Professional Documents

Culture Documents

General Training Air Conditioning - Module 04 S (Book4You) PDF

General Training Air Conditioning - Module 04 S (Book4You) PDF

Uploaded by

aramirezharo100%(1)100% found this document useful (1 vote)

557 views36 pagesOriginal Title

[]_General_Training_Air_conditioning_-_Module_04_S(Book4You).pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

100%(1)100% found this document useful (1 vote)

557 views36 pagesGeneral Training Air Conditioning - Module 04 S (Book4You) PDF

General Training Air Conditioning - Module 04 S (Book4You) PDF

Uploaded by

aramirezharoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 36

e Cf -j/4-02

GENERAL TRAINING AIR CONDITIONING I

Module 4

Systems

© GTAC

GENERAL TRAINING AIR CONDITIONING

MODULE 4 @

SYSTEMS

TABLE OF CONTENTS

Section Title Slide No. Page No.

Introduction 1-3 1

‘Types of Air Conditioning Systems 4-26 3

Refrigeration Systems 27-31 12

Packaged Products 32-52 14

Split Systems 53 - 59 23

Other Systems 60 - 62 26

Quiz Key 30

Objectives

This program will help you develop skills that will make your job easier and aid you in becoming more successtul.

By studying these materials, you will learn the fundamentals of refrigeration as they relate to air conditioning.

Presentation Instructions

1. Obtain necessary audio-visual equipment, air conditioning equipment, handout materials and program work- e

books for each participant.

2. Present video section by section. Review, discuss and ask questions at the end of each segment.

3. Show slides to highlight topics of importance and emphasize the basic leaning block approach.

4. Distribute and review handout materials (see suggested list of handout materials below).

5. Administer quiz, then review using slide/page references noted in the quiz key.

6. Certificates of Achievement are available through Literature Distribution.

Handout Materials/Additional Training Materials (Available through Literature Distribution.)

Educational Materials Air Conditioning and Refrigeration (Catalog No. 020-308)

Service and Engineering Instruction

Self Instruction

‘When using this program for self instruction, review the video tape, read the workbook in its entirety, and complete

the quiz. Quiz answers with paragraph references are located in the quiz key.

[WANUFACTURER RESERVES THE RIGHT TO DISCONTINUE, MODIFY, OR CHANGE SPECIFICATIONS ANDIOR DESIGNS AT ANY TIME WITHOUT NOT

(OF INCURRING OBLIGATION” Aasdianaly. THIS PROGRAM IS INTENDED FOR FEMILIARIZATION AND\OA TRAINING PURPOSES ONLY AND SHOULD

NOT BE CONSIDERED OR TREATED AS COMPLETE INSTALLATION. SERVICE, OR TROUBLESHOOTING REFERENCES FOR SUBJECT OR THER PRODUCTS

(CURRENT PRODUCT SPECIFIC INSTALLATION AND SERVICE LITERATURE SHOULD BE CONSULTED BEFORE ATTEMPTING THE PROCEDURES, PROCESSES

(OR TECHNIQUES DESCRIBED HEREN

Copyright © Carrier Corporation 1981

Orne General Tr

INTRODUCTION

The GTAC Program

eu Cea TF

ee

Conditioning

(GTAC) Program is divided into two parts. The

ten modules of Part | provide the information

and foundation you will need to understand the

basics of air conditioning. The nine modules

of Part Il contain more advanced material on

mechanical air conditioning systems.

To insure your understanding of the material,

answer the SKILLS CHECK questions scattered

throughout each module. Consult with your

instructor if you need additional help.

By reviewing the STUDENT SKILLS INVEN-

TORY at the end of this module, mastering the

material, and checking your knowledge through

the SKILLS CHECKS, you will be using the

“building block” learning process effectively. It

is important to understand the material in each

building block before moving on to the next.

In This Module

as

Raed

ed

4

@ this module focuses on two aspects of com-

fort air conditioning. First, we will introduce you

to the four basic types of comfort air conditioning

systems. Each of these types uses a mechanical

refrigeration system to remove heat from an oc-

cupied space. Then we will discuss the type

of mechanical refrigeration system or process

that each type uses to remove heat from an

occupied space. This will help you understand

the many types of air conditioning products. Ex-

amples of products will be provided to help you

visualize what each type of refrigeration system

looks like.

INTRODUCTION

Air Conditioning Functions

PAU maar es

RELATIVE HUMIDITY

PV) ete =7 (Na (3)

ODOR LEVEL

comfort air conditioning has come to be de-

fined as maintenance of the five basic aspects

of the atmosphere that surrounds us when we

are in a building. These aspects are: (1)

temperature, measured on anormal thermometer,

also called dry bulb temperature; (2) relative

humidity (the moisture contentinthe air, measured

in percent); (3) the cleanliness of the air; (4)

its odor; and (5) its motion. A total comfort air

conditioning system will control, at the same time,

all five of these aspects. Obviously, most of

the systems we call ‘air conditioning” do only

a partial job of conditioning the air. Cooling and

heating (temperature control) are usually the

minimum functions expected from any air

conditioning system.

@as you review the types of air conditioning

systems that follow, please pay close attention

to the location of the refrigeration components

in comparison with the air conditioned space.

‘As we have seen in prior modules, the refrigera-

tion system will always include the four basic

‘components: evaporator, compressor, condenser,

and liquid metering device. As long as the

compressor is activated, the refrigerant will ab-

sorb and reject heat by flowing from one compo-

ent to another through the refrigerant piping

The direction of flow is shown by the arrows. e

Le A TR

TYPES OF AIR CONDITIONING SYSTEMS

re

Ee

Ean

@ here is a typical office space in which a per-

‘son might work. Heat flows into the space from

people, equipment, lights and the outdoor

(ambient) air if itis warmer than the room. This

space must be cooled in order to prevent heat

buildup, which will quickly make it uncomfortable

Obviously, most buildings contain many spaces

that require cooling. The amount of cooling ca-

pacity sent to all the rooms may be controlled

by one or more thermostats. Each area that

has its capacity controlled by a thermostat is

called a control zone. The zone may be made

up of a single room, several rooms, a wing of

a building, an entire floor of a building, or an

entire building. Each air conditioned building has

atleast one control zone. The bigger the building,

the more control zones it needs.

Historically, most residences and small commer-

cial buildings have used a single control zone.

As the cost of energy has grown, however, so

also has the use of multiple zones of control.

In addition, the use of electronic controls has

increased the popularity of multiple control zones

even on small capacity jobs.

TAO 17)

ae

cen)

2, ALL WATER

CaN

4, DIRECT REFRIGERANT

@ there are four basic system types used to

air condition these zones. They are all-air, all-

water, air-water, and direct refrigerant. Some

of these are better than others for certain uses;

which is why each type has been developed.

The name of each of these types tells what

kind of fluid is circulated to the zone or zones

in the building

\ All-Air Systems

In order to cool the zones, an all-air system

supplies cool, dehumidified air. Once the air

enters the space, it absorbs heat and moisture.

The temperature of the space usually is main-

tained around 75°F and 50% relative humicity.

The cool air supplied to the space is usually

between 50° and 55°F.

Polat”

ar)

This supply air is cooled and dried by pass-

ing it through a coil with a surface temperature

colder than the air. The heat from the air flows

through the metal fins and tubes of the coll into

the refrigerant circulating through the coil. Mois-

ture is removed from the air as it condenses

from a vapor into a liquid on the cold coil surface

This is the same thing that happens when a

glass filled with a cold beverage “sweats.” The

condensed moisture is piped away from the coil

surface to a waste drain.

The cold, dry supply air leaving the cooling

Coil is transported from the coil to the conditioned

space by means of a supply air duct system.

The ductwork may be made from metal, plastic

or fiberglass and is insulated to prevent the air

from warming up before it gets to the space.

Energy required to move the air through the

ductwork is provided by a supply air fan

A supply air terminal or diffuser is used

to distribute the cool supply air to the space.

It is the most important factor in providing good

room air motion. Poor selection or location of

the diffuser(s) causes discomfort. Drafts, dead

air spots and dumping of cold air directly on

the occupants are symptoms of poor diffuser

selection and layout. No amount of service work

will fix a poor design

Since air has been pumped into the space

by the supply air fan, a return air grille must

be provided to relieve warm air from the space.

After entering the grille, the return air is drawn

back toward the coil through a ductwork system.

It can then be cooled once again and recycled

to the conditioned space.

Some systems include a retum air fan. It

is helpful in overcoming the resistance to air flow

in return ductwork systems that are very long

or which have many branches. Itis also preferred

by some engineers on systems that can deliver

up to 100% outside air to the space. Return

air fans tend to be the exception rather than

the rule on systems below 60 tons of cooling

capacity.

When the return air reaches the coil it is cooled

once more and sent back to the space. The

air conditioning cycle thus repeats itselt

Dirt particles, pollen, and other impurities are

removed from the circulating air by installing filters

inthe system. The filters are available in a variety

of types, depending upon the type of equipment

used and the degree of filtration efficiency de-

sired. Smaller capacity air handlers tend to offer

less efficient filtration and less variety in filter

types than do the larger capacity models.

The filters, coil, and supply air fan usually are

combined into a manufactured product called the

air handling unit, sometimes abbreviated AHU.

In sizes below about 20 tons, the air handling

unit is sometimes called the fan coil unit. We

shall see later in this module, the air handling

Unit is combined with other parts of the system.

2

(Odor is controlled within the space by diluting

it with outdoor air. The air handler brings the

outdoor air into the system, then filters it and

controls its temperature by moving it over coils

before sending it on to the space. The outdoor

air is mixed with air returning from the space

before being treated at the coil. Since outdoor

air is being brought into the system, an equal

quantity of stale, return air must be exhausted

from the system. Outdoor, return, and exhaust

air dampers work together to coordinate the

amount of outdoor air entering the system and

that exhausted from

Remember that air conditioning systems vary

and some residential designs don’t offer these

options.

od

Bes

rok

The source of cooling is the coil in the air

handling unit, which can be either a D-X (direct

expansion) or a chilled water coil

D-X coils are used in the vast majority of build-

ings; that is, those requiring less than 100 tons

of cooling capacity. Here the D-X coil is shown

connected by refrigerant lines to an outdoor unit

that contains the compressor and condenser.

The liquid metering device is right next to the

evaporator in the AHU.

The four basic refrigeration cycle components,

an be grouped in the manner shown here or

the compressor and condenser can be housed

as separate components. In either case, the

heat absorbed by the evaporator is moved

through the refrigerant piping and rejected by

the condenser to the outdoor air

Here is an all-air system that uses a chilled

water coil rather than a D-X coil to cool air going

to the zones. This type of arrangement grows

increasingly popular as the size of the building

increases. Buildings taller than three floors often

use one or two air handler units per floor with

chilled water coils in them. Buildings under 100

tons of cooling capacity rarely use chilled water

coils,

In these systems, chilled water flowing through

the cooling coil absorbs heat from the air passing

‘over it. This heat is pumped through water piping

to a water chiller containing the four basic com-

ponents of the refrigeration system. The chiller

absorbs the heat from the water in its evaporator,

which contains refrigerant.

orator is called a cooler.

This type of evap-

© The heat absorbed from the water into the

refrigerant is rejected from the refrigeration sys

tem by its condenser. In this diagram, the chiller

is located indoors, so the condenser is water-

cooled. Heat from the condenser is rejected to

water, which is pumped outside to a cooling tower

where the heat is rejected. This system could

also use an air-cooled or evaporative condenser,

located outdoors and separate from the rest of

the chiller. This design eliminates the need for

a cooling tower.

All-Water Systems

Ey Were ca CR Mga}

& 10 RISE=1 TON

OF COOLING

8” RD DUCT

400 CFM @ 1200FPM

OR

5” RD DUCT

PUKe a Moma)

TON OF COOLING

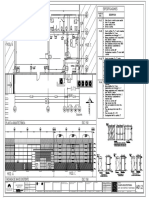

© {Din order to cool the control zones within a

building, an all-water system supplies chilled

water to the zones. As the building size and

number of floors grows, all-water systems be-

come increasingly popular. They are also popular

where the space for piping and ductwork is very

limited, A 5/8-inch outside diameter pipe carry-

ing chilled water at normal conditions provides

the same cooling capacity to a zone as does

an B-inch diameter, low velocity air duct or a

S.inch diameter, high velocity air duct

Daan

eines

Erne

Eonar

In an all-water system, chilled water is cir-

culated to each zone. A special type of terminal

unit receives the chilled water. This one is shown

mounted at the outside wall, but styles are also

available that may be installed in the corner,

above the ceiling, or mounted flush against an

interior wall

{) Each chilled water fan coil is basically a small

air handling unit that includes a chilled water

coil, fan and filter. Return air is drawn into the

| unit and over the filter by the suction of the fan.

itis then blown over a coil through which chilled

water is flowing. Normal chilled water tempera-

tures range from 40° to 48°F. The air is cooled

and dehumidifies as it passes over the coil. The

grille on the top of the fan coil directs the cool

air into the space, thus giving the needed motion

to the room air. As the cool air mixes with the

room air, it absorbs the heat in the room air.

The cycle repeats itself as long as the fan is

running and chilled water is supplied to the coil

Heat absorbed from the space by the chilled

water is pumped through water piping to a chiller.

This is the same kind of chiller shown previously

for an all-air system that uses a chilled water

coil at each air handler. The entire refrigeration

system is in the chiller and the method of heat

rejection from it may vary. This diagram shows

the most common application. The chiller and

water-cooled condenser are located indoors and

the cooling tower outdoors.

In air-water systems, both air and water are

‘sent to each control zone in order to provide

cooling capacity. From the diagram shown here,

you can see that this is a more complicated

system type. It is also the most expensive, but

it can provide a degree of comfort not available

from any of the other types. It has the potential

to provide the best performance qualities of both

systems. Jobs that are well-suited to an all-

water system may also be candidates for an air-

water system if the budget will tolerate it.

Direct Refrigerant Systems

All-air, all-water and air-water systems all use

a refrigeration system to provide cooling capacity

They then use air or water, or a combination

of the two, to distribute the cooling capacity to

the zones within the building. Direct refrigerant

systems, on the other hand, eliminate the need

to send air or water out from a central refrigera- ©:

tion system to each zone. This simplifies the ‘STOP! Review Skills Checks.

installation of the system by eliminating all or Circle those skills that need

oO most of the ductwork and piping that are required additional work. Go back

for the other types of systems. and review those sections

once again.

This approach is especially popular for resi-

dences, hotels, motels, apartments and other

low-rise commercial buildings.

eens aT

pene Cube)

® the uttimate example of this concept is

seen in window or through-the-wall air condi-

e@ tioning equipment. These are used for small

zones along the perimeter of abuilding. Depend-

ing upon the type of unit, heating may be avail-

able also. For example, some units have electric

heat, some are available as heat pumps, while

others are supplied with either a hot water or

steam coil. The hot water or steam would be

supplied by a separate central boiler system.

SKILLS CHECK 1

INTRODUCTION e

1. There are basic types of air conditioning systems used to cool buildings.

2. List the 5 air qualities which a total air conditioning system controls.

3. Number the items listed below in the order of increasing size (1, 2, 3, 4).

Refrigeration System Air Handling Unit

Evaporator Air Conditioning System

4. In the space below, draw, from memory, the four basic components of a refrigeration cycle

connected by refrigeration piping. Label each component and refrigeration line. Put arrows on

the refrigerant lines to show the direction of flow in the system.

5. The 4 types of air conditioning systems are:

6. T or F?_ A zone is one room.

TYPES OF AIR CONDITIONING SYSTEMS

1. “Al-air” means that:

a. only air is used to cool the building. Mechanical refrigeration is not required.

b. the central machine which provides the source of cooling for the building is an air

handling unit.

©. the cooling capacity is delivered to the control zones by air alone.

d. air is sent to all the control zones but part of the cooling capacity might also come from

another source.

2 °F is a typical supply air temperature to the zones of an all-air system which is

in its cooling mode.

10

10.

"

12.

13.

14.

The outlet which supplies air to the zone is called a

T or F? Service mechanics often fix the problems caused by poor diffuser selection and

layout by adjustment.

List the minimum components which make up an air handling unit.

It you work on all-air systems below tons of cooling capacity you will probably

not encounter many chilled water coils.

T or F?_ In an all-water system, chilled water is circulated to each control zone to provide

cooling capacity.

. Why would any designer want to use an all-water system?

Water at about F is supplied to the zones of an all-water system in the cooling

mode,

The technician will concentrate on the in an all-water system when it comes to

servicing the mechanical refrigeration system.

When the zones get their cooling capacity from a central machine which supplies both cool

air and cool water, the system is called.

a. all-air ©. air-water

b. all-water 4. direct refrigerant

In order to service the mechanical refrigeration system in a direct refrigerant system, you would

go to the

a. central machine room. ©. chiller.

b. central air handler which serves d. machine serving each zone.

the zones.

Which one of the following cannot be used on a direct refrigerant system?

a. Chilled water fan coils. c. Window air conditioners,

b. Thru-the-wall units. d. Rooftop units.

Window and thru-the-wall units have a maximum tonnage limit of about 3 tons because:

no one has gotten around to offering larger ones.

the refrigeration system works poorly above that size,

air distribution becomes a difficulty above that size.

the strength of the outside wall becomes a problem above that size.

Three tons is very heavy!

aoce

REFRIGERATION SYSTEMS

©@ we have seen that many types of comfort

air conditioning systems are used to coo! build-

ings. Each of these types uses a mechanical

refrigeration system to provide the cooling capac-

ity necessary to move heat from the occupied

spaces to the outdoors. An evaporator, com-

pressor, condenser, and liquid metering device

will be included in each system. What changes

from system to system and product to product

are the size, style, and arrangement of the

four basic refrigeration components. Large,

medium, and small-capacity components are

available to suit the size of the job. Sometimes

all four components are packaged in one as-

sembly; at other times they are split into two,

and even three, separate components. We will

now review the types of equipment sold in the

marketplace, paying particular attention to the

arrangement of refrigeration components within

them and where they are used.

ere tr

| 2. Split Systems

3. Others

©) Earlier we identified four types of comfort air

Conditioning systems. In order to make the task

of identifying products used in these systems

easier for you, we will be grouping all comfort

products into one of three categories:

1) Packaged Equipment

2) Split Systems

3) Others

As you will see, these are grouped according

to the arrangement of the components of the

refrigeration cycle.

PACKAGED

© Packaged equipment includes products that

have all four refrigeration system components

in one, factory-built package, such as a rooftop

unit. The trend over the past 20 years in the

commercial heating, ventilating and air condition-

ing (HVAC) industry has favored packaged

equipment over other types. Escalating field

costs for engineering and installation have

stimulated manufacturers to develop and market

packaged products generally ranging in capacity

from 1/4 ton room air conditioners all the way

oe up to 1,000 ton centrifugal chillers.

SPLIT SYSTEM

Cocks

© spiit systems are those products which

house the refrigeration system components in

two, factory-built assemblies. The compressor

and condenser are put in a package called the

condensing unit. The remaining components

— evaporator and liquid metering device — are

housed in an assembly called the air handling

unit or fan coil.

Split systems require field engineering work to

properly match the capacities of the condensing

unit with the evaporator. They also require proper

engineering of the refrigeration piping that in-

terconnects the two assemblies. Manufacturing

data supports these decisions and should be

consulted. Attention must be paid to locating

the equipment where it is safe, serviceable

and economical to install. Split systems require

more field installation labor than packaged equip-

ment because of the refrigeration piping involved,

and because two assemblies are being installed

instead of one.

Split systems are popular in both the residential

and commercial markets. A range of 11 to 250

tons is especially popular for these products.

rey) i]

ik:

."

@ other systems is a category we have created

to deal with products that do not fit into the other

two. This represents a small part of the total

products sold annually. Two types of “other

systems” will be discussed.

roast)

Careers

Built up systems are those where each com-

ponent is purchased separately and all system

engineering and installation are done in the field

These systems have the highest field costs and

often have high installed costs, but they provide

maximum opportunity for customizing the system

to the needs of the job.

Condenserless products are the other type that

comes under this heading. These products would

be called “packaged” except for the fact that the

condenser is field-selected and installed.

PACKAGED PRODUCTS

cre

ER ee nL)

reg

Se

ferric

Seer

ie

et

@ackaged products fall into eight categories,

as follows:

1) Room Air Conditioners (RAC). Mostly

residential (’4 to 3 tons).

Packaged Terminal Air Conditioners

(PTAC). Commercial (% to 1% tons).

Water Source Heat Pumps.

Commercial (14 to 20 tons)

Packaged Air Conditioners (PAC).

Residential and commercial rooftops

Electriccool/electricheat (1 4to 100tons).

Year-round Air Conditioners (YAC).

Residential and commercial rooftops

Electric cool/natural gas or LP gas heat

(1% to 100 tons),

Packaged Heat Pumps. Residential

and commercial rooftops. Electric cool/

heat pump heat (1% to 30 tons).

Vertical Air Conditioners (VAC). Com-

mercial indoor units (3 to 60 tons).

Packaged Chillers. Commercial recip-

rocating and centrifugal liquid chillers

(15 to 10,000+ tons).

now discuss each of these categories.

2)

3)

4)

5)

We will

RAC

(RESIDENTIAL: 1/3 TO 3 TONS)

© As their name implies, room air conditioners

are intended to cool a single room. While most

often installed through a window, they can also

be installed through an outside wall. These units

are designed for free-air discharge into the

space. No ductwork is used. The cool supply

air can be directed by the adjustable, decorative

discharge grille on the front of the unit, The

most common type of room air conditioner pro-

vides cooling capacity only. Models are also

available with electric resistance heat or heat

pump. The heat pump is a refrigeration system

that can reverse its cycle and move heat from

the outdoor air to the indoor air in the heating

season. It acts as an air conditioner; ie., moving

heat from the indoor air to the outdoor air during

the cooling season

14

PTAC Heating capacity is provided in these units to

: - avoid the need for a separate heating system.

(COMMERCIAL: 1/2 TO 1-1/2 TONS) Electric resistance heat and heat pump models

are available. Also, a steam or hot water coll

may be available. This coil would connect to

a separate boiler system.

Heat pumps that absorb heat from the outdoor

air during their heating cycle and move that

heat to the indoor air are called air source

or air-to-air heat pumps. They are called “Air

Source” because air is the source of their heat.

They are called “Air-to-Air” because they absorb

heat from the outdoor air and reject it to the

indoor air. Air-to-Air heat pump versions of PTAC

equipment are popular.

@backaged Terminal Air Concitioners (PTAC)

fulfill the same basic need for the commercial

market as room air conditioners do for the res-

dential market. Each unit contains an entire

refrigeration system for one zone of control,

Because of their capacity, PTACs are best suited

for conditioning one room or part of a room. Air

is discharged directly into the room through a

e decorative discharge grille.

@prac units slide into a wall sleeve which is

installed in the exterior wall of the building during

construction. The electrician provides the re-

ceptacle needed for the unit. Usually, installation

of the unit itself simply involves sliding it into

its sleeve and plugging it into the electrical outlet.

‘Some units are hard-wired to the power source,

@ towever

15

Water Source Heat Pumps

(COMMERCIAL: 1/2 TO 20 TONS)

16

Heat pumps that absorb heat from water dur-

ing the heating season and move that heat to

the indoor air are called water source or

water-to-air heat pumps. They are called “Water

Source” because water is the source of their

heat. They are also called “Water-to-Air’ because

they absorb heat from the water and reject it

to the indoor air.

Water source heat pump units have become in-

creasingly popular. They are available in styles

that mount within the room and need no ductwork

Ducted units, which go above the ceiling or in

an equipment room or closet, are also available.

Each zone of control has one water source heat

pump, with its complete refrigeration system, to

control it. Zone sizes can vary from 1/2 ton

of capacity up to 20 tons.

Gee MUL ele

©@ water is piped to each water source heat

pump from a water system which circulates

throughout the building. When a zone requires

cooling, the water source heat pump rejects heat

to the water system. When a zone needs heat-

ing, the heat pump absorbs heat from the water

system. Many commercial buildings have a

substantial inner or core area without any perime-

ter exposure. When the building is in use, these

areas never lose heat to the outdoors and,

consequently, have a year-round need for cool-

ing. They gain heat from lights, people and

equipment operation within them. When it is

7

cold outdoors, a water source heat pump system

can move heat from the core areas where it

is not needed to the perimeter areas where it

is needed. Heat rejected to the water system

by water source heat pumps in the core zones

{in a cooling mode) is reclaimed for the per-

imeter zones to absorb in their heating mode.

This saves energy when compared with other

methods of zone control that throw the core heat

away at the same time that heat is being

manufactured by the perimeter zone equipment.

The diagram shows a simple view of the water

piping “loop,” with the boiler and cooling tower

required to keep the water at the desired

temperature. Two perimeter area heat pumps

are shown as well as one in the core area of

the building. Other heat pumps that might be

needed have not been drawn in order to keep

the picture simple.

@®sror1 Review skils Checks.

Circle those skills that need

additional work. Go back

and review those sections

once again.

SE

SKILLS CHECK 2

ALL-AIR SYSTEMS

1. The 3 types of refrigeration systems used in the air conditioning systems discussed previously Oo

are: , and

2, What does “Packaged” mean?

3. The two components of a split system are the and the

4, The category “Other Systems” includes and

ALL-WATER SYSTEMS

1. To the right of each A.A.l." title write what the letters of the name stand for.

a RAC VAS

b. PTAC e. YAC

ce PAG * ALi the Air Conditioning and Refrigeration Institute.

2. Select the two differences between RAC and PTAC units:

a. RAC units are for small tonnage while PTAC units are for large tonnage jobs oO

b. RAC units are most often installed in a window while PTAC units are installed in a special

wall sleeve.

cc. RAC units are used on All-Air systems while PTAC units are used on Direct Refrigerant systems.

d. RAC units are most often used on residences while PTAC units are usually used on commercial

buildings.

3. Aheat pump:

a. has a refrigeration system which can reverse its cycle.

b. is rarely found on commercial jobs.

c. is called “air-source” when it absorbs heat from the outdoor air and moves it indoors.

d. is called ‘water-source" or “water-to-air” when it takes heat from water and moves it to the

indoor air.

4, An advantage the water source heat pump has over other systems is that

a. it can be used on direct refrigerant systems.

b. ittcan be used on commercial buildings.

¢. it requires only refrigerant piping for installation

d. ican reclaim excess heat from the core of the building and use it to heat the perimeter

zones which need it

5. In order to service the mechanical refrigeration system of a RAC, PTAC or WATER SOURCE

HEAT PUMP, you must:

a. go to the central machine room.

bb. go to the central air handler e

. goto the machine in the zone.

. look outside the building.

18

PAC

@ (RES/COMMERCIAL: 1-1/2 TO 100 TONS)

Packaged air conditioners or PAC’s represent

a large portion of the commercial comfort air

conditioning market. Unlike split system equip-

ment, no interior building space is required for

a packaged air conditioner. The interior space

saved in this way can become profitable rental

space. Access to equipment for servicing and

routine maintenance does not require the me-

chanic to enter the controlled zone, thereby

minimizing interruption of normal business.

Rooftop installations are most common for

PAC equipment, but many models are adaptable

for ground-mounting with side ductwork connec-

tions, Side connections allow direct alignment

with ductwork systems located in crawl spaces

above ground level. Most residential applications

19

of PAC equipmentuse side discharge connections

rather than roof mounting

Roof-mounted units are normally installed on a

factory-supplied roof cur which is built into the

toof by the contractor before installation of the

unit. At the time of unit installation, gaskets are

added and the unit is rigged into place.

PAC units are most often used as a direct

refrigerant system, with one PAC unit per zone

of temperature control. This is especially true

for sizes below 20 tons. PAC units above 20

tons, however, are sometimes used on all-air

systems that control multiple zones fed from the

same PAC unit. For some types of all-air systems,

such as variable air volume systems, a special

version of the PAC unit is required. For other

types, the standard unit is satisfactory.

YAC

(RES./COMMERCIAL: 1-1/2 TO 100 TONS)

ray

Pon)

a

@Pac units provide heating capacity from

electric resistance heaters mounted within them,

The year-round packaged air conditioner

(YAC) differs from the PAC only in the fact that

its heating capacity is provided by natural or LP

gas. All the other features mentioned above

about PACs also apply to YACs.

Packaged Heat Pumps

(RES.COMMERCIAL: 1-1/2 TO 30 TONS)

Pan

cu

@ ike the YAC, packaged heat pumps differ

from PAC units in the type of heat they provide.

As air source heat pumps, they extract heat

from the outdoor air and send it into the space,

supplemented by resistance heat when neces

sary. All the other features mentioned about

PACs also apply to packaged heat pumps.

VAC

(COMMERCIAL: 3 TO 60 TONS)

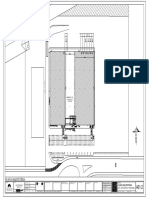

@ vertical air conditioners, or VACs, are used

as a direct refrigerant system for large zones

VACs are either water cooled, air cooled, or

condenserless. They can be installed in open

layout spaces, and discharge supply air directly

into the room,

@vacs can also be installed in an equipment

room or hallway with air ducted to the zone

(These products are frequently used to add air

conditioning to older buildings at minimal

expense.)

20

Air-cooled models make use of existing out-

side doorways and windows to reject condenser

heat.

The air-cooled condenser section on some

models can be moved apart from the rest of

the unit so that the main unit can accommodate

the furniture or equipment layout of the space

in which it is installed

Water-cooled models have the most flexibility

inlocation because they use a simple water piping

system which sends the condenser heat to a

cooling tower located on the ground or roof. Here

the building heat absorbed by the refrigeration

system is rejected to the outdoor air

Packaged Liquid Chillers

(COMMERCIAL: 15 TO 1000 TONS)

The chiller is a liquid cooling system made

up of all four refrigeration system components.

The evaporator in a chiller is called the cooler

and the liquid metering device may be a float

valve.

Chillers are used to supply chilled water to the

cooling coil(s) of all-air systems, or to the fan

coils on an all-water system. A chiller can be

purchased as a complete, factory-assembled

package or it can be selected and assembled

‘component-by-component, in the field. As with

other products, the escalating costs of labor for

engineering and installation have increased the

popularity of packaged chillers in all capacity

ranges. Some manufacturers produce packaged

chillers with as much as 20,000 tons of cooling

capacity.

The name of the chiller reflects the type of

compressor it uses. Packaged reciprocating

chillers use piston-type (reciprocating) com-

pressors. Traditionally, this type was used on

Jobs requiring less than about 120 tons of cool-

ing capacity. Today, however, reciprocating

chillers are gaining popularity on jobs up to about

280 tons because of improved partial-load

economics,

Here is shown a reciprocating chiller with a

water-cooled condenser. Water-cooled chillers

are installed inside the building. Heat from the

condenser is rejected to the water flowing

through it and carried outside the building to a

cooling tower which rejects the heat to the

outdoor air.

Ot

is

air-cooled reciprocating chillers are also

‘available. They look very much like air-cooled

condensing units, but use water piping rather

than refrigerant piping because the entire re-

frigeration system for the chiller is self-contained.

The packaged, air-cooled design allows the

chiller to be roof or ground-mounted, outside the

building. This arrangement offers the same

advantages as PAC and YAC equipment. Here

it is pictured supplying chilled water to the coil

‘of one air handling unit on an all-air system.

It usually would supply several air handling units

like this one.

Cee)

mie

©® centrifugal chillers are used on the vast

majority ofjobs above 100 tons of cooling capacity.

They get their name from the type of compressor

they use. Rather than compressing the refrig-

erant gas with pistons, as the reciprocating

compressor does, the centrifugal compressor

uses an impeller, or wheel, 10 compress the

gas. The centrifugal compressor typically uses

one or more wheels rotating at a high rate of

speed (approximately 3,000 - 20,000 RPM) to

accomplish its task. The distinctive appearance

of the centrifugal compressor makes it easy to

spot. Here is shown a water-cooled centrifugal

with both the cooler (evaporator) and condenser

in the same casing, or shell. On this model,

the cooler is on the bottom of the shell, while

the condenser is on the top. The two are divided

internally with a partition plate between the

condenser and the cover. The compressor is

mounted on top of the shell on this particular

model,

22

PACKAGED PRODUCTS

Deena)

lle)

Co ao

Here is a centrifugal chiller that uses a separate

‘shell for the condenser and cooler, rather than

‘one which houses both components. Once again,

the cooler is on the bottom and the condenser

fon the top. The large pipe connected to the

‘compressor is the suction line coming from the

cooler. Low temperature, low pressure gas from

the cooler enters the center of the first centrifugal

wheel of the compressor.

Both pictures illustrate machines that are installed

within the building. They use water-cooled

condensers and cooling towers to reject building

heat to the outdoor air. This is the normal case

for centrifugal chillers, although some manutac-

turers produce air-cooled centrifugal chillers for

outdoor installation

SPLIT SYSTEMS

al

l

© spit systems are used on both residential and

‘commercial jobs. An easy way to recognize a split

system is by the two refrigerant lines con-necting

the two sections of the equipment; a small diam-

eter liquid line and a larger diameter insulated

suction line. The hot gas line is located entirely

jin the condensing unit. The compressor and

condenser are housed in the condensing unit,

while the evaporator and metering device come in

a second, factory-assembled unit. Service valves.

normally are provided at the point where refrigera-

tion piping connectsto the condensing unit. Gauge

readings can be made at this point in order to start

up, check out, and service the refrigerant side of

the system.

The vast majority of residential condensing

units use an air-cooled condenser. They range

from 1 to 5 tons and may be designed for hori-

zontal air discharge or, as shown here, vertical

air discharge. Some manufacturers offer a style

which can be flushed-mounted on the outside

wall of a building. Split system heat pumps for

residential applications use air-cooled outdoor

units that are virtually identical to an air-cooled

condensing unit used in a cooling only system.

The condensing or outdoor unit contains a

compressor and a condenser. The heat pump

versions will also contain a reversing valve and

accumulator.

Air-cooled commercial condensing units, for

the most part, are simply a large version of the

residential variety. They range in capacity from

about 5 to 100 tons. As the capacity increases,

so too does the dimensions of the unit and the

number of fans. The concept, however, remains

unchanged.

24

Water-cooled condensing units are used on

‘commercial work from about 5 to 250 tons. The

compressor, condenser, and control panel are

installed in the equipment room or an appropriate

storage area of the building. Heat from the con-

denser is sent through water piping to a ground

or roof-mounted cooling tower which rejects the

heat to the outdoor air.

Residential and commercial evaporator units

take a variety of forms. Evaporator coil capacities

are designed to complement those of the con-

densing units manufactured by any company

selling both parts of the system. The coil, with

metering device, may be sold by itself, built into

its own casing, or be included within a small

air handling unit called a “fan coil.”

Ee -

PACKAGED PRODUCTS

@® tere the coil is installed in a residence on

top of a furnace. The condensing unit is outside.

This happens frequently when central air con-

ditioning is combined with a heating system. In

this particular case, the air from the furnace flows

up through the coil, in an upflow arrangement,

Coils are also available for horizontal installation

in attic, crawl space, or over-the-ceiling appli-

cations. Many packaged fan coils are designed

for either horizontal and vertical installations,

Deron ce

UNS

© Horizontal installation of the evaporator is

more common in commercial work, but vertical

fan coil styles are available throughout the

capacity range. On small tonnage commercial

jobs, split system products are often used for

only one zone of control. As the capacity of

a job increases, however, the likelihood of the

split system being used for one zone decreases.

Itis more likely to be used on an all-air system

serving several zones of temperature control from

a common air handler.

The indoor coil, or fan coil, for a split system

heat pump, whether residential or commercial,

is virtually identical to that for a standard, cooling

only split system.

OTHER SYSTEMS

o Built-up systems vary greatly, and thus defy

Complete description. Built up systems are most

often used on jobs with special needs that cannot

be met by packaged or split systems. They have

the advantage of being tailor-made for the job.

The separate nature of each component usually

is apparent when viewing the job. The absence

of factory-labeled cabinets is noticeable. Be-

cause of the amount of field engineering and

installation required, these systems are used

mostly on large capacity jobs for industrial pro-

cess work rather than on commercial comfort

work

By purchasing a condenserless version, the user

can take advantage of the benefits of a factory-

designed package while gaining the flexibility of

using a field selected air-cooled or evaporative

condenser. Field engineering and installation

time are increased, but are far less than those

of a built-up system.

@ The vac, for example, may be sold in three

‘separate versions; water-cooled condenser, air-

cooled condenser, or condenserless. Inits normal

form, it would have a water-cooled condenser

within the unit, which rejects its heat through

water piping to a cooling tower. Cooling towers

are expensive, and unless the job has several

VAC units, it may be difficult to justify one. The

condenserless version solves this problem by

allowing the selection of either an evaporative

or ait-cooled condenser to replace the need for

a cooling tower. It also works as well where

air conditioning is being added to only one or

a few zones, or when it is being added a little-

at-actime, There are also times when the owner

of the building prefers to avoid the maintenance

expense involved with a cooling tower. The

condenserless package is handy for adding air

conditioning to a building with an existing cooling

tower that can not handle any more load.

26

@Packaged reciprocating chillers are another

product that are sometimes purchased without

a condenser. The pair of water-cooled condens-

ers that would normally be at the bottom of this

chiller are absent, thus making it condenserless.

Hot gas (refrigerant) piping from the compressor

is piped to an air-cooled or evaporative con-

denser located outdoors. Liquid refrigerant is,

piped from the condenser to the metering de-

vices, shown here at the left of the cooler. As

with condenserless VAC equipment, conden:

serless chillers allow the engineer to provide

cooling capacity without having to add a cooling

tower

Coming Up Next

MODULE 5

COMPRESSORS

mu eel ave eLy

Compressor Types

Troubleshooting

©@ the compressor is the “heart” of any refrig-

eration system. In the next module, entitled Com-

pressors, we will train you in the types of

compressors usedin our business, how they work.

where they are used, and how their capacity

is controlled.

Taking Stock

REVIEW SKILL CHECKS

AND

STUDENT SKILLS

INVENTORY SHEET

@now is a good time to take stock of what

you have gained during your study of this module.

Review the skills shown on the STUDENT SKILLS

INVENTORY SHEET at the end of this module.

It should encourage you to see that you have

many more of these skills now than when you

first began this module. There are probably some

areas that need additional review. Repetition

is a normal part of the learning process. Why

Not circle those skills that need additional work?

Go back and review those sections once again,

then answer the SKILLS CHECK questions that

apply,

in this module, we have introduced you to many

new concepts about the refrigeration cycle. Keep

it in a handy place so that you can use it as

a reference whenever you need it.

SKILLS CHECK 3

AIR-WATER AND DIRECT REFRIGERANT SYSTEMS

1. The uses gas heat.

A servicing benefit with PAC equipment is that:

‘a. the machine is indoors.

b. the machine can be serviced without entering the occupied space.

c. service can be performed with the machine running

d. no interior space is required for refrigeration or air handling equipment.

3. The best market for VAC equipment is:

a. the renovation market.

b. the residential, new construction market.

c. the commercial, new construction market.

d. where interior floor space cannot be used for equipment.

4, The ‘cooler’ on a chiller is a (an)

5. Packaged liquid chillers are used on all but which one of the four types of air conditioning systems?

a. alkair . air-water

b. all-water d. direct refrigerant

6. Fill in the approximate tonnage ranges. oO

a. PAC tons. d. VAG tons.

b. YAC tons. e. Packaged Liquid Chillers tons.

cc, Packaged Heat Pumps tons.

7. The main difference between a packaged reciprocating liquid chiller and a packaged centrifugal

chilleris

8. The shell on a chiller:

a. has to do with the compressor.

b. is the valve which controls liquid flow.

c. is the outside casing of the transmis

d. is the casing which encloses the evaporator and condenser.

28

TYPES OF SYSTEMS

. On a split system, the two refrigerant lines connecting the condensing unit to the evaporator

with its metering device are the line and the line.

. Where in a split system would you expect to find service valves for making refrigerant system

gauge readings?

The main difference(s) between a residential and commercial, air-cooled condensing unit is (are):

a. its size. ¢. its number of fans.

b. its function. d. its capacity

You are going to service the compressor a commercial split system which uses a water-cooled

condensing unit. You should start your search:

@. outdoors on the ground. ¢. indoors near the occupied space.

b. outdoors on the root d. indoors in the machine room.

Where do you expect to find the liquid metering device on a split system?

Built-up systems:

offer the maximum in custom-built design.

usually are medium in price.

require a high level of field design and installation expertise.

are most often found on commercial comfort work.

poop

Condenserless equipment

always uses a water-cooled condenser.

. often uses a water-cooled condenser.

sometimes comes in the form of condenserless VAC equipment.

|. sometimes comes in the form of a condenserless packaged chiller.

aegp

29

QUIZ KEY

SKILLS CHECK 1 Qe

INTRODUCTION

14 (Paragraph 6)

2. Temperature, Moisture Content, (Paragraph 3)

Cleanliness, Odor, Motion

33,124 (Paragraph 2)

4 Spann (Paragraph 4)

it

ue

5. Al-air, all-water, air-water, direct refrigerant (Paragraph 6)

6. F. Each area which has its temperature (Paragraph 5)

separately controlled by a thermostat is a

control zone. It may be a part of a room,

a room, a group of rooms, or an entire

floor or building.

TYPES OF AIR CONDITIONING SYSTEMS

te (Paragraph 7)

2. 50-55 (55 is a good single temperature). (Paragraph 7)

3. "supply air terminal” or “diffuser” (Paragraph 10)

4. F. No amount of adjustment will fix a poor (Paragraph 10)

room air distribution design.

5. filters(s), coil(s), fan(s) (Paragraph 13)

6. 100 (Paragraph 15)

77 (Paragraph 17)

8. Space savings; Cost on large systems (Paragraph 19)

9. 40-48 (42 is a good single temperature) (Paragraph 21)

10. chiller (Paragraph 22)

We (Paragraph 23)

24 (Paragraph 24)

13. a (Paragraph 24)

14. ¢ (Paragraph 24) oO

30

SKILLS CHECK 2

oper

ALL-AIR SYSTEMS

packaged equipment, split systems, other

Packaged means that all 4, basic components

of the mechanical refrigeration system are

provided in one, factory-assembled unit

condensing univair handling unit

built up systems/condenseriess products

ALL-WATER SYSTEMS

Room Air Conditioner

Packaged Terminal Air Conditioner

Packaged Air Conditioner

Vertical Air Conditioner

Year-Round Air Conditioner

dd

seance

. a, od

od

©

SKILLS CHECK 3

AIR-WATER AND DIRECT REFRIGERANT SYSTEMS

oaens

YAC

b

a

Evaporator

d

a. 1-1/2 - 100

b. 1-1/2 - 100

c. 1-1/2 - 30

d. 3 - 60

e. 15 - 1000+

The compressor. It is reciprocating (piston)

on the former; centrifugal on the latter.

.d

31

(Paragraph

(Paragraph

(Paragraph

(Paragraph

(Paragraph

Paragraph

Paragraph

Paragraph

Paragraph

(Paragraph

(Paragraph

(Paragraph

(Paragraph

(Paragraph

(Paragraph

(Paragraph

(Paragraph

(Paragraph

(Paragraph

(Paragraph

(Paragraph

32)

34,35)

33-36)

37)

31-36)

42)

39)

44)

49)

49)

39)

42)

43)

44)

49)

49-51)

51)

QUIZ KEY

TYPES OF SYSTEMS

1. suctionliquid (Paragraph 53)

2. At the outdoor unit near the point where (Paragraph 53)

the refrigerant lines enter it

ZB aad (Paragraph 55)

4d (Paragraph 56)

5. Indoors, in the air handling unit near (Paragraph 57)

the evaporator.

6 ac (Paragraph 60)

7 bod (Paragraphs 60, 61, 62)

32

STUDENT SKILLS INVENTORY — SYSTEMS

@ By the conclusion of your study of the material in this module, you should be able to:

1. List, from memory, the four basic types of comfort air conditioning systems.

2. Explain how the refrigeration system fits in with the air conditioning system

3. List, from memory, the five air qualities that a total air conditioning system controls,

4, Make a simple drawing, from memory, of the four basic refrigeration cycle components

connected by refrigerant lines. Label those lines and use arrows to show the direction

of refrigerant flow.

5. Define “zone” and explain how big itis.

6. Identity the service problems that poor air diffuser selection and/or placement can create.

7. List, from memory, the three types of refrigeration systems used in comfort air conditioning

systems.

8. Tell what a “packaged” refrigeration system is.

@ 9. Tell what a “cooler” and “shell” are on a chiller.

10. List the two parts of a split system and identify the refrigeration components in each

11. Tell where you would expect to go in the building to do refrigeration service on a split

system.

12. Tell where you would expect to find service valves on a split system

| 13. Define “built-up” system.

14, Explain why condenserless equipment is used.

33

Carrier e

022-007 care Corporation» Syracuse, NY Prinacin USA siai9s

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- General Training Air Conditioning - Module 01 Introduction To Air Conditioning-Carrier Corporation (1991) PDFDocument32 pagesGeneral Training Air Conditioning - Module 01 Introduction To Air Conditioning-Carrier Corporation (1991) PDFsubaktianton100% (2)

- General Training Air Conditioning - Module 01 Introduction To Air Conditioning-Carrier Corporation (1991) PDFDocument32 pagesGeneral Training Air Conditioning - Module 01 Introduction To Air Conditioning-Carrier Corporation (1991) PDFsubaktianton100% (2)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- General Training Air Conditioning - Module 03 R (Book4You) PDFDocument36 pagesGeneral Training Air Conditioning - Module 03 R (Book4You) PDFaramirezharo0% (1)

- General Training Air Conditioning - Module 05 C (Book4You) PDFDocument44 pagesGeneral Training Air Conditioning - Module 05 C (Book4You) PDFaramirezharo100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Od Cig 021 - August 2019Document11 pagesOd Cig 021 - August 2019aramirezharoNo ratings yet

- Informe de Inspección de Fábrica (Dc-Fi 036)Document24 pagesInforme de Inspección de Fábrica (Dc-Fi 036)aramirezharoNo ratings yet

- Auditor VDA6-5Document13 pagesAuditor VDA6-5aramirezharo0% (1)

- A01.2 PLANO ARQUITECTÓNICO-A02.1 Planta ArquitectónicaDocument1 pageA01.2 PLANO ARQUITECTÓNICO-A02.1 Planta ArquitectónicaaramirezharoNo ratings yet

- Akron Hydraulic XLF 32, XLF 46, XLF 68Document7 pagesAkron Hydraulic XLF 32, XLF 46, XLF 68aramirezharoNo ratings yet

- 3M Super 77 ClassicDocument15 pages3M Super 77 ClassicaramirezharoNo ratings yet

- My Business Pays Me: Labourers and Entrepreneurs Among The Self-Employed Poor in Latin AmericaDocument15 pagesMy Business Pays Me: Labourers and Entrepreneurs Among The Self-Employed Poor in Latin AmericaaramirezharoNo ratings yet

- TraduccionDocument7 pagesTraduccionaramirezharoNo ratings yet

- Capturado en InglesDocument1 pageCapturado en InglesaramirezharoNo ratings yet

- A01.2 PLANO ARQUITECTÓNICO-A02.1 Planta ArquitectónicaDocument1 pageA01.2 PLANO ARQUITECTÓNICO-A02.1 Planta ArquitectónicaaramirezharoNo ratings yet

- Akron HydraulicDocument2 pagesAkron HydraulicaramirezharoNo ratings yet

- Akron Hydraulic XLF 32, XLF 46, XLF 68Document7 pagesAkron Hydraulic XLF 32, XLF 46, XLF 68aramirezharoNo ratings yet

- Cambridge University Press,.The Economics of Self-Employment and Entrepreneurship. (2004.ISBN0521828139)Document5 pagesCambridge University Press,.The Economics of Self-Employment and Entrepreneurship. (2004.ISBN0521828139)aramirezharoNo ratings yet

- Inicio h1 h2 Document Control Table of Rev and Apr: Document Quality Coordinator Manager Level Process Owner UserDocument1 pageInicio h1 h2 Document Control Table of Rev and Apr: Document Quality Coordinator Manager Level Process Owner UseraramirezharoNo ratings yet

- 2016 Mexico Salary Guide PDFDocument3 pages2016 Mexico Salary Guide PDFaramirezharoNo ratings yet

- General Training Air Conditioning - Module 02 T (Book4You) PDFDocument36 pagesGeneral Training Air Conditioning - Module 02 T (Book4You) PDFaramirezharo100% (1)

- Inicio h1 h2 Document Control Table of Rev and Apr: Document Quality Coordinator Manager Level Process Owner UserDocument1 pageInicio h1 h2 Document Control Table of Rev and Apr: Document Quality Coordinator Manager Level Process Owner UseraramirezharoNo ratings yet

- 4a Hoja 2Document2 pages4a Hoja 2aramirezharoNo ratings yet

- ISO Chapter Number Type of Document ID: 4A 2 of 3 Prep By: AR Rev By: Ar Ap. By: VR Rev# 1 Date 9/1/2015Document1 pageISO Chapter Number Type of Document ID: 4A 2 of 3 Prep By: AR Rev By: Ar Ap. By: VR Rev# 1 Date 9/1/2015aramirezharoNo ratings yet