojNo ratings yet

- 8218 CDLF 8-18 3PH 50HZ SS-304 7-5KWDocument2 pages8218 CDLF 8-18 3PH 50HZ SS-304 7-5KWPrafful ShrivastavaNo ratings yet

- Offer Pump Technical R1 - MF 40-45 PDFDocument1 pageOffer Pump Technical R1 - MF 40-45 PDFREMINGTON SALAYANo ratings yet

- CR1-33 A-FGJ-A-E-HQQE 3x400D 50HZ: Grundfos Pump 96513309Document15 pagesCR1-33 A-FGJ-A-E-HQQE 3x400D 50HZ: Grundfos Pump 96513309Muhammad GhufranNo ratings yet

- 1 1F531120548 PDFDocument4 pages1 1F531120548 PDFAtish ChandNo ratings yet

- Data Sheet For Ecp8x6x17Document1 pageData Sheet For Ecp8x6x17Srinu GudalaNo ratings yet

- Fawde 30 KVA (4DW92 - 39D) - 3 PhaseDocument4 pagesFawde 30 KVA (4DW92 - 39D) - 3 PhaseckondoyNo ratings yet

- Engine Specifications: H.Harada K.SanadaDocument5 pagesEngine Specifications: H.Harada K.SanadaJohn GarnetNo ratings yet

- Cummins 125 KVADocument4 pagesCummins 125 KVAZein Ardha101No ratings yet

- Kitchen WorkingDocument1 pageKitchen WorkingHEMANTNo ratings yet

- VISA Power 28th July - VGV R4Document37 pagesVISA Power 28th July - VGV R4HEMANTNo ratings yet

- User Manual For General Trade/Storage License Application - SDMC and NDMCDocument14 pagesUser Manual For General Trade/Storage License Application - SDMC and NDMCHEMANTNo ratings yet

- Summary of Cost For Ibef, Upcoming Office at 20Th Floor, STC Building Janpath, C.P. S.No Description of Item Page NoDocument32 pagesSummary of Cost For Ibef, Upcoming Office at 20Th Floor, STC Building Janpath, C.P. S.No Description of Item Page NoHEMANTNo ratings yet

- Technical Annexure - PODocument27 pagesTechnical Annexure - POHEMANTNo ratings yet

- Calculation of Heat and Mass BalanceDocument16 pagesCalculation of Heat and Mass BalanceHEMANTNo ratings yet

- 1639-U-008 R02 Data Sheet 16 Dec 18Document16 pages1639-U-008 R02 Data Sheet 16 Dec 18HEMANTNo ratings yet

- 1.1 Type of Check Shall Be D.P. Test in Place of VisualDocument1 page1.1 Type of Check Shall Be D.P. Test in Place of VisualHEMANTNo ratings yet

- 1639-U-005 - R06 Datasheet Latest DatasheetDocument4 pages1639-U-005 - R06 Datasheet Latest DatasheetHEMANTNo ratings yet

- 1639-U-005 - R05 Datasheet Latest DatasheetDocument4 pages1639-U-005 - R05 Datasheet Latest DatasheetHEMANTNo ratings yet

- Flow Meter Data SheetDocument1 pageFlow Meter Data SheetHEMANTNo ratings yet

- DCS Tags Description Instr. Type Wire Type Signal Type Signal Level Motor RatingDocument7 pagesDCS Tags Description Instr. Type Wire Type Signal Type Signal Level Motor RatingHEMANTNo ratings yet

- Spec. No. 7311-DE-041Document1 pageSpec. No. 7311-DE-041HEMANTNo ratings yet

- 9 IO and Parameter ListDocument5 pages9 IO and Parameter ListHEMANTNo ratings yet

- Spec. No. 7311-DE-042Document1 pageSpec. No. 7311-DE-042HEMANTNo ratings yet

- DGN-205 Doc. Rev.03 PDFDocument3 pagesDGN-205 Doc. Rev.03 PDFHEMANTNo ratings yet

- Control Philosophy of DearatorDocument2 pagesControl Philosophy of DearatorHEMANTNo ratings yet

- DGN-205 Doc. Rev.03 PDFDocument3 pagesDGN-205 Doc. Rev.03 PDFHEMANTNo ratings yet

- E-Mail - : Navinender - Gupta@korus - inDocument1 pageE-Mail - : Navinender - Gupta@korus - inHEMANTNo ratings yet

- Contador 542-072a-ManualDocument8 pagesContador 542-072a-ManualRONALD ALFONSO PACHECO TORRESNo ratings yet

- An Overview and Validation of The Fitness-For-Service Assessment Procedures For Local Thin AreasDocument280 pagesAn Overview and Validation of The Fitness-For-Service Assessment Procedures For Local Thin AreasCARLOS M.No ratings yet

- Walk Forward Optimization by John EhlersDocument3 pagesWalk Forward Optimization by John EhlersquimkoNo ratings yet

- 10 Computer Chapter WiseDocument7 pages10 Computer Chapter WiseZeba KhNo ratings yet

- Quantitative and Morphological Characterization of Wheat (Triticum Aestivum L.) in Middle LandDocument8 pagesQuantitative and Morphological Characterization of Wheat (Triticum Aestivum L.) in Middle LandNur Mega Febriyanti M. GalibNo ratings yet

- 12th Science HSC Chemistry IIDocument40 pages12th Science HSC Chemistry IIRajesh KaundalNo ratings yet

- Isometries of The Plane - BoswellDocument7 pagesIsometries of The Plane - BoswellGuido 125 LavespaNo ratings yet

- Iso 7790Document12 pagesIso 7790Fabio StuiNo ratings yet

- KS5 "Full Coverage": Connected Particles (Yr2) : (Edexcel M1 Jan 2008 Q7a)Document18 pagesKS5 "Full Coverage": Connected Particles (Yr2) : (Edexcel M1 Jan 2008 Q7a)Nazif MorshedNo ratings yet

- New Time Table 2081Document2 pagesNew Time Table 2081shankalprajkhanalNo ratings yet

- Class Work - 4 - Solutions PDFDocument9 pagesClass Work - 4 - Solutions PDFRaymond LeoNo ratings yet

- CoypuDocument20 pagesCoypuperfectNo ratings yet

- AC Circuits Module 1Document28 pagesAC Circuits Module 1YoNo ratings yet

- Retake Practical Quiz (Page 3 of 4)Document9 pagesRetake Practical Quiz (Page 3 of 4)Dương HoàngNo ratings yet

- v25 Algebra 1 5.02.odtDocument6 pagesv25 Algebra 1 5.02.odtSam's vrNo ratings yet

- Levers in Musculoskeletal SystemDocument22 pagesLevers in Musculoskeletal SystemGlenn JohnstonNo ratings yet

- Mechanical Component ToleranceDocument2 pagesMechanical Component ToleranceOmkar Kumar JhaNo ratings yet

- National T Esting Agency: GeographyDocument28 pagesNational T Esting Agency: GeographyMahesh B RajputNo ratings yet

- Chapter Two: Kinematics and Dynamics of ParticlesDocument129 pagesChapter Two: Kinematics and Dynamics of ParticlesEphrem ChernetNo ratings yet

- AGV 50 Gas Turbine Fuel ValveDocument4 pagesAGV 50 Gas Turbine Fuel Valvehzq1eNo ratings yet

- Practice Problem 2 PDFDocument2 pagesPractice Problem 2 PDFDeeksha MishraNo ratings yet

- Peak Flow Calculation-LunugalaDocument3 pagesPeak Flow Calculation-LunugalakanishkaNo ratings yet

- Warm Up Exam # 2 QuestionerDocument6 pagesWarm Up Exam # 2 QuestionerJimmy GutierrezNo ratings yet

- Major Takeaways of SDET ProgramDocument3 pagesMajor Takeaways of SDET ProgramMalli PikkiliNo ratings yet

- 9/6, Lpsohphqwdwlrqvri Duwlilfldoqhxudoqhwzrunv: Aboratoire de IcroélectroniqueDocument8 pages9/6, Lpsohphqwdwlrqvri Duwlilfldoqhxudoqhwzrunv: Aboratoire de Icroélectroniquevarsha raichalNo ratings yet

- Subwoofer Box For Skar VD10 - Ported Box - SlotDocument2 pagesSubwoofer Box For Skar VD10 - Ported Box - SlotMarvin RiveraNo ratings yet

- CS322 - Handout Computer Organization and Architecture - UpdatedDocument3 pagesCS322 - Handout Computer Organization and Architecture - UpdatedKiran TradeNo ratings yet

- MM103 Lab 4Document4 pagesMM103 Lab 4Shivneel SwamyNo ratings yet

- 45BDocument5 pages45BJamie SchultzNo ratings yet

1639-U-008 R02 Data Sheet

1639-U-008 R02 Data Sheet

Uploaded by

HEMANTOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1639-U-008 R02 Data Sheet

1639-U-008 R02 Data Sheet

Uploaded by

HEMANTCopyright:

Available Formats

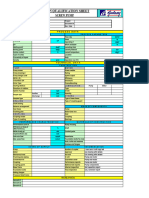

Korus Engineering Solutions Pvt. Ltd. Jindal Urban Waste Management (Guntur) Ltd.

TECHNICAL DATA SHEET & SCOPE OF SUPPLY

S.N. DESCRIPTION UNIT REQUIREMENTS VENDOR DETAILS REMARKS

1 PUMP HOUSE EQUIPMENTS - MECHANICAL

1.1 Main Cenrifugal Pump

a Technical Specifications

Horizontal Split Casing/Back Pull

Type of pump Out

No. of pumps 1

Pump model

Pump make

Pump design standard IS-5120

Service fluid temperature (max.) 50

Capacity of pump 273 m3/hr

Differential head 88 mWC

Speed 1440

Pump head at 150 % of rated capacity

Shut off head

Pump shaft power at 150 % of rated discharge

Type of impeller Closed

Rated impeller diameter

NPSHR

Pump efficiency at duty point

Pumpshaft input at duty point

Sealing type Gland

Type of coupling

MOC / Make of coupling

Bearing type / make

b Material of Construction of Main Parts

Casing CI IS 210 FG 260

Impeller SS / Bronze

Pump shaft EN8

c Motor Specifications

Motor rating

TS No 1639-U-008 R01 TECHNICAL DATA SHEET Page 1 of 15

TECHNICAL DATA SHEET & SCOPE OF SUPPLY

S.N. DESCRIPTION UNIT REQUIREMENTS VENDOR DETAILS REMARKS

Motor make Kirloskar/ABB / Alstom

Design/performance code IS 325

Design ambient temperature 50

Power supply 415 V +/- 10%,50 Hz +/- 5%

Protection class IP 55

Efficiency class of motor Eff. Class-3

Type of enclosure TEFC

Temperature rise Class B

Insulation class Class F

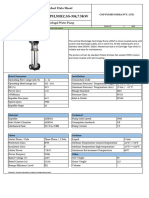

1.2 Diesel Engine Driven Pump

a Pump

Horizontal Split Casing/Back Pull

Type of pump Out

No. of pumps 1

Pump model

Pump make

Pump design standard IS-5120

Service fluid temperature (max.) 50

Capacity of pump 273 m3/hr

Differential head 88 mWC

Speed 1440 or vendor to specify

Pump head at 150 % of rated capacity

Shut off head

Pump shaft power at 150 % of rated discharge

Type of impeller Closed

Rated impeller diameter

NPSHR

Pump efficiency at duty point

Pumpshaft input at duty point

Sealing type Gland

Type of coupling

MOC / Make of coupling

Bearing type / make

b Material of Construction of Main Parts

Casing CI IS 210 FG 260

Impeller SS / bronze

Pump shaft EN8

c Drive Engine Specifications

TS No 1639-U-008 R01 TECHNICAL DATA SHEET Page 2 of 15

TECHNICAL DATA SHEET & SCOPE OF SUPPLY

S.N. DESCRIPTION UNIT REQUIREMENTS VENDOR DETAILS REMARKS

Make

Model no.

Engine type / no. of strokes

Cylinder configuration

RPM

Fuel type

Bore / Stoke

Cylinder displacement / swept volume

Compression ratio

Cylinder output

Mean piston speed

Mean effective pressure

Aspiration

Engine rating

Fuel tank capacity / retention time

Engine jacket cooling system

Lube oil cooling system

Type of coupling arrangement

Type of governor

Ttransient response time of governor

Anti-vibration mountings

Guaranteed transmission efficiency

Specific fuel oil consumption (gms/kwhr)

Specific lub oil consumption(litres/kwhr)

d Batteries

Type of batteries

Rating of batteries V / AH

No. of batteries

Make of batteries

Battery chager type and make

e Others

Accessories

Air cleaner Yes

Breather Yes

TS No 1639-U-008 R01 TECHNICAL DATA SHEET Page 3 of 15

TECHNICAL DATA SHEET & SCOPE OF SUPPLY

S.N. DESCRIPTION UNIT REQUIREMENTS VENDOR DETAILS REMARKS

Filter Yes

Lub oil cooler Yes

Exhaust for engine with silencer Yes

Master engine control switch Yes

Engine operation counter Yes

Alarm and control panel Yes

1.3 Jockey Pumps

Capacity 300 lpm

Quantity 2 (1W+1S)

Head 88 mWC

MOC of main parts Casing CI, SS or Bronze Impeller

Make of pump

Motor rating

Type of motor TEFC

Make of motor Kirloskar / ABB / Siemens

Dewatering mono block pump 5 m3/hr capacity- min. 2 HP

1.4 Priming Tank

Qty

Capacity As the pumps have positive

suction, so these are not

MOC required

Level switches for auto operation of pumps

1.5 Pump House Piping

a Pipe Specifications

up to 150 NB as per IS 1239 and

MOC

> 150 NB as per IS 3589

Up to 150 NB Class C / Medium

Thickness duty and above 150 NB min. 6.0

mm thick

Make of pipes Jindal / Tata

Make of fittings reputed make

b Painting for pipes

Painting 2 coats of red oxide primer and

1 coat of final enamel paint

TS No 1639-U-008 R01 TECHNICAL DATA SHEET Page 4 of 15

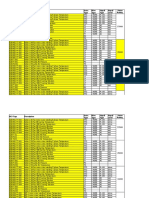

TECHNICAL DATA SHEET & SCOPE OF SUPPLY

S.N. DESCRIPTION UNIT REQUIREMENTS VENDOR DETAILS REMARKS

Make

350 NB pipeline from two reservors to suction header 6

250 NB pump suction line from main suction header 4

200 NB pipeline for individual pump's discharge 12

250 NB discharge header up to the pump house 8

boudary

80 NB suction of Jockey Pump 2

65 NB discharge of Jockey Pump 6

For recirculation, drains, vents, Instruments, As required

monoblock pump

1.6 Strainers

a Specifications

Design code / standard IS code

Rating PN 1.6

End connections Flanged, drilling as per IS 1538

Body -CI as per IS 210 FG 260,

MOC

internals- SS 410/ bronze

Make KSB / Fluidline

b BOQ

350 NB for main pumps suction line 2

1.7 Sluice valves/gate valves

a Specifications

Design code / standard IS:14846

Rating PN 1.6

End connections Flanged, drilling as per IS 1538

MOC Body -CI as per IS 210 FG 260,

spindle- SS 410/ bronze

Make KBL / Fluidline / Audco/KSB

b BOQ

350 NB for main connection lines from tanks 2+1

250 NB for main pumps suction line 2+1

80 NB for Jockey pump's discharge line 2+1

For recirulation line, drains, vents, instruments, As required

monoblock pump

TS No 1639-U-008 R01 TECHNICAL DATA SHEET Page 5 of 15

TECHNICAL DATA SHEET & SCOPE OF SUPPLY

S.N. DESCRIPTION UNIT REQUIREMENTS VENDOR DETAILS REMARKS

1.8 NRVs at the discharge of pumps

a Specifications

Design code / standard IS:5312

Rating PN 1.6

End connections Flanged, drilling as per IS 1538

MOC Body -CI as per IS 210 FG 260,

internals- SS 410/ bronze

Make KBL / Fluidline / Audco/KSB

b BOQ

200 NB for individual pumps discharge lines 2+1

65 NB for discharge of Jockey Pump 2+1

1.9 Other Miscellaneous Items

Flanges, reducers and other fittings As required

Steel supports for pipings within pump house As required

2 PUMP HOUSE EQUIPMENTS - ELECTRICAL

2.1 MCC and Control Panels

a Incoming feeder

1 nos. MCCB with required

Incoming Feeder for power supply to MCC switcgears

b Outgoing feeders

1 nos. MCCB with required

For main hydrant pump switcgears

1 nos. MCCB with required

Hydrant diesel engine starter panel/ battery charger switcgears

1 nos. MCCB with required

Hydrant jockey pump switcgears

1 nos. MCCB with required

Dewatering pump switcgears

One no. of 10 HP and one no. 5

Spare feeder with suitable MCCB HP MCCB with required

switchgears

External hooter 1 nos. MCB with required

switcgears

c Starters for individual feeders

Star-delta for main electric pump Yes

DOL/star-delta starter for jockey pump Yes

Diesel engine starter panel Yes

TS No 1639-U-008 R01 TECHNICAL DATA SHEET Page 6 of 15

TECHNICAL DATA SHEET & SCOPE OF SUPPLY

S.N. DESCRIPTION UNIT REQUIREMENTS VENDOR DETAILS REMARKS

Battery charger and battery bank Yes

Auto / manual starting of the diesel engine along with Yes

fault annunciator

Voltmeter and ammeter in each feeder Yes

On/off/trip lights, selector switches for auto/manual Yes

Alarm annunciator panel Yes

Potential free contactors for transfering pump status to

the fire alarm panel/DCS (running, fail to start, in Yes

manual mode)

Make of switchgears ABB/siemen/L&T

2.2 Cables

Copper conductor armoured

Type of cables cables with FRLS (fire retard low

smoke)

Cable from MCC panel to individual motors As required

Eathing strips inside pump house As required

Instrument and control cables inside pump house As required

Cable make TCI / Unistar/RPG

3 FIRE HYDRANT EQUIPMENTS AND PIPING

3.1 Fire Hydrant Valve

Single Outlet, SS 304 grade, 80

NB flanged inlet, SS

Details spindle,63mm female inst.

Oblique outlet, complete with

ABS blank cap & chain as per

IS:5290

Make Newage

3.2 Water Monitors

Water Monitor 32 NB Nozzle

Details bore

Nominal size 80

Maximum flow 3030 lpm

Swiwel joint, bronze with double

Type row of SS bearings as per

IS:8442

TS No 1639-U-008 R01 TECHNICAL DATA SHEET Page 7 of 15

TECHNICAL DATA SHEET & SCOPE OF SUPPLY

S.N. DESCRIPTION UNIT REQUIREMENTS VENDOR DETAILS REMARKS

360 deg rotation / 90 deg above

Rotation / through horizontal and 45 deg below

horizontal

Nos. 6

Make Newage / HD

3.3 Branch Pipe

Short, SS 304, 63 MM

Details male instantaneous inlet, male

threaded outlet, complete with

5/8” bore nozzle as per IS: 903.

Qty 66

Make Newage

3.4 Hose Reel and Hose

a Specifications

Type

Rubberized fabric Reinforced

MOC Rubber Lining (RRL),

working pressure 14 kg/cm2,

Design pressure proof pressure 22 kg/cm2

Design code as per IS : 636

Coupling SS male and female

Make Newage / Eversafe

3.5 Fire hose cabinet

Nos. 44

Fabricated from min. 16 SWG / 1.5 mm MS sheet

Size Suitable

Door glass thk. min. 4 mm thk.

Rubber beading Heavy duty

3.6 Fire Brigade Connections near Main Gate

Gun metal 4 way 63 mm

Type instantaneous coupling with

accessories

Fire Brigade inlet connection 2

Fire brigade draw out connection 1

Make Newage

3.7 Hydrant Pipes and fittings

TS No 1639-U-008 R01 TECHNICAL DATA SHEET Page 8 of 15

TECHNICAL DATA SHEET & SCOPE OF SUPPLY

S.N. DESCRIPTION UNIT REQUIREMENTS VENDOR DETAILS REMARKS

a Pipe Specifications

MOC up to 150 NB as per IS 1239 and

> 150 NB as per IS 3589

Up to 150 NB Class C / Medium

Thickness duty and above 150 NB min. 6.0

mm thick

Make of pipes Jindal / Tata

Make of fittings Lloyds / reputed make

b BOQ of Underground Pipes

250 NB 50

200 NB 700

150 NB 1800

100 NB 220

80 NB 210

50 NB 250

Drain, vents, instrument connection lines As required

Pipe fittings As required

c BOQ of above-ground pipes

MOC IS 1239, Black MS, heavy grade

350 NB 20

250 NB 20

200 NB 10

150 NB 400

100 NB 40

80 NB 190

65 NB 10

Drain, vents, instrument connection lines As required

d Wrapping and Coating for under ground pipes

Coal Tar tape as per IS:10221

Wrapping type and protective coating as per

AWWA C 203

Thickness 4 mm

Make Rustech / IWL

e Painting for above ground pipes

2 coats of red oxide primer and

Painting 1 coat of final enamel paint

TS No 1639-U-008 R01 TECHNICAL DATA SHEET Page 9 of 15

TECHNICAL DATA SHEET & SCOPE OF SUPPLY

S.N. DESCRIPTION UNIT REQUIREMENTS VENDOR DETAILS REMARKS

Make Burger / Asian Paints

3.8 Valve chambers

Size 1 m x 1 m x 1m

3.9 Butterfly valves

a Specifications

Design code / standard API 609/IS 13095

Rating PN 1.6

End connections Flanged, drilling as per IS 1538

MOC Body -CI as per IS 210 FG 260,

spindle- SS 410/ bronze

Make KBL / Fluidline / Audco / KSB

b BOQ

250 mm 3+1

200 mm 6+1

150 mm 10+1

100 mm 2

65 mm 2+1

3.10 Other Miscellaneous Items

Supply and Installation of Steel Structure Support As required

Air releasing vessels with air releasing valves As required

Hume pipes 300 mm dia. As per layout's requirements

4 CIVIL WORKS

Excavation and Backfilling in soft soil

Excavation and Backfilling in Hard soil

Road cutting (150 mm thickness)

PCC Breaking (150 mm thickness)

Valve Chambers

Strcture steel for supporting with painting

5 PORTABLE AND MOBILE FIRE EXTINGUISHERS

5.1 Dry Chemical Powder Type 5 Kgs

a Specifications

TS No 1639-U-008 R01 TECHNICAL DATA SHEET Page 10 of 15

TECHNICAL DATA SHEET & SCOPE OF SUPPLY

S.N. DESCRIPTION UNIT REQUIREMENTS VENDOR DETAILS REMARKS

Fire extiguisher complete with

gunmetal cap, bracket and initial

Details charge of 6 kgs Sodium -bi-

carbonate based dry chemical

powder and fully charged 120

gms CO2 gas catridge

Extinguisher as per IS: 15683,

dry powder as per IS:4308, gas

Design standards catridge as per IS:4947, body as

per IS: 513, gunmetal cap as per

IS: 318, Siphon tube as per

IS:3601

Filled weight 11.3 kgs

Test pressure 35 kgf/cm2 for 2

Testing minutes

b Quantity 35

5.3 CO2 Type portable fire extinguishers - 4.5 Kgs

a Specifications

Assembled from brand new

explosive approved cylinders,

Details complete with screw down /

squeeze grip type valve, internal

discharge tube, one meter high

pressure rayon braided hose etc.

Extinguisher as per IS: 2878, CO2

cylinder as per IS: 7285 CCE

Design standards approved, valve as per IS:3224,

CO2 gas as per IS:307, internal

discharge tube as per IS:708

Discharge duration 10 to 24 sec.

Filled weight 17 kgs

Testing Test pressure 250 kgf/cm2

b Quantity 30

5.4 Mechanical water Type Fire extinguishers -9 ltrs

a Specifications

TS No 1639-U-008 R01 TECHNICAL DATA SHEET Page 11 of 15

TECHNICAL DATA SHEET & SCOPE OF SUPPLY

S.N. DESCRIPTION UNIT REQUIREMENTS VENDOR DETAILS REMARKS

Extinguisher complete with

gunmetal cap, bracket, fitted

with flexible hose terminating in

branch pipe, initial charge of

Details AFFF concentrate and fully

charged CO2 gas catridge 60 gms

with powder coated internally

and externally towards

protection against corrosion.

Filled weight 14.35 kgs

Testing Test pressure 35 kgf/cm2 for 2

minutes

b Quantity 2

5.5 Mechanical Foam Type Fire extinguishers -50 ltrs

a Specifications

Extinguisher with gunmetal cap,

fitted with discharge hose and

foam making mounted on

Details rubber tyred wheels complete

with initial charge of AFFF

concentrate (6 %) and fully

charged CO2 gas catridge 300

gms and suitable for class B fire

Design standards As per IS:13386

Filled weight 80 kgs

Testing Test pressure 35 kgf/cm2 for 2

minutes

b Quantity 2

5.6 Fire sand bucket along with stand and canopy

Capacity 9 ltrs water volume

Nos. 17 sets of 4 buckets each

6 FIRE ALARM SYSTEM

6.1 Smoke Detectors

a Specification

Type Photoelectric or ionization

Operating voltage

TS No 1639-U-008 R01 TECHNICAL DATA SHEET Page 12 of 15

TECHNICAL DATA SHEET & SCOPE OF SUPPLY

S.N. DESCRIPTION UNIT REQUIREMENTS VENDOR DETAILS REMARKS

Current drawn at above operaing voltage

Automatic drift compensation Yes

Bi-colour LED detector status Yes

Make System sensors / Apollo

b Quantity

Photoelectric 39

Ionization 39

6.2 Heat Detectors

a Specification

Type Temperature thermal detector

Operating voltage

Current drawn at above operaing voltage

Bi-colour LED detector status Yes

Make System sensors / Apollo

b Quantity 2

6.3 Electronic Hooters

a Specifications

Powdered coated MS enclosure

Enclosure made from 1.5 mm thk sheet

Speaker rating Vendor to specify

Speaker make Philips

b Quantity 26

6.4 Manual Call Point

Enclosure MS enclosure made from 1.5

mm thk sheet

Make

Quantity 26

6.5 Fire Alarm Panel

Type of panel Conventional with LCD display

and battery , battery charger

Nos. 1

No. of zones 8

Battery back-up Yes

Make Daksh / Advance / National

Interconnecting cables as required

7 APPROVAL

TS No 1639-U-008 R01 TECHNICAL DATA SHEET Page 13 of 15

TECHNICAL DATA SHEET & SCOPE OF SUPPLY

S.N. DESCRIPTION UNIT REQUIREMENTS VENDOR DETAILS REMARKS

Inspection & Approval from TAC accredited third

party / FI / Delhi Fire Service Yes

8 OTHER MISC. SCOPE OF SUPPLY AND SERVICES

To prepare and subbmit the layout of fire hydrant

system for Owner's / Consultant's approval Yes

Supply of equipments / items under scope Yes

Packing and forwarding including any special packing, if

required. Yes

Receipt of material at site, unloading and storing at

site. Yes

Handling of material during erection Yes

Excavation and backfilling Yes

Erection and commissioning. Yes

Skilled, unskilled labour and tools and tackles required

for Erection and commissioning activities including the Yes

supervisory staff.

Submission of Quality Assurance Plan for approval Yes

Testing and inspection as per Approved QAP Yes

Training of Purchaser’s staff about the operation and

maintenance of the plant. Yes

First fill of lubricants. Yes

Maintenance service kit/special tools and tackles, if

any. Yes

A list of 2 years operation and maintenance spares (if Yes

any) to be provided with price list valid for 2 years.

Initial manufacturing schedule and bar chart. Yes

Monthly progress reports Yes

Any other item that is not mentioned but is necessary

for safe and efficient operation of the plant. Yes

Note:-

1. Autocad copy of the final layout will be provided to the vendor along with the floor plan details of building for preparing final layout.

2. Vendor will submit the hydrant layout for Owner's / Consultant's approval.

3. The above BOQ is only approximation based on the tentative layout. The final BOQ will be as per the approved layout. So vendor should give the unit prices.

TS No 1639-U-008 R01 TECHNICAL DATA SHEET Page 14 of 15

TECHNICAL DATA SHEET & SCOPE OF SUPPLY

S.N. DESCRIPTION UNIT REQUIREMENTS VENDOR DETAILS REMARKS

4. All the details which are not provided are to be considered as pet TAC rule and regulations.

5. Vendor should fill up the pending data and in case required vendor can add the data in the sheet.

TS No 1639-U-008 R01 TECHNICAL DATA SHEET Page 15 of 15

You might also like

- ELG2336 Lab 2 - Oscilloscope and Function GeneratorDocument7 pagesELG2336 Lab 2 - Oscilloscope and Function GeneratorJonathan Sergio100% (1)

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionFrom EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionRating: 4 out of 5 stars4/5 (1)

- 1639-U-008 R02 Data Sheet 16 Dec 18Document16 pages1639-U-008 R02 Data Sheet 16 Dec 18HEMANTNo ratings yet

- Sludge Screw Pump DatasheetDocument2 pagesSludge Screw Pump DatasheetVenkatesh SivaramanNo ratings yet

- Rating 460.8 m3h - 108m - CEP 150-630-250.0kW-1500rpm-380V-3Ph-50HzDocument3 pagesRating 460.8 m3h - 108m - CEP 150-630-250.0kW-1500rpm-380V-3Ph-50HzTrung TrịnhNo ratings yet

- Brochure LPDA, 50 HZDocument6 pagesBrochure LPDA, 50 HZTAUFIQ ARIEF NUGRAHANo ratings yet

- Bomba Centrifuga InoxDocument9 pagesBomba Centrifuga InoxGregorio Mata MartínezNo ratings yet

- C 15 EngineDocument2 pagesC 15 EngineAldo Cesar Mina SosaNo ratings yet

- PN11 - Deluge PumpDocument2 pagesPN11 - Deluge PumpFayez Al-ahmadiNo ratings yet

- Technical Specification Sheet For Auxiliaries Equipment OfJ - 420Document2 pagesTechnical Specification Sheet For Auxiliaries Equipment OfJ - 420Muhammad Mujtaba TariqNo ratings yet

- Annexure To Be AttachedDocument12 pagesAnnexure To Be AttachedAnonymous vspGaH8No ratings yet

- FACOR - TS 5.1 - Pumps - R1Document9 pagesFACOR - TS 5.1 - Pumps - R1Amit TiwariNo ratings yet

- TRHC 80-600-750Document5 pagesTRHC 80-600-750Sukron Nursalim100% (1)

- 5 KJ 4 e 75 YsabetrvrfDocument2 pages5 KJ 4 e 75 YsabetrvrfMohamed SelimNo ratings yet

- CNE 2AC - 341 m3ph @200 M (Sump Depth 2000m)Document3 pagesCNE 2AC - 341 m3ph @200 M (Sump Depth 2000m)Wibowo ArieNo ratings yet

- TDB FHA 50HZ Rev 2Document36 pagesTDB FHA 50HZ Rev 2quangsang1311No ratings yet

- Datasheet - PG G-Drive NEF45SM2X - 69kWDocument13 pagesDatasheet - PG G-Drive NEF45SM2X - 69kWcesar saavedra saavedraNo ratings yet

- CDL 20-14 3PH 50HZ Ci 15-0KWDocument2 pagesCDL 20-14 3PH 50HZ Ci 15-0KWthreephase electricNo ratings yet

- Technical Specification: General InformationDocument3 pagesTechnical Specification: General InformationAli BhaiNo ratings yet

- 4 Stroke Diesel Engine, Direct Injection: 126 X 155 MM 6 in Line 11.6 Litres 17/1 CCW 600 RPM 1200 KG Sae 1 SAE 14"Document2 pages4 Stroke Diesel Engine, Direct Injection: 126 X 155 MM 6 in Line 11.6 Litres 17/1 CCW 600 RPM 1200 KG Sae 1 SAE 14"NarcisaNo ratings yet

- Service Manual: Mjfcifss Diesel EnginesDocument16 pagesService Manual: Mjfcifss Diesel EnginesCiprian CojocaruNo ratings yet

- 2.6.4 Alimentación Al Sistema de Ultrafiltración (5450-PP-007 A-B)Document2 pages2.6.4 Alimentación Al Sistema de Ultrafiltración (5450-PP-007 A-B)Jennifer FigueroaNo ratings yet

- Perkins 650 KVADocument4 pagesPerkins 650 KVASulistiani ArlimNo ratings yet

- Technical Data Book Vertical In-Line Centrifugal Pump: Model Suction and Dicharge Size 100 200 MMDocument24 pagesTechnical Data Book Vertical In-Line Centrifugal Pump: Model Suction and Dicharge Size 100 200 MMpratikNo ratings yet

- Grundfos - CR 5 4 A A A E HQQE PDFDocument15 pagesGrundfos - CR 5 4 A A A E HQQE PDFabhe prasetyaNo ratings yet

- Mesin 1TR-FEDocument59 pagesMesin 1TR-FEkopler100% (1)

- 195 6lms3811 28084550Document6 pages195 6lms3811 28084550Mustafa FaisalNo ratings yet

- Grundfos CR 5 13 A FGJ A e HqqeDocument15 pagesGrundfos CR 5 13 A FGJ A e HqqeRadu-Stefan MusatNo ratings yet

- Amacan P 50 HZDocument52 pagesAmacan P 50 HZtejo murgiyantoNo ratings yet

- Parameter NSH-CGS1111-C22-320-C1Document2 pagesParameter NSH-CGS1111-C22-320-C1Didik SupriyantoNo ratings yet

- Qty. Description CR 5-13: Note! Product Picture May Differ From Actual ProductDocument2 pagesQty. Description CR 5-13: Note! Product Picture May Differ From Actual ProductMáy bơm Công nghiệpNo ratings yet

- Diesel Power 50Hz Open Type Generator SetDocument8 pagesDiesel Power 50Hz Open Type Generator Setchock channel 19No ratings yet

- Technical Specification: General InformationDocument3 pagesTechnical Specification: General InformationMuzaffar AliNo ratings yet

- Omega RDLDocument24 pagesOmega RDLOmar LamraniNo ratings yet

- CDL4 163ph50hzci30kwDocument2 pagesCDL4 163ph50hzci30kwthreephase electricNo ratings yet

- Cat® Engine SpecificationsDocument5 pagesCat® Engine SpecificationsadelabostatNo ratings yet

- SPECSHEET - CP150 - Perkins 1104Document3 pagesSPECSHEET - CP150 - Perkins 1104Abe BustomiNo ratings yet

- Deutz 30 KvaDocument4 pagesDeutz 30 Kvafirman harianjaNo ratings yet

- Etachrom NC Bomba 1700m011-m012-m013Document16 pagesEtachrom NC Bomba 1700m011-m012-m013Miguel Morales SandovalNo ratings yet

- Deutz Chin (s6K)Document1 pageDeutz Chin (s6K)ehsan alirezaeiNo ratings yet

- 195 6lms6006 28150403Document6 pages195 6lms6006 28150403Mustafa FaisalNo ratings yet

- Pump Duty Points - DesDocument8 pagesPump Duty Points - DesMaqsood NishatNo ratings yet

- CHLF4 603PH50HZSS 31611KWDocument2 pagesCHLF4 603PH50HZSS 31611KWKunal GadeNo ratings yet

- Offer No 9498 DTD 07.03.23Document1 pageOffer No 9498 DTD 07.03.23Shahab Z AhmedNo ratings yet

- Page 493 of 635Document30 pagesPage 493 of 635Sugadev SinghNo ratings yet

- Grundfos - CR 10 4 A FJ A E HQQEDocument15 pagesGrundfos - CR 10 4 A FJ A E HQQErosneyNo ratings yet

- C100 Service Training Manual: Engine Repair (2.4L DOHC)Document30 pagesC100 Service Training Manual: Engine Repair (2.4L DOHC)DangLuyenNo ratings yet

- Perkins 45 KVADocument4 pagesPerkins 45 KVASadiman SadimanNo ratings yet

- KAKFIREALARM04DESDocument3 pagesKAKFIREALARM04DESGilang ArdiNo ratings yet

- FW16 WP13 Engine Spec SheetDocument2 pagesFW16 WP13 Engine Spec Sheetwilmer andrade bustamanteNo ratings yet

- Amacan K: Submersible Motor Pump For Installation in Discharge Tubes With Channel-Type ImpellerDocument44 pagesAmacan K: Submersible Motor Pump For Installation in Discharge Tubes With Channel-Type Impellerst_calvoNo ratings yet

- Appl NT081 TDK FPS TDS 01 R0Document12 pagesAppl NT081 TDK FPS TDS 01 R0TILAK RAJ KambojNo ratings yet

- 8218 CDLF 8-18 3PH 50HZ SS-304 7-5KWDocument2 pages8218 CDLF 8-18 3PH 50HZ SS-304 7-5KWPrafful ShrivastavaNo ratings yet

- Offer Pump Technical R1 - MF 40-45 PDFDocument1 pageOffer Pump Technical R1 - MF 40-45 PDFREMINGTON SALAYANo ratings yet

- CR1-33 A-FGJ-A-E-HQQE 3x400D 50HZ: Grundfos Pump 96513309Document15 pagesCR1-33 A-FGJ-A-E-HQQE 3x400D 50HZ: Grundfos Pump 96513309Muhammad GhufranNo ratings yet

- 1 1F531120548 PDFDocument4 pages1 1F531120548 PDFAtish ChandNo ratings yet

- Data Sheet For Ecp8x6x17Document1 pageData Sheet For Ecp8x6x17Srinu GudalaNo ratings yet

- Fawde 30 KVA (4DW92 - 39D) - 3 PhaseDocument4 pagesFawde 30 KVA (4DW92 - 39D) - 3 PhaseckondoyNo ratings yet

- Engine Specifications: H.Harada K.SanadaDocument5 pagesEngine Specifications: H.Harada K.SanadaJohn GarnetNo ratings yet

- Cummins 125 KVADocument4 pagesCummins 125 KVAZein Ardha101No ratings yet

- Kitchen WorkingDocument1 pageKitchen WorkingHEMANTNo ratings yet

- VISA Power 28th July - VGV R4Document37 pagesVISA Power 28th July - VGV R4HEMANTNo ratings yet

- User Manual For General Trade/Storage License Application - SDMC and NDMCDocument14 pagesUser Manual For General Trade/Storage License Application - SDMC and NDMCHEMANTNo ratings yet

- Summary of Cost For Ibef, Upcoming Office at 20Th Floor, STC Building Janpath, C.P. S.No Description of Item Page NoDocument32 pagesSummary of Cost For Ibef, Upcoming Office at 20Th Floor, STC Building Janpath, C.P. S.No Description of Item Page NoHEMANTNo ratings yet

- Technical Annexure - PODocument27 pagesTechnical Annexure - POHEMANTNo ratings yet

- Calculation of Heat and Mass BalanceDocument16 pagesCalculation of Heat and Mass BalanceHEMANTNo ratings yet

- 1639-U-008 R02 Data Sheet 16 Dec 18Document16 pages1639-U-008 R02 Data Sheet 16 Dec 18HEMANTNo ratings yet

- 1.1 Type of Check Shall Be D.P. Test in Place of VisualDocument1 page1.1 Type of Check Shall Be D.P. Test in Place of VisualHEMANTNo ratings yet

- 1639-U-005 - R06 Datasheet Latest DatasheetDocument4 pages1639-U-005 - R06 Datasheet Latest DatasheetHEMANTNo ratings yet

- 1639-U-005 - R05 Datasheet Latest DatasheetDocument4 pages1639-U-005 - R05 Datasheet Latest DatasheetHEMANTNo ratings yet

- Flow Meter Data SheetDocument1 pageFlow Meter Data SheetHEMANTNo ratings yet

- DCS Tags Description Instr. Type Wire Type Signal Type Signal Level Motor RatingDocument7 pagesDCS Tags Description Instr. Type Wire Type Signal Type Signal Level Motor RatingHEMANTNo ratings yet

- Spec. No. 7311-DE-041Document1 pageSpec. No. 7311-DE-041HEMANTNo ratings yet

- 9 IO and Parameter ListDocument5 pages9 IO and Parameter ListHEMANTNo ratings yet

- Spec. No. 7311-DE-042Document1 pageSpec. No. 7311-DE-042HEMANTNo ratings yet

- DGN-205 Doc. Rev.03 PDFDocument3 pagesDGN-205 Doc. Rev.03 PDFHEMANTNo ratings yet

- Control Philosophy of DearatorDocument2 pagesControl Philosophy of DearatorHEMANTNo ratings yet

- DGN-205 Doc. Rev.03 PDFDocument3 pagesDGN-205 Doc. Rev.03 PDFHEMANTNo ratings yet

- E-Mail - : Navinender - Gupta@korus - inDocument1 pageE-Mail - : Navinender - Gupta@korus - inHEMANTNo ratings yet

- Contador 542-072a-ManualDocument8 pagesContador 542-072a-ManualRONALD ALFONSO PACHECO TORRESNo ratings yet

- An Overview and Validation of The Fitness-For-Service Assessment Procedures For Local Thin AreasDocument280 pagesAn Overview and Validation of The Fitness-For-Service Assessment Procedures For Local Thin AreasCARLOS M.No ratings yet

- Walk Forward Optimization by John EhlersDocument3 pagesWalk Forward Optimization by John EhlersquimkoNo ratings yet

- 10 Computer Chapter WiseDocument7 pages10 Computer Chapter WiseZeba KhNo ratings yet

- Quantitative and Morphological Characterization of Wheat (Triticum Aestivum L.) in Middle LandDocument8 pagesQuantitative and Morphological Characterization of Wheat (Triticum Aestivum L.) in Middle LandNur Mega Febriyanti M. GalibNo ratings yet

- 12th Science HSC Chemistry IIDocument40 pages12th Science HSC Chemistry IIRajesh KaundalNo ratings yet

- Isometries of The Plane - BoswellDocument7 pagesIsometries of The Plane - BoswellGuido 125 LavespaNo ratings yet

- Iso 7790Document12 pagesIso 7790Fabio StuiNo ratings yet

- KS5 "Full Coverage": Connected Particles (Yr2) : (Edexcel M1 Jan 2008 Q7a)Document18 pagesKS5 "Full Coverage": Connected Particles (Yr2) : (Edexcel M1 Jan 2008 Q7a)Nazif MorshedNo ratings yet

- New Time Table 2081Document2 pagesNew Time Table 2081shankalprajkhanalNo ratings yet

- Class Work - 4 - Solutions PDFDocument9 pagesClass Work - 4 - Solutions PDFRaymond LeoNo ratings yet

- CoypuDocument20 pagesCoypuperfectNo ratings yet

- AC Circuits Module 1Document28 pagesAC Circuits Module 1YoNo ratings yet

- Retake Practical Quiz (Page 3 of 4)Document9 pagesRetake Practical Quiz (Page 3 of 4)Dương HoàngNo ratings yet

- v25 Algebra 1 5.02.odtDocument6 pagesv25 Algebra 1 5.02.odtSam's vrNo ratings yet

- Levers in Musculoskeletal SystemDocument22 pagesLevers in Musculoskeletal SystemGlenn JohnstonNo ratings yet

- Mechanical Component ToleranceDocument2 pagesMechanical Component ToleranceOmkar Kumar JhaNo ratings yet

- National T Esting Agency: GeographyDocument28 pagesNational T Esting Agency: GeographyMahesh B RajputNo ratings yet

- Chapter Two: Kinematics and Dynamics of ParticlesDocument129 pagesChapter Two: Kinematics and Dynamics of ParticlesEphrem ChernetNo ratings yet

- AGV 50 Gas Turbine Fuel ValveDocument4 pagesAGV 50 Gas Turbine Fuel Valvehzq1eNo ratings yet

- Practice Problem 2 PDFDocument2 pagesPractice Problem 2 PDFDeeksha MishraNo ratings yet

- Peak Flow Calculation-LunugalaDocument3 pagesPeak Flow Calculation-LunugalakanishkaNo ratings yet

- Warm Up Exam # 2 QuestionerDocument6 pagesWarm Up Exam # 2 QuestionerJimmy GutierrezNo ratings yet

- Major Takeaways of SDET ProgramDocument3 pagesMajor Takeaways of SDET ProgramMalli PikkiliNo ratings yet

- 9/6, Lpsohphqwdwlrqvri Duwlilfldoqhxudoqhwzrunv: Aboratoire de IcroélectroniqueDocument8 pages9/6, Lpsohphqwdwlrqvri Duwlilfldoqhxudoqhwzrunv: Aboratoire de Icroélectroniquevarsha raichalNo ratings yet

- Subwoofer Box For Skar VD10 - Ported Box - SlotDocument2 pagesSubwoofer Box For Skar VD10 - Ported Box - SlotMarvin RiveraNo ratings yet

- CS322 - Handout Computer Organization and Architecture - UpdatedDocument3 pagesCS322 - Handout Computer Organization and Architecture - UpdatedKiran TradeNo ratings yet

- MM103 Lab 4Document4 pagesMM103 Lab 4Shivneel SwamyNo ratings yet

- 45BDocument5 pages45BJamie SchultzNo ratings yet