Professional Documents

Culture Documents

Phase 1 Procesengineering Assessment

Phase 1 Procesengineering Assessment

Uploaded by

Chakravarthy BharathCopyright:

Available Formats

You might also like

- PtrE 521 - Lecture 3 - Other Artificial Lift TechnologiesDocument144 pagesPtrE 521 - Lecture 3 - Other Artificial Lift TechnologiesGhoulemEllah Haithem IfreneNo ratings yet

- 3 CsDocument14 pages3 CsRavindra PawarNo ratings yet

- SAMPLE PROBLEMS Fluid Mechanics Pump DeNeversDocument2 pagesSAMPLE PROBLEMS Fluid Mechanics Pump DeNeversGeorge Isaac McQuilesNo ratings yet

- Fluid Mechanics-II AssignmentDocument7 pagesFluid Mechanics-II AssignmentMuntaha AnjumNo ratings yet

- Centrifugal Pump.......... Very ImpDocument22 pagesCentrifugal Pump.......... Very Impavi07me4u100% (2)

- Z Purlin Data SheetDocument17 pagesZ Purlin Data SheetErshadNo ratings yet

- 5.13. ProblemsDocument3 pages5.13. Problemsاسماعیل ادریس عبدالعزیزNo ratings yet

- SQ - 4.7 - Pumps (Table Format)Document5 pagesSQ - 4.7 - Pumps (Table Format)Amitav MishraNo ratings yet

- Tutorial 4Document1 pageTutorial 4Krivai NagarNo ratings yet

- The Sizing Boiler Feed Pumps CalculationDocument3 pagesThe Sizing Boiler Feed Pumps CalculationArun Kumar DeyNo ratings yet

- Cust (Department of Mechanical Engineering) Project Report Designing Steam Power PlantDocument14 pagesCust (Department of Mechanical Engineering) Project Report Designing Steam Power PlantShanzeh DaudNo ratings yet

- Turbo Assignment 1 - 2013Document2 pagesTurbo Assignment 1 - 2013Shreyash SinghNo ratings yet

- Chapter 8 McCabeDocument65 pagesChapter 8 McCabeConrad MonterolaNo ratings yet

- Santosh G Kelshekar - AssortedDocument10 pagesSantosh G Kelshekar - AssortedscemanjuNo ratings yet

- TD5 "Pumps, Compressor and Turbine"Document2 pagesTD5 "Pumps, Compressor and Turbine"M JNo ratings yet

- ConclusionDocument1 pageConclusionMuhammad Ali50% (2)

- Wang2015 UnlockedDocument11 pagesWang2015 UnlockedRaifel MoralesNo ratings yet

- Pump AgitationDocument1 pagePump AgitationhNo ratings yet

- Vacuum Excavator Truck DesignDocument8 pagesVacuum Excavator Truck DesignajcapetillogNo ratings yet

- 002 Catalogo CORNELL PUMP - REFRIGERACION Bombas IndustrialesDocument8 pages002 Catalogo CORNELL PUMP - REFRIGERACION Bombas IndustrialesADI OASNo ratings yet

- Sizing and Specifying Pumps R2Document27 pagesSizing and Specifying Pumps R2royNo ratings yet

- Pump by BoseDocument26 pagesPump by BoseSonu SinghNo ratings yet

- PumpsDocument2 pagesPumpsDan Bryan ApaNo ratings yet

- KBL Pump Test HouseDocument8 pagesKBL Pump Test Housegautamten1110No ratings yet

- HW 5 Problem SetDocument3 pagesHW 5 Problem SetJustinTimeNo ratings yet

- Guide To Submersible Well Pump Selection: 1. Well Capacity 6. 2-WIRE VS. 3-WIREDocument1 pageGuide To Submersible Well Pump Selection: 1. Well Capacity 6. 2-WIRE VS. 3-WIREBassel El Sayed AliNo ratings yet

- Summary Pocket BookDocument13 pagesSummary Pocket Booksas13No ratings yet

- 1 - DMX9402 - Thermal Energy Utilities (TEU) - LMS Assignment 1 - 2023Document3 pages1 - DMX9402 - Thermal Energy Utilities (TEU) - LMS Assignment 1 - 2023Sharath BogaNo ratings yet

- Solution Set # 1Document5 pagesSolution Set # 1Duckie McBeakNo ratings yet

- Pumps AG 7 - 1 PDFDocument4 pagesPumps AG 7 - 1 PDFquiron2010No ratings yet

- Levant Amien ToDocument8 pagesLevant Amien ToCharles CarreraNo ratings yet

- Training Overview: Presented by Akash KarpeDocument22 pagesTraining Overview: Presented by Akash KarpeMukesh Kumar VaishnavNo ratings yet

- Problemas Propuestos OTMDocument11 pagesProblemas Propuestos OTMAnna MtNo ratings yet

- Design BasisDocument11 pagesDesign BasisvasudhaNo ratings yet

- Final Exam - Advanced ThermodynamicsDocument1 pageFinal Exam - Advanced ThermodynamicsNelbert SumalpongNo ratings yet

- Underground Geothermal HeatpumpsDocument5 pagesUnderground Geothermal HeatpumpsSheryl MurchieNo ratings yet

- Fluid Machinery - Eng - Pump - Part2 (Compatibility Mode)Document65 pagesFluid Machinery - Eng - Pump - Part2 (Compatibility Mode)ณัฐวัศ มั่นบุญสมNo ratings yet

- Me8595 Iq R17Document2 pagesMe8595 Iq R17Narayanan SubramanianNo ratings yet

- Specification - Importance of Getting Them RightDocument6 pagesSpecification - Importance of Getting Them RightAnonymous QSfDsVxjZNo ratings yet

- Question Bank For GTU Exam Thermal Power Plant: Noble Group of Institutions, JunagadhDocument5 pagesQuestion Bank For GTU Exam Thermal Power Plant: Noble Group of Institutions, JunagadhSAJU UTHUPPANNo ratings yet

- 3.6 Pumps - Revised (Table Format)Document11 pages3.6 Pumps - Revised (Table Format)mtpiping2572No ratings yet

- 8.performance Evaluation of Centrifugal Type Boiler Feed Pump by Varying Blade NumberDocument6 pages8.performance Evaluation of Centrifugal Type Boiler Feed Pump by Varying Blade NumberHazim HazimNo ratings yet

- LUF617 - DW - 8Hx11 - F Gas WellDocument10 pagesLUF617 - DW - 8Hx11 - F Gas WellJosé TimanáNo ratings yet

- Fluid Machinery - PumpsDocument32 pagesFluid Machinery - PumpsIvan Jeremy AbilaNo ratings yet

- 2135 Tutorial 1Document4 pages2135 Tutorial 1Eezhar JumadiNo ratings yet

- When Sizing A Water Storage Tank For Exclusive Fire Protection UseDocument4 pagesWhen Sizing A Water Storage Tank For Exclusive Fire Protection UsemengineeringNo ratings yet

- Problem Set Number 1Document5 pagesProblem Set Number 1Johnlloyd BarretoNo ratings yet

- Brassengineeringinternational 151112220903 Lva1 App6891Document92 pagesBrassengineeringinternational 151112220903 Lva1 App6891cbt_71No ratings yet

- Utility Quick Stimate Rule of ThumbDocument11 pagesUtility Quick Stimate Rule of ThumbReguloNo ratings yet

- AODDs and Viscosity FluidsDocument3 pagesAODDs and Viscosity FluidsDarshan PatelNo ratings yet

- FLM3B0S Tutorial 2a TurbomachinesDocument3 pagesFLM3B0S Tutorial 2a TurbomachinesFabrizio NEBESSENo ratings yet

- SH1 RFP - P4 OTR - Ch8 Balance of Plant - p25-28Document4 pagesSH1 RFP - P4 OTR - Ch8 Balance of Plant - p25-28SonNguyenNo ratings yet

- DR NTTPSDocument41 pagesDR NTTPSnagasuresh100% (1)

- AED Design Requirements:: Jockey PumpsDocument5 pagesAED Design Requirements:: Jockey PumpsAsadullah KHANNo ratings yet

- Power Plant Engineering - 2 Marks - All 5 UnitsDocument25 pagesPower Plant Engineering - 2 Marks - All 5 UnitsMohan Prasad.M89% (9)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Airport To EilDocument3 pagesAirport To EilChakravarthy BharathNo ratings yet

- Property Rules and PoliciesDocument4 pagesProperty Rules and PoliciesChakravarthy BharathNo ratings yet

- Appendix A - DATASHEET - BilectricDocument11 pagesAppendix A - DATASHEET - BilectricChakravarthy BharathNo ratings yet

- Technical Specification 2 1 - 0 0 0 3 - 2 3 1 R e V - 0Document7 pagesTechnical Specification 2 1 - 0 0 0 3 - 2 3 1 R e V - 0Chakravarthy BharathNo ratings yet

- Booking Confirmation VoucherDocument1 pageBooking Confirmation VoucherChakravarthy BharathNo ratings yet

- FGC SimulationDocument1 pageFGC SimulationChakravarthy BharathNo ratings yet

- Typical P&IDDocument1 pageTypical P&IDChakravarthy BharathNo ratings yet

- Utility Costs LP SteamDocument1 pageUtility Costs LP SteamChakravarthy BharathNo ratings yet

- LPG Reprocessing MarkupDocument1 pageLPG Reprocessing MarkupChakravarthy BharathNo ratings yet

- Tharppana Manthram (Mantram) in Phonetic English - Srivaishnavam PracticesDocument33 pagesTharppana Manthram (Mantram) in Phonetic English - Srivaishnavam PracticesChakravarthy BharathNo ratings yet

- Appendix A - DATASHEET - DPDocument11 pagesAppendix A - DATASHEET - DPChakravarthy Bharath0% (1)

- 9952T-600 0004 PDS 0800: ClassDocument3 pages9952T-600 0004 PDS 0800: ClassChakravarthy BharathNo ratings yet

- PDS 1390 0002 9952T-600: ClassDocument2 pagesPDS 1390 0002 9952T-600: ClassChakravarthy BharathNo ratings yet

- 9952T-600 0003 PDS 0800: ClassDocument4 pages9952T-600 0003 PDS 0800: ClassChakravarthy BharathNo ratings yet

- 9952T-600 0003 PDS 1390: ClassDocument2 pages9952T-600 0003 PDS 1390: ClassChakravarthy BharathNo ratings yet

- 9952T 600 PDS 0800 0007 D PDFDocument5 pages9952T 600 PDS 0800 0007 D PDFChakravarthy BharathNo ratings yet

- PDS 0800 9952T-600 0008: ClassDocument4 pagesPDS 0800 9952T-600 0008: ClassChakravarthy BharathNo ratings yet

- PDS 4260 0001 9952T-600: ClassDocument2 pagesPDS 4260 0001 9952T-600: ClassChakravarthy BharathNo ratings yet

- PDS 0510 9952T-600 0001: ClassDocument5 pagesPDS 0510 9952T-600 0001: ClassChakravarthy BharathNo ratings yet

- 9952T-600 0006 PDS 0800: ClassDocument6 pages9952T-600 0006 PDS 0800: ClassChakravarthy BharathNo ratings yet

- 9952T-600 0005 PDS 0800: ClassDocument5 pages9952T-600 0005 PDS 0800: ClassChakravarthy BharathNo ratings yet

- 9952T-600 0009 PDS 0800: ClassDocument3 pages9952T-600 0009 PDS 0800: ClassChakravarthy BharathNo ratings yet

- Fluidized Catalytic Cracking-An: Luidized Atalytic Racking-AnDocument47 pagesFluidized Catalytic Cracking-An: Luidized Atalytic Racking-AnChakravarthy BharathNo ratings yet

- Flushing Oil PumpDocument49 pagesFlushing Oil PumpChakravarthy BharathNo ratings yet

- Mcpi - Software Requirements: SN Software Discipline No of Licenses Total Manmonths Duration (Months)Document4 pagesMcpi - Software Requirements: SN Software Discipline No of Licenses Total Manmonths Duration (Months)Chakravarthy BharathNo ratings yet

Phase 1 Procesengineering Assessment

Phase 1 Procesengineering Assessment

Uploaded by

Chakravarthy BharathOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Phase 1 Procesengineering Assessment

Phase 1 Procesengineering Assessment

Uploaded by

Chakravarthy BharathCopyright:

Available Formats

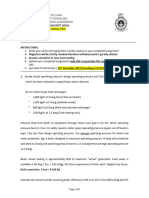

TECHNIP INDIA LIMITED, CHENNAI

PROCESS ENGINEERING TRAINEES, PHASE 1 ASSESSMENT

1. Kerosene product pump having 100m3/h capacity and delivering 90m head is

reused to pump vacuum residue. Flow rate of vacuum residue is 80 m3/h

and head is 88 m. Validate the usage of replacing the kero pump.

2. Effect of Prandtl number on heat transfer rate

3. What is the inference if the Nusselt number is more than 1

4. LPG is stored in bullets in IOCL Gujarat. Estimate the required design

pressure and temperature of LPG bullet

5. Differentiate DM water / Boiler Feed water and Polished water

6. Classify petroleum products as per flammability.

7. Pros and cons of vertical and horizontal vessel

8. What is the code followed for pressure-relieving and vapor depressuring

systems?

9. It is preferred to avoid slug flow in pipelines. What are measures to prevent

slug flow.

10. Boiler feed water pump is driven by steam turbine, supplies boiler feed water

to steam generator producing HP steam at 50 kg/cm2g. Estimate design

pressure of BFW pump discharge line.

11. 50000 kg/h of cooling water from cooling water pump is carried in a pipeline

of 10”. Client wants to add additional train capacity of 100000 kg/hr. What is

the line size required for the new train?

12. Advantage & Disadvantages of forced draft and induced draft fans

13. What is RAM study and how it is used in a project?

14. What is Criteria for sizing flare header and PSV outlet line

15. At one tray the pressure of vapor phase is 7 psi. hydraulic pressure drop is 2

psi and dry pressure drop is 4 psi. What is your inference

You might also like

- PtrE 521 - Lecture 3 - Other Artificial Lift TechnologiesDocument144 pagesPtrE 521 - Lecture 3 - Other Artificial Lift TechnologiesGhoulemEllah Haithem IfreneNo ratings yet

- 3 CsDocument14 pages3 CsRavindra PawarNo ratings yet

- SAMPLE PROBLEMS Fluid Mechanics Pump DeNeversDocument2 pagesSAMPLE PROBLEMS Fluid Mechanics Pump DeNeversGeorge Isaac McQuilesNo ratings yet

- Fluid Mechanics-II AssignmentDocument7 pagesFluid Mechanics-II AssignmentMuntaha AnjumNo ratings yet

- Centrifugal Pump.......... Very ImpDocument22 pagesCentrifugal Pump.......... Very Impavi07me4u100% (2)

- Z Purlin Data SheetDocument17 pagesZ Purlin Data SheetErshadNo ratings yet

- 5.13. ProblemsDocument3 pages5.13. Problemsاسماعیل ادریس عبدالعزیزNo ratings yet

- SQ - 4.7 - Pumps (Table Format)Document5 pagesSQ - 4.7 - Pumps (Table Format)Amitav MishraNo ratings yet

- Tutorial 4Document1 pageTutorial 4Krivai NagarNo ratings yet

- The Sizing Boiler Feed Pumps CalculationDocument3 pagesThe Sizing Boiler Feed Pumps CalculationArun Kumar DeyNo ratings yet

- Cust (Department of Mechanical Engineering) Project Report Designing Steam Power PlantDocument14 pagesCust (Department of Mechanical Engineering) Project Report Designing Steam Power PlantShanzeh DaudNo ratings yet

- Turbo Assignment 1 - 2013Document2 pagesTurbo Assignment 1 - 2013Shreyash SinghNo ratings yet

- Chapter 8 McCabeDocument65 pagesChapter 8 McCabeConrad MonterolaNo ratings yet

- Santosh G Kelshekar - AssortedDocument10 pagesSantosh G Kelshekar - AssortedscemanjuNo ratings yet

- TD5 "Pumps, Compressor and Turbine"Document2 pagesTD5 "Pumps, Compressor and Turbine"M JNo ratings yet

- ConclusionDocument1 pageConclusionMuhammad Ali50% (2)

- Wang2015 UnlockedDocument11 pagesWang2015 UnlockedRaifel MoralesNo ratings yet

- Pump AgitationDocument1 pagePump AgitationhNo ratings yet

- Vacuum Excavator Truck DesignDocument8 pagesVacuum Excavator Truck DesignajcapetillogNo ratings yet

- 002 Catalogo CORNELL PUMP - REFRIGERACION Bombas IndustrialesDocument8 pages002 Catalogo CORNELL PUMP - REFRIGERACION Bombas IndustrialesADI OASNo ratings yet

- Sizing and Specifying Pumps R2Document27 pagesSizing and Specifying Pumps R2royNo ratings yet

- Pump by BoseDocument26 pagesPump by BoseSonu SinghNo ratings yet

- PumpsDocument2 pagesPumpsDan Bryan ApaNo ratings yet

- KBL Pump Test HouseDocument8 pagesKBL Pump Test Housegautamten1110No ratings yet

- HW 5 Problem SetDocument3 pagesHW 5 Problem SetJustinTimeNo ratings yet

- Guide To Submersible Well Pump Selection: 1. Well Capacity 6. 2-WIRE VS. 3-WIREDocument1 pageGuide To Submersible Well Pump Selection: 1. Well Capacity 6. 2-WIRE VS. 3-WIREBassel El Sayed AliNo ratings yet

- Summary Pocket BookDocument13 pagesSummary Pocket Booksas13No ratings yet

- 1 - DMX9402 - Thermal Energy Utilities (TEU) - LMS Assignment 1 - 2023Document3 pages1 - DMX9402 - Thermal Energy Utilities (TEU) - LMS Assignment 1 - 2023Sharath BogaNo ratings yet

- Solution Set # 1Document5 pagesSolution Set # 1Duckie McBeakNo ratings yet

- Pumps AG 7 - 1 PDFDocument4 pagesPumps AG 7 - 1 PDFquiron2010No ratings yet

- Levant Amien ToDocument8 pagesLevant Amien ToCharles CarreraNo ratings yet

- Training Overview: Presented by Akash KarpeDocument22 pagesTraining Overview: Presented by Akash KarpeMukesh Kumar VaishnavNo ratings yet

- Problemas Propuestos OTMDocument11 pagesProblemas Propuestos OTMAnna MtNo ratings yet

- Design BasisDocument11 pagesDesign BasisvasudhaNo ratings yet

- Final Exam - Advanced ThermodynamicsDocument1 pageFinal Exam - Advanced ThermodynamicsNelbert SumalpongNo ratings yet

- Underground Geothermal HeatpumpsDocument5 pagesUnderground Geothermal HeatpumpsSheryl MurchieNo ratings yet

- Fluid Machinery - Eng - Pump - Part2 (Compatibility Mode)Document65 pagesFluid Machinery - Eng - Pump - Part2 (Compatibility Mode)ณัฐวัศ มั่นบุญสมNo ratings yet

- Me8595 Iq R17Document2 pagesMe8595 Iq R17Narayanan SubramanianNo ratings yet

- Specification - Importance of Getting Them RightDocument6 pagesSpecification - Importance of Getting Them RightAnonymous QSfDsVxjZNo ratings yet

- Question Bank For GTU Exam Thermal Power Plant: Noble Group of Institutions, JunagadhDocument5 pagesQuestion Bank For GTU Exam Thermal Power Plant: Noble Group of Institutions, JunagadhSAJU UTHUPPANNo ratings yet

- 3.6 Pumps - Revised (Table Format)Document11 pages3.6 Pumps - Revised (Table Format)mtpiping2572No ratings yet

- 8.performance Evaluation of Centrifugal Type Boiler Feed Pump by Varying Blade NumberDocument6 pages8.performance Evaluation of Centrifugal Type Boiler Feed Pump by Varying Blade NumberHazim HazimNo ratings yet

- LUF617 - DW - 8Hx11 - F Gas WellDocument10 pagesLUF617 - DW - 8Hx11 - F Gas WellJosé TimanáNo ratings yet

- Fluid Machinery - PumpsDocument32 pagesFluid Machinery - PumpsIvan Jeremy AbilaNo ratings yet

- 2135 Tutorial 1Document4 pages2135 Tutorial 1Eezhar JumadiNo ratings yet

- When Sizing A Water Storage Tank For Exclusive Fire Protection UseDocument4 pagesWhen Sizing A Water Storage Tank For Exclusive Fire Protection UsemengineeringNo ratings yet

- Problem Set Number 1Document5 pagesProblem Set Number 1Johnlloyd BarretoNo ratings yet

- Brassengineeringinternational 151112220903 Lva1 App6891Document92 pagesBrassengineeringinternational 151112220903 Lva1 App6891cbt_71No ratings yet

- Utility Quick Stimate Rule of ThumbDocument11 pagesUtility Quick Stimate Rule of ThumbReguloNo ratings yet

- AODDs and Viscosity FluidsDocument3 pagesAODDs and Viscosity FluidsDarshan PatelNo ratings yet

- FLM3B0S Tutorial 2a TurbomachinesDocument3 pagesFLM3B0S Tutorial 2a TurbomachinesFabrizio NEBESSENo ratings yet

- SH1 RFP - P4 OTR - Ch8 Balance of Plant - p25-28Document4 pagesSH1 RFP - P4 OTR - Ch8 Balance of Plant - p25-28SonNguyenNo ratings yet

- DR NTTPSDocument41 pagesDR NTTPSnagasuresh100% (1)

- AED Design Requirements:: Jockey PumpsDocument5 pagesAED Design Requirements:: Jockey PumpsAsadullah KHANNo ratings yet

- Power Plant Engineering - 2 Marks - All 5 UnitsDocument25 pagesPower Plant Engineering - 2 Marks - All 5 UnitsMohan Prasad.M89% (9)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Airport To EilDocument3 pagesAirport To EilChakravarthy BharathNo ratings yet

- Property Rules and PoliciesDocument4 pagesProperty Rules and PoliciesChakravarthy BharathNo ratings yet

- Appendix A - DATASHEET - BilectricDocument11 pagesAppendix A - DATASHEET - BilectricChakravarthy BharathNo ratings yet

- Technical Specification 2 1 - 0 0 0 3 - 2 3 1 R e V - 0Document7 pagesTechnical Specification 2 1 - 0 0 0 3 - 2 3 1 R e V - 0Chakravarthy BharathNo ratings yet

- Booking Confirmation VoucherDocument1 pageBooking Confirmation VoucherChakravarthy BharathNo ratings yet

- FGC SimulationDocument1 pageFGC SimulationChakravarthy BharathNo ratings yet

- Typical P&IDDocument1 pageTypical P&IDChakravarthy BharathNo ratings yet

- Utility Costs LP SteamDocument1 pageUtility Costs LP SteamChakravarthy BharathNo ratings yet

- LPG Reprocessing MarkupDocument1 pageLPG Reprocessing MarkupChakravarthy BharathNo ratings yet

- Tharppana Manthram (Mantram) in Phonetic English - Srivaishnavam PracticesDocument33 pagesTharppana Manthram (Mantram) in Phonetic English - Srivaishnavam PracticesChakravarthy BharathNo ratings yet

- Appendix A - DATASHEET - DPDocument11 pagesAppendix A - DATASHEET - DPChakravarthy Bharath0% (1)

- 9952T-600 0004 PDS 0800: ClassDocument3 pages9952T-600 0004 PDS 0800: ClassChakravarthy BharathNo ratings yet

- PDS 1390 0002 9952T-600: ClassDocument2 pagesPDS 1390 0002 9952T-600: ClassChakravarthy BharathNo ratings yet

- 9952T-600 0003 PDS 0800: ClassDocument4 pages9952T-600 0003 PDS 0800: ClassChakravarthy BharathNo ratings yet

- 9952T-600 0003 PDS 1390: ClassDocument2 pages9952T-600 0003 PDS 1390: ClassChakravarthy BharathNo ratings yet

- 9952T 600 PDS 0800 0007 D PDFDocument5 pages9952T 600 PDS 0800 0007 D PDFChakravarthy BharathNo ratings yet

- PDS 0800 9952T-600 0008: ClassDocument4 pagesPDS 0800 9952T-600 0008: ClassChakravarthy BharathNo ratings yet

- PDS 4260 0001 9952T-600: ClassDocument2 pagesPDS 4260 0001 9952T-600: ClassChakravarthy BharathNo ratings yet

- PDS 0510 9952T-600 0001: ClassDocument5 pagesPDS 0510 9952T-600 0001: ClassChakravarthy BharathNo ratings yet

- 9952T-600 0006 PDS 0800: ClassDocument6 pages9952T-600 0006 PDS 0800: ClassChakravarthy BharathNo ratings yet

- 9952T-600 0005 PDS 0800: ClassDocument5 pages9952T-600 0005 PDS 0800: ClassChakravarthy BharathNo ratings yet

- 9952T-600 0009 PDS 0800: ClassDocument3 pages9952T-600 0009 PDS 0800: ClassChakravarthy BharathNo ratings yet

- Fluidized Catalytic Cracking-An: Luidized Atalytic Racking-AnDocument47 pagesFluidized Catalytic Cracking-An: Luidized Atalytic Racking-AnChakravarthy BharathNo ratings yet

- Flushing Oil PumpDocument49 pagesFlushing Oil PumpChakravarthy BharathNo ratings yet

- Mcpi - Software Requirements: SN Software Discipline No of Licenses Total Manmonths Duration (Months)Document4 pagesMcpi - Software Requirements: SN Software Discipline No of Licenses Total Manmonths Duration (Months)Chakravarthy BharathNo ratings yet