Professional Documents

Culture Documents

Eneral-Purpose Injection Moulding Grade: POKETONE Polymer M630A

Eneral-Purpose Injection Moulding Grade: POKETONE Polymer M630A

Uploaded by

macCopyright:

Available Formats

You might also like

- Handstand Push Up ProgressionDocument7 pagesHandstand Push Up ProgressionsandeepbhutaniNo ratings yet

- SWANCOR 901-3: Epoxy Vinyl Ester ResinsDocument2 pagesSWANCOR 901-3: Epoxy Vinyl Ester ResinsSofya Andarina100% (1)

- Configuring Creo ParametricDocument21 pagesConfiguring Creo Parametricmac100% (1)

- Workshop Practice Series 02 Vertical Milling in The Home Workshop PDFDocument49 pagesWorkshop Practice Series 02 Vertical Milling in The Home Workshop PDFmac100% (1)

- SABIC® PP - 312MK40 - Global - Technical - Data - SheetDocument1 pageSABIC® PP - 312MK40 - Global - Technical - Data - SheetSayed RehanNo ratings yet

- R03RRDocument1 pageR03RRPiyush A JoshiNo ratings yet

- TDS ASTM LM915 Eng 210923Document2 pagesTDS ASTM LM915 Eng 210923PrashaNo ratings yet

- TDS LC670 Eng 220216Document1 pageTDS LC670 Eng 220216AthonioMourinhoNo ratings yet

- Y25GRDocument1 pageY25GRPiyush A JoshiNo ratings yet

- Pa66-G30 Ahbk003 Tds-Iso-EngDocument2 pagesPa66-G30 Ahbk003 Tds-Iso-EngVinoth SekarNo ratings yet

- SABIC® LLDPE - MG500026 - Global - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - MG500026 - Global - Technical - Data - Sheetabhimanyu.xplastNo ratings yet

- TDS - Mosten - MA 745 - enDocument2 pagesTDS - Mosten - MA 745 - enTo RaNo ratings yet

- Product Technical Data Sheet: Unit Value MethodDocument2 pagesProduct Technical Data Sheet: Unit Value Methodhamza OUADINo ratings yet

- SABIC® PP - 513MN40 - Global - Technical - Data - SheetDocument2 pagesSABIC® PP - 513MN40 - Global - Technical - Data - SheetmeshaktimanNo ratings yet

- 9421 - 66408 - Pipe Extrusion (Normal) - Datasheet ASTMDocument2 pages9421 - 66408 - Pipe Extrusion (Normal) - Datasheet ASTMqcsupNo ratings yet

- PP Compound - PP15T1020Document2 pagesPP Compound - PP15T1020Chaimae HanynyNo ratings yet

- Sabic® PP 575P: PP Homopolymer For Injection MouldingDocument1 pageSabic® PP 575P: PP Homopolymer For Injection MouldingPrinchipi YounesNo ratings yet

- Sabic 37MK10Document2 pagesSabic 37MK10Chu ChuNo ratings yet

- Y35GRDocument1 pageY35GRPiyush A JoshiNo ratings yet

- KNG1015 Pa6-Gf15Document2 pagesKNG1015 Pa6-Gf15pava16230.meNo ratings yet

- Polysure PP RB02CRDocument1 pagePolysure PP RB02CRPiyush A JoshiNo ratings yet

- F F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Document4 pagesF F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Karishma Prabhu100% (1)

- TDS - MT 950 - enDocument2 pagesTDS - MT 950 - enTo RaNo ratings yet

- Luran S KR2868C: Acrylonitrile Styrene Acrylate / Polycarbonate (ASA/PC)Document3 pagesLuran S KR2868C: Acrylonitrile Styrene Acrylate / Polycarbonate (ASA/PC)rosebifNo ratings yet

- Ficha Técnica Hdpe (Sabic)Document2 pagesFicha Técnica Hdpe (Sabic)Luis LiraNo ratings yet

- Iso-Superior Glycols-Plain: Product Features & ApplicationsDocument1 pageIso-Superior Glycols-Plain: Product Features & ApplicationsEldiyar AzamatovNo ratings yet

- LLDPE-218BJ EditDocument3 pagesLLDPE-218BJ EditChu ChuNo ratings yet

- SABIC® FORTIFY™ - C3080 - Global - Technical - Data - Sheet PDFDocument2 pagesSABIC® FORTIFY™ - C3080 - Global - Technical - Data - Sheet PDFvishal mehtaNo ratings yet

- SABIC® PP - 5271K - Global - Technical - Data - SheetDocument1 pageSABIC® PP - 5271K - Global - Technical - Data - SheetjituniNo ratings yet

- Astm Lupol gp3156f - EngDocument2 pagesAstm Lupol gp3156f - EngYo ANo ratings yet

- Palatal A408-972 (E) For PultrusionDocument1 pagePalatal A408-972 (E) For Pultrusionbourne029No ratings yet

- K300 TDSDocument2 pagesK300 TDSM. Kürşad ArslanNo ratings yet

- TDS - Vinyl 901-3 (En)Document2 pagesTDS - Vinyl 901-3 (En)OXY Composite TechNo ratings yet

- ALTECH ABS A 2020/100 GF20: Technical Data SheetDocument1 pageALTECH ABS A 2020/100 GF20: Technical Data SheetarmandoNo ratings yet

- Hopelex Pc-1100uDocument2 pagesHopelex Pc-1100uChu ChuNo ratings yet

- Aramco PP CP160NK TDS REV 01012019Document1 pageAramco PP CP160NK TDS REV 01012019AthonioMourinhoNo ratings yet

- Atlac 590 002126 - 1520269898Document2 pagesAtlac 590 002126 - 1520269898Jainam ShahNo ratings yet

- Atlac-580 001610Document2 pagesAtlac-580 001610flavio fiumiNo ratings yet

- TGSB (M) Turbine OilDocument3 pagesTGSB (M) Turbine OilQuy NguyenNo ratings yet

- Technyl Star S 218 V30 BK 31NDocument3 pagesTechnyl Star S 218 V30 BK 31Nratz23695No ratings yet

- Terluran GP-35: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-35: Acrylonitrile Butadiene Styrene (ABS)DiegoTierradentroNo ratings yet

- POM Delrin 500Document2 pagesPOM Delrin 500countzeroaslNo ratings yet

- SABIC® LLDPE - 324CNJ - Global - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 324CNJ - Global - Technical - Data - Sheettechnical kmiNo ratings yet

- SABIC® PP - 528K - Global - Technical - Data - SheetDocument1 pageSABIC® PP - 528K - Global - Technical - Data - SheetjituniNo ratings yet

- Aramco PP CP390NK TDS REV 01012019Document1 pageAramco PP CP390NK TDS REV 01012019AthonioMourinhoNo ratings yet

- 009 Polyester Ortho SP 5119 Am Tds Amr Egypt Pa. No 4Document1 page009 Polyester Ortho SP 5119 Am Tds Amr Egypt Pa. No 4Yousef LotfyNo ratings yet

- ALTECH ABS C 2017/500 GF17: Technical Data SheetDocument1 pageALTECH ABS C 2017/500 GF17: Technical Data SheetarmandoNo ratings yet

- SABIC PP 5703P Polypropylene Homopolymer For Injection MoldingDocument2 pagesSABIC PP 5703P Polypropylene Homopolymer For Injection MoldingMédi ChegmaNo ratings yet

- Transparent ABS: Mabs: Toray Plastics (Malaysia) Sdn. BNDDocument6 pagesTransparent ABS: Mabs: Toray Plastics (Malaysia) Sdn. BNDTungdinh NguyenNo ratings yet

- Top Coat Blue Pool Iso-Npg enDocument4 pagesTop Coat Blue Pool Iso-Npg enVICTOR MARCOSNo ratings yet

- Radilon A Cp300K 333 BK: Product InformationDocument4 pagesRadilon A Cp300K 333 BK: Product InformationmuthuNo ratings yet

- PLEXIGLAS Satinice df20 8N - ENDocument2 pagesPLEXIGLAS Satinice df20 8N - ENmstevkaNo ratings yet

- PP11280 SpecificationDocument2 pagesPP11280 Specificationudummy552No ratings yet

- Pei 0270 RTP 2183Document2 pagesPei 0270 RTP 2183Vincent NguyenNo ratings yet

- Tds Total Preslia 46 693 202003 enDocument2 pagesTds Total Preslia 46 693 202003 enhalasanNo ratings yet

- Solid Surface Resin - SpecsDocument3 pagesSolid Surface Resin - SpecsAmr Abdelmegid abdelsalam husseinNo ratings yet

- On Solar Hydrogen and NanotechnologyFrom EverandOn Solar Hydrogen and NanotechnologyLionel VayssieresNo ratings yet

- Functional Polymer Coatings: Principles, Methods, and ApplicationsFrom EverandFunctional Polymer Coatings: Principles, Methods, and ApplicationsRating: 1 out of 5 stars1/5 (1)

- Geared MotorsDocument477 pagesGeared MotorsmacNo ratings yet

- Savitribai Phule Pune University (Formerly University of Pune)Document34 pagesSavitribai Phule Pune University (Formerly University of Pune)macNo ratings yet

- MTech AVDocument10 pagesMTech AVmacNo ratings yet

- Technical Data Sheet Gpo-3 (Glass Polymer Laminate)Document1 pageTechnical Data Sheet Gpo-3 (Glass Polymer Laminate)macNo ratings yet

- Applicators: Premium Quality Manufacturing of Crimp ConnectionsDocument16 pagesApplicators: Premium Quality Manufacturing of Crimp ConnectionsmacNo ratings yet

- Self-Clinching Studs and PinsDocument36 pagesSelf-Clinching Studs and PinsmacNo ratings yet

- 2338133-1 - Terminator Overview CatalogDocument12 pages2338133-1 - Terminator Overview CatalogmacNo ratings yet

- Large - Wire-Crimping-Whitepaper-EngDocument8 pagesLarge - Wire-Crimping-Whitepaper-EngmacNo ratings yet

- Being Creative in DesignDocument20 pagesBeing Creative in DesignmacNo ratings yet

- Workshop Practice Series 14 Making Small Workshop Tools PDFDocument49 pagesWorkshop Practice Series 14 Making Small Workshop Tools PDFmac100% (1)

- SHARP SV 4328 5127 6332 Maintenance ManualDocument144 pagesSHARP SV 4328 5127 6332 Maintenance ManualmacNo ratings yet

- Synchronous Drive Design - Solution #35100, Drive #1Document1 pageSynchronous Drive Design - Solution #35100, Drive #1macNo ratings yet

- A Study On Consumer Behaviour Towards Reliance JioDocument94 pagesA Study On Consumer Behaviour Towards Reliance JioKhan YasinNo ratings yet

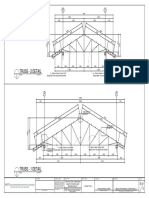

- Truss - 2 Detail: Scale 1: 50 MTRSDocument1 pageTruss - 2 Detail: Scale 1: 50 MTRSGerald MasangayNo ratings yet

- Gemba Walk Checklist QuestionsDocument2 pagesGemba Walk Checklist QuestionsDhurga SivanathanNo ratings yet

- (Download PDF) Pastoral Theology and Care Critical Trajectories in Theory and Practice First Edition Ramsay Online Ebook All Chapter PDFDocument42 pages(Download PDF) Pastoral Theology and Care Critical Trajectories in Theory and Practice First Edition Ramsay Online Ebook All Chapter PDFsarah.bronk892100% (11)

- Melon Growing Tips PDFDocument1 pageMelon Growing Tips PDFTaahirah Ben ZinatNo ratings yet

- Certificate in Sports Facilities ManagementDocument7 pagesCertificate in Sports Facilities ManagementAnkush SinghNo ratings yet

- April 5, 2018 Engr Alex Relampagos Subject: Supply, Delivery, Installation of Fire Detection and Alarm SystemDocument2 pagesApril 5, 2018 Engr Alex Relampagos Subject: Supply, Delivery, Installation of Fire Detection and Alarm SystemAlexander Luega Relampagos0% (1)

- Geberit HDPE Installation GuideDocument71 pagesGeberit HDPE Installation GuideinstalbuzauNo ratings yet

- Principals of Potato Storage PDFDocument91 pagesPrincipals of Potato Storage PDFplutocowNo ratings yet

- 1 CertDocument1 page1 CertWan Hakim Wan YaacobNo ratings yet

- DR Hanif Suhairi Cyberbullying Among AdolescentsDocument21 pagesDR Hanif Suhairi Cyberbullying Among AdolescentsnurulNo ratings yet

- Immunology Spe Dual Marker: 10553470 Mrs - Ananya MishraDocument3 pagesImmunology Spe Dual Marker: 10553470 Mrs - Ananya MishraÑîrañjañ JhåNo ratings yet

- Educational Marketing Strategies On The Market of Higher Education ServicesDocument11 pagesEducational Marketing Strategies On The Market of Higher Education ServicesGlobal Research and Development ServicesNo ratings yet

- 03 - Lecture Slide - Basic Models in TensorFlowDocument94 pages03 - Lecture Slide - Basic Models in TensorFlowRoberto PereiraNo ratings yet

- Explain FOUR Measures Which Governments Can Use To Encourage Entrepreneurial Activities in The Caribbean Region.Document2 pagesExplain FOUR Measures Which Governments Can Use To Encourage Entrepreneurial Activities in The Caribbean Region.Bridget SequeaNo ratings yet

- CO2 Content in Brine Under Pressure 084Document11 pagesCO2 Content in Brine Under Pressure 084Mari ParguilNo ratings yet

- Kami Export - SCOPE The Necklace PlayDocument4 pagesKami Export - SCOPE The Necklace Playava riciglianoNo ratings yet

- Blastocystis HominisDocument25 pagesBlastocystis HominisRO Sa RioNo ratings yet

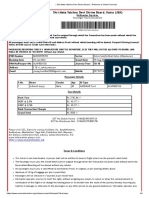

- Shri Mata Vaishno Devi Shrine Board - Welcome To Online ServicesDocument4 pagesShri Mata Vaishno Devi Shrine Board - Welcome To Online Servicesphool baghNo ratings yet

- EVK 7 8 M8 PCBVC D - UserGuide - (UBX 14002502)Document25 pagesEVK 7 8 M8 PCBVC D - UserGuide - (UBX 14002502)Rizwan AhmedNo ratings yet

- Sony XR Ca370Document32 pagesSony XR Ca370eugen26mNo ratings yet

- Technical Data Sheet Street Light - 120W: Description: Product Code VH04120010401Document1 pageTechnical Data Sheet Street Light - 120W: Description: Product Code VH04120010401Martin Takudzwa Chakadona100% (1)

- MFC-L9570CDW Brochure PDFDocument2 pagesMFC-L9570CDW Brochure PDFAnonymous n80oQosNo ratings yet

- Breach of ContractDocument27 pagesBreach of ContractTsholofelo50% (4)

- BJ S C, USA: Doug LehrDocument12 pagesBJ S C, USA: Doug LehrBalkis FatihaNo ratings yet

- A Review On The Law of Supply and Demand (Part 1)Document25 pagesA Review On The Law of Supply and Demand (Part 1)Janiña NatividadNo ratings yet

- Operating Process For Access To Gas Insulated SwitchgearDocument19 pagesOperating Process For Access To Gas Insulated SwitchgearMaharajaNo ratings yet

- Fundamental and Derived PositionDocument47 pagesFundamental and Derived PositionAmbusam Anita100% (1)

- Catalog KSPCDocument20 pagesCatalog KSPCThomas WilliamNo ratings yet

Eneral-Purpose Injection Moulding Grade: POKETONE Polymer M630A

Eneral-Purpose Injection Moulding Grade: POKETONE Polymer M630A

Uploaded by

macOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eneral-Purpose Injection Moulding Grade: POKETONE Polymer M630A

Eneral-Purpose Injection Moulding Grade: POKETONE Polymer M630A

Uploaded by

macCopyright:

Available Formats

General-purpose injection moulding grade

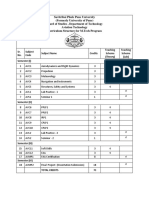

POKETONE Polymer M630A TABLE 1 : TYPICAL MECHANICAL PROPERTIES

OF POKETONE POLYMER M630A – Measured at 23℃ (74℉)

POKETONE Thermoplastic Polymers are Test Method ASTM ISO

aliphatic polyketones, a revolutionary new & Conditions Values Values

class of semi-crystalline thermoplastics. ASTM ISO SI SI

Tensile strength at yield D638 527-1 58 MPa 58 MPa

POKETONE Polymer M630A is a

general-purpose injection moulding grade with Tensile modulus D638 527-1 1,450 MPa 1,350 MPa

mechanical properties which classify it as an Tensile elongation at yield D638 527-1 22% 22%

engineering thermoplastic. This grade has an Tensile elongation at break D638 527-1 300% 300%

excellent balance of stiffness and toughness

Flexural strength D790 178 53 MPa 53 MPa

over a broad temperature range, high resilience

and good wear resistance.This grade exhibits Flexural modulus D790 178 1,350 MPa 1,250 MPa

very good processability, good impact Unnotched Izod impact strength D256 180/U N.B. N.B.

resistance, high resilience and good creep Notched Izod impact strength at

performance. POKETONE Polymer 23℃ 220 J/m 15 kJ/m2

-10℃ D256 180/A 65 J/m 6 kJ/m2

M630A can also withstand short-term 52 J/m 4 kJ/m2

-30℃

exposure to elevated temperatures. Moreover

Unnotched Charpy impact strength - 179/1eU - N.B.

this polymer exhibits a high resistance to

hydrocarbons, solvents, salt solutions, weak Notched Charpy impact strength at

acids and weak bases. 23℃ 17 kJ/m2

D256 179/1eA -

-10℃ 4 kJ/m2

-30℃ 3 kJ/m2

POKETONE Polymer M630A is easy to

process on standard injection moulding Falling Dart impact strength at 23℃ - 6603-2 - 50J

equipment. Cycle times are generally short.

Parts show good mould definition with glossy

TABLE 2: TYPICAL PHYSICAL PROPERTIES

mar-resistant surfaces. POKETONE OF POKETONE POLYMER M630A – Measured at 23℃ (74℉)

Polymer’s low moisture-sensitivity means that

no conditioning of parts before assembly or use

Test Method ASTM ISO

is necessary. & Conditions Values Values

Applications for POKETONE Polymer ASTM ISO SI SI

M630A may be found in the automotive,

electrical, electronics, industrial and consumer Specific gravity D792 1183 1.24g/cm3 1.24g/cm3

appliance markets.

Shore D hardness D2240 868 - 73

Hardness Rockwell D785 - 110 -

Water absorption equilibrium at

D570 62 0.5% 0.5%

50% RH

Water absorption at saturation D570 62 2.1% 2.1%

TABLE 3: TYPICAL THERMAL PROPERTIES TABLE 6: RECOMMENDED

OF POKETONE POLYMER M630A PROCESSING

Test Method ASTM ISO OF POKETONE POLYMER M630A

& Conditions Values Values Drying 80℃ x 2 ~ 4 hrs

ASTM ISO SI SI 220 ~ 235℃

Rear

Melting temperature D3418 11357 222℃ 222℃ Barrel Middle 230 ~ 240℃

Conefficient of linear thermal E831 temperature Front 235 ~ 245℃

Expansion, 25℃ to 55℃ - 1.0*10-4 - Nozzle 240 ~ 250℃

D1525 306/B50 Tool temperature 40 ~ 80℃MPa

Vicat softening point

5 kg 50 N 192℃ 190℃ Injection pressure 5.5 ~ 11.0MPa

D648(6.4mm) 75 (4mm)

Heat deflection temperature Holding pressure 3.5 ~ 6.5MPa

66psi 0.45 MPa 195℃ 185℃

(Start Temp. : 25℃) Back pressure 0.3 ~ 0.7

264psi 1.8 MPa 102℃ 90℃

Melt flow index 240℃/2.16kg D1238 1133 6g/10min 5.6㎖/10min Screw RPM 50 ~ 100

D955 Injection speed Slow ~ middle

MD, 3mm 2.1%

Mould shrinkage TD, 3 mm - 2.1% -

MD, 2 mm 1.6%

TD, 2 mm 1.5%

TABLE 4: TYPICAL WEAR & ABRASION RESISTANCE

OF POKETONE POLYMER M630A – Measured at 23℃ (74℉)

Test Method Pin on Disk Thrust Washer

& Conditions Valus Values

Pin on Thrust

SI SI

Disk Washer

Dynamic coefficient of 1.3 MPa 0.4 MPa

0.15 0.34

Friction agatinst self 0.06 m/sec 0.12 m/sec

Dynamic coefficient of 1.3 MPa 0.4 MPa

0.36 0.60

Friction against steel 0.06 m/sec 0.12 m/sec

Wear factor against self 1.3 MPa 0.4 MPa

0.0074 0.0044

(mm3/N∙km) 0.06 m/sec 0.12 m/sec

Wear factor against steel 1.3 MPa 0.4 MPa

0.073 0.04

(mm3/N∙km) 0.06 m/sec 0.12 m/sec

Taber abrasion

D1044 12 mg/1,000cycle

1 kg load, CS-17 wheel

TABLE 5: TYPICAL ELECTRICAL PROPERTIES

OF POKETONE POLYMER M630A

Test Method ASTM

& Conditions Values

ASTM SI

D149

Dielectric sterngth,

3 mm 15 kV/mm

Short term

2 mm 19 kV/mm

Volume resistivity D257 1014 ohm cm

Surface resistivity D257 1017 ohm/sq.

Dielectric constant

D150 6.1

at 60Hz

Dissipation factor

D150 0.009

at 60Hz

*POKETONE is a Hyosung Corporation Trademark

All products purchased from or supplied by Hyosung Corporation are subject to terms and conditions set out in the contract, order acknowledgement and/or bill of loading. Hyosung warrants only that its

product will meet those specifications designated as such herein or in other publications. All other information, including that herein, supplied by Hyosung is considered accurate but is furnished upon the

express condition that the customer shall make its own assessment to determine the product’s suitability for a particular purpose. Hyosung makes no other warranty, either express or implied, including

those regarding such other information, the data upon which the same is based, or the results to be obtained from the use thereof; that any product shall be merchantable or fit for any particular purpose;

or that the use of such other information or product will not infringe any patent Any references in this brochure to “Hyosung” refers to the collectivity of Hyosung engaged in the manufacture and sale of

chemical products. Particular contracts are entered into by any such company individually and any warranty, representation or any other commitment provided by Hyosung is the commitment of such

individual company only.

You might also like

- Handstand Push Up ProgressionDocument7 pagesHandstand Push Up ProgressionsandeepbhutaniNo ratings yet

- SWANCOR 901-3: Epoxy Vinyl Ester ResinsDocument2 pagesSWANCOR 901-3: Epoxy Vinyl Ester ResinsSofya Andarina100% (1)

- Configuring Creo ParametricDocument21 pagesConfiguring Creo Parametricmac100% (1)

- Workshop Practice Series 02 Vertical Milling in The Home Workshop PDFDocument49 pagesWorkshop Practice Series 02 Vertical Milling in The Home Workshop PDFmac100% (1)

- SABIC® PP - 312MK40 - Global - Technical - Data - SheetDocument1 pageSABIC® PP - 312MK40 - Global - Technical - Data - SheetSayed RehanNo ratings yet

- R03RRDocument1 pageR03RRPiyush A JoshiNo ratings yet

- TDS ASTM LM915 Eng 210923Document2 pagesTDS ASTM LM915 Eng 210923PrashaNo ratings yet

- TDS LC670 Eng 220216Document1 pageTDS LC670 Eng 220216AthonioMourinhoNo ratings yet

- Y25GRDocument1 pageY25GRPiyush A JoshiNo ratings yet

- Pa66-G30 Ahbk003 Tds-Iso-EngDocument2 pagesPa66-G30 Ahbk003 Tds-Iso-EngVinoth SekarNo ratings yet

- SABIC® LLDPE - MG500026 - Global - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - MG500026 - Global - Technical - Data - Sheetabhimanyu.xplastNo ratings yet

- TDS - Mosten - MA 745 - enDocument2 pagesTDS - Mosten - MA 745 - enTo RaNo ratings yet

- Product Technical Data Sheet: Unit Value MethodDocument2 pagesProduct Technical Data Sheet: Unit Value Methodhamza OUADINo ratings yet

- SABIC® PP - 513MN40 - Global - Technical - Data - SheetDocument2 pagesSABIC® PP - 513MN40 - Global - Technical - Data - SheetmeshaktimanNo ratings yet

- 9421 - 66408 - Pipe Extrusion (Normal) - Datasheet ASTMDocument2 pages9421 - 66408 - Pipe Extrusion (Normal) - Datasheet ASTMqcsupNo ratings yet

- PP Compound - PP15T1020Document2 pagesPP Compound - PP15T1020Chaimae HanynyNo ratings yet

- Sabic® PP 575P: PP Homopolymer For Injection MouldingDocument1 pageSabic® PP 575P: PP Homopolymer For Injection MouldingPrinchipi YounesNo ratings yet

- Sabic 37MK10Document2 pagesSabic 37MK10Chu ChuNo ratings yet

- Y35GRDocument1 pageY35GRPiyush A JoshiNo ratings yet

- KNG1015 Pa6-Gf15Document2 pagesKNG1015 Pa6-Gf15pava16230.meNo ratings yet

- Polysure PP RB02CRDocument1 pagePolysure PP RB02CRPiyush A JoshiNo ratings yet

- F F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Document4 pagesF F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Karishma Prabhu100% (1)

- TDS - MT 950 - enDocument2 pagesTDS - MT 950 - enTo RaNo ratings yet

- Luran S KR2868C: Acrylonitrile Styrene Acrylate / Polycarbonate (ASA/PC)Document3 pagesLuran S KR2868C: Acrylonitrile Styrene Acrylate / Polycarbonate (ASA/PC)rosebifNo ratings yet

- Ficha Técnica Hdpe (Sabic)Document2 pagesFicha Técnica Hdpe (Sabic)Luis LiraNo ratings yet

- Iso-Superior Glycols-Plain: Product Features & ApplicationsDocument1 pageIso-Superior Glycols-Plain: Product Features & ApplicationsEldiyar AzamatovNo ratings yet

- LLDPE-218BJ EditDocument3 pagesLLDPE-218BJ EditChu ChuNo ratings yet

- SABIC® FORTIFY™ - C3080 - Global - Technical - Data - Sheet PDFDocument2 pagesSABIC® FORTIFY™ - C3080 - Global - Technical - Data - Sheet PDFvishal mehtaNo ratings yet

- SABIC® PP - 5271K - Global - Technical - Data - SheetDocument1 pageSABIC® PP - 5271K - Global - Technical - Data - SheetjituniNo ratings yet

- Astm Lupol gp3156f - EngDocument2 pagesAstm Lupol gp3156f - EngYo ANo ratings yet

- Palatal A408-972 (E) For PultrusionDocument1 pagePalatal A408-972 (E) For Pultrusionbourne029No ratings yet

- K300 TDSDocument2 pagesK300 TDSM. Kürşad ArslanNo ratings yet

- TDS - Vinyl 901-3 (En)Document2 pagesTDS - Vinyl 901-3 (En)OXY Composite TechNo ratings yet

- ALTECH ABS A 2020/100 GF20: Technical Data SheetDocument1 pageALTECH ABS A 2020/100 GF20: Technical Data SheetarmandoNo ratings yet

- Hopelex Pc-1100uDocument2 pagesHopelex Pc-1100uChu ChuNo ratings yet

- Aramco PP CP160NK TDS REV 01012019Document1 pageAramco PP CP160NK TDS REV 01012019AthonioMourinhoNo ratings yet

- Atlac 590 002126 - 1520269898Document2 pagesAtlac 590 002126 - 1520269898Jainam ShahNo ratings yet

- Atlac-580 001610Document2 pagesAtlac-580 001610flavio fiumiNo ratings yet

- TGSB (M) Turbine OilDocument3 pagesTGSB (M) Turbine OilQuy NguyenNo ratings yet

- Technyl Star S 218 V30 BK 31NDocument3 pagesTechnyl Star S 218 V30 BK 31Nratz23695No ratings yet

- Terluran GP-35: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-35: Acrylonitrile Butadiene Styrene (ABS)DiegoTierradentroNo ratings yet

- POM Delrin 500Document2 pagesPOM Delrin 500countzeroaslNo ratings yet

- SABIC® LLDPE - 324CNJ - Global - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 324CNJ - Global - Technical - Data - Sheettechnical kmiNo ratings yet

- SABIC® PP - 528K - Global - Technical - Data - SheetDocument1 pageSABIC® PP - 528K - Global - Technical - Data - SheetjituniNo ratings yet

- Aramco PP CP390NK TDS REV 01012019Document1 pageAramco PP CP390NK TDS REV 01012019AthonioMourinhoNo ratings yet

- 009 Polyester Ortho SP 5119 Am Tds Amr Egypt Pa. No 4Document1 page009 Polyester Ortho SP 5119 Am Tds Amr Egypt Pa. No 4Yousef LotfyNo ratings yet

- ALTECH ABS C 2017/500 GF17: Technical Data SheetDocument1 pageALTECH ABS C 2017/500 GF17: Technical Data SheetarmandoNo ratings yet

- SABIC PP 5703P Polypropylene Homopolymer For Injection MoldingDocument2 pagesSABIC PP 5703P Polypropylene Homopolymer For Injection MoldingMédi ChegmaNo ratings yet

- Transparent ABS: Mabs: Toray Plastics (Malaysia) Sdn. BNDDocument6 pagesTransparent ABS: Mabs: Toray Plastics (Malaysia) Sdn. BNDTungdinh NguyenNo ratings yet

- Top Coat Blue Pool Iso-Npg enDocument4 pagesTop Coat Blue Pool Iso-Npg enVICTOR MARCOSNo ratings yet

- Radilon A Cp300K 333 BK: Product InformationDocument4 pagesRadilon A Cp300K 333 BK: Product InformationmuthuNo ratings yet

- PLEXIGLAS Satinice df20 8N - ENDocument2 pagesPLEXIGLAS Satinice df20 8N - ENmstevkaNo ratings yet

- PP11280 SpecificationDocument2 pagesPP11280 Specificationudummy552No ratings yet

- Pei 0270 RTP 2183Document2 pagesPei 0270 RTP 2183Vincent NguyenNo ratings yet

- Tds Total Preslia 46 693 202003 enDocument2 pagesTds Total Preslia 46 693 202003 enhalasanNo ratings yet

- Solid Surface Resin - SpecsDocument3 pagesSolid Surface Resin - SpecsAmr Abdelmegid abdelsalam husseinNo ratings yet

- On Solar Hydrogen and NanotechnologyFrom EverandOn Solar Hydrogen and NanotechnologyLionel VayssieresNo ratings yet

- Functional Polymer Coatings: Principles, Methods, and ApplicationsFrom EverandFunctional Polymer Coatings: Principles, Methods, and ApplicationsRating: 1 out of 5 stars1/5 (1)

- Geared MotorsDocument477 pagesGeared MotorsmacNo ratings yet

- Savitribai Phule Pune University (Formerly University of Pune)Document34 pagesSavitribai Phule Pune University (Formerly University of Pune)macNo ratings yet

- MTech AVDocument10 pagesMTech AVmacNo ratings yet

- Technical Data Sheet Gpo-3 (Glass Polymer Laminate)Document1 pageTechnical Data Sheet Gpo-3 (Glass Polymer Laminate)macNo ratings yet

- Applicators: Premium Quality Manufacturing of Crimp ConnectionsDocument16 pagesApplicators: Premium Quality Manufacturing of Crimp ConnectionsmacNo ratings yet

- Self-Clinching Studs and PinsDocument36 pagesSelf-Clinching Studs and PinsmacNo ratings yet

- 2338133-1 - Terminator Overview CatalogDocument12 pages2338133-1 - Terminator Overview CatalogmacNo ratings yet

- Large - Wire-Crimping-Whitepaper-EngDocument8 pagesLarge - Wire-Crimping-Whitepaper-EngmacNo ratings yet

- Being Creative in DesignDocument20 pagesBeing Creative in DesignmacNo ratings yet

- Workshop Practice Series 14 Making Small Workshop Tools PDFDocument49 pagesWorkshop Practice Series 14 Making Small Workshop Tools PDFmac100% (1)

- SHARP SV 4328 5127 6332 Maintenance ManualDocument144 pagesSHARP SV 4328 5127 6332 Maintenance ManualmacNo ratings yet

- Synchronous Drive Design - Solution #35100, Drive #1Document1 pageSynchronous Drive Design - Solution #35100, Drive #1macNo ratings yet

- A Study On Consumer Behaviour Towards Reliance JioDocument94 pagesA Study On Consumer Behaviour Towards Reliance JioKhan YasinNo ratings yet

- Truss - 2 Detail: Scale 1: 50 MTRSDocument1 pageTruss - 2 Detail: Scale 1: 50 MTRSGerald MasangayNo ratings yet

- Gemba Walk Checklist QuestionsDocument2 pagesGemba Walk Checklist QuestionsDhurga SivanathanNo ratings yet

- (Download PDF) Pastoral Theology and Care Critical Trajectories in Theory and Practice First Edition Ramsay Online Ebook All Chapter PDFDocument42 pages(Download PDF) Pastoral Theology and Care Critical Trajectories in Theory and Practice First Edition Ramsay Online Ebook All Chapter PDFsarah.bronk892100% (11)

- Melon Growing Tips PDFDocument1 pageMelon Growing Tips PDFTaahirah Ben ZinatNo ratings yet

- Certificate in Sports Facilities ManagementDocument7 pagesCertificate in Sports Facilities ManagementAnkush SinghNo ratings yet

- April 5, 2018 Engr Alex Relampagos Subject: Supply, Delivery, Installation of Fire Detection and Alarm SystemDocument2 pagesApril 5, 2018 Engr Alex Relampagos Subject: Supply, Delivery, Installation of Fire Detection and Alarm SystemAlexander Luega Relampagos0% (1)

- Geberit HDPE Installation GuideDocument71 pagesGeberit HDPE Installation GuideinstalbuzauNo ratings yet

- Principals of Potato Storage PDFDocument91 pagesPrincipals of Potato Storage PDFplutocowNo ratings yet

- 1 CertDocument1 page1 CertWan Hakim Wan YaacobNo ratings yet

- DR Hanif Suhairi Cyberbullying Among AdolescentsDocument21 pagesDR Hanif Suhairi Cyberbullying Among AdolescentsnurulNo ratings yet

- Immunology Spe Dual Marker: 10553470 Mrs - Ananya MishraDocument3 pagesImmunology Spe Dual Marker: 10553470 Mrs - Ananya MishraÑîrañjañ JhåNo ratings yet

- Educational Marketing Strategies On The Market of Higher Education ServicesDocument11 pagesEducational Marketing Strategies On The Market of Higher Education ServicesGlobal Research and Development ServicesNo ratings yet

- 03 - Lecture Slide - Basic Models in TensorFlowDocument94 pages03 - Lecture Slide - Basic Models in TensorFlowRoberto PereiraNo ratings yet

- Explain FOUR Measures Which Governments Can Use To Encourage Entrepreneurial Activities in The Caribbean Region.Document2 pagesExplain FOUR Measures Which Governments Can Use To Encourage Entrepreneurial Activities in The Caribbean Region.Bridget SequeaNo ratings yet

- CO2 Content in Brine Under Pressure 084Document11 pagesCO2 Content in Brine Under Pressure 084Mari ParguilNo ratings yet

- Kami Export - SCOPE The Necklace PlayDocument4 pagesKami Export - SCOPE The Necklace Playava riciglianoNo ratings yet

- Blastocystis HominisDocument25 pagesBlastocystis HominisRO Sa RioNo ratings yet

- Shri Mata Vaishno Devi Shrine Board - Welcome To Online ServicesDocument4 pagesShri Mata Vaishno Devi Shrine Board - Welcome To Online Servicesphool baghNo ratings yet

- EVK 7 8 M8 PCBVC D - UserGuide - (UBX 14002502)Document25 pagesEVK 7 8 M8 PCBVC D - UserGuide - (UBX 14002502)Rizwan AhmedNo ratings yet

- Sony XR Ca370Document32 pagesSony XR Ca370eugen26mNo ratings yet

- Technical Data Sheet Street Light - 120W: Description: Product Code VH04120010401Document1 pageTechnical Data Sheet Street Light - 120W: Description: Product Code VH04120010401Martin Takudzwa Chakadona100% (1)

- MFC-L9570CDW Brochure PDFDocument2 pagesMFC-L9570CDW Brochure PDFAnonymous n80oQosNo ratings yet

- Breach of ContractDocument27 pagesBreach of ContractTsholofelo50% (4)

- BJ S C, USA: Doug LehrDocument12 pagesBJ S C, USA: Doug LehrBalkis FatihaNo ratings yet

- A Review On The Law of Supply and Demand (Part 1)Document25 pagesA Review On The Law of Supply and Demand (Part 1)Janiña NatividadNo ratings yet

- Operating Process For Access To Gas Insulated SwitchgearDocument19 pagesOperating Process For Access To Gas Insulated SwitchgearMaharajaNo ratings yet

- Fundamental and Derived PositionDocument47 pagesFundamental and Derived PositionAmbusam Anita100% (1)

- Catalog KSPCDocument20 pagesCatalog KSPCThomas WilliamNo ratings yet