Professional Documents

Culture Documents

Technical Description

Technical Description

Uploaded by

pezhman arazpoorCopyright:

Available Formats

You might also like

- An Introduction To Scholarship Building AcademicDocument3 pagesAn Introduction To Scholarship Building AcademicNina Rosalee21% (29)

- Solution Manual For Theory and Design For Mechanical Measurements 6th Edition Richard S Figliola Donald e BeasleyDocument20 pagesSolution Manual For Theory and Design For Mechanical Measurements 6th Edition Richard S Figliola Donald e BeasleyLoriWilliamsonoqabx98% (46)

- Consultants List-ADCEDocument6 pagesConsultants List-ADCEJaveed Taji100% (3)

- Jankovic, J. 2001 Tourette's Syndrome. The New England Journal of Medicine 346.16 Pp.1184-1192Document9 pagesJankovic, J. 2001 Tourette's Syndrome. The New England Journal of Medicine 346.16 Pp.1184-1192Jesús Manuel CuevasNo ratings yet

- Antonia LoLordo Pierre Gassendi and The Birth of Early Modern PhilosophyDocument295 pagesAntonia LoLordo Pierre Gassendi and The Birth of Early Modern PhilosophyAllison Kasandra100% (3)

- Ge Jenbacher - Jgs 616dsDocument4 pagesGe Jenbacher - Jgs 616dsabdulkidwai2009No ratings yet

- HL-class Fact SheetDocument2 pagesHL-class Fact SheetadanasporNo ratings yet

- Guidelines For Technical Material: Unified English BrailleDocument93 pagesGuidelines For Technical Material: Unified English Brailleluana4No ratings yet

- Technical - Info MTU 20V4000L62Document7 pagesTechnical - Info MTU 20V4000L62Marvin Tejerina Garfias100% (1)

- Riello Rls M MX Ts0064uk03 Rev1Document32 pagesRiello Rls M MX Ts0064uk03 Rev1weweqweqwNo ratings yet

- Genelite GR12S NG Kubota 002Document4 pagesGenelite GR12S NG Kubota 002pecorepp.maesindoNo ratings yet

- TCG2000-NG: Standard Basic Module - Open TypeDocument6 pagesTCG2000-NG: Standard Basic Module - Open TypeСемен ГассеевNo ratings yet

- 116 MW Gas Based Power Plant - Tech Details PDFDocument5 pages116 MW Gas Based Power Plant - Tech Details PDFProject AnalysisNo ratings yet

- Fresh Diary & Juice Room Condesing UnitsDocument2 pagesFresh Diary & Juice Room Condesing Unitskskr_44No ratings yet

- SES 400kWDocument1 pageSES 400kWJafar ShojaNo ratings yet

- PUSH 400CTL K38热平衡表Document1 pagePUSH 400CTL K38热平衡表周庆卓No ratings yet

- Riello Gulliver RS5D Gas Burner df41c2dc.889 PDFDocument16 pagesRiello Gulliver RS5D Gas Burner df41c2dc.889 PDFVirgil CenariuNo ratings yet

- Riello Gulliver RS5D Gas Burner Df41c2dc.889Document16 pagesRiello Gulliver RS5D Gas Burner Df41c2dc.889Virgil CenariuNo ratings yet

- Condensador - Inverter - VRV - 171000btuDocument5 pagesCondensador - Inverter - VRV - 171000btuJuan Milton GonzalesNo ratings yet

- BITZER Output Data: Created On: 11.05.2023 13:44:33Document14 pagesBITZER Output Data: Created On: 11.05.2023 13:44:33Erymanthus NgânNo ratings yet

- 01 TS Cento 530 MAN NG C LB 50Hz S ENDocument2 pages01 TS Cento 530 MAN NG C LB 50Hz S ENDennis RamsumairNo ratings yet

- Modelo de Condensadora Puhy-P1200tkaDocument6 pagesModelo de Condensadora Puhy-P1200tkaBrandon Antonio Peralta LópezNo ratings yet

- CHP Unit TEDOM Cento T160 SPDocument4 pagesCHP Unit TEDOM Cento T160 SPHernan GiorgettiNo ratings yet

- Mtu 20V4000 DS4000: Diesel Generator SetDocument15 pagesMtu 20V4000 DS4000: Diesel Generator SetSlick72No ratings yet

- 20V4000 L33 FN Technical Data SheetDocument2 pages20V4000 L33 FN Technical Data SheetB-ENERGY INVESTMENTNo ratings yet

- Stratos MGM 160 Biogas: CogenerationDocument11 pagesStratos MGM 160 Biogas: CogenerationGeorge PircalabuNo ratings yet

- JMS 208 GS-B.L: Jenbacher Gas EnginesDocument4 pagesJMS 208 GS-B.L: Jenbacher Gas EnginesSunil WadekarNo ratings yet

- 2G Avus1000aDocument3 pages2G Avus1000ahamadaNo ratings yet

- Riello r40 G Ts0024uk04 Rev1Document24 pagesRiello r40 G Ts0024uk04 Rev1Patricio Fernandez BarbaNo ratings yet

- ENGINE DATA SHEET 350 KW 8V1600G70SDocument13 pagesENGINE DATA SHEET 350 KW 8V1600G70SAngel RiosNo ratings yet

- Jpflorez Cat-2000 NatGas EngineDocument1 pageJpflorez Cat-2000 NatGas Engineeduardo santosNo ratings yet

- 3516 1280kWDocument3 pages3516 1280kWKaala DNo ratings yet

- Peter Barr: Technical Specification and Scope of Supply MTU 20V4000 GS GG20V4000A1Document27 pagesPeter Barr: Technical Specification and Scope of Supply MTU 20V4000 GS GG20V4000A1Milad KerramatiNo ratings yet

- Model: Puhy-P450Tka (-BS) : 14-Ton Outdoor VRF Heat Pump SystemDocument4 pagesModel: Puhy-P450Tka (-BS) : 14-Ton Outdoor VRF Heat Pump SystemJesus SacramentoNo ratings yet

- Image Shown May Not Reflect Actual Configuration: Metric EnglishDocument3 pagesImage Shown May Not Reflect Actual Configuration: Metric EnglishUbarley CorreaNo ratings yet

- 40 kVA Specification SheetDocument2 pages40 kVA Specification SheetAlex MohanNo ratings yet

- Image Shown May Not Reflect Actual Configuration: Metric EnglishDocument3 pagesImage Shown May Not Reflect Actual Configuration: Metric EnglishUbarley CorreaNo ratings yet

- ENGINE DATA SHEET 300kW 6R1600G80SDocument11 pagesENGINE DATA SHEET 300kW 6R1600G80SAngel RiosNo ratings yet

- PCC790B Kta38 G1Document5 pagesPCC790B Kta38 G1Salih HusseinNo ratings yet

- 3516 - Technical Spec SheetDocument3 pages3516 - Technical Spec SheetAdewunmi OlufemiNo ratings yet

- Diesel Engine D 2842 LE21x Technical Data PreliminaryDocument3 pagesDiesel Engine D 2842 LE21x Technical Data PreliminaryAung MhNo ratings yet

- Riello Rls Ts0040uk03 Rev2Document32 pagesRiello Rls Ts0040uk03 Rev2Mantenimiento PuntoFlexNo ratings yet

- Press G - Ts0037uk01Document16 pagesPress G - Ts0037uk01Jacki FirdausNo ratings yet

- Jpflorez - Caterpillar - Gas Genset CG170-12 1200 KweDocument1 pageJpflorez - Caterpillar - Gas Genset CG170-12 1200 Kweeduardo santosNo ratings yet

- 6-3 - ODU CatalogueDocument61 pages6-3 - ODU CatalogueFareethAbdullahNo ratings yet

- Gps Waukesha 7042 BrochureDocument2 pagesGps Waukesha 7042 BrochureAlan SantosNo ratings yet

- J 312Document4 pagesJ 312shahzad 28390% (1)

- SCM 71, 80, 100Document3 pagesSCM 71, 80, 100Nguyen Anh HungNo ratings yet

- 30 kVA Specification SheetDocument2 pages30 kVA Specification SheetAlex MohanNo ratings yet

- Energy Consumption Breakdown of An Industrial Plant Is Given Below: Measured Data For Existing Chiller SystemsDocument2 pagesEnergy Consumption Breakdown of An Industrial Plant Is Given Below: Measured Data For Existing Chiller SystemsMeriem NguirNo ratings yet

- TSS DM8233 01 GS Epg 7335016Document3 pagesTSS DM8233 01 GS Epg 7335016MikaelNo ratings yet

- 3516 - Technical Spec SheetDocument3 pages3516 - Technical Spec Sheetadewunmi olufemiNo ratings yet

- PG Spec 20V4000DS3300 3130kVA 3F NOx 50HzDocument5 pagesPG Spec 20V4000DS3300 3130kVA 3F NOx 50HzkoosofehNo ratings yet

- BP400 Diesel Generating Set: Standby Power 50Hz Prime Power 50HzDocument5 pagesBP400 Diesel Generating Set: Standby Power 50Hz Prime Power 50HzAlwinNo ratings yet

- MTU 16V4000 DS2500: Diesel Generator SetDocument6 pagesMTU 16V4000 DS2500: Diesel Generator Setmohsen_cumminsNo ratings yet

- Project Survey: Selected CompressorsDocument4 pagesProject Survey: Selected CompressorsTedy ChriswandaNo ratings yet

- PG Spec 16V4000DS2500 2360kVA 3F NEA 50HzDocument5 pagesPG Spec 16V4000DS2500 2360kVA 3F NEA 50HzYousefNo ratings yet

- 200 kVA Specification SheetDocument2 pages200 kVA Specification SheetAlex MohanNo ratings yet

- Gas DM5645 03 GS Epg e 11859186 1Document5 pagesGas DM5645 03 GS Epg e 11859186 1Shoib MastoiNo ratings yet

- Cummins - 50 kVA SpecsDocument5 pagesCummins - 50 kVA SpecsJose Emmanuel A NavarroNo ratings yet

- Taurus T70 & Titan-130Document8 pagesTaurus T70 & Titan-130MRizwanSadiq313No ratings yet

- TRANE Product Report - ERTAF 355 HE - 5.6 - 11.2Document1 pageTRANE Product Report - ERTAF 355 HE - 5.6 - 11.2ZeeshanNo ratings yet

- AS-09UR4SGNPQ-service Manual PDFDocument51 pagesAS-09UR4SGNPQ-service Manual PDFColesha BarukaNo ratings yet

- Fluids and Lubricants SpecificationDocument46 pagesFluids and Lubricants Specificationpezhman arazpoorNo ratings yet

- 17 Gas Mobile Marine Arnd LielhammerDocument37 pages17 Gas Mobile Marine Arnd Lielhammerpezhman arazpoorNo ratings yet

- Hand-Held Refractometer For Brix: Patent Specifications TableDocument32 pagesHand-Held Refractometer For Brix: Patent Specifications Tablepezhman arazpoorNo ratings yet

- MMC PDFDocument161 pagesMMC PDFpezhman arazpoorNo ratings yet

- MCQ Question Answers Class 11 Physics Chapter 4 Motion in A PlaneDocument8 pagesMCQ Question Answers Class 11 Physics Chapter 4 Motion in A PlaneDisha Tripathi - 10-ENo ratings yet

- (1996) JOSA 13 Space-Bandwidth Product of Optical Signals and SyDocument4 pages(1996) JOSA 13 Space-Bandwidth Product of Optical Signals and Sythanhevt92No ratings yet

- Enrichment Activities 1Document2 pagesEnrichment Activities 1Maden betoNo ratings yet

- Industry Profile: K.S.S.K LTD, HaveriDocument42 pagesIndustry Profile: K.S.S.K LTD, HaveriManju PalegarNo ratings yet

- Xdr2 Memory ArchitectureDocument2 pagesXdr2 Memory ArchitectureElizabethNo ratings yet

- RV A. Paler: Technical SkillsDocument5 pagesRV A. Paler: Technical SkillsRv PalerNo ratings yet

- Pile Load Test MethodologyDocument4 pagesPile Load Test MethodologyAkhilesh Dwivedi100% (1)

- Power ResourcesDocument14 pagesPower ResourcesDawoodNo ratings yet

- Patrol GR: GI MA EM LC EC FE CL MT Automatic Transmission AT TF PD FA RA BR ST RS BT HA EL IDXDocument2 pagesPatrol GR: GI MA EM LC EC FE CL MT Automatic Transmission AT TF PD FA RA BR ST RS BT HA EL IDXAttila SomorjaiNo ratings yet

- Writing An ArticleDocument11 pagesWriting An ArticleNozima ToirovaNo ratings yet

- English EssayDocument32 pagesEnglish Essayapi-3731661100% (3)

- Love of Radhe-KrishnaDocument3 pagesLove of Radhe-KrishnaavncntnNo ratings yet

- Buddha and His ContemporariesDocument7 pagesBuddha and His ContemporariesAlok VermaNo ratings yet

- Cambridge International AS & A Level: BIOLOGY 9700/32Document16 pagesCambridge International AS & A Level: BIOLOGY 9700/32For GamingNo ratings yet

- Steps: To Personal EvangelismDocument20 pagesSteps: To Personal EvangelismDwayne Bob LerionNo ratings yet

- STULZ WIB 67C 0811 en PDFDocument49 pagesSTULZ WIB 67C 0811 en PDFJaime MendozaNo ratings yet

- 6 Speed Automatic Gearbox 09g EngDocument241 pages6 Speed Automatic Gearbox 09g EngGime PedrozaNo ratings yet

- Function GeneratorDocument5 pagesFunction GeneratorvenkumaniNo ratings yet

- Untitled: Pandas PD OsDocument55 pagesUntitled: Pandas PD OsGustavo Cano GallegosNo ratings yet

- Crystal Ball Installation GuideDocument40 pagesCrystal Ball Installation Guidebogdann_damianNo ratings yet

- Ibr CalculationsDocument9 pagesIbr CalculationsoperationmanagerNo ratings yet

- PR'S A-ZDocument65 pagesPR'S A-ZJesusNo ratings yet

- Counterfeit and Fraudulent Items - Mitigating The Increasing Risk - Rev1 of 1019163Document128 pagesCounterfeit and Fraudulent Items - Mitigating The Increasing Risk - Rev1 of 1019163diNo ratings yet

- Understanding The Gender Pay Gap: Women in Business and ManagementDocument8 pagesUnderstanding The Gender Pay Gap: Women in Business and Managementmostafa aliNo ratings yet

Technical Description

Technical Description

Uploaded by

pezhman arazpoorOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Description

Technical Description

Uploaded by

pezhman arazpoorCopyright:

Available Formats

Technical Description

.. GB...

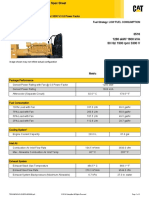

Genset without heat recovery box

AoE 20V4000L62 (robust)

1. Ratings and Emissions

For operation on NATURAL GAS

Methan number MZ ≥ 80

Low heat value (LHV) Hu = 8,0-11,5 kWh/m³n

Cooling water temperature 90 / 78 °C

Genset with synchronous generator for generating 3Ph, 50Hz

Intake air temperature 30 - 40 °C

st

Gas mixture cooler, intern (1 stage HT) integrated

Gas mixture cooler, extern (2

nd

stage LT) 53 °C

Nox < 500 mg/mn

3

1.1 Continuous Operating Data (100%)

8% tolerance for thermal outputs and 5% for total energy input listed. Performance data in accordance with ISO

3064. All data apply to continuous operation. Data for site operating conditions other than those mentioned,

available on demand. Max. reactive power in kVA, resp. nominal current acc. to nominal output of the generator.

AGG2500ME93

Generator voltage 400 V

Electrical output of generator (no overload capacity) 1948 kW el

st

Thermal output (Engine cooling / lube oil / 1 stage HT mixture

1244 kW th

cooler)

nd

Thermal output (2 stage LT mixture cooling) 99 kW th

Total energy input 4843 kW

1.2 Part Load Data (75 %)

Generator voltage 400 V

Electrical output of generator 1461 kW el

st

Thermal output (Engine cooling / lube oil / 1 stage HT mixture

922 kW th

cooler)

nd

Thermal output (2 stage LT mixture cooling) 72 kW th

Total energy input 3713 kW

1.3 Part Load Data (50 %)

Generator voltage 400 V

Electrical output of generator 972 kW el

st

Thermal output (Engine cooling / lube oil / 1 stage HT mixture

650 kW th

cooler)

nd

Thermal output (2 stage LT mixture cooling) 49 kW th

Total energy input 2600 kW

MTU Onsite Energy Systems GmbH

Rotthofer Straße 8, 94099 Ruhstorf / Germany / T +49 8531 9782-0 / www.mtu-online.com / www.aggretech.de

Geschäftsführung / Board of Management Hubert Diener (CEO), Stephan Hoffmann (CFO) Sitz der Gesellschaft / Domicile Ruhstorf

Handelsregister / Register Court Passau HRB 8570 USt-Ident-Nr. / V.A.T No. DE 249818731

QM zertifiziert nach / QM certified ISO 9001:2008

Seite/Sheet 1 von/of 9

Technical Description

.. GB...

1.4 Pollutant Emissions

Emission values related to dry exhaust gas with 5 % O2. (For exhaust gas volume flow see 3.5)

3

NOx, stated as NO2 < 500 mg/mn

3

CO, without catalyst <1000 mg/mn

3

Formaldehyde, without catalyst <140 mg/mn

3

CO, with catalyst (optional, delivered loose) <300 mg/mn

3

Formaldehyde, with catalyst (optional, delivered loose) <60 mg/mn

2 Design Principles / Scope of Supply

- Engine and flange-mounted alternator (SAE 00 housing) are connected via a torsionally resilient coupling and

mounted to welded steel base frame.

- Standby heater

2.1 Engine plus Accessories

Otto-Gas-Engine MTU 20V4000L62

Cyl. arrangement, no. of cyl. V 20

Bore / stroke 170 / 210 mm

Volume 95,33 Litre

Speed 1500 1/min

Mean piston speed 10,5 m/s

Compression ratio 10, 1:1

Mean effective pressure 16,8 bar

Standard power acc. to ISO 3046, (no overload capacity) 2000 kW mech

Specific full-load consumption (tolerance 5 %) 2,42 kWh/kWhmech

Gas consumption (based on LHV = 10,03 kWh/m3n) 482,9 3

m /h

Lube oil consumption (not guaranteed, at rated load and after 1000

0,3

Oh) g/kWhmech

Basic Engine

- Monobloc grey cast crankcase with inspection ports, flywheel housing SAE 00, flywheel 21“ cast iron oil pan

- Forged crankshaft

- Forged connecting rods

- Four-valve, individual cylinder heads with central pre-chamber armoured valves with „Rotocap“ rotators

- Light-metal solid-skirt pistons with oil cooling duct, piston cooling via oil spray nozzles

Mixture Formation

- Air intake via dry-type engine-mounted air filters

- Venturi type air-gas mixer with gas supply via electronically controlled gas metering valve

Turbocharging

- Turbocharger for gas-air mixture compression

- Two-stage mixture cooling

- Throttles between mixture coolers and intake manifold

MTU Onsite Energy Systems GmbH

Rotthofer Straße 8, 94099 Ruhstorf / Germany / T +49 8531 9782-0 / www.mtu-online.com / www.aggretech.de

Geschäftsführung / Board of Management Hubert Diener (CEO), Stephan Hoffmann (CFO) Sitz der Gesellschaft / Domicile Ruhstorf

Handelsregister / Register Court Passau HRB 8570 USt-Ident-Nr. / V.A.T No. DE 249818731

QM zertifiziert nach / QM certified ISO 9001:2008

Seite/Sheet 2 von/of 9

Technical Description

.. GB...

Exhaust System

- Dry-type, insulated exhaust manifolds in the engine Vee

Lube Oil System

- Engine mounted heat exchanger

- Lube oil filters with replaceable filter elements

- Engine-mounted device for automatic oil level control

- Oil dipstick

- Closed crankcase venting system with oil separator connected to mixture piping before turbo charger

- Connections for oil refill and oil draining

Cooling System (2-circuit)

- High temperature circuit for lube oil cooling, 1st stage of mixture cooling and engine jacket

- Connections with counter-flanges for external cooling- or heat recovery

system

- Integrated cooling preheating unit

Starting System

- Electric starter (2x 9 kW, 24 VDC)

Ignition System

- Microprocessor-controlled high-voltage spark-ignition system with low voltage distribution, no moving parts, no

wear

- Automatic control for ignition energy adjustment

- Variable timing control

- Timing sensors at camshaft and crankshaft

- One ignition coil per cylinder

- Industrial spark plugs

2.2 Generator

Self-regulating, brushless revolving-field synchronous generator with built-in exciter, voltage and cos-phi regulator,

designed to VDE 0530, radio interference class N, low-harmonic design.

Generator voltage 400 V

Rating (F) 3000 kVA

Insulation class H

Temperature-rise rating F

Cos-phi * 1,0 - 0,8

Frequency 50 Hz

Speed 1500 1/min

Efficiency 1948kW cos-phi 1 96,5 %

Stator connection Star

Voltage tolerance ±5 %

Frequency tolerance ±5 %

Max. ambient temperature. 40 °C

Installation altitude max. 1000 m

Type of protection IP 23

MTU Onsite Energy Systems GmbH

Rotthofer Straße 8, 94099 Ruhstorf / Germany / T +49 8531 9782-0 / www.mtu-online.com / www.aggretech.de

Geschäftsführung / Board of Management Hubert Diener (CEO), Stephan Hoffmann (CFO) Sitz der Gesellschaft / Domicile Ruhstorf

Handelsregister / Register Court Passau HRB 8570 USt-Ident-Nr. / V.A.T No. DE 249818731

QM zertifiziert nach / QM certified ISO 9001:2008

Seite/Sheet 3 von/of 9

Technical Description

.. GB...

*) Cos-phi must be over the whole power range in the defined range. Only inductive reactive power admissible

(over-erected).

In case of nominal mains voltage variations by ± 2 %, an automatic voltage adjustment must be used.

2.3 Gas Supply

Gas regulation lines delivered loose, components approved per Directive for Gas Components 90/356/EWG

Gas Regulation Line

- Gas filter

- two solenoid valves (or double solenoid valve)

- Low pressure regulator

- valve leakage monitor

- flexible stainless steel hose

2.4 Controller of Genset

EM93

- Operation and visualization

- Control of auxiliary drives (cogeneration unit / extern)

- Connection / seperation of the generator to/from the

grid

-

Control of generator and grid protection functions, see separate description "Technical Description MMC 4000

control"

EMU7

- Single exhaust temperature monitoring (cylinderhead)

SAM

- Providing CANopen interface

- Lube oil make up

- Monitoring of minimum load

Ignition

- Electronic ignition system

- Ignition time setting

- Speed monitoring

Knocking monitoring AKR

- Acoustic knocking monitoring system

- Individual ignition timing adjustment per cylinder

3 Technical Data Design / Operation

3.1 Operating Media

The binding specifications for cooling water, fuel, lube oil, exhaust condensate and heating water are stipulated in

the relevant MTU operating media regulations.

Values for cooling / heating water are based on water without antifrost and corrosions additives.

Admissible antifrost and corrosions additives see operating media. Values in brackets [ ] refer to 35% Glycol.

MTU Onsite Energy Systems GmbH

Rotthofer Straße 8, 94099 Ruhstorf / Germany / T +49 8531 9782-0 / www.mtu-online.com / www.aggretech.de

Geschäftsführung / Board of Management Hubert Diener (CEO), Stephan Hoffmann (CFO) Sitz der Gesellschaft / Domicile Ruhstorf

Handelsregister / Register Court Passau HRB 8570 USt-Ident-Nr. / V.A.T No. DE 249818731

QM zertifiziert nach / QM certified ISO 9001:2008

Seite/Sheet 4 von/of 9

Technical Description

.. GB...

3.2 Filling Quantities

Lube oil – quantity (first filling) 378 Liter

Lube oil – quantity (consecutive oil changes) 350 Liter

Engine cooling water, HT 310 Liter

Mixture cooling water, LT (without recooler and pipes) 23 Liter

3.3 Heat Generation

Engine Cooling (engine block with lube oil and 1st stage HT mixture cooling)

Thermal output (8 % tolerance) 1244 kW

Cooling water temperature, in- / outlet 78/90 °C

3

Cooling water volume flow 94 [101] m /h

Pressure loss 2,6 [3,0] bar

System pressure permitted max. 6,0 bar

Cooling water temperature, min. 40 °C

Mixture Cooling (2nd stage LT; discharged via radiator)

Thermal output (8 % tolerance) 99 kW

3

Mixture cooling water volume flow (8 % tolerance) 30 m /h

Inlet temperature mixture cooling water max. 52 °C

Outlet temperature mixture cooling water max. 55 °C

Max. permissible pressure loss outside the heat recovery 0,5 bar

System pressure permitted max. 6,0 bar

Note information pressure control valve.

3.4 Combustion Air / Ventilation

Heat radiated from the genset

(engine and generator without adjoining pipes) 126 kW

Engine room ventilation

Minimum intake air volume flow for engine room cooling.

3

(The engine room ventilation has to be calculated and adjusted 48237 m /h

according to the requirements for gaseous fuels valid at the

installation site)

3

Ventilation air volume flow 39443 m /h

3

Combustion air volume flow 8067 mn /h

Intake air temperature min.

(for other temperatures the limit values must be adapted after 30 °C

consultation)

Temperature difference intake / ventilation max. <10 K

max. permissible intake negative pressure at inlet air filter 3 mbar

MTU Onsite Energy Systems GmbH

Rotthofer Straße 8, 94099 Ruhstorf / Germany / T +49 8531 9782-0 / www.mtu-online.com / www.aggretech.de

Geschäftsführung / Board of Management Hubert Diener (CEO), Stephan Hoffmann (CFO) Sitz der Gesellschaft / Domicile Ruhstorf

Handelsregister / Register Court Passau HRB 8570 USt-Ident-Nr. / V.A.T No. DE 249818731

QM zertifiziert nach / QM certified ISO 9001:2008

Seite/Sheet 5 von/of 9

Technical Description

.. GB...

3.5 Exhaust Gas (Exhaust gas heat exchanger not included in scope of supply, optional)

Thermal output by 120 °C (8 %

tolerance) 1089 kW

Exhaust temperature (turbocharger outlet) 444 °C

Exhaust gas mass flow, dry 10027 kg/h

Exhaust gas mass flow, moist 10788 kg/h

3

Exhaust gas volume flow, dry (0 °C, 1013 mbar) 7607 mn /h

3

Exhaust gas volume flow, moist (0 °C, 1013 mbar) 8498 mn /h

Permissible back-pressure downstream of engine min. /

30 / 60 mbar

max.

In multi-genset systems, separate exhaust piping for each genset is recommended.

If a common exhaust header system is installed, exhaust flow back into any non-operationing gensets must be

avoided by use of a 100 % gastight exhaust shut-off flap.

In the range of partial load the exhaustive temperature rises up to 550 °C. In case of use of catalyzers, due to the

exothermic reaction the exhaustive temperature may increase up to 600 °C.

MTU Onsite Energy Systems GmbH

Rotthofer Straße 8, 94099 Ruhstorf / Germany / T +49 8531 9782-0 / www.mtu-online.com / www.aggretech.de

Geschäftsführung / Board of Management Hubert Diener (CEO), Stephan Hoffmann (CFO) Sitz der Gesellschaft / Domicile Ruhstorf

Handelsregister / Register Court Passau HRB 8570 USt-Ident-Nr. / V.A.T No. DE 249818731

QM zertifiziert nach / QM certified ISO 9001:2008

Seite/Sheet 6 von/of 9

Technical Description

.. GB...

3.6 Sound Levels

Engine surface noise emitted by the genset

(distance 1 m, free field measurement, Tolerance +5 dB for single 1/3-octave band, +2 db(A) for total

A-weighted level)

Frequency (Hz) Sound pressure levels (dB)

12,5

16

20

25 67,6

31,5 64,6

40 67,4

50 71,5

63 77,7

80 80,9

100 82,8

125 95,4

160 83,3

200 87,0

250 83,8

315 87,4

400 95,7

500 90,8

630 88,5

800 88,5

1000 89,6

1250 87,7

1600 86,8

2000 84,9

2500 83,3

3150 82,6

4000 80,5

5000 82,2

6300 100,4

8000 83,9

10k 77,9

Lin dB dB (A)

Sum of sound pressure levels (dB) 104,1 102,4

Sound power levels dB (A) 122,6

MTU Onsite Energy Systems GmbH

Rotthofer Straße 8, 94099 Ruhstorf / Germany / T +49 8531 9782-0 / www.mtu-online.com / www.aggretech.de

Geschäftsführung / Board of Management Hubert Diener (CEO), Stephan Hoffmann (CFO) Sitz der Gesellschaft / Domicile Ruhstorf

Handelsregister / Register Court Passau HRB 8570 USt-Ident-Nr. / V.A.T No. DE 249818731

QM zertifiziert nach / QM certified ISO 9001:2008

Seite/Sheet 7 von/of 9

Technical Description

.. GB...

undampened Exhaust noise

(distance of 1 m from outlet, Tolerance +5 dB for single 1/3-octave band, +3 db(A) for total A-weighted

level)

Frequency (Hz) Sound pressure levels (dB)

12,5

16

20 78,8

25 83,9

31,5 83,3

40 90,5

50 95,1

63 105,1

80 106,4

100 103,2

125 107,8

160 103,8

200 101,2

250 95,0

315 100,0

400 95,7

500 92,7

630 89,1

800 87,6

1000 85,2

1250 89,4

1600 85,2

2000 83,7

2500 83,8

3150 83,2

4000 77,8

5000 72,8

6300 69,5

8000 66,7

10k 65,2

Line dB dB (A)

Sum of sound pressure levels (dB) 113,4 101,1

Sound power levels dB (A) 113,1

3.7 Connections

Unless stated otherwise, the connecting flanges are to DIN 2501.

Nominal diameters and pressures are as follows:

Safety gas line * DN100 / PN16

Exhaust gas outlet (expansion

joint) 2x DN250 / PN6

Cooling water in- / outlet DN100 / PN16

Mixture cooling water in- / outlet DN50 / PN 16

*) Dimension depending on gas pressure and gas quality

3.8 Paints and Dimensions of the Genset

For binding dimensions please refer to the attached drawing. Number AGG2500ME93

Data are subject to change without notice in the interest of further development.

MTU Onsite Energy Systems GmbH

Rotthofer Straße 8, 94099 Ruhstorf / Germany / T +49 8531 9782-0 / www.mtu-online.com / www.aggretech.de

Geschäftsführung / Board of Management Hubert Diener (CEO), Stephan Hoffmann (CFO) Sitz der Gesellschaft / Domicile Ruhstorf

Handelsregister / Register Court Passau HRB 8570 USt-Ident-Nr. / V.A.T No. DE 249818731

QM zertifiziert nach / QM certified ISO 9001:2008

Seite/Sheet 8 von/of 9

Technical Description

.. GB...

MTU Onsite Energy Systems GmbH

Rotthofer Straße 8, 94099 Ruhstorf / Germany / T +49 8531 9782-0 / www.mtu-online.com / www.aggretech.de

Geschäftsführung / Board of Management Hubert Diener (CEO), Stephan Hoffmann (CFO) Sitz der Gesellschaft / Domicile Ruhstorf

Handelsregister / Register Court Passau HRB 8570 USt-Ident-Nr. / V.A.T No. DE 249818731

QM zertifiziert nach / QM certified ISO 9001:2008

Seite/Sheet 9 von/of 9

You might also like

- An Introduction To Scholarship Building AcademicDocument3 pagesAn Introduction To Scholarship Building AcademicNina Rosalee21% (29)

- Solution Manual For Theory and Design For Mechanical Measurements 6th Edition Richard S Figliola Donald e BeasleyDocument20 pagesSolution Manual For Theory and Design For Mechanical Measurements 6th Edition Richard S Figliola Donald e BeasleyLoriWilliamsonoqabx98% (46)

- Consultants List-ADCEDocument6 pagesConsultants List-ADCEJaveed Taji100% (3)

- Jankovic, J. 2001 Tourette's Syndrome. The New England Journal of Medicine 346.16 Pp.1184-1192Document9 pagesJankovic, J. 2001 Tourette's Syndrome. The New England Journal of Medicine 346.16 Pp.1184-1192Jesús Manuel CuevasNo ratings yet

- Antonia LoLordo Pierre Gassendi and The Birth of Early Modern PhilosophyDocument295 pagesAntonia LoLordo Pierre Gassendi and The Birth of Early Modern PhilosophyAllison Kasandra100% (3)

- Ge Jenbacher - Jgs 616dsDocument4 pagesGe Jenbacher - Jgs 616dsabdulkidwai2009No ratings yet

- HL-class Fact SheetDocument2 pagesHL-class Fact SheetadanasporNo ratings yet

- Guidelines For Technical Material: Unified English BrailleDocument93 pagesGuidelines For Technical Material: Unified English Brailleluana4No ratings yet

- Technical - Info MTU 20V4000L62Document7 pagesTechnical - Info MTU 20V4000L62Marvin Tejerina Garfias100% (1)

- Riello Rls M MX Ts0064uk03 Rev1Document32 pagesRiello Rls M MX Ts0064uk03 Rev1weweqweqwNo ratings yet

- Genelite GR12S NG Kubota 002Document4 pagesGenelite GR12S NG Kubota 002pecorepp.maesindoNo ratings yet

- TCG2000-NG: Standard Basic Module - Open TypeDocument6 pagesTCG2000-NG: Standard Basic Module - Open TypeСемен ГассеевNo ratings yet

- 116 MW Gas Based Power Plant - Tech Details PDFDocument5 pages116 MW Gas Based Power Plant - Tech Details PDFProject AnalysisNo ratings yet

- Fresh Diary & Juice Room Condesing UnitsDocument2 pagesFresh Diary & Juice Room Condesing Unitskskr_44No ratings yet

- SES 400kWDocument1 pageSES 400kWJafar ShojaNo ratings yet

- PUSH 400CTL K38热平衡表Document1 pagePUSH 400CTL K38热平衡表周庆卓No ratings yet

- Riello Gulliver RS5D Gas Burner df41c2dc.889 PDFDocument16 pagesRiello Gulliver RS5D Gas Burner df41c2dc.889 PDFVirgil CenariuNo ratings yet

- Riello Gulliver RS5D Gas Burner Df41c2dc.889Document16 pagesRiello Gulliver RS5D Gas Burner Df41c2dc.889Virgil CenariuNo ratings yet

- Condensador - Inverter - VRV - 171000btuDocument5 pagesCondensador - Inverter - VRV - 171000btuJuan Milton GonzalesNo ratings yet

- BITZER Output Data: Created On: 11.05.2023 13:44:33Document14 pagesBITZER Output Data: Created On: 11.05.2023 13:44:33Erymanthus NgânNo ratings yet

- 01 TS Cento 530 MAN NG C LB 50Hz S ENDocument2 pages01 TS Cento 530 MAN NG C LB 50Hz S ENDennis RamsumairNo ratings yet

- Modelo de Condensadora Puhy-P1200tkaDocument6 pagesModelo de Condensadora Puhy-P1200tkaBrandon Antonio Peralta LópezNo ratings yet

- CHP Unit TEDOM Cento T160 SPDocument4 pagesCHP Unit TEDOM Cento T160 SPHernan GiorgettiNo ratings yet

- Mtu 20V4000 DS4000: Diesel Generator SetDocument15 pagesMtu 20V4000 DS4000: Diesel Generator SetSlick72No ratings yet

- 20V4000 L33 FN Technical Data SheetDocument2 pages20V4000 L33 FN Technical Data SheetB-ENERGY INVESTMENTNo ratings yet

- Stratos MGM 160 Biogas: CogenerationDocument11 pagesStratos MGM 160 Biogas: CogenerationGeorge PircalabuNo ratings yet

- JMS 208 GS-B.L: Jenbacher Gas EnginesDocument4 pagesJMS 208 GS-B.L: Jenbacher Gas EnginesSunil WadekarNo ratings yet

- 2G Avus1000aDocument3 pages2G Avus1000ahamadaNo ratings yet

- Riello r40 G Ts0024uk04 Rev1Document24 pagesRiello r40 G Ts0024uk04 Rev1Patricio Fernandez BarbaNo ratings yet

- ENGINE DATA SHEET 350 KW 8V1600G70SDocument13 pagesENGINE DATA SHEET 350 KW 8V1600G70SAngel RiosNo ratings yet

- Jpflorez Cat-2000 NatGas EngineDocument1 pageJpflorez Cat-2000 NatGas Engineeduardo santosNo ratings yet

- 3516 1280kWDocument3 pages3516 1280kWKaala DNo ratings yet

- Peter Barr: Technical Specification and Scope of Supply MTU 20V4000 GS GG20V4000A1Document27 pagesPeter Barr: Technical Specification and Scope of Supply MTU 20V4000 GS GG20V4000A1Milad KerramatiNo ratings yet

- Model: Puhy-P450Tka (-BS) : 14-Ton Outdoor VRF Heat Pump SystemDocument4 pagesModel: Puhy-P450Tka (-BS) : 14-Ton Outdoor VRF Heat Pump SystemJesus SacramentoNo ratings yet

- Image Shown May Not Reflect Actual Configuration: Metric EnglishDocument3 pagesImage Shown May Not Reflect Actual Configuration: Metric EnglishUbarley CorreaNo ratings yet

- 40 kVA Specification SheetDocument2 pages40 kVA Specification SheetAlex MohanNo ratings yet

- Image Shown May Not Reflect Actual Configuration: Metric EnglishDocument3 pagesImage Shown May Not Reflect Actual Configuration: Metric EnglishUbarley CorreaNo ratings yet

- ENGINE DATA SHEET 300kW 6R1600G80SDocument11 pagesENGINE DATA SHEET 300kW 6R1600G80SAngel RiosNo ratings yet

- PCC790B Kta38 G1Document5 pagesPCC790B Kta38 G1Salih HusseinNo ratings yet

- 3516 - Technical Spec SheetDocument3 pages3516 - Technical Spec SheetAdewunmi OlufemiNo ratings yet

- Diesel Engine D 2842 LE21x Technical Data PreliminaryDocument3 pagesDiesel Engine D 2842 LE21x Technical Data PreliminaryAung MhNo ratings yet

- Riello Rls Ts0040uk03 Rev2Document32 pagesRiello Rls Ts0040uk03 Rev2Mantenimiento PuntoFlexNo ratings yet

- Press G - Ts0037uk01Document16 pagesPress G - Ts0037uk01Jacki FirdausNo ratings yet

- Jpflorez - Caterpillar - Gas Genset CG170-12 1200 KweDocument1 pageJpflorez - Caterpillar - Gas Genset CG170-12 1200 Kweeduardo santosNo ratings yet

- 6-3 - ODU CatalogueDocument61 pages6-3 - ODU CatalogueFareethAbdullahNo ratings yet

- Gps Waukesha 7042 BrochureDocument2 pagesGps Waukesha 7042 BrochureAlan SantosNo ratings yet

- J 312Document4 pagesJ 312shahzad 28390% (1)

- SCM 71, 80, 100Document3 pagesSCM 71, 80, 100Nguyen Anh HungNo ratings yet

- 30 kVA Specification SheetDocument2 pages30 kVA Specification SheetAlex MohanNo ratings yet

- Energy Consumption Breakdown of An Industrial Plant Is Given Below: Measured Data For Existing Chiller SystemsDocument2 pagesEnergy Consumption Breakdown of An Industrial Plant Is Given Below: Measured Data For Existing Chiller SystemsMeriem NguirNo ratings yet

- TSS DM8233 01 GS Epg 7335016Document3 pagesTSS DM8233 01 GS Epg 7335016MikaelNo ratings yet

- 3516 - Technical Spec SheetDocument3 pages3516 - Technical Spec Sheetadewunmi olufemiNo ratings yet

- PG Spec 20V4000DS3300 3130kVA 3F NOx 50HzDocument5 pagesPG Spec 20V4000DS3300 3130kVA 3F NOx 50HzkoosofehNo ratings yet

- BP400 Diesel Generating Set: Standby Power 50Hz Prime Power 50HzDocument5 pagesBP400 Diesel Generating Set: Standby Power 50Hz Prime Power 50HzAlwinNo ratings yet

- MTU 16V4000 DS2500: Diesel Generator SetDocument6 pagesMTU 16V4000 DS2500: Diesel Generator Setmohsen_cumminsNo ratings yet

- Project Survey: Selected CompressorsDocument4 pagesProject Survey: Selected CompressorsTedy ChriswandaNo ratings yet

- PG Spec 16V4000DS2500 2360kVA 3F NEA 50HzDocument5 pagesPG Spec 16V4000DS2500 2360kVA 3F NEA 50HzYousefNo ratings yet

- 200 kVA Specification SheetDocument2 pages200 kVA Specification SheetAlex MohanNo ratings yet

- Gas DM5645 03 GS Epg e 11859186 1Document5 pagesGas DM5645 03 GS Epg e 11859186 1Shoib MastoiNo ratings yet

- Cummins - 50 kVA SpecsDocument5 pagesCummins - 50 kVA SpecsJose Emmanuel A NavarroNo ratings yet

- Taurus T70 & Titan-130Document8 pagesTaurus T70 & Titan-130MRizwanSadiq313No ratings yet

- TRANE Product Report - ERTAF 355 HE - 5.6 - 11.2Document1 pageTRANE Product Report - ERTAF 355 HE - 5.6 - 11.2ZeeshanNo ratings yet

- AS-09UR4SGNPQ-service Manual PDFDocument51 pagesAS-09UR4SGNPQ-service Manual PDFColesha BarukaNo ratings yet

- Fluids and Lubricants SpecificationDocument46 pagesFluids and Lubricants Specificationpezhman arazpoorNo ratings yet

- 17 Gas Mobile Marine Arnd LielhammerDocument37 pages17 Gas Mobile Marine Arnd Lielhammerpezhman arazpoorNo ratings yet

- Hand-Held Refractometer For Brix: Patent Specifications TableDocument32 pagesHand-Held Refractometer For Brix: Patent Specifications Tablepezhman arazpoorNo ratings yet

- MMC PDFDocument161 pagesMMC PDFpezhman arazpoorNo ratings yet

- MCQ Question Answers Class 11 Physics Chapter 4 Motion in A PlaneDocument8 pagesMCQ Question Answers Class 11 Physics Chapter 4 Motion in A PlaneDisha Tripathi - 10-ENo ratings yet

- (1996) JOSA 13 Space-Bandwidth Product of Optical Signals and SyDocument4 pages(1996) JOSA 13 Space-Bandwidth Product of Optical Signals and Sythanhevt92No ratings yet

- Enrichment Activities 1Document2 pagesEnrichment Activities 1Maden betoNo ratings yet

- Industry Profile: K.S.S.K LTD, HaveriDocument42 pagesIndustry Profile: K.S.S.K LTD, HaveriManju PalegarNo ratings yet

- Xdr2 Memory ArchitectureDocument2 pagesXdr2 Memory ArchitectureElizabethNo ratings yet

- RV A. Paler: Technical SkillsDocument5 pagesRV A. Paler: Technical SkillsRv PalerNo ratings yet

- Pile Load Test MethodologyDocument4 pagesPile Load Test MethodologyAkhilesh Dwivedi100% (1)

- Power ResourcesDocument14 pagesPower ResourcesDawoodNo ratings yet

- Patrol GR: GI MA EM LC EC FE CL MT Automatic Transmission AT TF PD FA RA BR ST RS BT HA EL IDXDocument2 pagesPatrol GR: GI MA EM LC EC FE CL MT Automatic Transmission AT TF PD FA RA BR ST RS BT HA EL IDXAttila SomorjaiNo ratings yet

- Writing An ArticleDocument11 pagesWriting An ArticleNozima ToirovaNo ratings yet

- English EssayDocument32 pagesEnglish Essayapi-3731661100% (3)

- Love of Radhe-KrishnaDocument3 pagesLove of Radhe-KrishnaavncntnNo ratings yet

- Buddha and His ContemporariesDocument7 pagesBuddha and His ContemporariesAlok VermaNo ratings yet

- Cambridge International AS & A Level: BIOLOGY 9700/32Document16 pagesCambridge International AS & A Level: BIOLOGY 9700/32For GamingNo ratings yet

- Steps: To Personal EvangelismDocument20 pagesSteps: To Personal EvangelismDwayne Bob LerionNo ratings yet

- STULZ WIB 67C 0811 en PDFDocument49 pagesSTULZ WIB 67C 0811 en PDFJaime MendozaNo ratings yet

- 6 Speed Automatic Gearbox 09g EngDocument241 pages6 Speed Automatic Gearbox 09g EngGime PedrozaNo ratings yet

- Function GeneratorDocument5 pagesFunction GeneratorvenkumaniNo ratings yet

- Untitled: Pandas PD OsDocument55 pagesUntitled: Pandas PD OsGustavo Cano GallegosNo ratings yet

- Crystal Ball Installation GuideDocument40 pagesCrystal Ball Installation Guidebogdann_damianNo ratings yet

- Ibr CalculationsDocument9 pagesIbr CalculationsoperationmanagerNo ratings yet

- PR'S A-ZDocument65 pagesPR'S A-ZJesusNo ratings yet

- Counterfeit and Fraudulent Items - Mitigating The Increasing Risk - Rev1 of 1019163Document128 pagesCounterfeit and Fraudulent Items - Mitigating The Increasing Risk - Rev1 of 1019163diNo ratings yet

- Understanding The Gender Pay Gap: Women in Business and ManagementDocument8 pagesUnderstanding The Gender Pay Gap: Women in Business and Managementmostafa aliNo ratings yet