Professional Documents

Culture Documents

DRP10036 Screen Printed Electrodes Overview REV002

DRP10036 Screen Printed Electrodes Overview REV002

Uploaded by

simonCopyright:

Available Formats

You might also like

- Solved Problems Axial DeformationDocument6 pagesSolved Problems Axial DeformationChristopher Largado67% (3)

- Bipolar Plate Development With Additive Manufacturing and ProtectiveDocument9 pagesBipolar Plate Development With Additive Manufacturing and Protectivev.babalo68No ratings yet

- 4BO.5.6 PaperDocument4 pages4BO.5.6 PaperignaciadevotoNo ratings yet

- 1-s2.0-S246802302200774X-mainDocument12 pages1-s2.0-S246802302200774X-mainEngr Muhammad RashidNo ratings yet

- A Mesoscopic Platinized Graphite Carbon Black Counter Electrode For A Highly Efficient Monolithic Dye-Sensitized Solar CellDocument6 pagesA Mesoscopic Platinized Graphite Carbon Black Counter Electrode For A Highly Efficient Monolithic Dye-Sensitized Solar CellLaura González SossaNo ratings yet

- 1 s2.0 S0013468623008745 MainDocument11 pages1 s2.0 S0013468623008745 MainROBSON CardosoNo ratings yet

- Advances in Materials Science: Experience of Using Graphitized Cored Electrodes in Industrial AC Electric Arc FurnaceDocument13 pagesAdvances in Materials Science: Experience of Using Graphitized Cored Electrodes in Industrial AC Electric Arc FurnaceAbderraouf GhrissiNo ratings yet

- Additive Manufactured Bipolar Plate ForDocument7 pagesAdditive Manufactured Bipolar Plate Forv.babalo68No ratings yet

- 1 s2.0 S138824811730070X MainDocument5 pages1 s2.0 S138824811730070X Mainv.babalo68No ratings yet

- Optimization of Copper Electroplating Process Applied For Microfabrication On Flexible Polyethylene Terephthalate SubstrateDocument7 pagesOptimization of Copper Electroplating Process Applied For Microfabrication On Flexible Polyethylene Terephthalate SubstrateXyNo ratings yet

- Understanding The Calendering Processability of Li (Ni0.33Mn0.33Co0.33) O2-Based CathodesDocument11 pagesUnderstanding The Calendering Processability of Li (Ni0.33Mn0.33Co0.33) O2-Based CathodesMDRNo ratings yet

- Author's Accepted Manuscript: Energy Storage MaterialsDocument11 pagesAuthor's Accepted Manuscript: Energy Storage MaterialsLu YuNo ratings yet

- Ag NW-PPy Nanocomp For SCsDocument34 pagesAg NW-PPy Nanocomp For SCsanamurboyNo ratings yet

- Comparison Between Different Architectures of An Electrolyte-Gated Organic Thin-Film Transistor Fabricated On Flexible Kapton SubstratesDocument4 pagesComparison Between Different Architectures of An Electrolyte-Gated Organic Thin-Film Transistor Fabricated On Flexible Kapton SubstratesliviuNo ratings yet

- 6.02 Nitride-Based LEDs and Superluminescent LEDsDocument73 pages6.02 Nitride-Based LEDs and Superluminescent LEDsfojxNo ratings yet

- Tintas Electrodos 2Document20 pagesTintas Electrodos 2guiburNo ratings yet

- Journal of Alloys and CompoundsDocument8 pagesJournal of Alloys and Compoundsjeffry122333No ratings yet

- An Integrated Three-Electrode System With A Micromachined Liquid-Junction Ag/AgCl Reference ElectrodeDocument10 pagesAn Integrated Three-Electrode System With A Micromachined Liquid-Junction Ag/AgCl Reference ElectrodeAHMAD ANWARNo ratings yet

- Electrostatically Sprayed Reduced Graphene Oxide-Carbon Nanotubes Electrodes For Lithium-Ion CapacitorsDocument10 pagesElectrostatically Sprayed Reduced Graphene Oxide-Carbon Nanotubes Electrodes For Lithium-Ion CapacitorsTam Van TranNo ratings yet

- Schiavi Electrochemical-Synthesis 2019Document8 pagesSchiavi Electrochemical-Synthesis 2019kkamolvisitNo ratings yet

- Annealing TeoriDocument12 pagesAnnealing Teorienna hasnaNo ratings yet

- Research Article The Influence of Blood Glucose Meter Resistance Variation On The Performance of A Biosensor With A Gold-Coated Circuit BoardDocument9 pagesResearch Article The Influence of Blood Glucose Meter Resistance Variation On The Performance of A Biosensor With A Gold-Coated Circuit Boardglucose glucoseNo ratings yet

- Electroflotation of Wastewater 41011686Document6 pagesElectroflotation of Wastewater 41011686Mardaru AnamariaNo ratings yet

- JNMESciV12 2009arcop035Document8 pagesJNMESciV12 2009arcop035Moisés BautistaNo ratings yet

- Corrosion Behaviour of Tinplate in SynthDocument11 pagesCorrosion Behaviour of Tinplate in SynthdouslasNo ratings yet

- 1 s2.0 S0360319921037058 MainDocument9 pages1 s2.0 S0360319921037058 Mainv.babalo68No ratings yet

- A Powder Metallurgy Route To Produce Ni RaneyDocument8 pagesA Powder Metallurgy Route To Produce Ni RaneyLucas Vander MeyNo ratings yet

- Electroplated Core-Shell NanowDocument9 pagesElectroplated Core-Shell NanowjulianNo ratings yet

- Introduction To Electron Beam ProcessingDocument10 pagesIntroduction To Electron Beam Processingvntan1002No ratings yet

- Electropol Edot Sds TritonDocument8 pagesElectropol Edot Sds TritonGonzalo FenoyNo ratings yet

- Applied Catalysis B: EnvironmentalDocument6 pagesApplied Catalysis B: Environmentalkhan47pkNo ratings yet

- Single Wall Carbon Nanotubes/Polypyrrole Composite Thin Film Electrodes: Investigation of Interfacial Ion Exchange BehaviorDocument14 pagesSingle Wall Carbon Nanotubes/Polypyrrole Composite Thin Film Electrodes: Investigation of Interfacial Ion Exchange BehaviormiguelNo ratings yet

- Thick Electrodes For High Energy Lithium Ion BatteDocument6 pagesThick Electrodes For High Energy Lithium Ion BattePhạm TùngNo ratings yet

- Electrical Properties of SB and Cr-Doped Pbzro - Pbtio - PBMG NB O CeramicsDocument8 pagesElectrical Properties of SB and Cr-Doped Pbzro - Pbtio - PBMG NB O CeramicsrachnaselvamanigmailNo ratings yet

- PDF 16 WorkingElecDocument5 pagesPDF 16 WorkingElecThoifahMuthohharohNo ratings yet

- Reduction of Porous Carbon Al Contact Resistance For An Electric Double-LayerDocument6 pagesReduction of Porous Carbon Al Contact Resistance For An Electric Double-LayerİsmailBütünNo ratings yet

- Effect of The Thickness of The PT Film Coated On A Counter Electrode On The Performance of A Dye-Sensitized Solar CellDocument7 pagesEffect of The Thickness of The PT Film Coated On A Counter Electrode On The Performance of A Dye-Sensitized Solar CellOussama IkhlefNo ratings yet

- Electrochimica Acta: Bin Qin, Qun Wang, Xiaohua Zhang, Xiaoling Xie, Li'e Jin, Qing CaoDocument9 pagesElectrochimica Acta: Bin Qin, Qun Wang, Xiaohua Zhang, Xiaoling Xie, Li'e Jin, Qing CaoJanethAlcalaNo ratings yet

- 1 s2.0 S0955221921001643 MainDocument9 pages1 s2.0 S0955221921001643 Mainmroth11No ratings yet

- CV Spinel ChuẩnDocument6 pagesCV Spinel ChuẩnĐức Duy NgôNo ratings yet

- Accepted Manuscript: Electrochimica ActaDocument30 pagesAccepted Manuscript: Electrochimica ActayascheNo ratings yet

- Journal of Alloys and Compounds: SciencedirectDocument11 pagesJournal of Alloys and Compounds: SciencedirectEstudiante2346No ratings yet

- Ai Apl#241143Document15 pagesAi Apl#241143Anonymous UJFK2jk5gNo ratings yet

- Resnik MEET2019Document7 pagesResnik MEET2019Surya Chandra NamahaNo ratings yet

- Tryk Et Al 2000 - Recent Topics in Photoelectrochemistry Achievements and Future ProspectsDocument14 pagesTryk Et Al 2000 - Recent Topics in Photoelectrochemistry Achievements and Future Prospectssamusm.smNo ratings yet

- PB HydrothermalDocument6 pagesPB Hydrothermallxvinh9467No ratings yet

- Materials LettersDocument4 pagesMaterials LettersSahin CoskunNo ratings yet

- Solar Energy Materials & Solar CellsDocument6 pagesSolar Energy Materials & Solar Cellsadharsh27No ratings yet

- Yao 2017Document31 pagesYao 2017vijayamathubalan pandyNo ratings yet

- Photoelectrochemical Cell Design, Efficiency, Definitions, Standards, and ProtocolsDocument35 pagesPhotoelectrochemical Cell Design, Efficiency, Definitions, Standards, and ProtocolsLê Văn TrungNo ratings yet

- Characterization and Optimization of A Printed, Primary Silver-Zinc BatteryDocument6 pagesCharacterization and Optimization of A Printed, Primary Silver-Zinc BatteryMiguel Angel Ramos RuizNo ratings yet

- Correlative Electrochemical Acoustic Time-Of-Flight Spectroscopy and X-Rayimaging To Monitor The Performance of Single-Crystal Lithium-Ion BatteriesDocument13 pagesCorrelative Electrochemical Acoustic Time-Of-Flight Spectroscopy and X-Rayimaging To Monitor The Performance of Single-Crystal Lithium-Ion BatteriesSANTHAKUMAR SNo ratings yet

- Ion ExchangeDocument13 pagesIon Exchangebreadfalling752No ratings yet

- Modeling and Simulation of A Copper Electrolysis Cell Group: Ilkka - Laitinen@tut - Fi (Ilkka Laitinen)Document9 pagesModeling and Simulation of A Copper Electrolysis Cell Group: Ilkka - Laitinen@tut - Fi (Ilkka Laitinen)Jérôme KyabuNo ratings yet

- Reuter 2019 J. Electrochem. Soc. 166 A3265Document8 pagesReuter 2019 J. Electrochem. Soc. 166 A3265adilNo ratings yet

- High Power Electric Double Layer Capacitor EDLCsDocument13 pagesHigh Power Electric Double Layer Capacitor EDLCsFikri AdiansyahNo ratings yet

- XHP Technical ManualDocument23 pagesXHP Technical ManualsiavoshsaifNo ratings yet

- Kim 2019Document6 pagesKim 2019Chetan ChaudhariNo ratings yet

- Gao 2016Document6 pagesGao 2016Jorge Daniel Torres AlvarezNo ratings yet

- Materials and Design: Khairul Amilin Ibrahim, Billy Wu, Nigel P. BrandonDocument9 pagesMaterials and Design: Khairul Amilin Ibrahim, Billy Wu, Nigel P. BrandonjohnNo ratings yet

- PDF Retail Ux PlaybookDocument62 pagesPDF Retail Ux PlaybooksebaNo ratings yet

- Computerized Accounting Using Tally - Erp 9 - Student GuideDocument546 pagesComputerized Accounting Using Tally - Erp 9 - Student Guideshruti100% (1)

- UntitledDocument672 pagesUntitledMilton Righetto NassNo ratings yet

- 03AdvancedThinkAhead4 ExamSkillsPrac Mod5-6Document3 pages03AdvancedThinkAhead4 ExamSkillsPrac Mod5-6mariasanztiNo ratings yet

- FINAL EXAM 201820192 - Draf (270319)Document13 pagesFINAL EXAM 201820192 - Draf (270319)YuthishDheeranManiamNo ratings yet

- Damage Prevention From Diesel Crankcase Explosions: Enginemen's Magazine, February, 1952Document10 pagesDamage Prevention From Diesel Crankcase Explosions: Enginemen's Magazine, February, 1952Mike FinazziNo ratings yet

- 144 Daftar P2P Ilegal AprilDocument12 pages144 Daftar P2P Ilegal AprilSumiatiNo ratings yet

- Embedded Electronic System Design, MSC - ChalmersDocument9 pagesEmbedded Electronic System Design, MSC - ChalmerskamranNo ratings yet

- Loans and MortgagesDocument26 pagesLoans and Mortgagesparkerroach21No ratings yet

- Introduction To Mineral Processing 2010Document24 pagesIntroduction To Mineral Processing 2010elmonemNo ratings yet

- Mg23 Infill DevelopmentDocument52 pagesMg23 Infill Developmentsilaban HansNo ratings yet

- Chapter 3 - Entity Relationship ModellingDocument34 pagesChapter 3 - Entity Relationship ModellingShrawan Trivedi100% (1)

- Neurobiologic Theories and PsychopharmacologyDocument3 pagesNeurobiologic Theories and Psychopharmacologygeorgeloto12100% (1)

- Srikanth ImJDocument2 pagesSrikanth ImJTEJA unixNo ratings yet

- Clarkson Lumber Case QuestionsDocument2 pagesClarkson Lumber Case QuestionsJeffery KaoNo ratings yet

- Fábrica de Chocolate UNSAACDocument13 pagesFábrica de Chocolate UNSAACFrank Chulla Montes0% (1)

- N Endah 2019 J. Phys. Conf. Ser. 1179 012178 PDFDocument7 pagesN Endah 2019 J. Phys. Conf. Ser. 1179 012178 PDFfeow meowNo ratings yet

- An Automated Teller Machine (ATM) Is A Computerized Telecommunications Device That EnablesDocument2 pagesAn Automated Teller Machine (ATM) Is A Computerized Telecommunications Device That EnablesParvesh GeerishNo ratings yet

- Catalogo de Maquina de Soldar Marca Miller XMT 304 CC CV MA410427ADocument36 pagesCatalogo de Maquina de Soldar Marca Miller XMT 304 CC CV MA410427ALuis Eugenio Hernandez QuijaiteNo ratings yet

- Ferroresonance StudiesDocument9 pagesFerroresonance StudiesSandeep GuptaNo ratings yet

- Rais12 SM CH19Document29 pagesRais12 SM CH19Anton VitaliNo ratings yet

- Contoh Financial PlanDocument4 pagesContoh Financial PlanJonathan ChandhikaNo ratings yet

- DentinDocument133 pagesDentinMohammed hisham khan100% (3)

- Pressform Refractory PRINT Brochure PDFDocument44 pagesPressform Refractory PRINT Brochure PDFravikumarangNo ratings yet

- What Is Spend AnalysisDocument35 pagesWhat Is Spend AnalysisMahesh NaiduNo ratings yet

- Types of AssetsDocument19 pagesTypes of AssetsMylene SalvadorNo ratings yet

- Data Base Proyek KonstruksiDocument913 pagesData Base Proyek KonstruksiZefanyaNo ratings yet

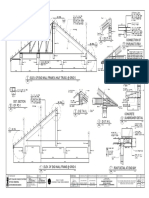

- Detail 6 Connection of Purlins To Rb-1 9Document1 pageDetail 6 Connection of Purlins To Rb-1 9Fritz NatividadNo ratings yet

- Strategic Operation ManagementDocument7 pagesStrategic Operation ManagementJayrald Delos SantosNo ratings yet

DRP10036 Screen Printed Electrodes Overview REV002

DRP10036 Screen Printed Electrodes Overview REV002

Uploaded by

simonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DRP10036 Screen Printed Electrodes Overview REV002

DRP10036 Screen Printed Electrodes Overview REV002

Uploaded by

simonCopyright:

Available Formats

Document #: DRP10036 (REV0022 | NOV 2019)

Screen-Printed Electrode Information

Carbon and Ceramic Electrode Information

Pine Research Instrumentation offers aqueous, screen-printed carbon electrodes (e.g. Pine Research

Part#: RRPE1001C or RRPE1002C) and ceramic screen-printed electrodes for non-aqueous use (e.g. Pine

Research Part#: RRPE2001AU or RRPE2001PT). The article herein aims to provide information on how to

activate, prepare, use, and clean screen-printed electrodes while also detailing system compatibility,

reference electrode stability, and example voltammetric response.

1. Description

Screen-printed electrodes (SPEs) offer some advantages over traditional electrodes in the areas of cost, solution

volume, and operating temperature. Due to these advantages, SPEs have been employed in biosensor

applications, teaching laboratories, and systems that require small volume or high temperature.

In the production of SPEs, mineral binders or insulating polymers are often added to carbon and gold or platinum

inks to improve the ink’s adhesion onto plastic and ceramic substrates, respectively. The proprietary binder

compounds found in the ink may introduce stray (but small) features in voltammograms, and the heterogeneous

kinetics at these electrode surfaces may be a bit sluggish (especially for screen-printed carbon electrodes, see

section 2). Additionally, the surfaces of SPEs are rough and not as pristine as more traditional electrodes fashioned

from glassy carbon, pyrolytic graphite, or pure metal rods and sheets. Consequently, the exact determination of

electrode area for an SPE is difficult. For academic teaching purposes and routine experiments, these problems do

not pose any great concern; however, the electrochemical purist is likely to find fault when comparing SPEs to more

expensive, traditional electrodes.

2. Screen-Printed Carbon Electrodes (SPCEs)

2.1 Background

Conductive carbon inks have been employed for many years1 in a variety of biosensor applications—most notably

in disposable blood glucose detectors due to their low-cost and accuracy. Typically, analyte-reactive enzymes are

placed on the working electrode (either by coating the electrode or pre-mixing the ink with the enzyme) to

enhance the electrochemical response for a given analyte. For example, a modified form of glucose oxidase is

present on the working electrode of most blood glucose detectors and, as this redox enzyme mediates the

oxidation of glucose, the electrochemical signal for glucose is boosted.

2.2 Available Electrode Patterns

Pine Research Instrumentation offers SPCEs in two different patterns; these patterns differ only with respect to the

working electrode geometry (2 𝑚𝑚 diameter disk and 5𝑚𝑚 x 4 𝑚𝑚 rectangle, see Figure 1). The card, composed

of polyethylene terephthalate (PET) plastic and a conductive silver track, has the dimensions: 15 x 61 x 0.36 𝑚𝑚. The

carbon working electrodes (disk or rectangles), 𝐴𝑔/𝐴𝑔𝐶𝑙 reference electrode (thin grey line), and carbon counter

electrode (thick black line) are adhered to the conductive silver layer in a recessed, insulating layer of the electrode

(see Figure 2).

Figure 1. Rectangular (left) and Disk (right) Carbon Screen-Printed Electrodes

Copyright © 2008-2019 Pine Research Instrumentation Page 1

Screen-Printed Electrode Information DRP10036 (REV002 | NOV 2019)

Figure 2. a) Reference Electrode, b) Working Electrode, and c) Counter Electrode for a SPCE

The disk-shaped electrode is suitable for routine use in an educational setting. The rectangular working electrodes

offer a larger area to those researchers wishing to drop coat an appreciable amount of enzyme on to the working

electrode. A blue insulating layer surrounds and also coats the extreme outside perimeter of the carbon working

electrode. The thickness of the carbon, silver, and insulating layers is typically 7-13 𝜇𝑚.

2.3 Screen Printed Silver-Chloride Reference Electrodes

The demand for commercial blood glucose detectors has also driven the development of silver/silver chloride inks

suitable for printing stable reference electrodes. Printed 𝐴𝑔/𝐴𝑔𝐶𝑙 reference electrodes are most stable when used

in an aqueous solution of chloride ions (such as 1.0𝑀 𝐾𝐶𝑙) but can also be used in nitrate-based electrolyte solutions

(such as 0.1 𝑀 𝐾𝑁𝑂3 ). When using a printed 𝐴𝑔/𝐴𝑔𝐶𝑙 reference electrode, it is important to allow the electrode to

equilibrate with the test solution for at least 60 𝑠𝑒𝑐𝑜𝑛𝑑𝑠 before experimenting.

2.4 Compatibility

SPCEs are only compatible with aqueous systems; the carbon ink used to print SPCEs will react with non-aqueous

solvents. Additionally, SPCEs are stable up to 80℃.

Chemical Compatibility:

Screen-printed carbon electrodes are for aqueous use only.

Thermal Stability:

Screen-printed carbon electrodes can be used from 𝟏𝟎℃ to 𝟖𝟎℃.

2.5 Mounting the Screen-Printed Electrodes

The Compact Voltammetry Cell Kit (Pine part #: AKSPEKIT) is designed for use with both the carbon and ceramic

SPEs. Since the carbon SPEs are thinner than the ceramic SPEs (0.36 𝑚𝑚 vs 0.67 𝑚𝑚, see sections 2.2 and 3.2), one or

more “spacers” are needed to mount the carbon SPE so that it can maintain a proper grip within the cell cap

(spacers are included upon purchase). Like the SPCE, the spacers are composed of polyethylene terephthalate,

an inert polymer, and it is approximately one-third the length of the SPCE. It is important to keep the spacer above

the solution level, as solution contact will create solution buildup between the spacer and SPCE by capillary action,

leading to a possible short of the electrode circuit and eventual corrosion of the grip. For this reason, it is not

recommended that two SPCEs be used back-to-back

Copyright © 2008-2019 Pine Research Instrumentation Page 2

Screen-Printed Electrode Information DRP10036 (REV002 | NOV 2019)

The Compact Voltammetry Cell features a custom cap with a built-in edge card connector into which the carbon

electrode card may be inserted. A mini-USB style connector on the top of the custom cap permits electrical

connection to be made to the electrode card. To connect to the card, always use the mini-USB style port which is

on the left when viewing the top of the card (see Figure 3). Connect the banana cables to their respective colors

on the potentiostat with which experiments are being performed.

Figure 3. Mounting a Screen-Printed Carbon Electrode

2.6 Typical Electrochemical Response

While the electrochemical response of different systems may vary wildly, there are two common factors seen in

many cyclic voltammograms performed with SPCEs: peaks in the background scan and slow electrode kinetics.

2.6.1 Background Scans

Hexaamineruthenium(III) chloride ([𝑅𝑢(𝑁𝐻3 )6 ]𝐶𝑙3) is a common source for the popular electroactive ion

hexaamineruthenium(III). This ion exhibits a well-behaved, reversible redox couple at about −0.44 𝑉 𝑣𝑠 𝐴𝑔/𝐴𝑔𝐶𝑙

(recall that the 𝐴𝑔/𝐴𝑔𝐶𝑙 reference electrode is printed on the same substrate). A potassium chloride electrolyte

solution can be used to prepare a solution of hexaamineruthenium(III) (10 𝑚𝑀 [𝑅𝑢(𝑁𝐻3 )6 ]3+ in 0.1 𝑀 𝐾𝐶𝑙). If a

background scan is taken using a SPCE, small features are revealed on both the anodic and cathodic scans (see

Figure 4a). The features are characteristic of the carbon ink itself and, in the presence of a reasonable

concentration of the target analyte (e.g.,10 𝑚𝑀), these background features tend to be dwarfed by the

voltammogram of interest (see Figure 4b). The electrochemical behavior of the hexaamineruthenium(III) ion at the

SPCE electrode is well suited for teaching cyclic voltammetry.

Copyright © 2008-2019 Pine Research Instrumentation Page 3

Screen-Printed Electrode Information DRP10036 (REV002 | NOV 2019)

Figure 4. Cyclic Voltammograms of a) 𝟎. 𝟏 𝑴 𝑲𝑪𝒍 (Background Scan) and b) 𝟏𝟎 𝒎𝑴 [𝑹𝒖(𝑵𝑯𝟑 )𝟔 ]𝟑+ with Background

2.6.2 Slow Electrode Kinetics

Many other popular electroactive ions (including hexacyanoferrate(III), dopamine, and ascorbic acid) are not as

well-suited for teaching purposes because sluggish heterogeneous kinetics significantly distort the shape of the

voltammogram. For example, the peak splitting on a cyclic voltammogram of dopamine may be as large as 400 𝑚𝑉

(much greater than the expected 59 𝑚𝑉, see Figure 5).

Figure 5. Cyclic Voltammogram of a Dopamine Solution

Researchers and laboratory instructors who still wish to use ions with sluggish heterogeneous kinetics are directed to

activate the carbon surface to improve electron transfer (see section 2.7).

2.7 Activating the Carbon Surface

Slow electrode kinetics are due (in part) to carbon ink binding factors that shelter electroactive carbon particles.

Over the years, researchers have developed many methods to activate the carbon electrode surface including

Copyright © 2008-2019 Pine Research Instrumentation Page 4

Screen-Printed Electrode Information DRP10036 (REV002 | NOV 2019)

potential cycling to extreme anodic potentials,2,3 heat treatment,4,5 and oxygen plasma treatment.6–8 Only

potential cycling will be discussed herein due to its simple and cheap procedure.

Potential cycling, or pretreatment, is an effective method to remove organic link-crossings from the carbon ink while

also increasing surface roughness and functionality. Best of all, it can be performed with minimal additional supplies,

making it perfect for teaching laboratories.

To activate an SPCE, cycle it via cyclic voltammetry in sulfuric acid at extreme anodic and cathodic potentials

(0.1 𝑁 𝐻2 𝑆𝑂4 will suffice, see Table 1 for specific parameters). During the pretreatment, oxygen and hydrogen gas

bubbles evolve on the carbon surface (see Figure 6a for a typical voltammetric response). After pretreatment, the

heterogeneous electron transfer kinetics of many electroactive ions are improved. To illustrate, the electron transfer

kinetics of a solution of dopamine (1 𝑚𝑀, sweep rate = 200 𝑚𝑉/𝑠) are quite sluggish before surface activation but

much faster after surface activation as evidenced by smaller peak-to-peak separation (see Figure 6b).

Parameter Input

Segments 𝟑

Initial Potential 0 𝑚𝑉 𝑣𝑠 𝑅𝐸𝐹

Initial Direction Rising

Upper Potential 2500 𝑚𝑉 𝑣𝑠 𝑅𝐸𝐹

Lower Potential -2500 𝑚𝑉 𝑣𝑠 𝑅𝐸𝐹

Final Potential 0 𝑚𝑉 𝑣𝑠 𝑅𝐸𝐹

Sweep Rate 100 𝑚𝑉/𝑠

Electrode Range Initial Range: 10000 𝜇𝐴

Autorange: Off

Table 1. Bulk Electrolysis Parameters to Activate Screen-Printed Carbon Electrode Surfaces

Figure 6. Cyclic Voltammograms of the a) Pretreatment and b) Dopamine Before (Red) and After (Blue) Activation

Copyright © 2008-2019 Pine Research Instrumentation Page 5

Screen-Printed Electrode Information DRP10036 (REV002 | NOV 2019)

2.8 Cleaning the Screen-Printed Carbon Electrodes

SPCEs are designed with low-cost materials and have a fairly short lifetime. For example, one SPCE is likely useful for

a single analysis in a research setting or a full laboratory period in a teaching setting. Research conditions will

dictate the lifetime of the SPCE and users should determine lifetime experimentally.

3. Ceramic Screen-Printed Electrodes

3.1 Background

The ceramic screen-printed electrodes offered by Pine Research Instrumentation are perfect for high temperature

and non-aqueous applications. With proper care, the ceramic SPEs can be reused many times, making them ideal

for routine electrochemistry.

3.2 Available Electrode Patterns

Ceramic SPEs have three electrodes on a single surface (see Figure 7). For all ceramic SPEs, the working electrode

is a 2.0 𝑚𝑚 𝑂𝐷 disk surrounded by a large counter electrode. Both the working and counter electrodes are available

in gold or platinum. There are two inks used to prepare the reference electrode (𝐴𝑔 and 𝐴𝑔/𝐴𝑔𝐶𝑙), but a pattern

that does not include a reference electrode is also available for purchase. All patterns share the same basic

electrode geometry with unit dimensions: 15 x 61 x 0.67 𝑚𝑚 (see Figure 8).

Figure 7. Gold (left) and Platinum (right) Ceramic Screen-Printed Electrodes

Figure 8. a) Reference Electrode, b) Working Electrode, and c) Counter Electrode for a Ceramic SPE

3.3 Reference Electrode Options

The reference electrode on a ceramic SPE is a small disk located between the working electrode and the counter

electrode. While the working and counter electrodes are fabricated from a noble metal (such as gold or platinum),

the reference electrode is silver (𝐴𝑔) or silver/silver chloride (𝐴𝑔/𝐴𝑔𝐶𝑙). When using 𝐴𝑔 or 𝐴𝑔/𝐴𝑔𝐶l reference

electrodes, it is important to allow the reference electrode to equilibrate with the solution for about 60 seconds

before use.

For work in aqueous solutions, the silver/silver chloride redox pair is the best reference electrode material. It is quite

stable when used in an aqueous solution containing chloride ions.

For work in non-aqueous solutions (or in cases where chloride ion may interfere with the electrochemical

experiment), Pine Research Instrumentation offers a silver “pseudo-reference” electrode. This electrode must be

standardized against a known redox couple. Typically, ferrocene (or one of its derivative compounds) is added to

the test solution as an internal standard, and potential measurements against the silver pseudo-reference are

corrected with respect to the known position of the ferrocene redox couple.

Copyright © 2008-2019 Pine Research Instrumentation Page 6

Screen-Printed Electrode Information DRP10036 (REV002 | NOV 2019)

The reference electrode has the shortest lifetime of the ceramic SPE. Depending on the conditions in which the SPE

is used, users should be aware of potential drift due to the screen printed 𝐴𝑔/𝐴𝑔𝐶𝑙 reference electrode response

decline. While this reference electrode deterioration will limit the immediate lifetime of the reference electrode, it

is quite easy to use a more typical reference external electrode instead of the reference spot on the SPE. Pine

Research Instrumentation offers 𝐴𝑔/𝐴𝑔𝐶𝑙 reference electrodes.

3.4 Compatibility

Ceramic SPEs can be used in aqueous and non-aqueous systems. They are compatible with systems up to 200℃.

Chemical Compatibility:

Ceramic screen-printed electrodes are stable in aqueous and non-aqueous

solvents.

Thermal Stability:

Ceramic screen-printed electrodes can be used from 𝟏𝟎℃ to 𝟐𝟎𝟎℃.

3.5 Mounting Ceramic Screen-Printed Electrodes

The Compact Voltammetry Cell Kit (Pine part #: AKSPEKIT) is designed for use with both carbon and ceramic SPEs.

The ceramic SPEs are thicker than the carbon SPEs (0.67 𝑚𝑚 vs 0.36 𝑚𝑚, see sections 2.2 and 3.2), and therefore a

“spacer” is not needed to mount the ceramic SPE.

The Compact Voltammetry Cell features a custom cap with a built-in edge card connector into which the ceramic

electrode card may be inserted. A mini-USB style connector on the top of the custom cap permits electrical

connection to be made to the electrode card. To connect to the card, always use the mini-USB style port which is

on the left when viewing the top of the card (see Figure 9). Connect the banana cables to their respective colors

on the potentiostat with which experiments are being performed.

Figure 9. Ceramic Screen-Printed Electrode Cell Connection

Copyright © 2008-2019 Pine Research Instrumentation Page 7

Screen-Printed Electrode Information DRP10036 (REV002 | NOV 2019)

3.6 Typical Electrochemical Response

Ceramic SPEs can be used to perform electrochemical experiments in solutions that are classically known to

undergo slow heterogeneous kinetics on a screen-printed carbon electrode (e.g. dopamine, potassium

hexacyanoferrate(III), and ferrocene) without electrode activation.

3.6.1 Potassium Hexacyanoferrate(III) Electrochemistry on a Gold Ceramic Screen-Printed

Electrode

Potassium hexacyanoferrate(III) (𝐾3 𝐹𝑒(𝐶𝑁)6 ) is a common source for the electroactive ion hexacyanoferrate(III).

This ion exhibits a well-behaved redox couple at ~ + 0.22 𝑉 𝑣𝑠 𝐴𝑔/𝐴𝑔𝐶𝑙 on the ceramic, gold-patterned substrate; its

well-behaved kinetics can be evidenced by peak-to-peak separation of approximately 60 𝑚𝑉 and a nearly linear

current dependence upon concentration (see Figure 10, sweep rate = 100 𝑚𝑉/𝑠𝑒𝑐). As a reminder, slow

heterogeneous electron transfer from a screen-printed carbon electrode to a substrate like dopamine or

hexacyanoferrate(III) typically manifests itself through large peak-to-peak separation (see Figure 5).

Figure 10. 𝑲𝟑 𝑭𝒆(𝑪𝑵)𝟔 Solution Electrochemistry on a Gold Screen-Printed Electrode a) Cyclic Voltammogram of

Varying Concentration and b) Cathodic Current as a Function of Concentration

3.6.2 Ferrocene Electrochemistry on a Platinum Ceramic Screen-Printed Electrode

Ferrocene is often used as a non-aqueous internal standard for solutions that require the absence of silver or chloride

ions. The Ceramic SPEs produced by Pine Research Instrumentation can be used in conjunction with ferrocene

internal standard solutions and behave well at multiple scan rates (see Figure 11, sweep rate = 100 𝑚𝑉/𝑠ec).

Interested readers are directed to Bard and Faulkner’s book10 for more information on current and concentration

interdependency.

Copyright © 2008-2019 Pine Research Instrumentation Page 8

Screen-Printed Electrode Information DRP10036 (REV002 | NOV 2019)

Figure 11. Ferrocene Solution Electrochemistry on a Platinum Screen-Printed Electrode a) Cyclic Voltammogram of

Varying Concentration and b) Anodic Current as a Function of Concentration

3.7 Activating and Cleaning the Ceramic Screen-Printed Electrode

Before a sensitive, electrochemical experiment is performed, or if the electrode surface becomes fouled, it may be

desirable to clean and/or activate the electrode surface. One way to do this is via repeated cycling of the working

electrode potential in a dilute sulfuric acid solution (for specific parameters, see Table 2).

Parameter Platinum Electrode Gold Electrode

Number of Segments At least 20 At least 20

Initial Potential -300 𝑚𝑉 -375 𝑚𝑉

Upper Potential 1700 𝑚𝑉 1800 𝑚𝑉

Lower Potential -300 𝑚𝑉 -375 𝑚𝑉

Final Potential -300 𝑚𝑉 -375 𝑚𝑉

Sweep Rate 500 𝑚𝑉/𝑠 500 𝑚𝑉/𝑠

Electrolyte 0.5 𝑀 𝐻2 𝑆𝑂4 0.5 𝑀 𝐻2 𝑆𝑂4

Table 2. Parameters to Clean Ceramic Screen-Printed Electrodes by Cyclic Voltammetry

Repeated cycling removes surface contamination and improves subsequent cyclic voltammetry results. As a result,

the cyclic voltammogram obtained with each scan evolves over time, often manifesting in the resolution of peaks

that were previously unresolved and/or the reduction of other peaks. Clean gold and platinum surfaces have

characteristic peaks; a clean gold surface typically shows an onset of gold oxidation around 1100 𝑚𝑉 𝑣𝑠. 𝐴𝑔/

𝐴𝑔𝐶𝑙 and a sharp reduction peak around 900 𝑚𝑉 𝑣𝑠. 𝐴𝑔/𝐴𝑔𝐶𝑙 (see Figure 12a) while a clean platinum surface

typically shows an onset of platinum oxidation around 600 𝑚𝑉 𝑣𝑠. 𝐴𝑔/𝐴𝑔𝐶𝑙, a sharp reduction peak around

450 𝑚𝑉 𝑣𝑠. 𝐴𝑔/𝐴𝑔𝐶𝑙, and two hydrogen adsorption and desorption peaks (sometimes called the “butterfly region”)

at near zero negative potential. (Figure 12b). When performing an electrochemical cleaning, be sure to compare

the cycled cyclic voltammogram output to the signature response; once they match, the electrode has been

refreshed/cleaned.

Copyright © 2008-2019 Pine Research Instrumentation Page 9

Screen-Printed Electrode Information DRP10036 (REV002 | NOV 2019)

Figure 12. Characteristic Features of Ceramic SPEs with a) Gold and b) Platinum Working Electrodes

4. References

(1) Hart, J. P.; Crew, A.; Crouch, E.; Honeychurch, K. C.; Pemberton, R. M. Anal. Lett. 2004, 37, 789.

(2) W. J Blaedel; Roger A. Jenkins. Anal. Chem. 1952, 46, 1952.

(3) Engstrom, R. C. Anal. Chem. 1982, 54, 2310.

(4) Hance, G. W.; Kuwana, T. Anal. Chem. 1987, 59, 131.

(5) Fagan, D. T.; Hu, I.; Kuwana, T. Anal. Chem. 1985, 57, 2759.

(6) Evans, J. F.; Kuwana, T. Anal. Chem. 1979, 51, 358.

(7) Evans, J. F.; Kuwana, T. Anal. Chem. 1977, 49, 1632.

(8) Kim, E. J.; Haruyama, T.; Yanagida, Y.; Kobatake, E.; Aizawa, M. Anal. Chim. Acta 394AD, 394, 225.

(9) Wang, S. C.; Chang, K. S.; Yuan, C. J. Electrochim. Acta 2009, 54, 4937.

(10) Faulkner, L. R. . A. J. B. Electrochemical Methods: Fundamentals and Applications, 2nd ed.; John Wiley &

Sons, Inc., 2001.

5. Support

If you have any questions about the screen printed electrode materials described in this document, please contact

us via the means provided below:

5.1 Email

Reach us by emailing the entire sales department: pinewire@pineresearch.com.

5.2 Website

There is a contact us form on our website. There may also be additional resources for the products mentioned here:

http://www.pineresearch.com

Copyright © 2008-2019 Pine Research Instrumentation Page 10

You might also like

- Solved Problems Axial DeformationDocument6 pagesSolved Problems Axial DeformationChristopher Largado67% (3)

- Bipolar Plate Development With Additive Manufacturing and ProtectiveDocument9 pagesBipolar Plate Development With Additive Manufacturing and Protectivev.babalo68No ratings yet

- 4BO.5.6 PaperDocument4 pages4BO.5.6 PaperignaciadevotoNo ratings yet

- 1-s2.0-S246802302200774X-mainDocument12 pages1-s2.0-S246802302200774X-mainEngr Muhammad RashidNo ratings yet

- A Mesoscopic Platinized Graphite Carbon Black Counter Electrode For A Highly Efficient Monolithic Dye-Sensitized Solar CellDocument6 pagesA Mesoscopic Platinized Graphite Carbon Black Counter Electrode For A Highly Efficient Monolithic Dye-Sensitized Solar CellLaura González SossaNo ratings yet

- 1 s2.0 S0013468623008745 MainDocument11 pages1 s2.0 S0013468623008745 MainROBSON CardosoNo ratings yet

- Advances in Materials Science: Experience of Using Graphitized Cored Electrodes in Industrial AC Electric Arc FurnaceDocument13 pagesAdvances in Materials Science: Experience of Using Graphitized Cored Electrodes in Industrial AC Electric Arc FurnaceAbderraouf GhrissiNo ratings yet

- Additive Manufactured Bipolar Plate ForDocument7 pagesAdditive Manufactured Bipolar Plate Forv.babalo68No ratings yet

- 1 s2.0 S138824811730070X MainDocument5 pages1 s2.0 S138824811730070X Mainv.babalo68No ratings yet

- Optimization of Copper Electroplating Process Applied For Microfabrication On Flexible Polyethylene Terephthalate SubstrateDocument7 pagesOptimization of Copper Electroplating Process Applied For Microfabrication On Flexible Polyethylene Terephthalate SubstrateXyNo ratings yet

- Understanding The Calendering Processability of Li (Ni0.33Mn0.33Co0.33) O2-Based CathodesDocument11 pagesUnderstanding The Calendering Processability of Li (Ni0.33Mn0.33Co0.33) O2-Based CathodesMDRNo ratings yet

- Author's Accepted Manuscript: Energy Storage MaterialsDocument11 pagesAuthor's Accepted Manuscript: Energy Storage MaterialsLu YuNo ratings yet

- Ag NW-PPy Nanocomp For SCsDocument34 pagesAg NW-PPy Nanocomp For SCsanamurboyNo ratings yet

- Comparison Between Different Architectures of An Electrolyte-Gated Organic Thin-Film Transistor Fabricated On Flexible Kapton SubstratesDocument4 pagesComparison Between Different Architectures of An Electrolyte-Gated Organic Thin-Film Transistor Fabricated On Flexible Kapton SubstratesliviuNo ratings yet

- 6.02 Nitride-Based LEDs and Superluminescent LEDsDocument73 pages6.02 Nitride-Based LEDs and Superluminescent LEDsfojxNo ratings yet

- Tintas Electrodos 2Document20 pagesTintas Electrodos 2guiburNo ratings yet

- Journal of Alloys and CompoundsDocument8 pagesJournal of Alloys and Compoundsjeffry122333No ratings yet

- An Integrated Three-Electrode System With A Micromachined Liquid-Junction Ag/AgCl Reference ElectrodeDocument10 pagesAn Integrated Three-Electrode System With A Micromachined Liquid-Junction Ag/AgCl Reference ElectrodeAHMAD ANWARNo ratings yet

- Electrostatically Sprayed Reduced Graphene Oxide-Carbon Nanotubes Electrodes For Lithium-Ion CapacitorsDocument10 pagesElectrostatically Sprayed Reduced Graphene Oxide-Carbon Nanotubes Electrodes For Lithium-Ion CapacitorsTam Van TranNo ratings yet

- Schiavi Electrochemical-Synthesis 2019Document8 pagesSchiavi Electrochemical-Synthesis 2019kkamolvisitNo ratings yet

- Annealing TeoriDocument12 pagesAnnealing Teorienna hasnaNo ratings yet

- Research Article The Influence of Blood Glucose Meter Resistance Variation On The Performance of A Biosensor With A Gold-Coated Circuit BoardDocument9 pagesResearch Article The Influence of Blood Glucose Meter Resistance Variation On The Performance of A Biosensor With A Gold-Coated Circuit Boardglucose glucoseNo ratings yet

- Electroflotation of Wastewater 41011686Document6 pagesElectroflotation of Wastewater 41011686Mardaru AnamariaNo ratings yet

- JNMESciV12 2009arcop035Document8 pagesJNMESciV12 2009arcop035Moisés BautistaNo ratings yet

- Corrosion Behaviour of Tinplate in SynthDocument11 pagesCorrosion Behaviour of Tinplate in SynthdouslasNo ratings yet

- 1 s2.0 S0360319921037058 MainDocument9 pages1 s2.0 S0360319921037058 Mainv.babalo68No ratings yet

- A Powder Metallurgy Route To Produce Ni RaneyDocument8 pagesA Powder Metallurgy Route To Produce Ni RaneyLucas Vander MeyNo ratings yet

- Electroplated Core-Shell NanowDocument9 pagesElectroplated Core-Shell NanowjulianNo ratings yet

- Introduction To Electron Beam ProcessingDocument10 pagesIntroduction To Electron Beam Processingvntan1002No ratings yet

- Electropol Edot Sds TritonDocument8 pagesElectropol Edot Sds TritonGonzalo FenoyNo ratings yet

- Applied Catalysis B: EnvironmentalDocument6 pagesApplied Catalysis B: Environmentalkhan47pkNo ratings yet

- Single Wall Carbon Nanotubes/Polypyrrole Composite Thin Film Electrodes: Investigation of Interfacial Ion Exchange BehaviorDocument14 pagesSingle Wall Carbon Nanotubes/Polypyrrole Composite Thin Film Electrodes: Investigation of Interfacial Ion Exchange BehaviormiguelNo ratings yet

- Thick Electrodes For High Energy Lithium Ion BatteDocument6 pagesThick Electrodes For High Energy Lithium Ion BattePhạm TùngNo ratings yet

- Electrical Properties of SB and Cr-Doped Pbzro - Pbtio - PBMG NB O CeramicsDocument8 pagesElectrical Properties of SB and Cr-Doped Pbzro - Pbtio - PBMG NB O CeramicsrachnaselvamanigmailNo ratings yet

- PDF 16 WorkingElecDocument5 pagesPDF 16 WorkingElecThoifahMuthohharohNo ratings yet

- Reduction of Porous Carbon Al Contact Resistance For An Electric Double-LayerDocument6 pagesReduction of Porous Carbon Al Contact Resistance For An Electric Double-LayerİsmailBütünNo ratings yet

- Effect of The Thickness of The PT Film Coated On A Counter Electrode On The Performance of A Dye-Sensitized Solar CellDocument7 pagesEffect of The Thickness of The PT Film Coated On A Counter Electrode On The Performance of A Dye-Sensitized Solar CellOussama IkhlefNo ratings yet

- Electrochimica Acta: Bin Qin, Qun Wang, Xiaohua Zhang, Xiaoling Xie, Li'e Jin, Qing CaoDocument9 pagesElectrochimica Acta: Bin Qin, Qun Wang, Xiaohua Zhang, Xiaoling Xie, Li'e Jin, Qing CaoJanethAlcalaNo ratings yet

- 1 s2.0 S0955221921001643 MainDocument9 pages1 s2.0 S0955221921001643 Mainmroth11No ratings yet

- CV Spinel ChuẩnDocument6 pagesCV Spinel ChuẩnĐức Duy NgôNo ratings yet

- Accepted Manuscript: Electrochimica ActaDocument30 pagesAccepted Manuscript: Electrochimica ActayascheNo ratings yet

- Journal of Alloys and Compounds: SciencedirectDocument11 pagesJournal of Alloys and Compounds: SciencedirectEstudiante2346No ratings yet

- Ai Apl#241143Document15 pagesAi Apl#241143Anonymous UJFK2jk5gNo ratings yet

- Resnik MEET2019Document7 pagesResnik MEET2019Surya Chandra NamahaNo ratings yet

- Tryk Et Al 2000 - Recent Topics in Photoelectrochemistry Achievements and Future ProspectsDocument14 pagesTryk Et Al 2000 - Recent Topics in Photoelectrochemistry Achievements and Future Prospectssamusm.smNo ratings yet

- PB HydrothermalDocument6 pagesPB Hydrothermallxvinh9467No ratings yet

- Materials LettersDocument4 pagesMaterials LettersSahin CoskunNo ratings yet

- Solar Energy Materials & Solar CellsDocument6 pagesSolar Energy Materials & Solar Cellsadharsh27No ratings yet

- Yao 2017Document31 pagesYao 2017vijayamathubalan pandyNo ratings yet

- Photoelectrochemical Cell Design, Efficiency, Definitions, Standards, and ProtocolsDocument35 pagesPhotoelectrochemical Cell Design, Efficiency, Definitions, Standards, and ProtocolsLê Văn TrungNo ratings yet

- Characterization and Optimization of A Printed, Primary Silver-Zinc BatteryDocument6 pagesCharacterization and Optimization of A Printed, Primary Silver-Zinc BatteryMiguel Angel Ramos RuizNo ratings yet

- Correlative Electrochemical Acoustic Time-Of-Flight Spectroscopy and X-Rayimaging To Monitor The Performance of Single-Crystal Lithium-Ion BatteriesDocument13 pagesCorrelative Electrochemical Acoustic Time-Of-Flight Spectroscopy and X-Rayimaging To Monitor The Performance of Single-Crystal Lithium-Ion BatteriesSANTHAKUMAR SNo ratings yet

- Ion ExchangeDocument13 pagesIon Exchangebreadfalling752No ratings yet

- Modeling and Simulation of A Copper Electrolysis Cell Group: Ilkka - Laitinen@tut - Fi (Ilkka Laitinen)Document9 pagesModeling and Simulation of A Copper Electrolysis Cell Group: Ilkka - Laitinen@tut - Fi (Ilkka Laitinen)Jérôme KyabuNo ratings yet

- Reuter 2019 J. Electrochem. Soc. 166 A3265Document8 pagesReuter 2019 J. Electrochem. Soc. 166 A3265adilNo ratings yet

- High Power Electric Double Layer Capacitor EDLCsDocument13 pagesHigh Power Electric Double Layer Capacitor EDLCsFikri AdiansyahNo ratings yet

- XHP Technical ManualDocument23 pagesXHP Technical ManualsiavoshsaifNo ratings yet

- Kim 2019Document6 pagesKim 2019Chetan ChaudhariNo ratings yet

- Gao 2016Document6 pagesGao 2016Jorge Daniel Torres AlvarezNo ratings yet

- Materials and Design: Khairul Amilin Ibrahim, Billy Wu, Nigel P. BrandonDocument9 pagesMaterials and Design: Khairul Amilin Ibrahim, Billy Wu, Nigel P. BrandonjohnNo ratings yet

- PDF Retail Ux PlaybookDocument62 pagesPDF Retail Ux PlaybooksebaNo ratings yet

- Computerized Accounting Using Tally - Erp 9 - Student GuideDocument546 pagesComputerized Accounting Using Tally - Erp 9 - Student Guideshruti100% (1)

- UntitledDocument672 pagesUntitledMilton Righetto NassNo ratings yet

- 03AdvancedThinkAhead4 ExamSkillsPrac Mod5-6Document3 pages03AdvancedThinkAhead4 ExamSkillsPrac Mod5-6mariasanztiNo ratings yet

- FINAL EXAM 201820192 - Draf (270319)Document13 pagesFINAL EXAM 201820192 - Draf (270319)YuthishDheeranManiamNo ratings yet

- Damage Prevention From Diesel Crankcase Explosions: Enginemen's Magazine, February, 1952Document10 pagesDamage Prevention From Diesel Crankcase Explosions: Enginemen's Magazine, February, 1952Mike FinazziNo ratings yet

- 144 Daftar P2P Ilegal AprilDocument12 pages144 Daftar P2P Ilegal AprilSumiatiNo ratings yet

- Embedded Electronic System Design, MSC - ChalmersDocument9 pagesEmbedded Electronic System Design, MSC - ChalmerskamranNo ratings yet

- Loans and MortgagesDocument26 pagesLoans and Mortgagesparkerroach21No ratings yet

- Introduction To Mineral Processing 2010Document24 pagesIntroduction To Mineral Processing 2010elmonemNo ratings yet

- Mg23 Infill DevelopmentDocument52 pagesMg23 Infill Developmentsilaban HansNo ratings yet

- Chapter 3 - Entity Relationship ModellingDocument34 pagesChapter 3 - Entity Relationship ModellingShrawan Trivedi100% (1)

- Neurobiologic Theories and PsychopharmacologyDocument3 pagesNeurobiologic Theories and Psychopharmacologygeorgeloto12100% (1)

- Srikanth ImJDocument2 pagesSrikanth ImJTEJA unixNo ratings yet

- Clarkson Lumber Case QuestionsDocument2 pagesClarkson Lumber Case QuestionsJeffery KaoNo ratings yet

- Fábrica de Chocolate UNSAACDocument13 pagesFábrica de Chocolate UNSAACFrank Chulla Montes0% (1)

- N Endah 2019 J. Phys. Conf. Ser. 1179 012178 PDFDocument7 pagesN Endah 2019 J. Phys. Conf. Ser. 1179 012178 PDFfeow meowNo ratings yet

- An Automated Teller Machine (ATM) Is A Computerized Telecommunications Device That EnablesDocument2 pagesAn Automated Teller Machine (ATM) Is A Computerized Telecommunications Device That EnablesParvesh GeerishNo ratings yet

- Catalogo de Maquina de Soldar Marca Miller XMT 304 CC CV MA410427ADocument36 pagesCatalogo de Maquina de Soldar Marca Miller XMT 304 CC CV MA410427ALuis Eugenio Hernandez QuijaiteNo ratings yet

- Ferroresonance StudiesDocument9 pagesFerroresonance StudiesSandeep GuptaNo ratings yet

- Rais12 SM CH19Document29 pagesRais12 SM CH19Anton VitaliNo ratings yet

- Contoh Financial PlanDocument4 pagesContoh Financial PlanJonathan ChandhikaNo ratings yet

- DentinDocument133 pagesDentinMohammed hisham khan100% (3)

- Pressform Refractory PRINT Brochure PDFDocument44 pagesPressform Refractory PRINT Brochure PDFravikumarangNo ratings yet

- What Is Spend AnalysisDocument35 pagesWhat Is Spend AnalysisMahesh NaiduNo ratings yet

- Types of AssetsDocument19 pagesTypes of AssetsMylene SalvadorNo ratings yet

- Data Base Proyek KonstruksiDocument913 pagesData Base Proyek KonstruksiZefanyaNo ratings yet

- Detail 6 Connection of Purlins To Rb-1 9Document1 pageDetail 6 Connection of Purlins To Rb-1 9Fritz NatividadNo ratings yet

- Strategic Operation ManagementDocument7 pagesStrategic Operation ManagementJayrald Delos SantosNo ratings yet