Professional Documents

Culture Documents

314 HW#1

314 HW#1

Uploaded by

Abdullah0 ratings0% found this document useful (0 votes)

27 views1 pageCopyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

0 ratings0% found this document useful (0 votes)

27 views1 page314 HW#1

314 HW#1

Uploaded by

AbdullahCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 1

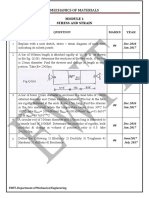

بسم هللا الرحمن الرحيم

Materials Engineering Department

Manufacturing Processes (0703314)

Homework #1 24/3/2020

______________________________________________________________________

Q1-A- Identify two advantages and two disadvantages of hot deformation versus cold

deformation of metals.

B- Account for each of the followings:

1. The stress in hot deformation depends on the strain rate while in cold

deformation, it depends on strain.

2. The multiplying factor for closed die forging process is higher than that for open

die forging process.

Q2- Starting from aluminum, ore show by using a suitable flow chart how aluminum

profile can be produced.

Q3- A cylinder, having an initial thickness of 8 cm and initial diameter of 6 cm, is

compressed by open die forging process at room temperature. The true strain to

fracture the cylinder is 2 and the governing deformation relationship is

. The lubricant used provides a friction coefficient of 0.2. The

process is limited by either platen yielding of fracture. If the yield stress of platens

is 1000 MPa, do the platens yield or does the specimen fracture?

Q4- The rolls are used to cold rolling a metal (K = 800 MPa, strain hardening exponent =

0.5). The rectangular shape is 12 cm wide and has an initial thickness of 2 mm. If the

contact length is 10 mm, Qp is 1.5, and the roll force is 300 kN, calculate the exit

thickness.

Good Luck

Dr. Raed Ma’ali

You might also like

- TSH5600G Welding SpotDocument6 pagesTSH5600G Welding SpotKrzysztof KołodziejczykNo ratings yet

- Excersises For Essentials and Engineering of MaterialsDocument5 pagesExcersises For Essentials and Engineering of MaterialsBraulio BolañosNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- 314 HW#1Document1 page314 HW#1AbdullahNo ratings yet

- HW#1Document1 pageHW#1salahyousef443No ratings yet

- PDF MEC3102 Tutorial No 1-ASSIGMENT 1Document4 pagesPDF MEC3102 Tutorial No 1-ASSIGMENT 1Beckham ChaileNo ratings yet

- Hot & Cold WorkingDocument18 pagesHot & Cold WorkingMadushan MadushaNo ratings yet

- A New Lead Alloy For Automotive Batteries Operating Under High TemperatureDocument7 pagesA New Lead Alloy For Automotive Batteries Operating Under High Temperatureehsan453No ratings yet

- Advanced Ceramics Excel in High-SpeedDocument4 pagesAdvanced Ceramics Excel in High-SpeedgzmyldsNo ratings yet

- Manukau Institute of Technology: Faculty of Mechanical Engineering and TradesDocument5 pagesManukau Institute of Technology: Faculty of Mechanical Engineering and Tradesrohit22eNo ratings yet

- 3094 HW ECBDocument2 pages3094 HW ECBradarskiNo ratings yet

- HW2 Mat e 202 W18Document5 pagesHW2 Mat e 202 W18TahirNo ratings yet

- High Speed SteelDocument6 pagesHigh Speed SteelLvl100% (1)

- 2002 - Forming Limit of Magnesium Alloy at Elevated Temperatures For Precision ForgingDocument8 pages2002 - Forming Limit of Magnesium Alloy at Elevated Temperatures For Precision ForgingNguyen Hoang DungNo ratings yet

- Class Tutorial 3 (24!8!16)Document1 pageClass Tutorial 3 (24!8!16)neelam1206sharma_310No ratings yet

- Assign 7Document2 pagesAssign 7Varun PatidarNo ratings yet

- Carbon Steel or Alloy and High Yield Point Steel Plates, Strips and Straps For Slight Drawings or Non-Severe Bending Standard No. 2 3 5 2Document13 pagesCarbon Steel or Alloy and High Yield Point Steel Plates, Strips and Straps For Slight Drawings or Non-Severe Bending Standard No. 2 3 5 2anhtho100% (1)

- Fatigue Crack Growth Behaviour of Nitrided and Shot Peened SpecimensDocument15 pagesFatigue Crack Growth Behaviour of Nitrided and Shot Peened SpecimenskarimNo ratings yet

- Analysis of Die Casting Tool Material: Keywords: Die Casting, Die Defect, Thermal Fatigue, Surface CracksDocument6 pagesAnalysis of Die Casting Tool Material: Keywords: Die Casting, Die Defect, Thermal Fatigue, Surface CrackshotschiNo ratings yet

- Metal Forming ProcessDocument10 pagesMetal Forming ProcessSiddharth ShahNo ratings yet

- Tutorial Last AnswerDocument9 pagesTutorial Last AnswerEswaran ManakorNo ratings yet

- Effects of Normalizing Processes On Microstructure and Impact Toughness in Ti-Bearing Weld Metal of Multilayer MAG Welded HSLA SteelDocument6 pagesEffects of Normalizing Processes On Microstructure and Impact Toughness in Ti-Bearing Weld Metal of Multilayer MAG Welded HSLA Steelarjun prajapatiNo ratings yet

- Review QuestionsDocument2 pagesReview QuestionsMinh Nguyễn AnhNo ratings yet

- The Microstructure and Mechanical Properties of Inconel 718 Fine Grain Ring ForgingDocument7 pagesThe Microstructure and Mechanical Properties of Inconel 718 Fine Grain Ring ForgingAnonymous lmCR3SkPrKNo ratings yet

- Deep Cryogenic Treatment For Aluminium AlloysDocument7 pagesDeep Cryogenic Treatment For Aluminium Alloysvishal shirsatNo ratings yet

- Ijetae 0712 58Document6 pagesIjetae 0712 58Prof. Arshad Noor Siddiqui (D/o Mechanical Engineering)No ratings yet

- Assignment ProcessDocument2 pagesAssignment ProcessMuhammad Nazmul Hassan KhanNo ratings yet

- Musonda 2018 IOP Conf. Ser. Mater. Sci. Eng. 423 012162Document7 pagesMusonda 2018 IOP Conf. Ser. Mater. Sci. Eng. 423 012162JUANNo ratings yet

- Metals 10 01087 v2Document15 pagesMetals 10 01087 v2Rameesha ImtiazNo ratings yet

- 2022-Dec ME-312 53Document2 pages2022-Dec ME-312 53Aakash TiwariNo ratings yet

- Hot and Cold Rolling of High Nitrogen Cr-Ni and CR-MN Austenitic Stainless SteelsDocument6 pagesHot and Cold Rolling of High Nitrogen Cr-Ni and CR-MN Austenitic Stainless SteelsLuana CarolineNo ratings yet

- Chapter 1Document12 pagesChapter 1LAOUAR BelgacemNo ratings yet

- QB All Module MomDocument11 pagesQB All Module MomRakshith GowdaNo ratings yet

- Assignment 1Document3 pagesAssignment 1Pawan Kumar GoyalNo ratings yet

- Ex. U78 Rec - MATERIALS. ALUMNES - NOU MESTALLADocument3 pagesEx. U78 Rec - MATERIALS. ALUMNES - NOU MESTALLAVicent J. Sala CamarenaNo ratings yet

- Final Exam Key AnswerDocument6 pagesFinal Exam Key Answergirma worku100% (1)

- APSC 278 Midterm Feb 13 2013 SolutionsDocument9 pagesAPSC 278 Midterm Feb 13 2013 SolutionsykfungNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityHerat HirparaNo ratings yet

- Modelling Microstructural and Mechanical Properties of Ferritic Ductile Cast IronDocument9 pagesModelling Microstructural and Mechanical Properties of Ferritic Ductile Cast IronpdonelanNo ratings yet

- Assignment 1 ENG 173 METAL FORMINGDocument2 pagesAssignment 1 ENG 173 METAL FORMINGtoursena44No ratings yet

- Assignment 1Document3 pagesAssignment 1Pawan Kumar GoyalNo ratings yet

- Mechanical Properties of Thermally Stable Nanocrystalline Bainitic SteelsDocument13 pagesMechanical Properties of Thermally Stable Nanocrystalline Bainitic SteelsP. R. SREENIVASANNo ratings yet

- Question Bank: Module 1:design For Static StrengthDocument22 pagesQuestion Bank: Module 1:design For Static Strengthcrazy hjNo ratings yet

- Reparación de Casco de Horno RotativoDocument13 pagesReparación de Casco de Horno RotativoErick OlavarriaNo ratings yet

- Assignment MD IDocument7 pagesAssignment MD Iprajitsen damleNo ratings yet

- Assignment 1 ENG 173 METAL FORMING First 2023 2024Document2 pagesAssignment 1 ENG 173 METAL FORMING First 2023 2024toursena44No ratings yet

- Assignment-3 - CML-231 - Materials Science and EnggDocument1 pageAssignment-3 - CML-231 - Materials Science and EnggGajanan SawantNo ratings yet

- Manufacturing ProcessesDocument9 pagesManufacturing ProcessesAzhar SyedNo ratings yet

- DMM 1 Assignment Questions FinalDocument2 pagesDMM 1 Assignment Questions FinalSrimanthula SrikanthNo ratings yet

- DME-I Model Paper-3 2Document3 pagesDME-I Model Paper-3 2Srinivas KosuriNo ratings yet

- ME-6503 Design of Machine Elements - 16 MarksDocument12 pagesME-6503 Design of Machine Elements - 16 MarksMadhu MithaNo ratings yet

- Article CSIRO TRC-MG Magnesium Technology 2001Document5 pagesArticle CSIRO TRC-MG Magnesium Technology 2001Frederic BassonNo ratings yet

- Mechanical Properties of Nanostructured Nickel BasDocument6 pagesMechanical Properties of Nanostructured Nickel BasMaryam TorfehNo ratings yet

- A Study On Micromachining and Effects of Cryogenic Treatment On Micro End Mill CuttersDocument5 pagesA Study On Micromachining and Effects of Cryogenic Treatment On Micro End Mill CuttersgauravNo ratings yet

- Mechanical Comportement of A Cement Plant Rotary KilnDocument6 pagesMechanical Comportement of A Cement Plant Rotary KilnCorrosion FactoryNo ratings yet

- Optimization of Extrusion Process Parameters of Incoloy028 Alloy Based On Hot Compression Test and SimulationDocument10 pagesOptimization of Extrusion Process Parameters of Incoloy028 Alloy Based On Hot Compression Test and SimulationChigoChigoNo ratings yet

- Assignment# 03: BlankingDocument1 pageAssignment# 03: BlankingengineerNo ratings yet

- Warm Hemming MG Sheet GMDocument8 pagesWarm Hemming MG Sheet GMChandra ClarkNo ratings yet

- rr321401 Principles of Machine DesignDocument8 pagesrr321401 Principles of Machine DesignSRINIVASA RAO GANTANo ratings yet

- Introduction To ManufacturingDocument10 pagesIntroduction To ManufacturingAbdullahNo ratings yet

- Syllabus - Electronic Materials - 2nd Semester 2019.2020Document3 pagesSyllabus - Electronic Materials - 2nd Semester 2019.2020Abdullah100% (1)

- ميحرلا نمحرلا الله مسب Manufacturing Processes 0703314: Solidification and Casting ProcessesDocument45 pagesميحرلا نمحرلا الله مسب Manufacturing Processes 0703314: Solidification and Casting ProcessesAbdullahNo ratings yet

- Bulk Deformation ProcessesDocument41 pagesBulk Deformation ProcessesAbdullahNo ratings yet

- HW - 3 - 16.4.2020 - Electronic Materials - 2020Document3 pagesHW - 3 - 16.4.2020 - Electronic Materials - 2020AbdullahNo ratings yet

- Medical Problem Assignment: Hyperthyroidism EtiologyDocument10 pagesMedical Problem Assignment: Hyperthyroidism EtiologyAbdullahNo ratings yet

- 314 HW#1Document1 page314 HW#1AbdullahNo ratings yet

- ميحرلا نمحرلا الله مسب Manufacturing Techniques 0703314: Powder MetallurgyDocument33 pagesميحرلا نمحرلا الله مسب Manufacturing Techniques 0703314: Powder MetallurgyAbdullahNo ratings yet

- Second Edition (: 2001 Mcgraw-Hill)Document11 pagesSecond Edition (: 2001 Mcgraw-Hill)AbdullahNo ratings yet

- HW - 2 - 4.4.2020 - Pol. Sci. Tech - CorrectedDocument5 pagesHW - 2 - 4.4.2020 - Pol. Sci. Tech - CorrectedAbdullahNo ratings yet

- HW2 - Electronic Materials - 2020Document4 pagesHW2 - Electronic Materials - 2020AbdullahNo ratings yet