Professional Documents

Culture Documents

106R COUPLING GEAR CMS 106R Version 1.2 New PDF

106R COUPLING GEAR CMS 106R Version 1.2 New PDF

Uploaded by

daniel1424Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

106R COUPLING GEAR CMS 106R Version 1.2 New PDF

106R COUPLING GEAR CMS 106R Version 1.2 New PDF

Uploaded by

daniel1424Copyright:

Available Formats

CMS106R

8081 Arco Corporate Dr., Raleigh, North Carolina 27617

Phone (919) 847 8764, Fax (919) 847 8647

E-mail: info@idcon.com, Web site: www.idcon.com

CONDITION MONITORING STANDARD Version 1.2

COUPLING GEAR

Basic Principle

©Copyright IDCON, INC. – Do Not Copy

The function of the gear coupling is to connect two shafts. The gear coupling consists of two inside metal gear

halves each connecting to one shaft and to the external gear, and a metal external gear connecting the inside gears.

This coupling is designed to handle heavy loads. Remember to consider driving and driven components loading

and stress before accepting misalignment in any type of coupling.

Gear Couplings are best suited for heavy load, slow speed applications.

Picture Courtesy: Falk Corporation

NOTE: Visual and thermal inspection requires direct access to coupling, thus coupling guard must allow safe access

to coupling. If coupling cannot be seen, modify guard at earliest convenience.

KEY WHAT WHY

Listen for abnormal noise. Wearing/broken coupling may have a high pitched Noise may be due to:

squeak or rattle. • Misalignment.

Noise

• Imbalance

• Loose Bolts

• Lack of Lubricant

• Chipped Teeth

Version 1.2 CMS 106R Page 1 of 4 © IDCON, INC. 2003

KEY WHAT WHAT

Use a stroboscope to visually “stop” the coupling. Look for excessive dirt and Dirt and buildup on

buildup on coupling. Look for grease emitting from coupling. Look for coupling may cause

loose/missing bolts or cracks on flanges. Look for looseness in coupling outside imbalance. Metal

flanges. Check for moisture on coupling particles indicate wear

inside coupling.

When grease is

coming out of the

Bolt Missing coupling the seal is

broken and needs to be

replaced.

Visual

Gear coupling with

shrouded Bolt Design Missing bolts will

loosen the coupling,

and may also cause

imbalance and this in

turn will damage

driven and driving

components.

Excessive moisture

will tend to shorten the

lubrication life span of

the coupling.

Check coupling for increased temperature. Scan across the coupling for the Temperatures in

highest temperature reading. Maximum allowed coupling temperature should excess of 250ºF will

not exceed 40ºF above ambient temperature (depending on grease used). When permanently damage

temperature is too high, check vibration and balancing of entire system (Ex. the seal (Unless

Temperature

Motor – Coupling – Pump) and modify to correct. Further ensure that coupling special seal).

is greased properly on following shutdown. (Falk suggests 3 year lubrication Coupling temp. in

interval on their Long Term Grease used for Gear Couplings) excess of 40ºF above

ambient temperature

may be due to

misalignment,

imbalance or lack of

lubrication.

Misalignment will

wear coupling shaft

and gear.

Version 1.2 CMS 106R Page 2 of 4 © IDCON, INC. 2003

KEY WHAT WHY

The reliability of the

Look for leaking grease from flanges. There is a gasket between the flanges gear coupling is highly

that seals the coupling from leaking. The gasket may deteriorate due to heat, dependent on the

or mechanical movement from imbalance or misalignment. Look inside the quality of grease

coupling guard for grease (that leaked from coupling). inside the coupling.

The manufacturer recommends changing grease in the gear couplings every 6

months. Most process plant will change grease on an annual or bi-annual

Leaking grease

frequency.

Gasket

Look for signs of

leaking grease

The guard has to have an inspection opening to enable an on-the-run inspection Guard modification is

of the coupling. Some guards must be modified. Inspection ports with wire a prerequisite for

mesh metal or inspection lids with a hinge are examples of guard modifications performing safe and

that will enable coupling inspection. Paint mesh matte black to increase effective condition

visibility. monitoring on-the-run.

Guards

When modifying guards, refer to OSHA standard 1910.212 (for USA). The

allowed size of the wire mesh depends on the distance from the coupling to the

mesh. For example a 1-inch (25.4 mm) wire mesh must be at least 1.5 inches

(38.1 mm) away from the coupling. If your plant applies higher standards than

OSHA, make a wire mesh according to OSHA standard, then apply a hinged lid

over the wire mesh.

Version 1.2 CMS 106R Page 3 of 4 © IDCON, INC. 2003

KEY WHAT WHAT

Use a stroboscope and make sure the coupling appears to be stopped. Inspect The radius of keyways

shaft key for damage, cracks, corrosion and looseness could be sharp. Sharp

edges create stress

concentration,

therefore carefully

check around keys and

keyways when

inspecting shaft

Keyway

keyways.

Stress

concentration

Inspect key and keyway for

damage, cracks, corrosion,

and looseness.

Version 1.2 CMS 106R Page 4 of 4 © IDCON, INC. 2003

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Quality Policy: Weinu Curtain Trading PLCDocument1 pageQuality Policy: Weinu Curtain Trading PLCMansoor KhanaliNo ratings yet

- Dail Visit Report: Discussion About ProporsalDocument3 pagesDail Visit Report: Discussion About ProporsalMansoor KhanaliNo ratings yet

- Illumination Conditions and Visual Comfort in Production Spaces of Ready-Made Garments Factories in DhakaDocument6 pagesIllumination Conditions and Visual Comfort in Production Spaces of Ready-Made Garments Factories in DhakaMansoor KhanaliNo ratings yet

- We Are The Leaders in Knitted Fabrics of All Kinds in The Sub ContinentDocument6 pagesWe Are The Leaders in Knitted Fabrics of All Kinds in The Sub ContinentMansoor KhanaliNo ratings yet

- Count, Construction and Width of Common Cotton FabricsDocument3 pagesCount, Construction and Width of Common Cotton FabricsMansoor KhanaliNo ratings yet

- 1 No of Looms A.New Summum B.Omni Plus 585 90 465 89 3 2 Type 3 No Frames 4 Assign No of Looms To WeaverDocument3 pages1 No of Looms A.New Summum B.Omni Plus 585 90 465 89 3 2 Type 3 No Frames 4 Assign No of Looms To WeaverMansoor KhanaliNo ratings yet

- Mansoor Ali Khan: Summary of QualificationsDocument6 pagesMansoor Ali Khan: Summary of QualificationsMansoor Khanali100% (1)

- Commonwealth of Independent States )Document3 pagesCommonwealth of Independent States )Mansoor KhanaliNo ratings yet

- Sample Resume - Executive CVDocument4 pagesSample Resume - Executive CVMansoor KhanaliNo ratings yet

- Parts RequestDocument4 pagesParts RequestMansoor KhanaliNo ratings yet

- Homeopathy in Intensive Care and Emergency Medicine Michael Frass Martin Buendner.14188 1Document10 pagesHomeopathy in Intensive Care and Emergency Medicine Michael Frass Martin Buendner.14188 1Mansoor Khanali100% (2)

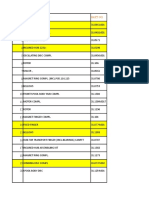

- Pcs 45000 8203 36797 26th March 12000 Pcs 14400 6852 7548 7th MarchDocument2 pagesPcs 45000 8203 36797 26th March 12000 Pcs 14400 6852 7548 7th MarchMansoor KhanaliNo ratings yet

- 11 - Chapter 6 PDFDocument14 pages11 - Chapter 6 PDFMansoor KhanaliNo ratings yet

- 44 45 Spinning HRS CardingDocument2 pages44 45 Spinning HRS CardingMansoor KhanaliNo ratings yet

- AESA Air Engineering ProjectsDocument2 pagesAESA Air Engineering ProjectsMansoor KhanaliNo ratings yet

- Economizer 01 No. S. # Description SizeDocument1 pageEconomizer 01 No. S. # Description SizeMansoor KhanaliNo ratings yet

- Developing An Incentive Scheme For A ProjectDocument14 pagesDeveloping An Incentive Scheme For A ProjectMansoor KhanaliNo ratings yet

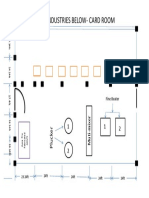

- Amna Below RoomDocument1 pageAmna Below RoomMansoor KhanaliNo ratings yet

- Mantex Carbon BobbinsDocument2 pagesMantex Carbon BobbinsMansoor KhanaliNo ratings yet

- Stenter Exhaust Heat Recovery For Combustion Air PreheatingDocument17 pagesStenter Exhaust Heat Recovery For Combustion Air PreheatingMansoor Khanali100% (1)

- Hall Exb 4Document2 pagesHall Exb 4Mansoor KhanaliNo ratings yet

- Complex Plant For Denim Yarn Spinning, Fabric Weaving, Finishing and Garment ProductionDocument1 pageComplex Plant For Denim Yarn Spinning, Fabric Weaving, Finishing and Garment ProductionMansoor KhanaliNo ratings yet

- YarnsDocument2 pagesYarnsvin_sinNo ratings yet

- TB1-004 Boiler Water CarryoverDocument2 pagesTB1-004 Boiler Water Carryoverjesus_manrique2753100% (2)

- Electrical Knowledge - Transmission & Distribution MCQDocument28 pagesElectrical Knowledge - Transmission & Distribution MCQBaskar El100% (1)

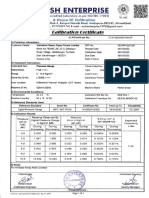

- 54-Pressure Gauge OIT Calibration CartificateDocument1 page54-Pressure Gauge OIT Calibration CartificateCustomer Support100% (1)

- 03 Doetsch PDFDocument10 pages03 Doetsch PDFNeelima MishraNo ratings yet

- Vibrations of Beams PDFDocument10 pagesVibrations of Beams PDFSathish UppuNo ratings yet

- KANNUR UNIVERSITY BTech.S1S2 SyllabusDocument23 pagesKANNUR UNIVERSITY BTech.S1S2 SyllabusManu K MNo ratings yet

- DTE150 2 150ccDocument18 pagesDTE150 2 150ccAlex GP ScarpazzaNo ratings yet

- Science 7 - Q3 - Episode 6 - SLMDocument5 pagesScience 7 - Q3 - Episode 6 - SLMCaryll BaylonNo ratings yet

- Objective:: Material Aluminium 7075 GradeDocument12 pagesObjective:: Material Aluminium 7075 Gradevishal yadav100% (1)

- Chapter 6. Sampling and Pulse Modulation: Husheng Li The University of TennesseeDocument19 pagesChapter 6. Sampling and Pulse Modulation: Husheng Li The University of TennesseeSampath KumarNo ratings yet

- Gambit Write Neutral FileDocument43 pagesGambit Write Neutral FileChez GabiNo ratings yet

- Gmaw STTDocument4 pagesGmaw STTAnonymous 0rt9KWmNNo ratings yet

- Emf - Theory-Ilovepdf-Compressed (1) - MinDocument1,133 pagesEmf - Theory-Ilovepdf-Compressed (1) - Minferenin gonsalesNo ratings yet

- Introduction To Organic Chemistry Unit 2Document25 pagesIntroduction To Organic Chemistry Unit 2DanelNo ratings yet

- 45 - 6575 - EE231 - 2013 - 1 - 1 - 1 - EE 231 - Lect - 02Document11 pages45 - 6575 - EE231 - 2013 - 1 - 1 - 1 - EE 231 - Lect - 02mohamed.abdmosbahNo ratings yet

- Anatomy and Structure of Human Sense OrgansDocument3 pagesAnatomy and Structure of Human Sense OrgansMelanie GialogoNo ratings yet

- Contact Rolling Bearing PDFDocument19 pagesContact Rolling Bearing PDFjanuzajmuchNo ratings yet

- Capacitor 2Document31 pagesCapacitor 2Shaheer MirzaNo ratings yet

- Physics Kcet 2023Document12 pagesPhysics Kcet 2023Prajwal MNo ratings yet

- Soln Class Problems CH 1-4 Spring 2017Document4 pagesSoln Class Problems CH 1-4 Spring 2017Syed Qassam Mustafa SadiqullahNo ratings yet

- Intro Thermo Public in Felt A PartialDocument67 pagesIntro Thermo Public in Felt A PartialWade WattsNo ratings yet

- Test Sets For 2019 AprilDocument15 pagesTest Sets For 2019 AprilnishuNo ratings yet

- A Self-Consistent GE MR For CEoS Derivation and Fugacity CoefficientsDocument4 pagesA Self-Consistent GE MR For CEoS Derivation and Fugacity Coefficientsmurdanetap957No ratings yet

- TMP EFBCDocument10 pagesTMP EFBCFrontiersNo ratings yet

- Dynamics Q1Document4 pagesDynamics Q1heheheNo ratings yet

- Unit 1 ExercisesDocument4 pagesUnit 1 ExercisesSung ParkNo ratings yet

- Chapter 4Document49 pagesChapter 4Ibrahim Al-HammadiNo ratings yet

- s10706 009 9295 7 PDFDocument11 pagess10706 009 9295 7 PDFjuan carlos molano toroNo ratings yet

- Activity # 1 States of Matter (Basic)Document6 pagesActivity # 1 States of Matter (Basic)ArebeeJayBelloNo ratings yet

- An Approach To Defining Tortuosity and CDocument7 pagesAn Approach To Defining Tortuosity and CvslogNo ratings yet