Professional Documents

Culture Documents

How To Size An IBM Machine

How To Size An IBM Machine

Uploaded by

Faisal AftabOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

How To Size An IBM Machine

How To Size An IBM Machine

Uploaded by

Faisal AftabCopyright:

Available Formats

HOW TO SIZE A MACHINE

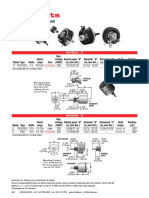

There are 2 main design features that decide how

many cavities of a particular bottle can be made CORE ROD

TRANSFER

HEAD

on any size Jomar IBM machine. RETAINER

1 The preform clamp tonnage. The preform cavities

are designed to contain the required amount of DUMMY

COREROD

plastic to produce the finished article.

The thickness of the preform and the material

being processed dictate the holding pressure

required to fill the cavity. This figure,

multiplied by the cross-sectional area of the

preform along the vertical axis through the neck

O RING

section divided into the machine tonnage will

indicate the number of cavities. Typically the COREROD

holding pressure varies between 250 -400 kgs/cm²

CORE ROD

(3,500 - 4500 lbs/in²), depending on the material CORE ROD HOLDER ASSEMBLY

HOLDER

TRIGGER (CAM) BAR

processed. Illustration below shows the cross-

sectional preform for a typical jar.

2 The second feature is the length of the trigger bar used in the rotary transfer head to open the core

rods to blow the bottle at the blowing station. For this calculation, take the outside diameter in the

case of a round bottle, the major axis for an oval bottle or the width across the split line + 10mm

(0.4") to establish the cavity size of the blow mold. This dimension divided into the length of the

trigger bar + 1 cavity gives the number of bottles that can be fitted on the blow station dieset.

The specification sheets give the standard lengths of trigger bar available.

65.2mm2.568"

However, it is possible to manufacture

Core rod length

alternative length trigger bars for non-

3.3mm

Wall standard components.

2.5mm 0.130" R3.2 Contact Jomar for details.

"S" thread start 0.1" Wall 0.125"

1.5mm 21mm Drawing at upper right shows a typical

.06" Wall 0.827" transfer head layout.

You will also need a plastifier that can

produce the shot weight required in the

"T" Ø "E" Ø I/Dia "I"

R2.3

"D" Ø

expected cycle time.

0.09"

47.5mm 46mm 43mm 57mm

1.870" 1.810" 1.693" 2.24" The lowest number from above will be the

number of cavities that can be made on

the size of Jomar IBM machine.

"H" neck height

11.9mm

0.468" Metric US

Preform Standard Preform Standard

20.5mm 35.2mm

1.385"Ø Jomar Clamp Trigger bar Clamp Trigger bar

0.808"

Model Tonnes mms Tons mms

M15 11.4 166 12.6 6.4"

67.7mm M40 34.6 304 38.2 12.0"

2.668" M65 47.1 552 52 21.75"

ParisonLength

M85S 65.4 552 72.1 21.75"

Parison Layout for 100 gram jar. M135 122.9 914.4 135.4 36"

M175 158.9 1016 175 44"

You might also like

- B. Velde (Auth.) - Introduction To Clay Minerals - Chemistry, Origins, Uses and Environmental Significance-Springer Netherlands (1992) PDFDocument205 pagesB. Velde (Auth.) - Introduction To Clay Minerals - Chemistry, Origins, Uses and Environmental Significance-Springer Netherlands (1992) PDFLeonardo TejedorNo ratings yet

- Via Afrika Mathematics Grade 12 Study Guide Checked PDFDocument173 pagesVia Afrika Mathematics Grade 12 Study Guide Checked PDFKhumbulani CindiNo ratings yet

- SMD TR60 DatasheetDocument4 pagesSMD TR60 DatasheetAlfred GandNo ratings yet

- Tubing PDFDocument20 pagesTubing PDFTheEdge100% (1)

- Forming Taps: The Right Tool at The Right TimeDocument9 pagesForming Taps: The Right Tool at The Right TimeĐức Nguyễn VănNo ratings yet

- STPE600 - Dadi A ProiezioneDocument17 pagesSTPE600 - Dadi A ProiezioneLucaNo ratings yet

- Comitrol Processor Model 1700: Versatile Size ReductionDocument2 pagesComitrol Processor Model 1700: Versatile Size Reductionthaihoangminh93No ratings yet

- Rheostats: (Potentiometers) WirewoundDocument3 pagesRheostats: (Potentiometers) WirewoundJumail SobaNo ratings yet

- Mastermilling Final 98-10Document14 pagesMastermilling Final 98-10Aboozar FathinejadNo ratings yet

- MicroCentric Diaphragm Chuck Catalog 1010 - UnlockedDocument15 pagesMicroCentric Diaphragm Chuck Catalog 1010 - UnlockedcontrolorNo ratings yet

- ProseamDocument12 pagesProseamShailendra TembeNo ratings yet

- VAM SFC 0511 SPDocument8 pagesVAM SFC 0511 SP11tkt11No ratings yet

- Cutless CatalogueDocument21 pagesCutless CatalogueGlobal CHNo ratings yet

- Data Sheet AluminaDocument10 pagesData Sheet AluminaXin EnNo ratings yet

- Iso Met 1000Document4 pagesIso Met 1000aspoiuNo ratings yet

- RAPTOR Cone CrusherDocument4 pagesRAPTOR Cone CrusherLuis Miguel La TorreNo ratings yet

- Pump Installation and Maintenance: Learning OutcomeDocument6 pagesPump Installation and Maintenance: Learning OutcomeMohammed Amin BenharkatNo ratings yet

- Metric Thread Dimensions CalculatorDocument6 pagesMetric Thread Dimensions CalculatorTaner DemirelNo ratings yet

- KR Mini Mill SeriesDocument31 pagesKR Mini Mill SeriesShani KhanNo ratings yet

- Model 9 Series: Fusion (Gtaw) Weld HeadsDocument4 pagesModel 9 Series: Fusion (Gtaw) Weld HeadskyongngNo ratings yet

- Johnson Screens Nozzles PDFDocument2 pagesJohnson Screens Nozzles PDFVICTORNo ratings yet

- Kristeel CatalogueDocument52 pagesKristeel CatalogueRam TejaNo ratings yet

- Accurate, Temperature Readings Through Radio or Conduction EnvironmentsDocument2 pagesAccurate, Temperature Readings Through Radio or Conduction EnvironmentsGERMANNo ratings yet

- Corobore® 825: Fine Boring Tools With Silent Tools™ TechnologyDocument2 pagesCorobore® 825: Fine Boring Tools With Silent Tools™ TechnologyNILOHAYASHINo ratings yet

- Boa Coil: Heavy-Duty, Reusable FasteningDocument2 pagesBoa Coil: Heavy-Duty, Reusable Fasteningblessed cccNo ratings yet

- StdrillserratedDocument2 pagesStdrillserratedSaul AguilarNo ratings yet

- Wire & Cable 202312261659586681900588413Document24 pagesWire & Cable 202312261659586681900588413Amir IqbalNo ratings yet

- IndexerDocument40 pagesIndexerAnonymous 9q5GEfm8INo ratings yet

- #3 Domed Head Plow Bolt: Earnest Technical BulletinDocument3 pages#3 Domed Head Plow Bolt: Earnest Technical BulletinNarvaxisNo ratings yet

- Section MillingDocument2 pagesSection MillingCharles DesmazuresNo ratings yet

- General Production Hose Crimper: Cc200 / Cc400 Crimpers Operators Manual With Dial Micrometer Style AdjustmentDocument18 pagesGeneral Production Hose Crimper: Cc200 / Cc400 Crimpers Operators Manual With Dial Micrometer Style AdjustmentLoki C GowdaNo ratings yet

- Dormer Reamer TolerancesDocument12 pagesDormer Reamer TolerancesHenrique MarquesNo ratings yet

- Dormer Reamer Tolerances PDFDocument12 pagesDormer Reamer Tolerances PDFHenrique MarquesNo ratings yet

- EZG Series Slurry Pump: Excellence Pump Industry Co., LTDDocument6 pagesEZG Series Slurry Pump: Excellence Pump Industry Co., LTDCristobal BernalNo ratings yet

- The Widest Range of Orbital Welding Equipment in The World: "Pulled-Tee" Type JointsDocument2 pagesThe Widest Range of Orbital Welding Equipment in The World: "Pulled-Tee" Type Jointsmakmak9No ratings yet

- Anchor-Bolts in CMU Wall DesignDocument26 pagesAnchor-Bolts in CMU Wall DesignWenxuan WangNo ratings yet

- Turboflex High Performance High Speed StållamellkopplingDocument4 pagesTurboflex High Performance High Speed StållamellkopplingAli KianersiNo ratings yet

- XCD DrillBit BrochureDocument2 pagesXCD DrillBit BrochureebayksNo ratings yet

- Metal Tek ScrewDocument2 pagesMetal Tek ScrewAmin SalahNo ratings yet

- Fan Coil UnitsDocument4 pagesFan Coil UnitsAbdul SamadNo ratings yet

- Collet Chuck Catalog 2007 PDFDocument28 pagesCollet Chuck Catalog 2007 PDFAlexandru Marius-catalinNo ratings yet

- JENNMAR ThreadBarDocument1 pageJENNMAR ThreadBarjailon.wyattNo ratings yet

- Data Sheet 29B - Fig TC704 Conical (Witches Hat) StrainerDocument1 pageData Sheet 29B - Fig TC704 Conical (Witches Hat) StrainerSteve NewmanNo ratings yet

- Catalogo Ponta RotativoDocument26 pagesCatalogo Ponta Rotativomarcello camaraoNo ratings yet

- Datasheet S 400Document2 pagesDatasheet S 400Sơn Lê CaoNo ratings yet

- 12.25 DD507TSX X32146Document1 page12.25 DD507TSX X32146mtchembouNo ratings yet

- Kurt WorkholdingDocument88 pagesKurt WorkholdingAbdul AzizNo ratings yet

- C1.1.0 Ajiya - 2018 - Roofing Catalogue Clip Lock ProfileDocument8 pagesC1.1.0 Ajiya - 2018 - Roofing Catalogue Clip Lock ProfileFahmi YusoffNo ratings yet

- TECON Scaffolding RinglockDocument9 pagesTECON Scaffolding RinglockSergio RebazaNo ratings yet

- Begg Cousland Tower InternalsDocument4 pagesBegg Cousland Tower InternalsHavocFireNo ratings yet

- 501/453 UNIVERSAL Hazardous Area Cable GlandDocument1 page501/453 UNIVERSAL Hazardous Area Cable Glandhashmin karuvathilNo ratings yet

- Cable Solenoid: FeaturesDocument2 pagesCable Solenoid: FeaturesJohn GarnetNo ratings yet

- TEX 10 Pneumatic Pick Hammer: Long Stroke. Hard Hitting. Low WeightDocument4 pagesTEX 10 Pneumatic Pick Hammer: Long Stroke. Hard Hitting. Low Weightalexander_1985No ratings yet

- General Properties: Element Tekan Komponen Struktur Menahan LenturDocument5 pagesGeneral Properties: Element Tekan Komponen Struktur Menahan LenturOecoep IteemNo ratings yet

- Hitachi - Excavator - ZX200LC-5G, ZX240LC-5G, ZX280LC-5G, ZX330LC-5G - KA-EN164Document11 pagesHitachi - Excavator - ZX200LC-5G, ZX240LC-5G, ZX280LC-5G, ZX330LC-5G - KA-EN164patrickhoyer93No ratings yet

- Brochure Sieve Shakers enDocument4 pagesBrochure Sieve Shakers enjesusNo ratings yet

- Silo Fluidizer Mini Disk: Mini Fluidizing Disk Keeps Material Moving in Tight CurvaturesDocument2 pagesSilo Fluidizer Mini Disk: Mini Fluidizing Disk Keeps Material Moving in Tight Curvaturesseeralan_1986No ratings yet

- F Nestable - CSP BrochureDocument2 pagesF Nestable - CSP BrochureGibbs PerNo ratings yet

- WOM ChokeDocument16 pagesWOM Chokegacm9875% (4)

- Optimized Design of Inserts For Maximum Drilling EfficiencyDocument28 pagesOptimized Design of Inserts For Maximum Drilling EfficiencyZoran VučkovićNo ratings yet

- Injection Blow Moulding PVC Containers: by Ralph Abramo, SRDocument8 pagesInjection Blow Moulding PVC Containers: by Ralph Abramo, SRFaisal AftabNo ratings yet

- IBM Maximum CavitationDocument1 pageIBM Maximum CavitationFaisal AftabNo ratings yet

- Barrier Properties: Jomar Europe LTDDocument5 pagesBarrier Properties: Jomar Europe LTDFaisal AftabNo ratings yet

- Pet and Injection Blow Molding (Ibm) : A B C D EDocument2 pagesPet and Injection Blow Molding (Ibm) : A B C D EFaisal AftabNo ratings yet

- IBM Material GradesDocument2 pagesIBM Material GradesFaisal AftabNo ratings yet

- Barex - BPDocument4 pagesBarex - BPFaisal AftabNo ratings yet

- Sample Engineering CVDocument1 pageSample Engineering CVFaisal AftabNo ratings yet

- Agv Statement of NeedDocument1 pageAgv Statement of NeedFaisal AftabNo ratings yet

- Wind Speed - Is-875 Part-3 - Civil MasterDocument14 pagesWind Speed - Is-875 Part-3 - Civil MasterSUNIL KUMARNo ratings yet

- Measurement Grid Mgi-Xxa: Photoelectric SensorDocument6 pagesMeasurement Grid Mgi-Xxa: Photoelectric SensorAmanda Kaizer FerreiraNo ratings yet

- Standard Test Method For Kinematic Viscosity of Transparent and Opaque Liquids (And Calculation of Dynamic Viscosity)Document18 pagesStandard Test Method For Kinematic Viscosity of Transparent and Opaque Liquids (And Calculation of Dynamic Viscosity)LuisEduardoRomeroNo ratings yet

- GEA/Test 1: Sample QuestionDocument11 pagesGEA/Test 1: Sample Questionselimreza_862998017No ratings yet

- Introduction of New IGBT Generation 7: Application NoteDocument15 pagesIntroduction of New IGBT Generation 7: Application NoteBrunophb2012No ratings yet

- Soil CompactionDocument45 pagesSoil CompactionMark Ian Mislang De VeraNo ratings yet

- Commercial Catalogue 2Document54 pagesCommercial Catalogue 2TEC INDIANo ratings yet

- Hi-Performance Fan CoilsDocument24 pagesHi-Performance Fan CoilsJorge Cardona GilNo ratings yet

- V-316 SERIES: Bulletin: 2018Document36 pagesV-316 SERIES: Bulletin: 2018DianaNo ratings yet

- PTS-20WM319 - 05 - Materials and Technical SpecificationsDocument25 pagesPTS-20WM319 - 05 - Materials and Technical SpecificationsDurgaprasad RyaliNo ratings yet

- Lab Report 6 Saaim Ahmed - 417524Document9 pagesLab Report 6 Saaim Ahmed - 417524Zain AhmedNo ratings yet

- Unit-3 Solved Examples: Example 1: Using Graph Paper, Draw The Example3. What Type of Quadrilateral IsDocument6 pagesUnit-3 Solved Examples: Example 1: Using Graph Paper, Draw The Example3. What Type of Quadrilateral IsMoin KhanNo ratings yet

- ECW - Digital Contacting Encoder: FeaturesDocument3 pagesECW - Digital Contacting Encoder: FeaturesYavuz KansuNo ratings yet

- Rig-Train-Well-Control-Hydro Stat DynaDocument31 pagesRig-Train-Well-Control-Hydro Stat DynaALEX MAKANGANo ratings yet

- 7UG Monitoring RelaysDocument10 pages7UG Monitoring RelaysRoy VNo ratings yet

- The Leading-Edge Diesel Rotary Uninterruptible Power Supply SystemDocument36 pagesThe Leading-Edge Diesel Rotary Uninterruptible Power Supply SystemEhab AllazyNo ratings yet

- Certificate of Conformity: No. CLS1A 080567 0062 Rev. 00Document2 pagesCertificate of Conformity: No. CLS1A 080567 0062 Rev. 00annamalaiNo ratings yet

- Lost Circulation & Stuck Pipe Prevention QP Second CourseDocument47 pagesLost Circulation & Stuck Pipe Prevention QP Second CourseMes JcNo ratings yet

- Cause and Effect - Ig541 System at Ro Electrical Building - Third FloorDocument2 pagesCause and Effect - Ig541 System at Ro Electrical Building - Third FloorWaseem SiddiqueNo ratings yet

- Timber Design Chapter 1Document10 pagesTimber Design Chapter 1Mac MacNo ratings yet

- Eng CS Epp-2443 1510Document106 pagesEng CS Epp-2443 1510Sang SekNo ratings yet

- Improved Methanol Yield and Selectivity From CO2 Hydrogenation Using A Novel Cu-ZnO-ZrO2 Catalyst Supported On Mg-Al Layered Double Hydroxide (LDH)Document8 pagesImproved Methanol Yield and Selectivity From CO2 Hydrogenation Using A Novel Cu-ZnO-ZrO2 Catalyst Supported On Mg-Al Layered Double Hydroxide (LDH)Nguyễn TuânNo ratings yet

- Chemistry of SulphurDocument52 pagesChemistry of SulphurKennedy ChitayiNo ratings yet

- Geometry Lesson 4 Symmetry of 2D and 3D ShapesDocument15 pagesGeometry Lesson 4 Symmetry of 2D and 3D ShapesNagy ElrahebNo ratings yet

- ZnO PLY NCPDocument9 pagesZnO PLY NCPkamalugarba93No ratings yet

- Electronic Noises Interface Circuits and OscillatorsDocument21 pagesElectronic Noises Interface Circuits and Oscillatorslucaplat11No ratings yet

- Physical Sciences P2 Grade 12 JUNE 2024 MG FinalDocument9 pagesPhysical Sciences P2 Grade 12 JUNE 2024 MG Finalscorpioboss23No ratings yet

- Disperse DyeDocument8 pagesDisperse DyeSifat RaihanNo ratings yet