Professional Documents

Culture Documents

Passive Fire Protection

Passive Fire Protection

Uploaded by

kaamCopyright:

Available Formats

You might also like

- Specification For Phenolic Duct Works SystemsDocument2 pagesSpecification For Phenolic Duct Works Systemspsn_kylm100% (1)

- UL 1479 Handout PDFDocument2 pagesUL 1479 Handout PDFnaser71250% (2)

- Quiz Review: FIT Level 1 Exam: Student: Paul ColmenaresDocument8 pagesQuiz Review: FIT Level 1 Exam: Student: Paul ColmenaresNegro Tour's Reicin'gNo ratings yet

- OMM-Kandis Residences (2019) PDFDocument38 pagesOMM-Kandis Residences (2019) PDFjo_eli_No ratings yet

- Volume Control DampersDocument13 pagesVolume Control Damperssreejeshkeralam100% (1)

- Firestopping Book Firestopping Book PDFDocument188 pagesFirestopping Book Firestopping Book PDFMoni Sankar HazraNo ratings yet

- 12.0 - Inspection Testing & CommissioningDocument17 pages12.0 - Inspection Testing & CommissioningAmando GonzalesNo ratings yet

- Duct Installation LiningDocument5 pagesDuct Installation Liningم.وليد شكرNo ratings yet

- VRF UnitDocument18 pagesVRF UnitmakeencvNo ratings yet

- Certificado Ul - BeldenDocument1 pageCertificado Ul - BeldenEdwin Villegas JimenezNo ratings yet

- 01 - Bavaria CO2 FiresearchDocument3 pages01 - Bavaria CO2 FiresearchDaryl Gomez Timatim100% (1)

- Frequently Asked Questions Uae Fire CodeDocument20 pagesFrequently Asked Questions Uae Fire CodeImranAtheeqNo ratings yet

- Specification For Phenolic Duct Works SystemsDocument2 pagesSpecification For Phenolic Duct Works Systemspsn_kylmNo ratings yet

- HVAC Specs - ComplianceDocument32 pagesHVAC Specs - ComplianceArchanaShenoyNo ratings yet

- CHECKLSITDocument2 pagesCHECKLSITaboobacker siddiqueNo ratings yet

- Magnatrol Solenoid ValveDocument34 pagesMagnatrol Solenoid ValveWeb LogueandoNo ratings yet

- FireRated Ventilation Duct PresentationDocument25 pagesFireRated Ventilation Duct Presentationkenard291No ratings yet

- HVAC Ductwork SpecificationDocument4 pagesHVAC Ductwork SpecificationhvacwallyNo ratings yet

- Fan Coil Units PDFDocument4 pagesFan Coil Units PDFAnonymous hxj75CHM5No ratings yet

- Ball Valve Operation Maintenance ManualDocument7 pagesBall Valve Operation Maintenance Manualj8164322100% (1)

- DuraSystems - Grease Duct Access Doors BrochureDocument2 pagesDuraSystems - Grease Duct Access Doors BrochureDuraSystemsNo ratings yet

- 200622-Fcu & Refrigerant Pipe & Insulation SizeDocument1 page200622-Fcu & Refrigerant Pipe & Insulation Sizegukan rajNo ratings yet

- PalDuct Phenolic Datasheet MEDocument2 pagesPalDuct Phenolic Datasheet MERamadan RashadNo ratings yet

- Ruskin Fire DamperDocument4 pagesRuskin Fire DamperRAGANNo ratings yet

- Techinical Guide ZF 078 Thru 150 R410A Predator Single Packaged Unitr (Generation 6) - 528194-Ytg-M-0813Document68 pagesTechinical Guide ZF 078 Thru 150 R410A Predator Single Packaged Unitr (Generation 6) - 528194-Ytg-M-0813Rolando VenegasNo ratings yet

- Klambon Steel PipingDocument5 pagesKlambon Steel PipingshaunswanbyNo ratings yet

- Foam System - V.0 - WS PDFDocument82 pagesFoam System - V.0 - WS PDFSajjadNo ratings yet

- Check List Chilled Water PipingDocument3 pagesCheck List Chilled Water PipingARUL SANKARANNo ratings yet

- Fire, Smoke and Control Dampers: Manual - Maintenance, Testing and Inspection RecommendationsDocument8 pagesFire, Smoke and Control Dampers: Manual - Maintenance, Testing and Inspection RecommendationsSamiYousifNo ratings yet

- Royal Oman Police (English)Document191 pagesRoyal Oman Police (English)Khizer ArifNo ratings yet

- English Book A4 Final UpdateDocument221 pagesEnglish Book A4 Final UpdateVinay PallivalppilNo ratings yet

- Twin City Fan&BlowerDocument24 pagesTwin City Fan&BloweryaidragonNo ratings yet

- Project Standard Specification: Split-System Air-Conditioning Units 15738 - Page 1/6Document6 pagesProject Standard Specification: Split-System Air-Conditioning Units 15738 - Page 1/6adel rihanaNo ratings yet

- Methodology Mechanicalr02Document20 pagesMethodology Mechanicalr02damianNo ratings yet

- LPG From Uae Fire and Life Safety CodeDocument63 pagesLPG From Uae Fire and Life Safety CodeMohamed SalahNo ratings yet

- Project Standard Specification: Condensers) (Integral Air-Cooled Condensers)Document6 pagesProject Standard Specification: Condensers) (Integral Air-Cooled Condensers)adel rihanaNo ratings yet

- HVAC Duct InsulationDocument1 pageHVAC Duct InsulationPageduesca RouelNo ratings yet

- Fire Fighting SpecificationsDocument50 pagesFire Fighting SpecificationsPabbathi VinayNo ratings yet

- Drawings VRF SystemsDocument2 pagesDrawings VRF Systemscalvin.bloodaxe4478No ratings yet

- SABIC Flat ProductDocument15 pagesSABIC Flat ProductAiman AliNo ratings yet

- Fire Fighting System - Tech SpecDocument22 pagesFire Fighting System - Tech SpecBhavin PatelNo ratings yet

- AHU CatalogueDocument16 pagesAHU CatalogueWai Ee YapNo ratings yet

- Ricwil Catalog 10 Final PDFDocument32 pagesRicwil Catalog 10 Final PDFHermanuadi100% (2)

- Damper Manual - AMCADocument6 pagesDamper Manual - AMCASaransh GuptaNo ratings yet

- 0983 03 Method Statement For Installation Testing of Fire Fighting PipesDocument3 pages0983 03 Method Statement For Installation Testing of Fire Fighting PipesAnkit KumarNo ratings yet

- Hvac Equipment Boq-EpcDocument15 pagesHvac Equipment Boq-EpcJami MnNo ratings yet

- Fire-Suppression Piping System-13915 PDFDocument21 pagesFire-Suppression Piping System-13915 PDFMohammad Jugnu100% (1)

- T10 - 2011 - Tender DocumentDocument38 pagesT10 - 2011 - Tender DocumentblindjaxxNo ratings yet

- Uniform Mechanical Code - 2009 Chapter 6Document14 pagesUniform Mechanical Code - 2009 Chapter 6memosplumbing100% (1)

- Chapter 7 - Mechanical Ventillation and Smoke Control SystemsDocument23 pagesChapter 7 - Mechanical Ventillation and Smoke Control SystemsBalgo BalgobinNo ratings yet

- Fire Alarm SpecificationsDocument13 pagesFire Alarm SpecificationsDyeri FloresNo ratings yet

- Easy Duct PDFDocument8 pagesEasy Duct PDFSameera Sri VidurangaNo ratings yet

- Saudi Aramco Test Report: Refrigerant Pipe Vacuum Test SATR-K-4004 15-Dec-09 HvacDocument1 pageSaudi Aramco Test Report: Refrigerant Pipe Vacuum Test SATR-K-4004 15-Dec-09 HvacWaleed MedhatNo ratings yet

- 15-3-1 - Fire ProtectionDocument10 pages15-3-1 - Fire Protectionfarshan296015No ratings yet

- Operating and Installation Manual FKA-EUDocument24 pagesOperating and Installation Manual FKA-EURex LimNo ratings yet

- Cgk063 Rfa Mos M XXX - Cooling Tower InstallationDocument24 pagesCgk063 Rfa Mos M XXX - Cooling Tower Installationdiki anggriawanNo ratings yet

- 4 - HDPE Vs GI PipesDocument6 pages4 - HDPE Vs GI PipesMohammad RizwanNo ratings yet

- Wild Air SystemDocument1 pageWild Air SystemJunaid Bin NaseerNo ratings yet

- GREASE, SAND + OIL INTERCEPTORS Inspection Checklist V 1.0 - 201511041303368641Document4 pagesGREASE, SAND + OIL INTERCEPTORS Inspection Checklist V 1.0 - 201511041303368641bradalbiNo ratings yet

- Fire & Smoke DamperDocument24 pagesFire & Smoke Dampershahin msNo ratings yet

- Romold TrapDocument2 pagesRomold Traprajkumar_chinniah100% (1)

- Spec Section 07-84-00 For Firestopping Specification Text ASSET DOC LOC 1619205Document13 pagesSpec Section 07-84-00 For Firestopping Specification Text ASSET DOC LOC 1619205Ahmed OmarNo ratings yet

- Spec Section 23 00 00 For Firestopping For HVACDocument9 pagesSpec Section 23 00 00 For Firestopping For HVACblahblahNo ratings yet

- Chilled Water Schedule-1Document2 pagesChilled Water Schedule-1kaamNo ratings yet

- Chilled Water ScheduleDocument1 pageChilled Water SchedulekaamNo ratings yet

- Air Handling Units Schedule: Floresta Gardens Retail Buildings Fan Coil Units ScheduleDocument1 pageAir Handling Units Schedule: Floresta Gardens Retail Buildings Fan Coil Units SchedulekaamNo ratings yet

- Resume AZIZ BHAIDocument6 pagesResume AZIZ BHAIkaamNo ratings yet

- Fan Coil UnitDocument1 pageFan Coil UnitkaamNo ratings yet

- Pressurisation Units: Unit Ref PU-RB-BF-01Document1 pagePressurisation Units: Unit Ref PU-RB-BF-01kaamNo ratings yet

- Add: 410Rm, No.12, Jianmeili, Xiamen Area, China, (Fujian) Pilot Free Trade ZoneDocument8 pagesAdd: 410Rm, No.12, Jianmeili, Xiamen Area, China, (Fujian) Pilot Free Trade ZonekaamNo ratings yet

- Water Storage Tanks: Tank Reference WT-RB-BF-04 WT-RB-BF-03 WT-RB-BF-02 WT-RB-BF-01Document2 pagesWater Storage Tanks: Tank Reference WT-RB-BF-04 WT-RB-BF-03 WT-RB-BF-02 WT-RB-BF-01kaamNo ratings yet

- 19.2.9 Control Valves: Floresta Garden Infrastucture Project - The Pearl DohaDocument1 page19.2.9 Control Valves: Floresta Garden Infrastucture Project - The Pearl DohakaamNo ratings yet

- Ahu SelectionDocument28 pagesAhu SelectionkaamNo ratings yet

- Fire Hose Cabinet: Unit Reference FHC (Class Iii)Document1 pageFire Hose Cabinet: Unit Reference FHC (Class Iii)kaamNo ratings yet

- Ahu SelectionDocument28 pagesAhu SelectionkaamNo ratings yet

- Firestop Resource GuideDocument91 pagesFirestop Resource GuideFrancisco M. RamosNo ratings yet

- Guideline On Through-Penetration Firestopping: Second Edition - August 2007Document48 pagesGuideline On Through-Penetration Firestopping: Second Edition - August 2007Francisco M. Ramos100% (1)

- Firestop System Code DevelopmentDocument11 pagesFirestop System Code DevelopmentvikaspisalNo ratings yet

- Pocket Guide For Firestopping Inspection ManualDocument40 pagesPocket Guide For Firestopping Inspection ManualMikey Meniano100% (1)

- Tek 07-03a1 PDFDocument4 pagesTek 07-03a1 PDFJustin UyarNo ratings yet

- Astm E814Document3 pagesAstm E814MGNo ratings yet

- Guideline On Smacna Through Penetration Fire StoppingDocument48 pagesGuideline On Smacna Through Penetration Fire Stoppingwguindy70No ratings yet

- Firestop 101:: An Introduction To Firestopping To FirestoppingDocument42 pagesFirestop 101:: An Introduction To Firestopping To FirestoppingErica Lindsey100% (1)

- 6 Penetration Fire Stopping PDFDocument2 pages6 Penetration Fire Stopping PDFMMMOH200No ratings yet

- 3M Fire Protection Full Products Catalogue CatalogDocument24 pages3M Fire Protection Full Products Catalogue CatalogArshadNo ratings yet

- Effective Fire Stop For Penetration On Fire Compartmentation BarriersDocument42 pagesEffective Fire Stop For Penetration On Fire Compartmentation Barriershafizmon75% (4)

- Astm E814Document1 pageAstm E814RigobertoGuerra0% (1)

- Fire StopDocument48 pagesFire StopRoberto CuevasNo ratings yet

- Hilti Firestop Submittal - Balamand UniversityDocument32 pagesHilti Firestop Submittal - Balamand UniversitybasbousrNo ratings yet

- Fire Protection Full Line BRO RevDDocument32 pagesFire Protection Full Line BRO RevDEduleofNo ratings yet

- Epcot Building Codes 2015 Edition Code Change Submittals Effective 10/01/2015Document48 pagesEpcot Building Codes 2015 Edition Code Change Submittals Effective 10/01/2015LALA0% (1)

- Max 6inch Non Metallic Pipe With LCI Sealant & Wrap StripsDocument3 pagesMax 6inch Non Metallic Pipe With LCI Sealant & Wrap StripsvikaspisalNo ratings yet

- XHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQDocument4 pagesXHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQMd. Atiqul IslamNo ratings yet

- Fire Stopping GuideDocument6 pagesFire Stopping GuidestephlyonNo ratings yet

- System No. C-AJ-2346: F Rating - 3 HR T Rating - 0 HRDocument2 pagesSystem No. C-AJ-2346: F Rating - 3 HR T Rating - 0 HRArulNo ratings yet

- 66-165 - A804 - Fire Penetration Details (Version)Document1 page66-165 - A804 - Fire Penetration Details (Version)Parth DaxiniNo ratings yet

- Hilti - Firestop Application Handbook - 6th EditionDocument84 pagesHilti - Firestop Application Handbook - 6th EditionKwok MorrisNo ratings yet

- Penetration-Fire StoppingDocument8 pagesPenetration-Fire StoppingTaher AmmarNo ratings yet

- SMACNA HVAC FirestoppingDocument28 pagesSMACNA HVAC FirestoppingsunmechanicalNo ratings yet

- Fire Stopping Mechanical and ElectricalDocument7 pagesFire Stopping Mechanical and Electricaljack.simpson.changNo ratings yet

- Passive Fire ProtectionDocument3 pagesPassive Fire ProtectionkaamNo ratings yet

- Spec Section 15084 For Firestopping For MechanicalDocument7 pagesSpec Section 15084 For Firestopping For MechanicalblahblahNo ratings yet

Passive Fire Protection

Passive Fire Protection

Uploaded by

kaamOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Passive Fire Protection

Passive Fire Protection

Uploaded by

kaamCopyright:

Available Formats

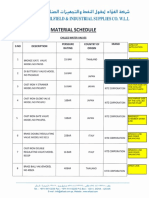

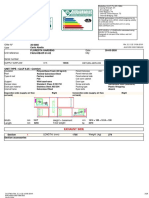

Mechanical Specification MZ & Partners W.L.L.

GP14019 – Mozoon Four Towers

PASSIVE FIRE PROTECTION

SECTION 15320

PART 1 - GENERAL

1.01 DESCRIPTION

A. Provide a U.L. approved fire stopping system in accordance with the Contract Documents.

1.02 WORK INCLUDED

A. Firestop Caulk.

B. Fire Rated Board.

C. Fire intumescent sealant.

D. Fire resistant coating.

1.03 SUBMITTALS

A. Submit shop drawings, product data, and manufacturer’s installation instructions for all materials

and prefabricated devices, providing description sufficient for identification at the job site.

B. Submit shop drawings showing proposed material, reinforcement, anchorage, fastenings and

method of installation. Construction details shall accurately reflect actual job conditions.

C. Submit Material Safety Data Sheets with product delivered to job site.

D. Submit certification by F.S>D. and U.L. for the complete system of fire stopping for each type

penetration.

E. Submit complete details of each type of penetration to be used indicating the proper U.L.

approved firestop system and U.L. system number.

1.04 QUALITY ASSURANCE

A. Fire system installation shall conform to requirements of qualified designs or manufacturer

approved modifications, as supported by engineering reports.

B. Install firestop materials and systems as required by these Tender Documents and meet and be

accepted for use by applicable design building and construction codes.

C. Submit manufacturer’s product data, letter of certified laboratory test report that the material or

combination of materials (firestop system) meets the requirements specified in accordance with

the applicable referenced standards.

D. The firestop compound shall not contain any solvents of inorganic fibers. The penetration seal

material must be unaffected by moisture and must maintain the integrity of the floor or wall

assembly for its rated time period when tested in accordance with ASTM E814 (UL1479). The

system shall be U.L. classified for up to and including 3 hours.

PART 2 - PRODUCTS

2.01 FIRESTOPPING

A. Provide firestop compound of in tumescent expandable nature for collar or strip application.

B. Provide firestop compounds for caulk application. Material must be capable of sealing openings

around single or multiple ducts, pipes cables, wire or conduits against fire, smoke and toxic

gases, and maintaining rating with a thickness no greater than the structure.

C. Provide a board material, where required as per manufacturer’s recommendations and/or shown

on the drawings.

Passive Fire Protection July 2017 15320 - 1

Mechanical Specification MZ & Partners W.L.L. GP14019 – Mozoon Four Towers

D. Provide a firestop system consisting of a material or combination of materials, to retain the

integrity of fire-rated construction by maintaining an effective barrier against the spread of flame,

smoke and toxic gases through penetrations in fire-rated barriers. It shall be used in specific

locations as follows:

1. Penetrations for the passage of duct piping cable, tray conduit, and electrical busways and

raceways through fire-rated vertical barriers (walls and partitions), horizontal barriers (floor

slabs and floor/ceiling assemblies), and vertical service shafts.

2. Provide FS Boards at the typical floor plant rooms.

2.02 MATERIALS

A. Firestopping materials/system shall be flexible to allow for normal movement of building structure

and penetrating item(s) without effecting the adhesion or integrity of the system.

B. Firestopping materials shall not require hazardous waste disposal of used containers/packages.

C. Provide firestopping materials free of solvents which will not experience shrinkage while curing.

D. Provide Fire Rated boards to provide 2 or 4 hour fire resistance as specified compliance with FSD

and Building Requirements.

E. The fire resistant board cladding material shall be non-combustible to BS476 Part 4, Class 1

surface spread of flame to BS476 Class 7, and class 0 to UK Building Regulations. The fire

resistant board shall be of monolithic asbestos-free calcium silicate material. The performance

shall not be affected by moisture absorption Mechanical strength shall be maintained and the

board shall not delaminate or the fire resisting properties shall not deteriorate even under 100%

water saturation. The fire resistant board shall be not attracts pests and shall not rot or support

the growth of mould.

F. Fire resistant coating over life emergency and security system cables crossing different fire

compartments than intended for cable use. This coating shall provide minimum 3 hour protection.

Such space include basement, car park, kitchen and similar areas.

PART 3 - EXECUTION

A. Deliver material to site in original unopened containers or packages bearing the manufacturer’s

name, brand designation, product description and U.L. Classification Mark.

B. Coordinate delivery of materials with scheduled installation date to allow minimum storage time at

job site.

C. Store materials under cover and protect from weather and damage in compliance with

manufacturer’s requirements.

D. Comply with recommended procedures, precautions or remedies described in Material Safety

Data Sheets a applicable.

3.01 EXAMINATION

A. Examine areas and conditions under which work is to be performed and notify the Engineer in

writing of conditions detrimental to proper and timely completion of the work.

B. Verify that openings are properly sized and in suitable condition to receive the work of this

section.

3.02 PREPARATION

A. Clean substrate of dirt, dust, grease, oil, loose materials, rust or other matter that may effect the

proper fitting or adhesion of the firestopping.

B. Clean metal and glass surfaces with a non-alcohol solvent.

Passive Fire Protection July 2017 15320 - 2

Mechanical Specification MZ & Partners W.L.L. GP14019 – Mozoon Four Towers

3.03 INSTALLATION

A. Install firestop materials as indicated in accordance with design requirements and manufacturer’s

instruction.

B. Seal all holes or voids made by penetrations to ensure an air, smoke and water-tight seal.

C. Firestopping may be required by other Contractors under related sections of the project

specifications. Identify all locations requiring firestopping and coordinate the work of this section

with work performed under other sections of the project to provide a uniform system of

firestopping.

D. Schedule installation of firestopping after completion of penetrating item installation but prior to

covering or concealing of openings.

E. Do not proceed with installation of firestop materials when temperature’s exceed the

manufacturer’s recommended limitations for installation.

F. Horizontal Cables

1. Install a cable sleeve with an inside diameter large enough to pass the cable through.

2. Install firestop in tumescent sealant material between the sleeve and the cable as per

manufacturers.

G. Fire Rated Board

Provide the Fire Rated Boards (2) between the top of the Hardy Wall and the underside of the floor

slab between the core walls forming the typical floor plant room. Provide the openings in the board for

ducts, trunking, conduits and cables. Seal the space around all penetrations with Fire Rated Caulking.

H. Fire Resistant Coating

Provide 4-hour fire protection coating for cables of life safety, security and emergency system

crossing hazardous zones of Car Parking, generator room, kitchen and alike.

END OF SECTION 15320

Passive Fire Protection July 2017 15320 - 3

You might also like

- Specification For Phenolic Duct Works SystemsDocument2 pagesSpecification For Phenolic Duct Works Systemspsn_kylm100% (1)

- UL 1479 Handout PDFDocument2 pagesUL 1479 Handout PDFnaser71250% (2)

- Quiz Review: FIT Level 1 Exam: Student: Paul ColmenaresDocument8 pagesQuiz Review: FIT Level 1 Exam: Student: Paul ColmenaresNegro Tour's Reicin'gNo ratings yet

- OMM-Kandis Residences (2019) PDFDocument38 pagesOMM-Kandis Residences (2019) PDFjo_eli_No ratings yet

- Volume Control DampersDocument13 pagesVolume Control Damperssreejeshkeralam100% (1)

- Firestopping Book Firestopping Book PDFDocument188 pagesFirestopping Book Firestopping Book PDFMoni Sankar HazraNo ratings yet

- 12.0 - Inspection Testing & CommissioningDocument17 pages12.0 - Inspection Testing & CommissioningAmando GonzalesNo ratings yet

- Duct Installation LiningDocument5 pagesDuct Installation Liningم.وليد شكرNo ratings yet

- VRF UnitDocument18 pagesVRF UnitmakeencvNo ratings yet

- Certificado Ul - BeldenDocument1 pageCertificado Ul - BeldenEdwin Villegas JimenezNo ratings yet

- 01 - Bavaria CO2 FiresearchDocument3 pages01 - Bavaria CO2 FiresearchDaryl Gomez Timatim100% (1)

- Frequently Asked Questions Uae Fire CodeDocument20 pagesFrequently Asked Questions Uae Fire CodeImranAtheeqNo ratings yet

- Specification For Phenolic Duct Works SystemsDocument2 pagesSpecification For Phenolic Duct Works Systemspsn_kylmNo ratings yet

- HVAC Specs - ComplianceDocument32 pagesHVAC Specs - ComplianceArchanaShenoyNo ratings yet

- CHECKLSITDocument2 pagesCHECKLSITaboobacker siddiqueNo ratings yet

- Magnatrol Solenoid ValveDocument34 pagesMagnatrol Solenoid ValveWeb LogueandoNo ratings yet

- FireRated Ventilation Duct PresentationDocument25 pagesFireRated Ventilation Duct Presentationkenard291No ratings yet

- HVAC Ductwork SpecificationDocument4 pagesHVAC Ductwork SpecificationhvacwallyNo ratings yet

- Fan Coil Units PDFDocument4 pagesFan Coil Units PDFAnonymous hxj75CHM5No ratings yet

- Ball Valve Operation Maintenance ManualDocument7 pagesBall Valve Operation Maintenance Manualj8164322100% (1)

- DuraSystems - Grease Duct Access Doors BrochureDocument2 pagesDuraSystems - Grease Duct Access Doors BrochureDuraSystemsNo ratings yet

- 200622-Fcu & Refrigerant Pipe & Insulation SizeDocument1 page200622-Fcu & Refrigerant Pipe & Insulation Sizegukan rajNo ratings yet

- PalDuct Phenolic Datasheet MEDocument2 pagesPalDuct Phenolic Datasheet MERamadan RashadNo ratings yet

- Ruskin Fire DamperDocument4 pagesRuskin Fire DamperRAGANNo ratings yet

- Techinical Guide ZF 078 Thru 150 R410A Predator Single Packaged Unitr (Generation 6) - 528194-Ytg-M-0813Document68 pagesTechinical Guide ZF 078 Thru 150 R410A Predator Single Packaged Unitr (Generation 6) - 528194-Ytg-M-0813Rolando VenegasNo ratings yet

- Klambon Steel PipingDocument5 pagesKlambon Steel PipingshaunswanbyNo ratings yet

- Foam System - V.0 - WS PDFDocument82 pagesFoam System - V.0 - WS PDFSajjadNo ratings yet

- Check List Chilled Water PipingDocument3 pagesCheck List Chilled Water PipingARUL SANKARANNo ratings yet

- Fire, Smoke and Control Dampers: Manual - Maintenance, Testing and Inspection RecommendationsDocument8 pagesFire, Smoke and Control Dampers: Manual - Maintenance, Testing and Inspection RecommendationsSamiYousifNo ratings yet

- Royal Oman Police (English)Document191 pagesRoyal Oman Police (English)Khizer ArifNo ratings yet

- English Book A4 Final UpdateDocument221 pagesEnglish Book A4 Final UpdateVinay PallivalppilNo ratings yet

- Twin City Fan&BlowerDocument24 pagesTwin City Fan&BloweryaidragonNo ratings yet

- Project Standard Specification: Split-System Air-Conditioning Units 15738 - Page 1/6Document6 pagesProject Standard Specification: Split-System Air-Conditioning Units 15738 - Page 1/6adel rihanaNo ratings yet

- Methodology Mechanicalr02Document20 pagesMethodology Mechanicalr02damianNo ratings yet

- LPG From Uae Fire and Life Safety CodeDocument63 pagesLPG From Uae Fire and Life Safety CodeMohamed SalahNo ratings yet

- Project Standard Specification: Condensers) (Integral Air-Cooled Condensers)Document6 pagesProject Standard Specification: Condensers) (Integral Air-Cooled Condensers)adel rihanaNo ratings yet

- HVAC Duct InsulationDocument1 pageHVAC Duct InsulationPageduesca RouelNo ratings yet

- Fire Fighting SpecificationsDocument50 pagesFire Fighting SpecificationsPabbathi VinayNo ratings yet

- Drawings VRF SystemsDocument2 pagesDrawings VRF Systemscalvin.bloodaxe4478No ratings yet

- SABIC Flat ProductDocument15 pagesSABIC Flat ProductAiman AliNo ratings yet

- Fire Fighting System - Tech SpecDocument22 pagesFire Fighting System - Tech SpecBhavin PatelNo ratings yet

- AHU CatalogueDocument16 pagesAHU CatalogueWai Ee YapNo ratings yet

- Ricwil Catalog 10 Final PDFDocument32 pagesRicwil Catalog 10 Final PDFHermanuadi100% (2)

- Damper Manual - AMCADocument6 pagesDamper Manual - AMCASaransh GuptaNo ratings yet

- 0983 03 Method Statement For Installation Testing of Fire Fighting PipesDocument3 pages0983 03 Method Statement For Installation Testing of Fire Fighting PipesAnkit KumarNo ratings yet

- Hvac Equipment Boq-EpcDocument15 pagesHvac Equipment Boq-EpcJami MnNo ratings yet

- Fire-Suppression Piping System-13915 PDFDocument21 pagesFire-Suppression Piping System-13915 PDFMohammad Jugnu100% (1)

- T10 - 2011 - Tender DocumentDocument38 pagesT10 - 2011 - Tender DocumentblindjaxxNo ratings yet

- Uniform Mechanical Code - 2009 Chapter 6Document14 pagesUniform Mechanical Code - 2009 Chapter 6memosplumbing100% (1)

- Chapter 7 - Mechanical Ventillation and Smoke Control SystemsDocument23 pagesChapter 7 - Mechanical Ventillation and Smoke Control SystemsBalgo BalgobinNo ratings yet

- Fire Alarm SpecificationsDocument13 pagesFire Alarm SpecificationsDyeri FloresNo ratings yet

- Easy Duct PDFDocument8 pagesEasy Duct PDFSameera Sri VidurangaNo ratings yet

- Saudi Aramco Test Report: Refrigerant Pipe Vacuum Test SATR-K-4004 15-Dec-09 HvacDocument1 pageSaudi Aramco Test Report: Refrigerant Pipe Vacuum Test SATR-K-4004 15-Dec-09 HvacWaleed MedhatNo ratings yet

- 15-3-1 - Fire ProtectionDocument10 pages15-3-1 - Fire Protectionfarshan296015No ratings yet

- Operating and Installation Manual FKA-EUDocument24 pagesOperating and Installation Manual FKA-EURex LimNo ratings yet

- Cgk063 Rfa Mos M XXX - Cooling Tower InstallationDocument24 pagesCgk063 Rfa Mos M XXX - Cooling Tower Installationdiki anggriawanNo ratings yet

- 4 - HDPE Vs GI PipesDocument6 pages4 - HDPE Vs GI PipesMohammad RizwanNo ratings yet

- Wild Air SystemDocument1 pageWild Air SystemJunaid Bin NaseerNo ratings yet

- GREASE, SAND + OIL INTERCEPTORS Inspection Checklist V 1.0 - 201511041303368641Document4 pagesGREASE, SAND + OIL INTERCEPTORS Inspection Checklist V 1.0 - 201511041303368641bradalbiNo ratings yet

- Fire & Smoke DamperDocument24 pagesFire & Smoke Dampershahin msNo ratings yet

- Romold TrapDocument2 pagesRomold Traprajkumar_chinniah100% (1)

- Spec Section 07-84-00 For Firestopping Specification Text ASSET DOC LOC 1619205Document13 pagesSpec Section 07-84-00 For Firestopping Specification Text ASSET DOC LOC 1619205Ahmed OmarNo ratings yet

- Spec Section 23 00 00 For Firestopping For HVACDocument9 pagesSpec Section 23 00 00 For Firestopping For HVACblahblahNo ratings yet

- Chilled Water Schedule-1Document2 pagesChilled Water Schedule-1kaamNo ratings yet

- Chilled Water ScheduleDocument1 pageChilled Water SchedulekaamNo ratings yet

- Air Handling Units Schedule: Floresta Gardens Retail Buildings Fan Coil Units ScheduleDocument1 pageAir Handling Units Schedule: Floresta Gardens Retail Buildings Fan Coil Units SchedulekaamNo ratings yet

- Resume AZIZ BHAIDocument6 pagesResume AZIZ BHAIkaamNo ratings yet

- Fan Coil UnitDocument1 pageFan Coil UnitkaamNo ratings yet

- Pressurisation Units: Unit Ref PU-RB-BF-01Document1 pagePressurisation Units: Unit Ref PU-RB-BF-01kaamNo ratings yet

- Add: 410Rm, No.12, Jianmeili, Xiamen Area, China, (Fujian) Pilot Free Trade ZoneDocument8 pagesAdd: 410Rm, No.12, Jianmeili, Xiamen Area, China, (Fujian) Pilot Free Trade ZonekaamNo ratings yet

- Water Storage Tanks: Tank Reference WT-RB-BF-04 WT-RB-BF-03 WT-RB-BF-02 WT-RB-BF-01Document2 pagesWater Storage Tanks: Tank Reference WT-RB-BF-04 WT-RB-BF-03 WT-RB-BF-02 WT-RB-BF-01kaamNo ratings yet

- 19.2.9 Control Valves: Floresta Garden Infrastucture Project - The Pearl DohaDocument1 page19.2.9 Control Valves: Floresta Garden Infrastucture Project - The Pearl DohakaamNo ratings yet

- Ahu SelectionDocument28 pagesAhu SelectionkaamNo ratings yet

- Fire Hose Cabinet: Unit Reference FHC (Class Iii)Document1 pageFire Hose Cabinet: Unit Reference FHC (Class Iii)kaamNo ratings yet

- Ahu SelectionDocument28 pagesAhu SelectionkaamNo ratings yet

- Firestop Resource GuideDocument91 pagesFirestop Resource GuideFrancisco M. RamosNo ratings yet

- Guideline On Through-Penetration Firestopping: Second Edition - August 2007Document48 pagesGuideline On Through-Penetration Firestopping: Second Edition - August 2007Francisco M. Ramos100% (1)

- Firestop System Code DevelopmentDocument11 pagesFirestop System Code DevelopmentvikaspisalNo ratings yet

- Pocket Guide For Firestopping Inspection ManualDocument40 pagesPocket Guide For Firestopping Inspection ManualMikey Meniano100% (1)

- Tek 07-03a1 PDFDocument4 pagesTek 07-03a1 PDFJustin UyarNo ratings yet

- Astm E814Document3 pagesAstm E814MGNo ratings yet

- Guideline On Smacna Through Penetration Fire StoppingDocument48 pagesGuideline On Smacna Through Penetration Fire Stoppingwguindy70No ratings yet

- Firestop 101:: An Introduction To Firestopping To FirestoppingDocument42 pagesFirestop 101:: An Introduction To Firestopping To FirestoppingErica Lindsey100% (1)

- 6 Penetration Fire Stopping PDFDocument2 pages6 Penetration Fire Stopping PDFMMMOH200No ratings yet

- 3M Fire Protection Full Products Catalogue CatalogDocument24 pages3M Fire Protection Full Products Catalogue CatalogArshadNo ratings yet

- Effective Fire Stop For Penetration On Fire Compartmentation BarriersDocument42 pagesEffective Fire Stop For Penetration On Fire Compartmentation Barriershafizmon75% (4)

- Astm E814Document1 pageAstm E814RigobertoGuerra0% (1)

- Fire StopDocument48 pagesFire StopRoberto CuevasNo ratings yet

- Hilti Firestop Submittal - Balamand UniversityDocument32 pagesHilti Firestop Submittal - Balamand UniversitybasbousrNo ratings yet

- Fire Protection Full Line BRO RevDDocument32 pagesFire Protection Full Line BRO RevDEduleofNo ratings yet

- Epcot Building Codes 2015 Edition Code Change Submittals Effective 10/01/2015Document48 pagesEpcot Building Codes 2015 Edition Code Change Submittals Effective 10/01/2015LALA0% (1)

- Max 6inch Non Metallic Pipe With LCI Sealant & Wrap StripsDocument3 pagesMax 6inch Non Metallic Pipe With LCI Sealant & Wrap StripsvikaspisalNo ratings yet

- XHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQDocument4 pagesXHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQMd. Atiqul IslamNo ratings yet

- Fire Stopping GuideDocument6 pagesFire Stopping GuidestephlyonNo ratings yet

- System No. C-AJ-2346: F Rating - 3 HR T Rating - 0 HRDocument2 pagesSystem No. C-AJ-2346: F Rating - 3 HR T Rating - 0 HRArulNo ratings yet

- 66-165 - A804 - Fire Penetration Details (Version)Document1 page66-165 - A804 - Fire Penetration Details (Version)Parth DaxiniNo ratings yet

- Hilti - Firestop Application Handbook - 6th EditionDocument84 pagesHilti - Firestop Application Handbook - 6th EditionKwok MorrisNo ratings yet

- Penetration-Fire StoppingDocument8 pagesPenetration-Fire StoppingTaher AmmarNo ratings yet

- SMACNA HVAC FirestoppingDocument28 pagesSMACNA HVAC FirestoppingsunmechanicalNo ratings yet

- Fire Stopping Mechanical and ElectricalDocument7 pagesFire Stopping Mechanical and Electricaljack.simpson.changNo ratings yet

- Passive Fire ProtectionDocument3 pagesPassive Fire ProtectionkaamNo ratings yet

- Spec Section 15084 For Firestopping For MechanicalDocument7 pagesSpec Section 15084 For Firestopping For MechanicalblahblahNo ratings yet