Professional Documents

Culture Documents

PU Drum Scraper: Contact Us

PU Drum Scraper: Contact Us

Uploaded by

TRU CONVEYOR SYSTEMS DRC SARLCopyright:

Available Formats

You might also like

- BMW 3 Series E46 1997 2006 Workshop ManualDocument1,257 pagesBMW 3 Series E46 1997 2006 Workshop ManualTakács Dániel100% (4)

- C7-C9 Electrical Electronic GuideDocument204 pagesC7-C9 Electrical Electronic GuideElibey Cuadros Berbesi93% (42)

- Halil İnalcık - The Ottoman Economic Mind and Aspects of The Ottoman Economy PDFDocument10 pagesHalil İnalcık - The Ottoman Economic Mind and Aspects of The Ottoman Economy PDFA Seven HasdemirNo ratings yet

- Installation Reference, DPI Transom ShieldDocument2 pagesInstallation Reference, DPI Transom ShieldSON100% (1)

- Vortex Quantum SeriesDocument34 pagesVortex Quantum SeriesmiguelcNo ratings yet

- BTM 940Document28 pagesBTM 940arlgmuserNo ratings yet

- WK-Vulcanizing Press System: Application AreasDocument2 pagesWK-Vulcanizing Press System: Application AreasTRU CONVEYOR SYSTEMS DRC SARLNo ratings yet

- 1 TLC Analysis of Analgesic DrugsDocument6 pages1 TLC Analysis of Analgesic DrugsnanaNo ratings yet

- ITT Mackay Instruction Manual For Model 3030A-3030AR Synthesized Receiver Issue 3 June 1982Document110 pagesITT Mackay Instruction Manual For Model 3030A-3030AR Synthesized Receiver Issue 3 June 1982antoniNo ratings yet

- Standard Bar Scraper: Contact UsDocument1 pageStandard Bar Scraper: Contact UsTRU CONVEYOR SYSTEMS DRC SARLNo ratings yet

- Vertex Hose ClampDocument8 pagesVertex Hose ClampRamasamy PNo ratings yet

- Application Field of Slipper Rings and FLUOR S TapesDocument2 pagesApplication Field of Slipper Rings and FLUOR S TapesAnurag JainNo ratings yet

- Timber Purlin Screw Armourcoat Blue 2020Document2 pagesTimber Purlin Screw Armourcoat Blue 2020alive stayNo ratings yet

- Rotex Poly-Norm: Torsionally Flexible CouplingsDocument32 pagesRotex Poly-Norm: Torsionally Flexible CouplingsAlessandro OliveiraNo ratings yet

- Bucket Teeth AdaptersDocument36 pagesBucket Teeth AdaptersSzilárd S100% (1)

- 2010 Penn CatalogDocument29 pages2010 Penn CatalogMohamed TelebNo ratings yet

- Drop-In Anchor in Zinc-Plated Steel For Suitable Hammerset InstallationDocument2 pagesDrop-In Anchor in Zinc-Plated Steel For Suitable Hammerset InstallationcoolkaisyNo ratings yet

- BTM Catalog 940 Tog L Loc ToolingDocument32 pagesBTM Catalog 940 Tog L Loc ToolingAbrão GarciaNo ratings yet

- The Worlds Most Trusted: Bucket Tooth SystemDocument19 pagesThe Worlds Most Trusted: Bucket Tooth SystemMarcoNo ratings yet

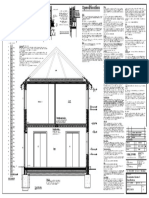

- BR124-04A Construction Section & SpecificationsDocument1 pageBR124-04A Construction Section & SpecificationsLaurentiu NaeNo ratings yet

- Brake Lining, Rivetting & De-Rivetting SystemsDocument2 pagesBrake Lining, Rivetting & De-Rivetting SystemsC S KumarNo ratings yet

- ZS022-Stem (English-20090112) v0Document2 pagesZS022-Stem (English-20090112) v0manuelNo ratings yet

- Mitersawstation PDFDocument9 pagesMitersawstation PDFJose Amenta100% (1)

- The Advanced: Choice For Building With StrengthDocument2 pagesThe Advanced: Choice For Building With StrengthchenwaiyewNo ratings yet

- Tapcon: SCOTS AnchorsDocument2 pagesTapcon: SCOTS Anchorsblessed cccNo ratings yet

- D-Series Rack & Pinion Pneumatic ActuatorsDocument6 pagesD-Series Rack & Pinion Pneumatic ActuatorsJandri JacobNo ratings yet

- ptd06 18enDocument2 pagesptd06 18enLuis LopezNo ratings yet

- Breeze V-Band Clamps: High-Strength Joining With Positive Sealing Integrity Three Latch Styles AvailableDocument2 pagesBreeze V-Band Clamps: High-Strength Joining With Positive Sealing Integrity Three Latch Styles AvailableMuhammad SyaqirinNo ratings yet

- Pulleys and Sheaves 1060Document84 pagesPulleys and Sheaves 1060m s sankar raoNo ratings yet

- Spek Alat Potong TubingDocument2 pagesSpek Alat Potong TubingAS dNo ratings yet

- Everything Under Control... : Rotolok UsaDocument4 pagesEverything Under Control... : Rotolok UsaJimmy BallonNo ratings yet

- PE Squeeze Off Flyer 03 20Document2 pagesPE Squeeze Off Flyer 03 20fdo.casanovaNo ratings yet

- Rubber Ceramic Lagging CatalogueDocument6 pagesRubber Ceramic Lagging Cataloguetechlibrary072023No ratings yet

- BTM Catalog Tog L Loc Tooling (Non 940)Document36 pagesBTM Catalog Tog L Loc Tooling (Non 940)Abrão GarciaNo ratings yet

- TSP - Kito CanadaDocument3 pagesTSP - Kito CanadasalesNo ratings yet

- The High Performance Concrete Anchor That Cuts Its Own Threads!Document4 pagesThe High Performance Concrete Anchor That Cuts Its Own Threads!blessed cccNo ratings yet

- Brochure Heads enDocument4 pagesBrochure Heads enDiego Barboza PenteadoNo ratings yet

- Rosta - TechnologyDocument7 pagesRosta - TechnologyseanfsmythNo ratings yet

- Brochure JSM 1 2Document2 pagesBrochure JSM 1 2vrajkrunalshahNo ratings yet

- Knitting: Products and Services For The Flat Knitting SectorDocument16 pagesKnitting: Products and Services For The Flat Knitting SectorAbhinav GuptaNo ratings yet

- Rubber: TracksDocument6 pagesRubber: TracksNasr PooyaNo ratings yet

- Denso TapeDocument2 pagesDenso TapeagusjuliNo ratings yet

- Brochure 1243 - 333eDocument2 pagesBrochure 1243 - 333eMarceloNo ratings yet

- Clamps: Slurry Hose SystemsDocument2 pagesClamps: Slurry Hose Systemsmih1No ratings yet

- Manual Basic MZ04Document2 pagesManual Basic MZ04Pedro Javier Pingo TalledoNo ratings yet

- Link BeltDocument6 pagesLink Beltnelson santosNo ratings yet

- Heritage Grease FittingsDocument20 pagesHeritage Grease FittingsG.L. HuyettNo ratings yet

- Xylem PumpsDocument4 pagesXylem PumpsRonald ValenciaNo ratings yet

- General Information: Wire Rope SheavesDocument2 pagesGeneral Information: Wire Rope SheavesFayyaz NadeemNo ratings yet

- 2agujas PDFDocument4 pages2agujas PDFMeneses Chino ChinoNo ratings yet

- Guarnizioni Per PISTONE PISTON Seals: Versione Standard Standard VersionDocument4 pagesGuarnizioni Per PISTONE PISTON Seals: Versione Standard Standard VersionCasa das VedacoesNo ratings yet

- Reversing Camera Installation GuideDocument5 pagesReversing Camera Installation GuideMuhammad ZamanNo ratings yet

- 5 Router Table UpgradesDocument3 pages5 Router Table Upgradesgmand68100% (3)

- Solve Special Material Handling Problems: Built To Work in Your ApplicationsDocument45 pagesSolve Special Material Handling Problems: Built To Work in Your Applicationsshubham tadeNo ratings yet

- Manual Pro14 19Document8 pagesManual Pro14 19MetalacSmzrNo ratings yet

- Wrapid Tape™: Product DescriptionDocument2 pagesWrapid Tape™: Product DescriptionCristobal Leal Aranda100% (1)

- Understanding Synchronous Belt Nomenclature: Example: 8MXT - 640 - 12Document1 pageUnderstanding Synchronous Belt Nomenclature: Example: 8MXT - 640 - 12Puji NugrohoNo ratings yet

- Pump SelectionDocument7 pagesPump SelectionSakir ZakNo ratings yet

- Tesa Wire Harnessing SolutionsDocument4 pagesTesa Wire Harnessing Solutionsacarlessi1No ratings yet

- 03 - SeAH Metal - Company - EngDocument4 pages03 - SeAH Metal - Company - EngHOSSIENNo ratings yet

- Work Holding - Cutting ToolsDocument16 pagesWork Holding - Cutting Toolsherysyam1980No ratings yet

- Advanced Material Handling BrochureDocument8 pagesAdvanced Material Handling BrochureJoelCristobalNo ratings yet

- Piling Systems: Ductile Iron SolutionsDocument16 pagesPiling Systems: Ductile Iron SolutionsDaniel MarínNo ratings yet

- BBR VT Cona Cmmsingles2 Flyer Rev2 0420Document2 pagesBBR VT Cona Cmmsingles2 Flyer Rev2 0420wenix oniralcoNo ratings yet

- Lead Screw Lead Screw: Lead Screws - Overview Lead Screw Specifications / Technical CalculationsDocument1 pageLead Screw Lead Screw: Lead Screws - Overview Lead Screw Specifications / Technical CalculationsMyint Myat NaingNo ratings yet

- Steel FlyersDocument4 pagesSteel FlyersTRU CONVEYOR SYSTEMS DRC SARLNo ratings yet

- Cisco Routing and Switching Certification Program: How You BenefitDocument3 pagesCisco Routing and Switching Certification Program: How You BenefitTRU CONVEYOR SYSTEMS DRC SARLNo ratings yet

- VICTOR ELECTRICAL CONNECTORS b130320Document1 pageVICTOR ELECTRICAL CONNECTORS b130320TRU CONVEYOR SYSTEMS DRC SARLNo ratings yet

- Standard Bar Scraper: Contact UsDocument1 pageStandard Bar Scraper: Contact UsTRU CONVEYOR SYSTEMS DRC SARLNo ratings yet

- Insulin TherapyDocument14 pagesInsulin TherapyElimar Alejandra David GilNo ratings yet

- 6.VLSI Architecture Design For Analysis of Fast Locking ADPLL Via Feed Forward Compensation Algorithm (33-38)Document6 pages6.VLSI Architecture Design For Analysis of Fast Locking ADPLL Via Feed Forward Compensation Algorithm (33-38)ijcctsNo ratings yet

- 7 E'sDocument9 pages7 E'sShiello JuanicoNo ratings yet

- KopenhagenDocument20 pagesKopenhagenŠime Novi Profil NimacNo ratings yet

- Unit-I PPC & Functions PDFDocument5 pagesUnit-I PPC & Functions PDFHari Prasad Reddy YedulaNo ratings yet

- Weighted Average MethodDocument16 pagesWeighted Average MethodKevin Estay100% (2)

- ECO #10 - 6th Dec, 2012Document2 pagesECO #10 - 6th Dec, 2012adoptnegotiatorNo ratings yet

- ChirdsDocument5 pagesChirdsWise FidelityNo ratings yet

- Conduction Convection Radiation PowerpointDocument27 pagesConduction Convection Radiation PowerpointApet Satusembilansembilan JieNo ratings yet

- Msds LicowaxDocument5 pagesMsds LicowaxciswandiNo ratings yet

- Norma IVet-5 Print 20200603Document2 pagesNorma IVet-5 Print 20200603Dani JuhaszNo ratings yet

- Superjunction SiC TCOX-MOSFET Study and ComparisonDocument3 pagesSuperjunction SiC TCOX-MOSFET Study and ComparisonpatrikNo ratings yet

- Octopus Crochet Pattern - v1Document6 pagesOctopus Crochet Pattern - v1Baitiar CallejaNo ratings yet

- PSmarkup - Module 7 - ECE 11 - Transmission Line, Antenna System and DesignDocument13 pagesPSmarkup - Module 7 - ECE 11 - Transmission Line, Antenna System and DesignMike FinezaNo ratings yet

- Ecube 9Document13 pagesEcube 9Ishaan JindalNo ratings yet

- Data Sheet: Elcometer 415 Paint & Powder Coating Thickness GaugeDocument2 pagesData Sheet: Elcometer 415 Paint & Powder Coating Thickness Gaugemalaya tripathyNo ratings yet

- Corrosion Probe TypeDocument26 pagesCorrosion Probe TypeFirman MuttaqinNo ratings yet

- Oishi GroupDocument20 pagesOishi GroupCamilleJoyceAdrianoNo ratings yet

- Manual Zte 8900 PDFDocument51 pagesManual Zte 8900 PDFAhmed IsmailNo ratings yet

- Manitou MSI (EN)Document8 pagesManitou MSI (EN)ManitouNo ratings yet

- Electronics System Design Manufacturing ESDM May 2021Document35 pagesElectronics System Design Manufacturing ESDM May 2021wofedor973No ratings yet

- Rohith R Fouress Report 1Document22 pagesRohith R Fouress Report 1Nithish ChandrashekarNo ratings yet

- DC SimpDocument3 pagesDC SimpNikhil HiremathNo ratings yet

- Indigenous Religion Institutions and Rituals of The Mamanwas of Caraga Region PhilippinesDocument19 pagesIndigenous Religion Institutions and Rituals of The Mamanwas of Caraga Region PhilippinesMomay Ü100% (1)

- Bts 7960Document28 pagesBts 7960Nairo FilhoNo ratings yet

PU Drum Scraper: Contact Us

PU Drum Scraper: Contact Us

Uploaded by

TRU CONVEYOR SYSTEMS DRC SARLOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PU Drum Scraper: Contact Us

PU Drum Scraper: Contact Us

Uploaded by

TRU CONVEYOR SYSTEMS DRC SARLCopyright:

Available Formats

P8

CONTACT US

Tel: +27 (0) 11 979 3094 / 5

Fax: +27 (0) 11 979 1414

Fax to Email:

+27 (0) 86 657 0126 PU Drum Scraper

Mobile:

+27 (0) 83 252 4889

O NL IN E Primary Scraper

Suitable for sticky

Web: www.tis-za.co.za Material

Self-adjusting through

Email: info@tis-za.co.za Material used for

Segments

Segments adjust to fit

profile of drum

P R O DU C T S

Low on Maintenance

Conveyor Belt Scrapers No moving Parts

Suitable for conveyors

Trough Training Rollers where belts of

different thicknesses

Impact Stations

have been joined

Torsion Elements together

Chute Liners

Super-Screw Belt Splicing

HDPE Rollers

SER VI C E S

Professional and timely

installation of all our

products

The Drum Scraper is installed on the centre of the head pulley. It is a primary

Full maintenance contracts

Scraper, cleaning your belt to about 80% only. Therefore it is necessary with a

Immediate break-down Drum Scraper, to install a second, solid Blade scraper behind it. All Segments

repairs adjust themselves due to the nature of the Polyurethane to fit the profile of the

On-site training Head Pulley. The design of the scraper makes Blade changes and

maintenance quick and easy. The Polyurethane is of a high grade which

Professional training

courses at the T.I.S. makes it last for a reasonable time. This Scraper can be installed on belts fitted

premises with Clip Joints.This Scraper is patented in South Africa and other countries in

the world.

All scrapers are also available in Stainless Steel

You might also like

- BMW 3 Series E46 1997 2006 Workshop ManualDocument1,257 pagesBMW 3 Series E46 1997 2006 Workshop ManualTakács Dániel100% (4)

- C7-C9 Electrical Electronic GuideDocument204 pagesC7-C9 Electrical Electronic GuideElibey Cuadros Berbesi93% (42)

- Halil İnalcık - The Ottoman Economic Mind and Aspects of The Ottoman Economy PDFDocument10 pagesHalil İnalcık - The Ottoman Economic Mind and Aspects of The Ottoman Economy PDFA Seven HasdemirNo ratings yet

- Installation Reference, DPI Transom ShieldDocument2 pagesInstallation Reference, DPI Transom ShieldSON100% (1)

- Vortex Quantum SeriesDocument34 pagesVortex Quantum SeriesmiguelcNo ratings yet

- BTM 940Document28 pagesBTM 940arlgmuserNo ratings yet

- WK-Vulcanizing Press System: Application AreasDocument2 pagesWK-Vulcanizing Press System: Application AreasTRU CONVEYOR SYSTEMS DRC SARLNo ratings yet

- 1 TLC Analysis of Analgesic DrugsDocument6 pages1 TLC Analysis of Analgesic DrugsnanaNo ratings yet

- ITT Mackay Instruction Manual For Model 3030A-3030AR Synthesized Receiver Issue 3 June 1982Document110 pagesITT Mackay Instruction Manual For Model 3030A-3030AR Synthesized Receiver Issue 3 June 1982antoniNo ratings yet

- Standard Bar Scraper: Contact UsDocument1 pageStandard Bar Scraper: Contact UsTRU CONVEYOR SYSTEMS DRC SARLNo ratings yet

- Vertex Hose ClampDocument8 pagesVertex Hose ClampRamasamy PNo ratings yet

- Application Field of Slipper Rings and FLUOR S TapesDocument2 pagesApplication Field of Slipper Rings and FLUOR S TapesAnurag JainNo ratings yet

- Timber Purlin Screw Armourcoat Blue 2020Document2 pagesTimber Purlin Screw Armourcoat Blue 2020alive stayNo ratings yet

- Rotex Poly-Norm: Torsionally Flexible CouplingsDocument32 pagesRotex Poly-Norm: Torsionally Flexible CouplingsAlessandro OliveiraNo ratings yet

- Bucket Teeth AdaptersDocument36 pagesBucket Teeth AdaptersSzilárd S100% (1)

- 2010 Penn CatalogDocument29 pages2010 Penn CatalogMohamed TelebNo ratings yet

- Drop-In Anchor in Zinc-Plated Steel For Suitable Hammerset InstallationDocument2 pagesDrop-In Anchor in Zinc-Plated Steel For Suitable Hammerset InstallationcoolkaisyNo ratings yet

- BTM Catalog 940 Tog L Loc ToolingDocument32 pagesBTM Catalog 940 Tog L Loc ToolingAbrão GarciaNo ratings yet

- The Worlds Most Trusted: Bucket Tooth SystemDocument19 pagesThe Worlds Most Trusted: Bucket Tooth SystemMarcoNo ratings yet

- BR124-04A Construction Section & SpecificationsDocument1 pageBR124-04A Construction Section & SpecificationsLaurentiu NaeNo ratings yet

- Brake Lining, Rivetting & De-Rivetting SystemsDocument2 pagesBrake Lining, Rivetting & De-Rivetting SystemsC S KumarNo ratings yet

- ZS022-Stem (English-20090112) v0Document2 pagesZS022-Stem (English-20090112) v0manuelNo ratings yet

- Mitersawstation PDFDocument9 pagesMitersawstation PDFJose Amenta100% (1)

- The Advanced: Choice For Building With StrengthDocument2 pagesThe Advanced: Choice For Building With StrengthchenwaiyewNo ratings yet

- Tapcon: SCOTS AnchorsDocument2 pagesTapcon: SCOTS Anchorsblessed cccNo ratings yet

- D-Series Rack & Pinion Pneumatic ActuatorsDocument6 pagesD-Series Rack & Pinion Pneumatic ActuatorsJandri JacobNo ratings yet

- ptd06 18enDocument2 pagesptd06 18enLuis LopezNo ratings yet

- Breeze V-Band Clamps: High-Strength Joining With Positive Sealing Integrity Three Latch Styles AvailableDocument2 pagesBreeze V-Band Clamps: High-Strength Joining With Positive Sealing Integrity Three Latch Styles AvailableMuhammad SyaqirinNo ratings yet

- Pulleys and Sheaves 1060Document84 pagesPulleys and Sheaves 1060m s sankar raoNo ratings yet

- Spek Alat Potong TubingDocument2 pagesSpek Alat Potong TubingAS dNo ratings yet

- Everything Under Control... : Rotolok UsaDocument4 pagesEverything Under Control... : Rotolok UsaJimmy BallonNo ratings yet

- PE Squeeze Off Flyer 03 20Document2 pagesPE Squeeze Off Flyer 03 20fdo.casanovaNo ratings yet

- Rubber Ceramic Lagging CatalogueDocument6 pagesRubber Ceramic Lagging Cataloguetechlibrary072023No ratings yet

- BTM Catalog Tog L Loc Tooling (Non 940)Document36 pagesBTM Catalog Tog L Loc Tooling (Non 940)Abrão GarciaNo ratings yet

- TSP - Kito CanadaDocument3 pagesTSP - Kito CanadasalesNo ratings yet

- The High Performance Concrete Anchor That Cuts Its Own Threads!Document4 pagesThe High Performance Concrete Anchor That Cuts Its Own Threads!blessed cccNo ratings yet

- Brochure Heads enDocument4 pagesBrochure Heads enDiego Barboza PenteadoNo ratings yet

- Rosta - TechnologyDocument7 pagesRosta - TechnologyseanfsmythNo ratings yet

- Brochure JSM 1 2Document2 pagesBrochure JSM 1 2vrajkrunalshahNo ratings yet

- Knitting: Products and Services For The Flat Knitting SectorDocument16 pagesKnitting: Products and Services For The Flat Knitting SectorAbhinav GuptaNo ratings yet

- Rubber: TracksDocument6 pagesRubber: TracksNasr PooyaNo ratings yet

- Denso TapeDocument2 pagesDenso TapeagusjuliNo ratings yet

- Brochure 1243 - 333eDocument2 pagesBrochure 1243 - 333eMarceloNo ratings yet

- Clamps: Slurry Hose SystemsDocument2 pagesClamps: Slurry Hose Systemsmih1No ratings yet

- Manual Basic MZ04Document2 pagesManual Basic MZ04Pedro Javier Pingo TalledoNo ratings yet

- Link BeltDocument6 pagesLink Beltnelson santosNo ratings yet

- Heritage Grease FittingsDocument20 pagesHeritage Grease FittingsG.L. HuyettNo ratings yet

- Xylem PumpsDocument4 pagesXylem PumpsRonald ValenciaNo ratings yet

- General Information: Wire Rope SheavesDocument2 pagesGeneral Information: Wire Rope SheavesFayyaz NadeemNo ratings yet

- 2agujas PDFDocument4 pages2agujas PDFMeneses Chino ChinoNo ratings yet

- Guarnizioni Per PISTONE PISTON Seals: Versione Standard Standard VersionDocument4 pagesGuarnizioni Per PISTONE PISTON Seals: Versione Standard Standard VersionCasa das VedacoesNo ratings yet

- Reversing Camera Installation GuideDocument5 pagesReversing Camera Installation GuideMuhammad ZamanNo ratings yet

- 5 Router Table UpgradesDocument3 pages5 Router Table Upgradesgmand68100% (3)

- Solve Special Material Handling Problems: Built To Work in Your ApplicationsDocument45 pagesSolve Special Material Handling Problems: Built To Work in Your Applicationsshubham tadeNo ratings yet

- Manual Pro14 19Document8 pagesManual Pro14 19MetalacSmzrNo ratings yet

- Wrapid Tape™: Product DescriptionDocument2 pagesWrapid Tape™: Product DescriptionCristobal Leal Aranda100% (1)

- Understanding Synchronous Belt Nomenclature: Example: 8MXT - 640 - 12Document1 pageUnderstanding Synchronous Belt Nomenclature: Example: 8MXT - 640 - 12Puji NugrohoNo ratings yet

- Pump SelectionDocument7 pagesPump SelectionSakir ZakNo ratings yet

- Tesa Wire Harnessing SolutionsDocument4 pagesTesa Wire Harnessing Solutionsacarlessi1No ratings yet

- 03 - SeAH Metal - Company - EngDocument4 pages03 - SeAH Metal - Company - EngHOSSIENNo ratings yet

- Work Holding - Cutting ToolsDocument16 pagesWork Holding - Cutting Toolsherysyam1980No ratings yet

- Advanced Material Handling BrochureDocument8 pagesAdvanced Material Handling BrochureJoelCristobalNo ratings yet

- Piling Systems: Ductile Iron SolutionsDocument16 pagesPiling Systems: Ductile Iron SolutionsDaniel MarínNo ratings yet

- BBR VT Cona Cmmsingles2 Flyer Rev2 0420Document2 pagesBBR VT Cona Cmmsingles2 Flyer Rev2 0420wenix oniralcoNo ratings yet

- Lead Screw Lead Screw: Lead Screws - Overview Lead Screw Specifications / Technical CalculationsDocument1 pageLead Screw Lead Screw: Lead Screws - Overview Lead Screw Specifications / Technical CalculationsMyint Myat NaingNo ratings yet

- Steel FlyersDocument4 pagesSteel FlyersTRU CONVEYOR SYSTEMS DRC SARLNo ratings yet

- Cisco Routing and Switching Certification Program: How You BenefitDocument3 pagesCisco Routing and Switching Certification Program: How You BenefitTRU CONVEYOR SYSTEMS DRC SARLNo ratings yet

- VICTOR ELECTRICAL CONNECTORS b130320Document1 pageVICTOR ELECTRICAL CONNECTORS b130320TRU CONVEYOR SYSTEMS DRC SARLNo ratings yet

- Standard Bar Scraper: Contact UsDocument1 pageStandard Bar Scraper: Contact UsTRU CONVEYOR SYSTEMS DRC SARLNo ratings yet

- Insulin TherapyDocument14 pagesInsulin TherapyElimar Alejandra David GilNo ratings yet

- 6.VLSI Architecture Design For Analysis of Fast Locking ADPLL Via Feed Forward Compensation Algorithm (33-38)Document6 pages6.VLSI Architecture Design For Analysis of Fast Locking ADPLL Via Feed Forward Compensation Algorithm (33-38)ijcctsNo ratings yet

- 7 E'sDocument9 pages7 E'sShiello JuanicoNo ratings yet

- KopenhagenDocument20 pagesKopenhagenŠime Novi Profil NimacNo ratings yet

- Unit-I PPC & Functions PDFDocument5 pagesUnit-I PPC & Functions PDFHari Prasad Reddy YedulaNo ratings yet

- Weighted Average MethodDocument16 pagesWeighted Average MethodKevin Estay100% (2)

- ECO #10 - 6th Dec, 2012Document2 pagesECO #10 - 6th Dec, 2012adoptnegotiatorNo ratings yet

- ChirdsDocument5 pagesChirdsWise FidelityNo ratings yet

- Conduction Convection Radiation PowerpointDocument27 pagesConduction Convection Radiation PowerpointApet Satusembilansembilan JieNo ratings yet

- Msds LicowaxDocument5 pagesMsds LicowaxciswandiNo ratings yet

- Norma IVet-5 Print 20200603Document2 pagesNorma IVet-5 Print 20200603Dani JuhaszNo ratings yet

- Superjunction SiC TCOX-MOSFET Study and ComparisonDocument3 pagesSuperjunction SiC TCOX-MOSFET Study and ComparisonpatrikNo ratings yet

- Octopus Crochet Pattern - v1Document6 pagesOctopus Crochet Pattern - v1Baitiar CallejaNo ratings yet

- PSmarkup - Module 7 - ECE 11 - Transmission Line, Antenna System and DesignDocument13 pagesPSmarkup - Module 7 - ECE 11 - Transmission Line, Antenna System and DesignMike FinezaNo ratings yet

- Ecube 9Document13 pagesEcube 9Ishaan JindalNo ratings yet

- Data Sheet: Elcometer 415 Paint & Powder Coating Thickness GaugeDocument2 pagesData Sheet: Elcometer 415 Paint & Powder Coating Thickness Gaugemalaya tripathyNo ratings yet

- Corrosion Probe TypeDocument26 pagesCorrosion Probe TypeFirman MuttaqinNo ratings yet

- Oishi GroupDocument20 pagesOishi GroupCamilleJoyceAdrianoNo ratings yet

- Manual Zte 8900 PDFDocument51 pagesManual Zte 8900 PDFAhmed IsmailNo ratings yet

- Manitou MSI (EN)Document8 pagesManitou MSI (EN)ManitouNo ratings yet

- Electronics System Design Manufacturing ESDM May 2021Document35 pagesElectronics System Design Manufacturing ESDM May 2021wofedor973No ratings yet

- Rohith R Fouress Report 1Document22 pagesRohith R Fouress Report 1Nithish ChandrashekarNo ratings yet

- DC SimpDocument3 pagesDC SimpNikhil HiremathNo ratings yet

- Indigenous Religion Institutions and Rituals of The Mamanwas of Caraga Region PhilippinesDocument19 pagesIndigenous Religion Institutions and Rituals of The Mamanwas of Caraga Region PhilippinesMomay Ü100% (1)

- Bts 7960Document28 pagesBts 7960Nairo FilhoNo ratings yet