Professional Documents

Culture Documents

En 1090 2 Ex3 PDF

En 1090 2 Ex3 PDF

Uploaded by

lai nguyenOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

En 1090 2 Ex3 PDF

En 1090 2 Ex3 PDF

Uploaded by

lai nguyenCopyright:

Available Formats

101

According to Table 2, the quality level D of welded joints 3. Acceptance criteria for welding imperfections on

is required while executing structures in accordance with the grounds of radiographic tests following EN ISO 5817 and

least restrictive execution class EXC1. The quality levels C EN 1090-2

and D (specified only due to the presence of some imperfec-

tions) are valid in case of a more restrictive execution class The comparison of acceptance criteria for welding im-

i.e. EXC2. The quality level B is required in case of a more perfections detected by means of radiography were carried

restrictive structure execution class EXC3. The most restrictive out for butt-welded steel joints. Table 3 presents requirements

requirements related to welded joints (quality level B+) apply concerning individual imperfections in case of the quality lev-

to the execution of special steel structures or structures, the els B and B+.

failure of which might cause grave consequences. If, in the The analysis of Table 3 allows a conclusion that recom-

design of structure, no execution class has been specified, one mendations presented in comparable standards are very strict

should apply class EXC2. about the presence of such imperfections in welded joints as

It is anticipated that the nearest future will see a wide continuous or intermittent undercuts on the face of a weld

range of application of standard EN 1090-2. For this reason, (5011, 5012). The presence of the aforesaid imperfections is

from a technical point of view, it is crucial to analyse proposed not allowed in case of the thickness of base metal of 0.5 – 3

requirements compared to the so-far applied regulations. mm. In case of thickness exceeding 3 mm, the recommenda-

tions of standard EN ISO 5817 allow the presence of small

undercuts on the face of a weld, provided that h 6 0.5mm

(Fig.3.)

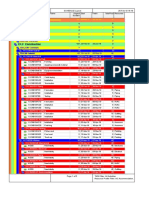

TABLE 3

Comparison of acceptance criteria for welding imperfections for quality levels B and B+ acc. to EN ISO 5817 and EN 1090-2, for

butt-welded joints made of steels tested with radiographic method

ACCEPTANCE CRITERIA

No. IMPERFECTION

Acc. to EN ISO 5817 Acc. to EN 1090-2

Quality level ”B“ Quality level ”B+“

For t = 0.5-3 mm:

UNDERCUTS not allowed

1. For t >3mm: not allowed

(5011, 5012)

h 6 0.05t; max 0.5 mm

BLOWHOLES (2011) AND EVENLY w.p. A1 6 1%;

2. w.w A1 6 2%; d 6 0.1s; max 2 mm

DISTRTIBUTED (2012) d 6 0.2s; max 3 mm

A1 6 4%

3. POROSITY CLUSTER (LOCATED) (2013) d 6 0.1s; max 2 mm

d 6 0.2s; max 2 mm

w.p. A1 6 2%

4. LINEAR POROSITY (2014) w.w. A1 6 4% d 6 0.1s; max 2 mm

d 6 0.2s; max 2 mm

SLAG INCLUSION (301) h 6 0.2s; max 2 mm h 6 0.1s; max 1 mm

5. FLUX INCLUSION (302)

OXIDE INCLUSION (303) l 6 s; max 25 mm l 6 s; max 10 mm

METALLIC INCLUSIONS (304) OTHER h 6 0.1s; max 1 mm

6. h 6 0.2s; max 2 mm

THAN COPPER l 6 s; max 10 mm

h 6 0.1s; max 1 mm

7. COPPER INCLUSION (3042) not allowed

l 6 s; max 10 mm

Plates and longitudinal welds

for t = 0.5-3 mm: h 6 0.2 mm + 0.1t.

Plates and longitudinal welds

8. LINEAR SHIFT (507) for t >3 mm: h 6 0.1t; max. 3 mm. h 60.05t; max. 2 mm

Circumferential welds

for t > 0.5 mm: h 60.5t; max. 2 mm.

For t = 0.5-3 mm: not allowed

9. ROOT CONCAVITY (515) For t >3 mm: h 6 0.05t; max. 0.5 mm. not allowed

Short imperfections allowed

t – wall or plate thickness (nominal); l – length of imperfection or indication; w.p. – single layer;

w.w. – numerous layers; h – height or width of imperfection; d – blister diameter; A1 – area containing blisters;

s - nominal thickness of butt weld.

You might also like

- D0107 (2013-N) NES: Characteristic of Car Body Spot WeldsDocument8 pagesD0107 (2013-N) NES: Characteristic of Car Body Spot WeldsRicardo F.A.No ratings yet

- En 50504 ReportDocument1 pageEn 50504 ReportPascal DumontNo ratings yet

- Surface Finish StandardDocument3 pagesSurface Finish StandardvinodmysoreNo ratings yet

- Standard Machining Tolerance JIS B 0405Document6 pagesStandard Machining Tolerance JIS B 0405fsijestNo ratings yet

- Formulation and Evaluation of Activated Charcoal Peel Off MaskDocument6 pagesFormulation and Evaluation of Activated Charcoal Peel Off MaskEnggar Saraswati hidayat100% (1)

- List of Din Standardspdf PDFDocument84 pagesList of Din Standardspdf PDFZoran DjuricicNo ratings yet

- VDI3345Document9 pagesVDI3345Cássio HerediaNo ratings yet

- GD & TDocument63 pagesGD & THemanth KumarNo ratings yet

- Claw Pole Forging ProcessDocument8 pagesClaw Pole Forging ProcessBhagat SinghNo ratings yet

- En 1717sr DFFDocument1 pageEn 1717sr DFFIsael CJNo ratings yet

- ASTM A333 GR.6 Seamless Low Temperature Pipes PDFDocument7 pagesASTM A333 GR.6 Seamless Low Temperature Pipes PDFraditya putraNo ratings yet

- TM-0026M-F (Property Requirements of Externally-Threaded Fasteners, Steel)Document5 pagesTM-0026M-F (Property Requirements of Externally-Threaded Fasteners, Steel)方綵樺100% (1)

- Documentation of Welding Procedure TestDocument5 pagesDocumentation of Welding Procedure Testrty2No ratings yet

- 36 - Declaration of PerformanceDocument1 page36 - Declaration of PerformanceScott TrainorNo ratings yet

- Korloy Grades and Chip BreakersDocument33 pagesKorloy Grades and Chip Breakersznovak77No ratings yet

- Design of Jigs and Fixtures.Document27 pagesDesign of Jigs and Fixtures.madala ajay kumarNo ratings yet

- BSP ThreadsDocument6 pagesBSP ThreadsVinod YbNo ratings yet

- Clauses IATF16949 2016Document2 pagesClauses IATF16949 2016Javier BustamanteNo ratings yet

- Blackodizing CPDocument1 pageBlackodizing CPx yNo ratings yet

- Computer Aided Manufacturability Analysis of Die-Cast Parts: Pvmrao@mech - Iitd.ac - in Tkkundra@mech - Iitd.ac - inDocument12 pagesComputer Aided Manufacturability Analysis of Die-Cast Parts: Pvmrao@mech - Iitd.ac - in Tkkundra@mech - Iitd.ac - indamonlanglois100% (1)

- Root and Face Bend TestsDocument3 pagesRoot and Face Bend TestsErlinawati Bintu SupiyoNo ratings yet

- CE Mark and DoP - QHPSDocument2 pagesCE Mark and DoP - QHPSHoangNo ratings yet

- M&I 04-Dimensional Chains Stack Up2017 V02uncovDocument20 pagesM&I 04-Dimensional Chains Stack Up2017 V02uncovMritunjay SharmaNo ratings yet

- Difference Between ISO Vs AWS Welding SymbolDocument2 pagesDifference Between ISO Vs AWS Welding SymbolLee Chong EeNo ratings yet

- En 1371-2-1998Document14 pagesEn 1371-2-1998Pippo LandiNo ratings yet

- DIN Fittings and TubesDocument92 pagesDIN Fittings and TubesJosé A. RamírezNo ratings yet

- Threads - NPTF Taper Thread GagingDocument5 pagesThreads - NPTF Taper Thread GagingTrushantNo ratings yet

- Metal Table JISDocument1 pageMetal Table JISNakkolopNo ratings yet

- PIPE THREADS Japanese PDFDocument2 pagesPIPE THREADS Japanese PDFOMAR CECEÑASNo ratings yet

- Shot BlastingDocument2 pagesShot BlastingDinesh DhaipulleNo ratings yet

- Metrology & Mech. Measurement Ch. 02 System of Limits, Fits, Tolerance and GaugingDocument20 pagesMetrology & Mech. Measurement Ch. 02 System of Limits, Fits, Tolerance and GaugingAjij MujawarNo ratings yet

- 2.defects and RepairDocument9 pages2.defects and Repairpaeg6512No ratings yet

- Trapezoidal ScrewsDocument34 pagesTrapezoidal ScrewsDejanNo ratings yet

- Bossard Taptite Self Tapping Screw CatalogueDocument10 pagesBossard Taptite Self Tapping Screw CataloguepmlmkpNo ratings yet

- GB-T 232-2010 Metallic Materials-Bend TestDocument14 pagesGB-T 232-2010 Metallic Materials-Bend TestH. Camer E.No ratings yet

- PDF Iso 3834 Checklist 2 CompressDocument6 pagesPDF Iso 3834 Checklist 2 CompressViệt VũNo ratings yet

- Structural Bolts, Steel, Heat Treated, 120/105 Ksi Minimum Tensile StrengthDocument8 pagesStructural Bolts, Steel, Heat Treated, 120/105 Ksi Minimum Tensile StrengthRoberto Gutierrez SaldañaNo ratings yet

- Vdocuments - MX Din 405 Universo For Knuckle Thread Din 405Document7 pagesVdocuments - MX Din 405 Universo For Knuckle Thread Din 405wauwio1906No ratings yet

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesTanveer Rajput EngrNo ratings yet

- Din en Iso 544Document18 pagesDin en Iso 544Mahmoud GaberNo ratings yet

- Limit Gauge PDFDocument11 pagesLimit Gauge PDFParamasivam VeerappanNo ratings yet

- RMG 4015 Crack Depth MeasurementDocument4 pagesRMG 4015 Crack Depth MeasurementJozmel Blancas CamarenaNo ratings yet

- JIS B0419-1991 (Dung Sai Kich Thuoc)Document1 pageJIS B0419-1991 (Dung Sai Kich Thuoc)Giang Nguyễn BáNo ratings yet

- Welding Process, DefectsDocument44 pagesWelding Process, DefectskundanNo ratings yet

- PFI ES-25-1993 Random Radiography of Pressure Retaining Girth Butt WeldsDocument6 pagesPFI ES-25-1993 Random Radiography of Pressure Retaining Girth Butt WeldsThao NguyenNo ratings yet

- DIN 439 B ISO 4035 04: Hex Jam Nuts 0,5dDocument1 pageDIN 439 B ISO 4035 04: Hex Jam Nuts 0,5dParvee K NakwalNo ratings yet

- Flow Process ChartDocument1 pageFlow Process ChartjakimlmNo ratings yet

- Specification No: LMB-COI-TRG-001 Rev No. R0 Page ofDocument16 pagesSpecification No: LMB-COI-TRG-001 Rev No. R0 Page ofApoorv MathurNo ratings yet

- Normalizing Temperature and Time Effect On Micro Structure and Change in Mechanical Properties of Forged Steel Billet For Axle ProductionDocument3 pagesNormalizing Temperature and Time Effect On Micro Structure and Change in Mechanical Properties of Forged Steel Billet For Axle ProductionAnonymous izrFWiQNo ratings yet

- Asme SawDocument3 pagesAsme Sawhalil ozgunNo ratings yet

- NS-1-60. Disposition of DefectsDocument4 pagesNS-1-60. Disposition of DefectsWHWENNo ratings yet

- Cranes Today March 2004 What To Look ForDocument3 pagesCranes Today March 2004 What To Look FordomsonengNo ratings yet

- Weldwell Catalogue 2015Document8 pagesWeldwell Catalogue 2015jaganelrNo ratings yet

- RESIDUAL STRESSES, Distortion and Weld Defects DISTORTION & WELD DEFECTSDocument18 pagesRESIDUAL STRESSES, Distortion and Weld Defects DISTORTION & WELD DEFECTSManoj NirgudeNo ratings yet

- Minimum Requirements For The Education, Training, Examination and QualificationDocument41 pagesMinimum Requirements For The Education, Training, Examination and QualificationAntónio PintoNo ratings yet

- Burrs SnippetDocument3 pagesBurrs SnippetNurul HudaNo ratings yet

- Rolleri Scule Abkant - Press Brake Tooling Catalogue SM PDFDocument134 pagesRolleri Scule Abkant - Press Brake Tooling Catalogue SM PDFDamir HadzicNo ratings yet

- Metal Repairs: Laser WeldingDocument24 pagesMetal Repairs: Laser WeldingV DhinakaranNo ratings yet

- Non-Alloy Structural Steels: Mechanical Properties Available DimensionsDocument1 pageNon-Alloy Structural Steels: Mechanical Properties Available Dimensionssorin robertNo ratings yet

- Anti-Corrosion Coating: StandardsDocument2 pagesAnti-Corrosion Coating: StandardsMuhamad Rizky KurniawanNo ratings yet

- Wind Turbine Project ReportDocument19 pagesWind Turbine Project Reportlai nguyenNo ratings yet

- Fabrication Quality Procedure Document at Factory Update 2017 PDFDocument33 pagesFabrication Quality Procedure Document at Factory Update 2017 PDFlai nguyenNo ratings yet

- BMB Brochure 2015 PDFDocument38 pagesBMB Brochure 2015 PDFlai nguyenNo ratings yet

- XX CORSAIR CRUZE 970 Schedule XX CORSAIR CRUZE 970 ScheduleDocument3 pagesXX CORSAIR CRUZE 970 Schedule XX CORSAIR CRUZE 970 Schedulelai nguyenNo ratings yet

- XX CORSAIR CRUZE 970 Schedule XX CORSAIR CRUZE 970 ScheduleDocument5 pagesXX CORSAIR CRUZE 970 Schedule XX CORSAIR CRUZE 970 Schedulelai nguyenNo ratings yet

- Moews Petrucci 1964 The Oxidation of Iodide Ion by Persulfate IonDocument3 pagesMoews Petrucci 1964 The Oxidation of Iodide Ion by Persulfate IonAnnie C SouzaNo ratings yet

- Cracks in ConcreteDocument8 pagesCracks in ConcreteFarhanNo ratings yet

- Formulation and Evaluation of Herbal Anti - Inflammatory Lollipop Using Sterculia Lychnophora Seed ExtractDocument6 pagesFormulation and Evaluation of Herbal Anti - Inflammatory Lollipop Using Sterculia Lychnophora Seed ExtractInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Steam Piping and CalculationsDocument15 pagesSteam Piping and CalculationsMuller RezqNo ratings yet

- Is 8757 1999Document15 pagesIs 8757 1999Rajveer Singh PawarNo ratings yet

- Bhopal Gas Tradedy: Case StudyDocument15 pagesBhopal Gas Tradedy: Case StudyRahul RajeevNo ratings yet

- Extrasction and Catalytic Action of Polyphenol Oxidase On Pigment Formation From Mushroom Cap and StalkDocument4 pagesExtrasction and Catalytic Action of Polyphenol Oxidase On Pigment Formation From Mushroom Cap and StalkBophepa MaseletsaneNo ratings yet

- (Lian - Zhuge, 2010) Optimum Mix Design of Enhanced Permeable Concrete - An Experimental InvestigationDocument8 pages(Lian - Zhuge, 2010) Optimum Mix Design of Enhanced Permeable Concrete - An Experimental InvestigationPSirotinNo ratings yet

- Isolation and Identification of Bacteria ThesisDocument7 pagesIsolation and Identification of Bacteria Thesisafbtbegxe100% (2)

- Aspen 3 Design of PFR EdtDocument8 pagesAspen 3 Design of PFR EdtethanNo ratings yet

- BhushanDocument46 pagesBhushanbrijkishor2017No ratings yet

- Cable Trench Installation Guide: 1.0 IndexDocument12 pagesCable Trench Installation Guide: 1.0 IndexThangarajan NagarajanNo ratings yet

- How To Calibrate A Graduated CylinderDocument7 pagesHow To Calibrate A Graduated CylinderSwayne BrownNo ratings yet

- Aama907 96Document3 pagesAama907 96hasan jouranNo ratings yet

- Pharmaceutical Standardization of Panchaguna Taila (Medicated Oil) .....Document6 pagesPharmaceutical Standardization of Panchaguna Taila (Medicated Oil) .....Anonymous pqtS3tcu1No ratings yet

- API Recommended Practice For The Design and Installation of Pressure Relieving Systems in RefineriesDocument22 pagesAPI Recommended Practice For The Design and Installation of Pressure Relieving Systems in RefineriesWADENo ratings yet

- Biochem OBTLDocument5 pagesBiochem OBTLQ Annang TomanggongNo ratings yet

- DNA PCR DNA Degradation Solutions: Product Information SheetDocument2 pagesDNA PCR DNA Degradation Solutions: Product Information SheetchiralicNo ratings yet

- Belgian Standard ISO 660 - 2020 EN ISO 660 - 2020 NBN EN ISO 660 - 2020Document10 pagesBelgian Standard ISO 660 - 2020 EN ISO 660 - 2020 NBN EN ISO 660 - 2020AJ ManurungNo ratings yet

- An Experimental Investigationofthe Effective Parameterson Wet Washingof BiodieselpurificationDocument14 pagesAn Experimental Investigationofthe Effective Parameterson Wet Washingof BiodieselpurificationAdilla PratiwiNo ratings yet

- 1 Identification: Acc. To OSHA HCSDocument8 pages1 Identification: Acc. To OSHA HCSbidangNo ratings yet

- Kar Et Al 2021 Green Chemistry in The Synthesis of Pharmaceuticals 1Document74 pagesKar Et Al 2021 Green Chemistry in The Synthesis of Pharmaceuticals 169 krishna AgrawalNo ratings yet

- أسس كيمياء التربة.ـ مكتبة الفريد الإلكترونية PDFDocument43 pagesأسس كيمياء التربة.ـ مكتبة الفريد الإلكترونية PDFRedouaneLabiadNo ratings yet

- Bovine Spongiform Encephalopathy-Scrapie Antigen Test Kit (BSE-Scrapie)Document180 pagesBovine Spongiform Encephalopathy-Scrapie Antigen Test Kit (BSE-Scrapie)pmarcelopontesNo ratings yet

- 5.stabilisation and SolidificationDocument18 pages5.stabilisation and SolidificationFx NiubieNo ratings yet

- WPS-Nozzle Without Reinforcement Pad (CS-CS) .Document1 pageWPS-Nozzle Without Reinforcement Pad (CS-CS) .suria qaqcNo ratings yet

- Papuci Cupru Tip D - Klauke - Gerkon ElectroDocument2 pagesPapuci Cupru Tip D - Klauke - Gerkon ElectroVasilicaNo ratings yet

- Class Notes - CH (CHE) - 302 Module 1 - Colloid (2) - 1646550962248Document13 pagesClass Notes - CH (CHE) - 302 Module 1 - Colloid (2) - 1646550962248Rohit Kumar BaghelNo ratings yet

- Electrochimica ActaDocument6 pagesElectrochimica ActabecobeliNo ratings yet