Professional Documents

Culture Documents

Comparison of Pavement Structures in Tunnels: Ivan Rimac Miroslav Šimun Sanja Dimter

Comparison of Pavement Structures in Tunnels: Ivan Rimac Miroslav Šimun Sanja Dimter

Uploaded by

diana cristina arias aldanaCopyright:

Available Formats

You might also like

- PD 6691-2022Document74 pagesPD 6691-2022sghrkorkzan43100% (1)

- 1 Technical ProposalDocument64 pages1 Technical ProposalNana BarimaNo ratings yet

- Uganda Standard Specification Series 4000 - Bituminous Layers and SealsDocument52 pagesUganda Standard Specification Series 4000 - Bituminous Layers and SealsKintu Munabangogo100% (3)

- 2018 IjbeconditionassessmentDocument13 pages2018 Ijbeconditionassessmentmahajansakshee10No ratings yet

- Fire 06 00065 v2Document18 pagesFire 06 00065 v2baranNo ratings yet

- Lecture 4. Pipes Materials and LoadsDocument13 pagesLecture 4. Pipes Materials and LoadsjsmnjasminesNo ratings yet

- Pengertian, Sejarah Dan Kelebihan TerowonganDocument33 pagesPengertian, Sejarah Dan Kelebihan TerowonganSalwa SaputriNo ratings yet

- Railway Plate Girder Bridges As A Source of NoiseDocument7 pagesRailway Plate Girder Bridges As A Source of NoiseGabut ManNo ratings yet

- Detailed Design of EuroTunnelDocument7 pagesDetailed Design of EuroTunnelNdanu MercyNo ratings yet

- Current Safety Issues in Traffic TunnelsDocument11 pagesCurrent Safety Issues in Traffic TunnelsEmin AlakbarliNo ratings yet

- Railway Ballast Requirements For High Speed and Heavy Haul LinesDocument7 pagesRailway Ballast Requirements For High Speed and Heavy Haul Lineskgiannakos_3No ratings yet

- Track Modulus 8Document9 pagesTrack Modulus 8Marius Diaconu100% (1)

- Track Modulus 9Document12 pagesTrack Modulus 9Marius DiaconuNo ratings yet

- Civil Engineers Book - TunnellingDocument20 pagesCivil Engineers Book - TunnellingIain Glenny100% (1)

- Lecture 4. Pipes Materials and Loads1 PDFDocument13 pagesLecture 4. Pipes Materials and Loads1 PDFHizbar ArsjadNo ratings yet

- 04 - NTH - Project Report 1-94 Hard Rock Tunnel BoringDocument165 pages04 - NTH - Project Report 1-94 Hard Rock Tunnel Boringcastille1956100% (1)

- A Modeling Approach of Heat Transfer of Bridges Considering Vehicle-Induced Thermal EffectsDocument19 pagesA Modeling Approach of Heat Transfer of Bridges Considering Vehicle-Induced Thermal EffectsSuguang XiaoNo ratings yet

- 30 Twin Tube... International Conference On Tunnelling Asia 2004 New DelhiDocument15 pages30 Twin Tube... International Conference On Tunnelling Asia 2004 New Delhiعصام السامرائيNo ratings yet

- 7 International Conference On Concrete Pavements - Orlando, Florida, USA - September 9-13, 2001Document13 pages7 International Conference On Concrete Pavements - Orlando, Florida, USA - September 9-13, 2001nanga1970No ratings yet

- Mechanical Properties of High Volume Fly Ash Concrete: F.N.Okoye, N.B.SinghDocument8 pagesMechanical Properties of High Volume Fly Ash Concrete: F.N.Okoye, N.B.SinghIOSRjournalNo ratings yet

- WTC 2013 - Design of SCL in Soft Ground A UK Perspective - J SuDocument9 pagesWTC 2013 - Design of SCL in Soft Ground A UK Perspective - J SuJorge Baños LloredoNo ratings yet

- Eupave Safety of Tunnels in Case of FireDocument32 pagesEupave Safety of Tunnels in Case of FireEdgar Nieto UmañaNo ratings yet

- Tunnel Performance (Tunnel Boom & Viberation)Document11 pagesTunnel Performance (Tunnel Boom & Viberation)Hamdy GamalNo ratings yet

- CFD Assessment of Railway Tunnel Train FireDocument16 pagesCFD Assessment of Railway Tunnel Train FireodmanNo ratings yet

- Vb2008 Angol FEHERVARI Page56-60Document5 pagesVb2008 Angol FEHERVARI Page56-60a_korinNo ratings yet

- Design Aspects For Wearing Courses On Orthotropic Steel Bridge DecksDocument18 pagesDesign Aspects For Wearing Courses On Orthotropic Steel Bridge DecksBui Tat ThanhNo ratings yet

- The Five-Point Bending Test Applied On Wearing Courses Laid On Orthotropic Steel DecksDocument8 pagesThe Five-Point Bending Test Applied On Wearing Courses Laid On Orthotropic Steel DecksEmilioLimberArredondoOyolaNo ratings yet

- Application of Ultrasonic Method in Asphalt Concrete Testing For Fatigue Life EstimationDocument6 pagesApplication of Ultrasonic Method in Asphalt Concrete Testing For Fatigue Life EstimationFelipe ArceNo ratings yet

- Concrete Pavements in Germany Eurotour92-6Document18 pagesConcrete Pavements in Germany Eurotour92-6جميل عبد الله الحماطيNo ratings yet

- Bored Tunnels in Soft SoilsDocument7 pagesBored Tunnels in Soft SoilsDEBASISNo ratings yet

- Youlandha Emylyo Irawan - 30-8-21Document3 pagesYoulandha Emylyo Irawan - 30-8-21Youlandha Emylyo IrawanNo ratings yet

- 2analysis of Asphalt Concrete Permeability Data Using Representative Pore SizeDocument14 pages2analysis of Asphalt Concrete Permeability Data Using Representative Pore SizeFasdarsyahNo ratings yet

- Tunnelling and Underground Space Technology: SciencedirectDocument12 pagesTunnelling and Underground Space Technology: SciencedirectBen Habib BambaNo ratings yet

- Structural Design of Asphalt Pavements in GermanyDocument10 pagesStructural Design of Asphalt Pavements in GermanyDr. Abdulhaq Hadi Abedali Al-HaddadNo ratings yet

- Universities of Leeds, Sheffield and York: Promoting Access To White Rose Research PapersDocument44 pagesUniversities of Leeds, Sheffield and York: Promoting Access To White Rose Research PapersDuta LiviuNo ratings yet

- 9368 11590 1 PB PDFDocument7 pages9368 11590 1 PB PDFmamayo magzNo ratings yet

- Vehicular Emission Factors of CO, HC and NO From Freeway Tunnel in ChinaDocument6 pagesVehicular Emission Factors of CO, HC and NO From Freeway Tunnel in ChinaHarold TaylorNo ratings yet

- 2013 Jiang Su Design of SCL Tunnel Using Sprayed WaterproofingDocument11 pages2013 Jiang Su Design of SCL Tunnel Using Sprayed WaterproofingParmeshwar KushwahaNo ratings yet

- Comparative Study of Using Flexible and Rigid Pavements For Roads: A Review StudyDocument13 pagesComparative Study of Using Flexible and Rigid Pavements For Roads: A Review StudyJobaer Al-MahmudNo ratings yet

- Cable Vibration DamperDocument17 pagesCable Vibration DamperAyman ShamaNo ratings yet

- تحليل المخاطر فى مشروع انشاء النفق بين فرنسا وبريطانياDocument23 pagesتحليل المخاطر فى مشروع انشاء النفق بين فرنسا وبريطانياSuleiman BaruniNo ratings yet

- Reasons of Premature Cracking Pavement Deterioration - A Case StudyDocument11 pagesReasons of Premature Cracking Pavement Deterioration - A Case StudyCivilax.comNo ratings yet

- Safety in Railway TunnelsDocument12 pagesSafety in Railway TunnelsIsmet Hizyolu100% (1)

- Application of Expansion Joints in DiaphDocument8 pagesApplication of Expansion Joints in DiaphLuthfi NNo ratings yet

- Applied Sciences: Fatigue Assessment of Prestressed Concrete Slab-Between-Girder BridgesDocument19 pagesApplied Sciences: Fatigue Assessment of Prestressed Concrete Slab-Between-Girder BridgesefvjNo ratings yet

- Study of The Interaction Between Two Parallel Tunnels in The Case Where The Second Tunnel Is Excavated After The Construction of The First TunnelDocument10 pagesStudy of The Interaction Between Two Parallel Tunnels in The Case Where The Second Tunnel Is Excavated After The Construction of The First Tunnelkksamy2007No ratings yet

- Evaluation of Load-Transfer Efficiency of Steel Mesh Reinforced Contraction Joints in Concrete Pavement: Accelerated Pavement Test and FE AnalysisDocument24 pagesEvaluation of Load-Transfer Efficiency of Steel Mesh Reinforced Contraction Joints in Concrete Pavement: Accelerated Pavement Test and FE AnalysisMuhammet ÇelikNo ratings yet

- D HAB Porto 2Document20 pagesD HAB Porto 2Sheikh Nasir WahidNo ratings yet

- Aérodynamics, Ventilation and Tunnel SafetyDocument20 pagesAérodynamics, Ventilation and Tunnel SafetyJohn Muñoz100% (1)

- Omran Maadani, PH.D Civil Engineering Construction Portfolio, National Research Council CanadaDocument18 pagesOmran Maadani, PH.D Civil Engineering Construction Portfolio, National Research Council CanadaMuhamet KurtiNo ratings yet

- Riviera Et Al 2014 - Tunnel Muck For Subgrade in Road ConstructionDocument14 pagesRiviera Et Al 2014 - Tunnel Muck For Subgrade in Road ConstructionPinipini PujaNo ratings yet

- G E A P S: Research & Development - Conference PapersDocument0 pagesG E A P S: Research & Development - Conference PapersMai Lan NguyenNo ratings yet

- Jsvi 1999 2542Document18 pagesJsvi 1999 2542Pungky Rachma DewiNo ratings yet

- Kavvadas Monitoring and PDFDocument19 pagesKavvadas Monitoring and PDFAndyara DuarteNo ratings yet

- Ultra-Thin Whitetopping (UTW) Project: UTW Thickness (MM) Joint Spacing (M) Fiber Concrete Plain ConcreteDocument3 pagesUltra-Thin Whitetopping (UTW) Project: UTW Thickness (MM) Joint Spacing (M) Fiber Concrete Plain ConcreteEric GironNo ratings yet

- 12 Tunnels and GeologyDocument7 pages12 Tunnels and Geology22100204No ratings yet

- Driven Ductile Iron PilesDocument61 pagesDriven Ductile Iron PilesFrans van der MerweNo ratings yet

- CICE 2021 Quadrino Et Al PREPRINTDocument18 pagesCICE 2021 Quadrino Et Al PREPRINTxstaNo ratings yet

- Gupta 2010 Soil Dynamics and Earthquake EngineeringDocument16 pagesGupta 2010 Soil Dynamics and Earthquake EngineeringquentindelvigneNo ratings yet

- Tunnelling and Underground Space Technology: Yong Fang, Jianguo Fan, Bernadette Kenneally, Michael MooneyDocument10 pagesTunnelling and Underground Space Technology: Yong Fang, Jianguo Fan, Bernadette Kenneally, Michael MooneyBrahayan Adrian Gómez SilvaNo ratings yet

- Keller 39 03E Vibration Mitigation RailwayDocument4 pagesKeller 39 03E Vibration Mitigation RailwayDanielSierraNo ratings yet

- Experimental Research On The Corrosion of X Series Pipel - 2017 - Engineering Fa PDFDocument12 pagesExperimental Research On The Corrosion of X Series Pipel - 2017 - Engineering Fa PDFXONΔΡΑΚΗΣ ΓΙΩΡΓΟΣNo ratings yet

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- Tuttle Stark Axtell Soil Inclusions DFI 09Document13 pagesTuttle Stark Axtell Soil Inclusions DFI 09diana cristina arias aldanaNo ratings yet

- 1010 Auxiliary Lanes: 1010.01 General 1010.03 DefinitionsDocument14 pages1010 Auxiliary Lanes: 1010.01 General 1010.03 Definitionsdiana cristina arias aldanaNo ratings yet

- Muir Wood 2015-BD PDFDocument56 pagesMuir Wood 2015-BD PDFdiana cristina arias aldanaNo ratings yet

- The Groundbreaking Tunnel: Allplan Engineering in PracticeDocument5 pagesThe Groundbreaking Tunnel: Allplan Engineering in Practicediana cristina arias aldanaNo ratings yet

- Simplified Mining Sequence ExampleDocument9 pagesSimplified Mining Sequence Examplediana cristina arias aldanaNo ratings yet

- Calculo Soil Nail FHWADocument91 pagesCalculo Soil Nail FHWAdiana cristina arias aldanaNo ratings yet

- Hydraulic Design of Road-Edge Surface Water Channels: StandardsDocument40 pagesHydraulic Design of Road-Edge Surface Water Channels: Standardsdiana cristina arias aldanaNo ratings yet

- Tutorial RocSupportDocument13 pagesTutorial RocSupportdiana cristina arias aldanaNo ratings yet

- 347 Foamjett GBDocument4 pages347 Foamjett GBdiana cristina arias aldanaNo ratings yet

- Aluvial: Determinación Del Coeficiente de Reacción Horizontal Formación Elemento Estr. Parámetros Del SueloDocument5 pagesAluvial: Determinación Del Coeficiente de Reacción Horizontal Formación Elemento Estr. Parámetros Del Suelodiana cristina arias aldanaNo ratings yet

- ScourAssessmentofUnlinedRockSpillways George UCBGT12 02Document75 pagesScourAssessmentofUnlinedRockSpillways George UCBGT12 02diana cristina arias aldanaNo ratings yet

- Slope Stabilization With High-Performance Steel Wire Meshes in Combination With Nails and Anchors PDFDocument36 pagesSlope Stabilization With High-Performance Steel Wire Meshes in Combination With Nails and Anchors PDFdiana cristina arias aldanaNo ratings yet

- Aua Guidelines For Backfilling and Contact Grouting of Tunnels A 2003 PDFDocument270 pagesAua Guidelines For Backfilling and Contact Grouting of Tunnels A 2003 PDFdiana cristina arias aldana100% (1)

- Case Studies in Construction Materials: A. Koutous, E. HilaliDocument16 pagesCase Studies in Construction Materials: A. Koutous, E. Hilalidiana cristina arias aldanaNo ratings yet

- Pore Water Pressure Manipulation in Computerised Slope Stability AnalysisDocument12 pagesPore Water Pressure Manipulation in Computerised Slope Stability Analysisdiana cristina arias aldanaNo ratings yet

- Rock Mechanics Advances of Underground Construction and MiningDocument15 pagesRock Mechanics Advances of Underground Construction and Miningdiana cristina arias aldanaNo ratings yet

- Energies 10 00563Document16 pagesEnergies 10 00563diana cristina arias aldanaNo ratings yet

- ROCKTOPPLE v1.0.3Document2,751 pagesROCKTOPPLE v1.0.3diana cristina arias aldanaNo ratings yet

- New Austrian Tunneling Method (NATM) in Himalayan Geology: Emphasis On Execution Cycle MethodologyDocument14 pagesNew Austrian Tunneling Method (NATM) in Himalayan Geology: Emphasis On Execution Cycle Methodologydiana cristina arias aldana100% (1)

- Fischer Tunnel ConstructionDocument20 pagesFischer Tunnel Constructiondiana cristina arias aldanaNo ratings yet

- Mechanistic-Empirical Pavement Design A Brief OverviewDocument8 pagesMechanistic-Empirical Pavement Design A Brief OverviewedgomurNo ratings yet

- DMDE Construction Supervision Manual (Draft) PDFDocument54 pagesDMDE Construction Supervision Manual (Draft) PDFKidanemariam67% (3)

- Chapter 2 - Footways and WalkwaysDocument35 pagesChapter 2 - Footways and WalkwaysDiyoke HenryNo ratings yet

- Example Project NarrativeDocument9 pagesExample Project Narrativeayu cahyaNo ratings yet

- RCD Bihar SOR 2021 Volume IDocument734 pagesRCD Bihar SOR 2021 Volume ILalitesh KumarNo ratings yet

- RoadsDocument35 pagesRoadssalahudinNo ratings yet

- Laboratory Evaluation of Lime Modified Asphalt Concrete Mixes With Respective To Moisture Susceptibility PDFDocument8 pagesLaboratory Evaluation of Lime Modified Asphalt Concrete Mixes With Respective To Moisture Susceptibility PDFbala subramanyamNo ratings yet

- AASHTO R 30-02 Standard PracticeDocument4 pagesAASHTO R 30-02 Standard PracticeAzlan AbdNo ratings yet

- Title DefenseDocument34 pagesTitle DefenseHerwinn Ruiz ReyesNo ratings yet

- Univ Jordan GradationDocument13 pagesUniv Jordan GradationHafiz IrzaNo ratings yet

- Seminar Topics Al Ameen CollegeDocument14 pagesSeminar Topics Al Ameen CollegejinshadNo ratings yet

- Item 200-201 & 310Document19 pagesItem 200-201 & 310KaJong JaclaNo ratings yet

- TCS (DRAIN) - Model PDFDocument1 pageTCS (DRAIN) - Model PDFYAZERNo ratings yet

- Transportation Engg: Compiled By: Engr Muhammad Abbas KhanDocument9 pagesTransportation Engg: Compiled By: Engr Muhammad Abbas KhanMuhammad Abbas KhanNo ratings yet

- Use of Plastic Waste in Construction of Flexible Pavement 8Document50 pagesUse of Plastic Waste in Construction of Flexible Pavement 8Ujwal Jaiswal100% (2)

- Schedule 2021Document213 pagesSchedule 2021shahpubg68No ratings yet

- Asphalt Base, Binder and Wearing Course - Adm Part SpecDocument9 pagesAsphalt Base, Binder and Wearing Course - Adm Part SpecRolando de GuzmanNo ratings yet

- Materials: Study On The Durability of Bamboo Fiber Asphalt MixtureDocument22 pagesMaterials: Study On The Durability of Bamboo Fiber Asphalt MixtureCesar Idrogo MontalvoNo ratings yet

- Ec 068Document113 pagesEc 068Gezim GezimNo ratings yet

- Chapter 1Document40 pagesChapter 1Wia AbdullahNo ratings yet

- BP Bitumen - Guide To Bituminous Binders in Asphalt and Sprayed Sealing Applications-2014Document32 pagesBP Bitumen - Guide To Bituminous Binders in Asphalt and Sprayed Sealing Applications-2014Jacques Van HeerdenNo ratings yet

- Irc Specifications, Standards, Design Codes - Help The EngineerDocument14 pagesIrc Specifications, Standards, Design Codes - Help The EngineerK SWETHANo ratings yet

- Gamma Construction BlogDocument4 pagesGamma Construction BlogQuality ControlNo ratings yet

- Fly Ash UtilizationDocument15 pagesFly Ash Utilizationsarkar82722No ratings yet

- Full ThesisDocument210 pagesFull ThesisMd. Shofiul IslamNo ratings yet

- Sor 01 04 2018 PDFDocument658 pagesSor 01 04 2018 PDFSushantKumarNo ratings yet

- Annex Road53 19Document294 pagesAnnex Road53 19AAeltayebNo ratings yet

Comparison of Pavement Structures in Tunnels: Ivan Rimac Miroslav Šimun Sanja Dimter

Comparison of Pavement Structures in Tunnels: Ivan Rimac Miroslav Šimun Sanja Dimter

Uploaded by

diana cristina arias aldanaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Comparison of Pavement Structures in Tunnels: Ivan Rimac Miroslav Šimun Sanja Dimter

Comparison of Pavement Structures in Tunnels: Ivan Rimac Miroslav Šimun Sanja Dimter

Uploaded by

diana cristina arias aldanaCopyright:

Available Formats

e-GFOS 5, 8 (2014) Pages 12-18

Comparison of Pavement Structures in Tunnels

COMPARISON OF PAVEMENT STRUCTURES IN TUNNELS

Ivan Rimac

Josip Juraj Strossmayer University of Osijek, Faculty of Civil Engineering Osijek, student

Miroslav Šimun

Institut IGH d.d. Zagreb, PhD.

Sanja Dimter

Josip Juraj Strossmayer University of Osijek, Faculty of Civil Engineering Osijek, Associate Professor

Abstract: Tunnels pose many fire risks. It is difficult to fight fires in tunnels due to their limited accessibility, the

quantity of smoke, and high thermal radiation. Temperatures in tunnel fires can reach 1000 °C, and these fires

can spread quickly and persist for long periods, the longest recorded in Europe lasting 53 h. The main

requirements of tunnel pavement structures are driving safety and comfort, as well as low construction and

maintenance costs. Choosing between using concrete or asphalt pavement structures in tunnels requires the

assessment of many criteria, including safety, cost, ecology, and energy use. One must also consider the

availability of technologies (finishers) and resources (bitumen or cement), as well as the probability of achieving

the required contractor experience level, which impacts pavement management. This paper describes our

analysis and process for deciding the pavement structure to be used in tunnels, as well as current European

technical regulations for safe traffic flow in tunnels.

Key words: tunnels, user safety, concrete pavement, asphalt pavement, multiple criteria analysis

USPOREDBA TIPOVA KOLNIČKIH KONSTRUKCIJA U TUNELIMA

Sažetak: Tuneli predstavljaju i potencijalna mjesta opasnosti za korisnike u slučaju požara. Borba protiv požara u

tunelima teža je zbog ograničene pristupačnosti, količine dima i velikog toplinskog zračenja. Temperature koje se

razvijaju tijekom požara u tunelima dostižu i do 1000°C, vatra se širi vrlo brzo i traje dugo – čak do 53 sata.

Osnovni zahtjevi kojima trebaju odgovoriti tunelske kolničke konstrukcije su sigurnost i udubnost vožnje, ali i

racionalnost, odnosno isplativost u pogledu investicije i troškova održavanja u eksploatacijskim uvjetima. Kod

donošenja odluke o izvedbi betonske ili asfaltne kolničke konstrukcije u tunelima, potrebno je proučiti čitav niz

kriterija: sigurnosni, ekonomski, ekološki, energetski. U procesu razmatranja treba sagledati raspoloživost

određene tehnologije (finišeri) i resursa (bitumen ili cement), ali i iskustvo kao uvjet postizanja tražene razine

uporabne kvalitete, a koja ima utjecaj na gospodarenje kolnicima. U radu je opisana analiza prilikom donošenja

odluke o tipu kolnika u tunelima te prikazana postojeća tehnička regulativa europskih zemalja vezana za

povećanje sigurnosti prometa u tunelima.

Ključne riječi: tuneli, sigurnost korisnika, betonski kolnik, asfaltni kolnik, višekriterijska analiza

Rimac, I; Šimun, M; Dimter, S

http://dx.doi.org/10.13167/2014.8.2 12

e-GFOS 5, 8 (2014) Pages 12-18

Comparison of Pavement Structures in Tunnels

1 Introduction

Modern pavement structures of roads, airports, and other traffic areas have asphalt or concrete surfaces. The

main difference between pavement structures with asphalt courses (flexible and semi-rigid structures) and those

with concrete slabs (rigid pavement structures) is how they transfer the traffic load and distribute it to the

subgrade [1]. In asphalt pavements, all the structure courses transfer the traffic load, evenly distributing the load

over the subgrade at ~60 °. In concrete pavements, the concrete slab takes most of the traffic load because of its

rigidity and large surface area, transferring less load to the subgrade (Fig. 1).

strain

strain

Figure 1. Transfer of load to subgrade [1]: a) concrete pavement; b) asphalt pavement

Because of how concrete pavements transfer traffic load, they are most often used in areas exposed to very

heavy and frequent traffic, such as motorways, airports, and container terminals. They are also often used for the

pavement slabs of bridges, border crossings, motorway toll stations, waste disposal areas, roundabouts, gas

stations, bus stations, and road tunnels [2, 3]. The main requirements of pavement structures in tunnels are

driving safety and comfort, as well as cost efficiency in building and maintenance.

2 Comparison of Concrete Pavements with Asphalt Pavements

Recently, asphalt and concrete pavements have been frequently compared [1, 4], mainly because the global

financial crisis has heightened the need to choose wise investments. In these comparisons, both the initial

construction and maintenance costs must be accounted for. It is also important to assess the environmental

impacts and sustainability of asphalt versus concrete, as well as the method used to produce the material (natural

or industrial production). To preserve the environment with “green” building practices, we must use materials that

can be produced using little energy, emit few or no hazardous gases, and are completely recyclable.

Comparisons between asphalt and concrete pavement in tunnels can be made based on several criteria [5],

described in Sections 2.1–2.4.

2.1 Skidding Resistance of the Pavement Structure Driving Surface – Adhesion

The range of friction coefficients for rubber-asphalt materials is 0.6–0.85 and for rubber-concrete materials is 0.5–

0.80, indicating rubber adheres relatively uniformly to both asphalt and concrete bases. These data are not

significantly different, even for wet driving surfaces.

Rimac, I; Šimun, M; Dimter, S

http://dx.doi.org/10.13167/2014.8.2 13

e-GFOS 5, 8 (2014) Pages 12-18

Comparison of Pavement Structures in Tunnels

2.2 Cost-Effectiveness of Lighting and Contrast

Pavement surfaces, especially those in tunnels, require clearly distinguishable markings. Concrete pavements

are more easily colored due to their lighter color. In tunnels, reflected light from the pavement surface can

illuminate their interiors. Because concrete pavement is lighter colored and more reflective than asphalt, tunnels

built with concrete surfaces can be illuminated with less generated light, reducing power consumption. However,

safety and visibility in tunnels benefit from stronger contrast among the base, walls, and pavement marks. In this

case, the darker asphalt base provides better contrast than the lighter concrete.

2.3 Longitudinal and Transversal Roughness of Driving Surface

The roughness of the final pavement course can significantly change the quality of the driving surface from the

designed state. Considering surface roughness, concrete and asphalt differ mostly in that concrete pavements

are more rigid and require expansion joints. Greater rigidity decreases the roughness of the pavement surface,

and the presence of expansion joints (at each 5.5 m) roughens the pavement and decreases driving comfort.

2.4 Traffic Noise

The main source of traffic noise now comes from contact between vehicle tires and the road surface. Pavement

surfaces with high shares of voids and fine-grained materials produce less noise than traditional asphalt and

concretes. Concrete pavements increase vibrations because of their higher rigidity, increasing noise. Also, the

expansion joints needed in concrete pavements cause dynamic impact every 0.3 s (at 100 km/h), further

increasing noise.

3 Safety in Tunnels Made from Concrete or Asphalt

Tunnels pose many fire risks. It is difficult to fight fires in tunnels due to their limited accessibility, the quantity of

smoke, and high thermal radiation. Temperatures in tunnel fires can reach 1000 °C, and these fires can spread

quickly and persist for long periods: the longest recorded in Europe lasted 53 h. Table 1 shows historical data on

tunnel fires on the European road network [6].

Table 1. Fires in European tunnels [6]

Recent fires disasters in tunnels in Europe

Duration & Vehicles

Fire Tunnel Type Year Victims

Temperature damaged

St. Gotthard Road (1 tube) 24 h 10 cars

2001 11 deaths

Switzerland 16.3 km 1200 °C 23 lorries

Gleinalm Road (1 tube)

2001 37 min 5 deaths 2 cars

Austria 8.3 km

Kitzsteinhorn Funicular rail

2000 Not known 155 deaths 1 shuttle train

Austria 3.2 km

Tauren Road (1 tube) 14 h 26 cars

1999 12 deaths

Austria 6.4 km 1200 °C 14 lorries

Mont-Blanc Road (1 tube) 53 h 10 cars

1999 39 deaths

France-Italy 11.6 km 1000 °C 23 lorries

Palermo 19 cars

Road 1999 Not known 5 deaths

Italy 1 coach

Eurotunnel 10 h

Rail 52 km 1996 2 injured 1 shuttle train

Channel 1100 °C

Rimac, I; Šimun, M; Dimter, S

http://dx.doi.org/10.13167/2014.8.2 14

e-GFOS 5, 8 (2014) Pages 12-18

Comparison of Pavement Structures in Tunnels

Ideally, tunnel surfaces should be made from non-combustible, non-toxic pavements. Using this type of

surface improves safety, protects the tunnel structure and equipment, and protects the environment. Concrete is

non-combustible and not emit toxic gasses when heated, providing maximal safety in fires. Because of concrete’s

mineral composition, it is inert, stable, and non-combustible. It has a high fire safety factor and does not

contribute to fire spreading, easing evacuation of people from the tunnel during fires. Furthermore, concrete

pavement is less easily damaged by fire than asphalt. This shortens the repairs when needed, reducing

consequent traffic disruptions and accidents. Comparing asphalt and concrete specimens exposed to high

temperatures, researchers at Cergy–Pontoise University [7] found concrete superior to asphalt for pavement

structures in tunnels for the following reasons (Fig. 2):

- Asphalt is flammable in a temperature range of 428–530 °C, which fires can reach after only 8 min

- Asphalt emits toxic gases after only 5 min; the emitted gases are toxic, some are asphyxiants (CO), and they

are carcinogenic

- Asphalt becomes mechanical unstable in fire (the aggregates are still present, but unbound) and can no

longer fulfill its main purpose

- Concrete is not flammable and does not emit toxic gases in fire

- Concrete only becomes mechanically unstable when at temperatures exceeding 700°C (Fig. 3).

Figure 2. Temperatures of concrete and asphalt over one hour [6]

Figure 3. Comparison of asphalt (left) and concrete (right) specimens after heating to 750 °C [6]

Some European countries explicitly require or recommend in their regulations that tunnel pavement be

concrete [6]:

- The Austrian Decree of September 2001 related to tunnel projects directives “Projektierungsrichtlinien RVS

09.01.23” [8], requires concrete road pavement in new tunnels longer than 1 km.

Rimac, I; Šimun, M; Dimter, S

http://dx.doi.org/10.13167/2014.8.2 15

e-GFOS 5, 8 (2014) Pages 12-18

Comparison of Pavement Structures in Tunnels

- Slovenia requires concrete pavements in tunnels longer than 1 km.

- In Slovakia, the Ministry of Transport and the Slovak Road Administration have required concrete road

pavements in new tunnels since 2001.

- In Spain, public authorities recommend using concrete road pavement in tunnels.

In contrast, in October of 2013, JP Autoceste Federacije BiH d.o.o. Mostar, Bosnia, and Herzegovina

formulated instructions [5] requiring the use of asphalt pavement structures in tunnels. They justified the fire

resistance of asphalt pavement and its effects on the tunnel structure based on the World Road Association

PIARC report “Fire and Smoke Control in Road Tunnels” [9], which reviewed many studies of how pavement

structure affected the force of fires. This document concluded that standard asphalt pavements do not

significantly decrease fire safety during the first phase of the fire—during which tunnel evacuation occurs—and

may be used in tunnels. These instructions [5] presented the conclusions of certain studies/professional papers,

including:

- “Performance of pavements in asphalt and concrete in tunnels, particularly in case of fire” (Germany) –

“There is no reason for which Germany would adopt the Austrian decision not to use asphalt pavements in

new tunnels whose length exceeds 1000 metres”;

- “Sustainable and Advanced Materials for Road Infrastructure: Review on Reaction to Fire of Pavements

Materials“ (Samaris) [10] – “Review and investigation of incidents does not indicate an increase of risk due to

the selection of pavement structure material, even in cases of catastrophic fires, as shown in the case of the

fire in the St. Gotthard tunnel;

- “Fire behaviour of asphalt pavement in case of road tunnel fire” (France) [11] – “In the fire in the Mont Blanc

tunnel and according to the temperatures estimates based on the conducted investigation, asphalt pavement

was not the cause of the fire spreading”;

- “Fire performance of road tunnels” (France) [10] – “A general rule is to recommend using non-combustible

materials for the ceiling and low-combustible materials for the sides, but there are no recommendations for

utilisation of pavement materials. Furthermore, it is recommended to pay special attention to the possibility of

presence of galleries under the pavement”;

- “Brief Introduction to Tunnel Pavements Technologies” (China) [12] – “Coating the concrete or asphalt

pavement with an epoxy layer can achieve, among other effects, characteristics of non-combustible

materials”;

- “Fire performance of asphalt concrete” (France) [13] – “Bitumen-based pavement is not easily combustible,

and significant exposure to heat is required to achieve self-combustion. This level of exposure can be

achieved only in the immediate proximity of a vehicle already burning. Research results indicate that, in the

case of self-combustion of bitumen course, only the surface course participates in fire. The quantity of

measured pyrolytic flow is very low compared to that achieved in the case of a burning vehicle. The quantity

of produced gases and temperatures due to the burning of asphalt are not great enough to significantly

aggravate the situation of users during evacuation.”

Existing Croatian regulations do not discuss concrete pavement, and these pavements are not widely used

outside of toll stations, gas stations, border crossings, and some bus terminals and bays. In Croatia over the last

20 years, asphalt pavements have been used in tunnels, for which no reported safety problems have been

caused by fire. When choosing a pavement type for use in a tunnel, it is important to provide a fire-alarm system,

establish a fire-extinguishing procedure, and plan a passenger evacuation strategy.

4 Construction and Maintenance of Pavement Structure in Tunnels

The construction cost of concrete and asphalt pavements can be calculated by assessing the individual tenders

submitted by contractors. In our region, concrete pavement is ~30% more expensive than asphalt pavement.

Concrete pavements have longer lifespans (40 years), almost twice those of asphalt pavements, but their

construction and maintenance costs are higher. Croatia has never used concrete pavements in tunnels, making it

difficult to estimate the exact maintenance cost. Maintenance of pavement structures can be very costly, so it is

important to select the most appropriate technology, technical solutions, and materials.

Rimac, I; Šimun, M; Dimter, S

http://dx.doi.org/10.13167/2014.8.2 16

e-GFOS 5, 8 (2014) Pages 12-18

Comparison of Pavement Structures in Tunnels

The method of repair for concrete pavement depends on the defects present, such as cracks, deterioration

of expansion joints, and surface defects). For partial repairs of non-reinforced slabs through their whole thickness,

additional expansion joints must be introduce, which can roughen the driving surface. For partial repairs of slabs

up to one third of the thickness at their expansion joints or damaged borders, they are performed using materials

with high rigidity and low shrinkage or materials based on epoxy resins and special cements. These repairs

require quality materials, leading to high cost. In contrast, asphalt pavements with local defects can be repaired

inexpensively with a simple, high-quality connection between the new and the old asphalt, applying classical

technology and materials. Asphalt pavement has an estimated lifespan of 7–10 years, after which it is

recommended to remove the wearing course and to construct a new one.

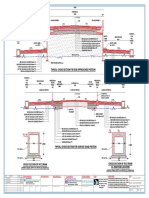

For the Corridor Vc motorway through the Federation of Bosnia and Herzegovina, including the Gorica–

Bilješevo section with the “Vijenac” tunnel with two parallel pipes of length amounting to 3.2 km, concrete

pavement was contracted to match the structure’s design. However, the investor ordered an amended pavement

structure to be designed in order to comply with Mostar instructions [5], which required asphalt pavement (Fig. 4).

The investor also ordered all designers, supervision teams, and contractors to use asphalt pavements in tunnels

to comply with current standards and regulations, on all sections being designed, being prepared for construction,

or being constructed. The pavement structures in tunnels will have identical composition and dimensions as those

on open routes, outside the tunnels, in compliance with “Instruction No. 14 for designing and execution of

pavement structures on motorway route”:

- Wearing Course: SMA 11s (SBM11s), PmB 45/80-65, Eruptive

- Binding Course: AGNS 22s, PmB 45/80-65, Carbonate

- Bearing Course: AGNS 32s or AGNS 22s, B 35/50, Carbonate

- Cement-stabilized course (thickness of 20 cm), complying with the requirements of current technical

conditions

- Unbound Mechanical Compacted (Sub-Base) Course: NNS 0/45 mm, f5, Ev2 ≥ 120 MPa.

Figure 4. Cross-section D-D of the “Vijenac” tunnel in the Corridor Vc in FB&H

The minimum thickness of the bearing unbound course of the pavement structure (sub-base) is 25 cm. In

case the tunnel structure contains an invert, the space between the pavement structure and the invert is filled with

25 cm of filter fill and then with fill made of 0/63 mm stone mixture, whose grain-size distribution corresponds to

the sub-base mixture with dmax = 63 mm (U=d60/d10 of 15–80) and fine-particle loading of up to 12% m/m

(category f12) and whose mechanical properties meet the criteria of sub-base mixtures. After filling and leveling,

the filter fill is compacted using light machinery to avoid damaging the drainage pipe. Geotextile is then placed

Rimac, I; Šimun, M; Dimter, S

http://dx.doi.org/10.13167/2014.8.2 17

e-GFOS 5, 8 (2014) Pages 12-18

Comparison of Pavement Structures in Tunnels

over the filter fill, overlapping in the filling direction of the first fill layer to a thickness of 25 cm. The fill material

must be filled and leveled from the front to avoid disturbing the filter fill, geotextile, or drainage pipe. The first fill

layer must achieve ~75% of the bearing level of the subgrade; i.e., minEv2 = 60 MPa. The final bearing level must

achieve minEv2 = 80 MPa.

5 Conclusion

Concrete is environmentally friendly, as its production and use requires less energy and thus emits less CO2, and

concrete batching plants produce less atmospheric pollution than asphalt plants. Concrete is non-combustible

and safe in fires, improving traffic safety in road tunnels. However, concrete pavements are costly and more

demanding in execution and maintenance technologies. Choosing between using concrete or asphalt pavement

structures in tunnels requires the assessment of many criteria, including safety, cost, ecology, and energy use.

One must also consider the availability of technologies (finishers) and resources (bitumen or cement), as well as

the probability of achieving the required contractor experience level, which impacts pavement management.

References

[1] Rajzer R.; Kolnici B. 2012: osnovni tipovi, povijesni razvoj i primjena u razvijenim državama svijeta i u

Hrvatskoj, Mineral, Volumen 6, pp. 26-31 (in Croatian)

[2] Rimac I. 2012: Usporedba asfaltnih i betonskih zastora, diplomski rad, Sveučilište Josipa Jurja Strossmayera

u Osijeku, Građevinski fakultet Osijek, mentor: izv. prof. dr. sc. Sanja Dimter, pp. 108 (in Croatian)

[3] Lakušić S.; Šimun M.; Rajzer R. 2011: Primjena betonskih kolnika u Hrvatskoj, Projektiranje prometne

infrastrukture, Dani prometnica 2011, Građevinski fakultet Sveučilišta u Zagrebu, Zagreb, pp. 275-320 (in

Croatian)

[4] Bjegović D. 2007: Betonski kolnici – prednosti i mane, Almanac Savremena građevinska praksa, Novi Sad,

pp 7-18 (in Croatian)

[5] Upute za projektovanje i izvođenje kolovoznih konstrukcija u tunelima, Set uputa za projektovanje, nabavku,

ugradnju i održavanje elemenata, objekata ili dijelova objekata na autocestama, Javno preduzeće Autoceste

Federacije Bosne i Hercegovine, No.: 01-5871-1/13. Mostar (in Croatian)

[6] Improving fire safety in tunnels: The concrete pavement solution, Concrete road pavement improves tunnel

safety CEMBUREAU, 2004. Accessed 13 May 2012.

Available on: http://www.febelcem.be/fileadmin/user_upload/autres-publications/en/firesafety.pdf

[7] Noumowe A. 2003: Characterisation of asphalt exposed to high temperature: Application to fire case of

asphalt pavement, Cergy–Pontoise University (English version)

[8] RVS 09.01.23: Projektierungsrichtlinien - Bauliche Gestaltung – Tunnel, Innenausbau, Bundesministerium für

Verkehr, Innovation und Technologie, Wien, 2001

[9] Comité technique 5 Tunnels routiers (Technical Committee 5 Road Tunnels), Systems and equipment for fire

and smoke control in road tunnels, PIARC Ref. 05.16.BEN, 2007

[10] Jofre C.; Romero J.; Rueda R. 2010: Contribution of concrete pavements to the safety of tunnels in case of

fire, European Concrete Paving Association.

[11] Jacobs J.-P. 2007: Comprehensive fire protection and safety with concrete, European Concrete

Platform.

[12] The 4th IACIP Annual Workshop, The Fourth US-China Workshop on Research and Education Collaboration

in Transportation Infrastructure, 2014

[13] European Asphalt Pavement Association, Asphalt pavements in tunnels, Brussels, Belgium, 2008

Rimac, I; Šimun, M; Dimter, S

http://dx.doi.org/10.13167/2014.8.2 18

You might also like

- PD 6691-2022Document74 pagesPD 6691-2022sghrkorkzan43100% (1)

- 1 Technical ProposalDocument64 pages1 Technical ProposalNana BarimaNo ratings yet

- Uganda Standard Specification Series 4000 - Bituminous Layers and SealsDocument52 pagesUganda Standard Specification Series 4000 - Bituminous Layers and SealsKintu Munabangogo100% (3)

- 2018 IjbeconditionassessmentDocument13 pages2018 Ijbeconditionassessmentmahajansakshee10No ratings yet

- Fire 06 00065 v2Document18 pagesFire 06 00065 v2baranNo ratings yet

- Lecture 4. Pipes Materials and LoadsDocument13 pagesLecture 4. Pipes Materials and LoadsjsmnjasminesNo ratings yet

- Pengertian, Sejarah Dan Kelebihan TerowonganDocument33 pagesPengertian, Sejarah Dan Kelebihan TerowonganSalwa SaputriNo ratings yet

- Railway Plate Girder Bridges As A Source of NoiseDocument7 pagesRailway Plate Girder Bridges As A Source of NoiseGabut ManNo ratings yet

- Detailed Design of EuroTunnelDocument7 pagesDetailed Design of EuroTunnelNdanu MercyNo ratings yet

- Current Safety Issues in Traffic TunnelsDocument11 pagesCurrent Safety Issues in Traffic TunnelsEmin AlakbarliNo ratings yet

- Railway Ballast Requirements For High Speed and Heavy Haul LinesDocument7 pagesRailway Ballast Requirements For High Speed and Heavy Haul Lineskgiannakos_3No ratings yet

- Track Modulus 8Document9 pagesTrack Modulus 8Marius Diaconu100% (1)

- Track Modulus 9Document12 pagesTrack Modulus 9Marius DiaconuNo ratings yet

- Civil Engineers Book - TunnellingDocument20 pagesCivil Engineers Book - TunnellingIain Glenny100% (1)

- Lecture 4. Pipes Materials and Loads1 PDFDocument13 pagesLecture 4. Pipes Materials and Loads1 PDFHizbar ArsjadNo ratings yet

- 04 - NTH - Project Report 1-94 Hard Rock Tunnel BoringDocument165 pages04 - NTH - Project Report 1-94 Hard Rock Tunnel Boringcastille1956100% (1)

- A Modeling Approach of Heat Transfer of Bridges Considering Vehicle-Induced Thermal EffectsDocument19 pagesA Modeling Approach of Heat Transfer of Bridges Considering Vehicle-Induced Thermal EffectsSuguang XiaoNo ratings yet

- 30 Twin Tube... International Conference On Tunnelling Asia 2004 New DelhiDocument15 pages30 Twin Tube... International Conference On Tunnelling Asia 2004 New Delhiعصام السامرائيNo ratings yet

- 7 International Conference On Concrete Pavements - Orlando, Florida, USA - September 9-13, 2001Document13 pages7 International Conference On Concrete Pavements - Orlando, Florida, USA - September 9-13, 2001nanga1970No ratings yet

- Mechanical Properties of High Volume Fly Ash Concrete: F.N.Okoye, N.B.SinghDocument8 pagesMechanical Properties of High Volume Fly Ash Concrete: F.N.Okoye, N.B.SinghIOSRjournalNo ratings yet

- WTC 2013 - Design of SCL in Soft Ground A UK Perspective - J SuDocument9 pagesWTC 2013 - Design of SCL in Soft Ground A UK Perspective - J SuJorge Baños LloredoNo ratings yet

- Eupave Safety of Tunnels in Case of FireDocument32 pagesEupave Safety of Tunnels in Case of FireEdgar Nieto UmañaNo ratings yet

- Tunnel Performance (Tunnel Boom & Viberation)Document11 pagesTunnel Performance (Tunnel Boom & Viberation)Hamdy GamalNo ratings yet

- CFD Assessment of Railway Tunnel Train FireDocument16 pagesCFD Assessment of Railway Tunnel Train FireodmanNo ratings yet

- Vb2008 Angol FEHERVARI Page56-60Document5 pagesVb2008 Angol FEHERVARI Page56-60a_korinNo ratings yet

- Design Aspects For Wearing Courses On Orthotropic Steel Bridge DecksDocument18 pagesDesign Aspects For Wearing Courses On Orthotropic Steel Bridge DecksBui Tat ThanhNo ratings yet

- The Five-Point Bending Test Applied On Wearing Courses Laid On Orthotropic Steel DecksDocument8 pagesThe Five-Point Bending Test Applied On Wearing Courses Laid On Orthotropic Steel DecksEmilioLimberArredondoOyolaNo ratings yet

- Application of Ultrasonic Method in Asphalt Concrete Testing For Fatigue Life EstimationDocument6 pagesApplication of Ultrasonic Method in Asphalt Concrete Testing For Fatigue Life EstimationFelipe ArceNo ratings yet

- Concrete Pavements in Germany Eurotour92-6Document18 pagesConcrete Pavements in Germany Eurotour92-6جميل عبد الله الحماطيNo ratings yet

- Bored Tunnels in Soft SoilsDocument7 pagesBored Tunnels in Soft SoilsDEBASISNo ratings yet

- Youlandha Emylyo Irawan - 30-8-21Document3 pagesYoulandha Emylyo Irawan - 30-8-21Youlandha Emylyo IrawanNo ratings yet

- 2analysis of Asphalt Concrete Permeability Data Using Representative Pore SizeDocument14 pages2analysis of Asphalt Concrete Permeability Data Using Representative Pore SizeFasdarsyahNo ratings yet

- Tunnelling and Underground Space Technology: SciencedirectDocument12 pagesTunnelling and Underground Space Technology: SciencedirectBen Habib BambaNo ratings yet

- Structural Design of Asphalt Pavements in GermanyDocument10 pagesStructural Design of Asphalt Pavements in GermanyDr. Abdulhaq Hadi Abedali Al-HaddadNo ratings yet

- Universities of Leeds, Sheffield and York: Promoting Access To White Rose Research PapersDocument44 pagesUniversities of Leeds, Sheffield and York: Promoting Access To White Rose Research PapersDuta LiviuNo ratings yet

- 9368 11590 1 PB PDFDocument7 pages9368 11590 1 PB PDFmamayo magzNo ratings yet

- Vehicular Emission Factors of CO, HC and NO From Freeway Tunnel in ChinaDocument6 pagesVehicular Emission Factors of CO, HC and NO From Freeway Tunnel in ChinaHarold TaylorNo ratings yet

- 2013 Jiang Su Design of SCL Tunnel Using Sprayed WaterproofingDocument11 pages2013 Jiang Su Design of SCL Tunnel Using Sprayed WaterproofingParmeshwar KushwahaNo ratings yet

- Comparative Study of Using Flexible and Rigid Pavements For Roads: A Review StudyDocument13 pagesComparative Study of Using Flexible and Rigid Pavements For Roads: A Review StudyJobaer Al-MahmudNo ratings yet

- Cable Vibration DamperDocument17 pagesCable Vibration DamperAyman ShamaNo ratings yet

- تحليل المخاطر فى مشروع انشاء النفق بين فرنسا وبريطانياDocument23 pagesتحليل المخاطر فى مشروع انشاء النفق بين فرنسا وبريطانياSuleiman BaruniNo ratings yet

- Reasons of Premature Cracking Pavement Deterioration - A Case StudyDocument11 pagesReasons of Premature Cracking Pavement Deterioration - A Case StudyCivilax.comNo ratings yet

- Safety in Railway TunnelsDocument12 pagesSafety in Railway TunnelsIsmet Hizyolu100% (1)

- Application of Expansion Joints in DiaphDocument8 pagesApplication of Expansion Joints in DiaphLuthfi NNo ratings yet

- Applied Sciences: Fatigue Assessment of Prestressed Concrete Slab-Between-Girder BridgesDocument19 pagesApplied Sciences: Fatigue Assessment of Prestressed Concrete Slab-Between-Girder BridgesefvjNo ratings yet

- Study of The Interaction Between Two Parallel Tunnels in The Case Where The Second Tunnel Is Excavated After The Construction of The First TunnelDocument10 pagesStudy of The Interaction Between Two Parallel Tunnels in The Case Where The Second Tunnel Is Excavated After The Construction of The First Tunnelkksamy2007No ratings yet

- Evaluation of Load-Transfer Efficiency of Steel Mesh Reinforced Contraction Joints in Concrete Pavement: Accelerated Pavement Test and FE AnalysisDocument24 pagesEvaluation of Load-Transfer Efficiency of Steel Mesh Reinforced Contraction Joints in Concrete Pavement: Accelerated Pavement Test and FE AnalysisMuhammet ÇelikNo ratings yet

- D HAB Porto 2Document20 pagesD HAB Porto 2Sheikh Nasir WahidNo ratings yet

- Aérodynamics, Ventilation and Tunnel SafetyDocument20 pagesAérodynamics, Ventilation and Tunnel SafetyJohn Muñoz100% (1)

- Omran Maadani, PH.D Civil Engineering Construction Portfolio, National Research Council CanadaDocument18 pagesOmran Maadani, PH.D Civil Engineering Construction Portfolio, National Research Council CanadaMuhamet KurtiNo ratings yet

- Riviera Et Al 2014 - Tunnel Muck For Subgrade in Road ConstructionDocument14 pagesRiviera Et Al 2014 - Tunnel Muck For Subgrade in Road ConstructionPinipini PujaNo ratings yet

- G E A P S: Research & Development - Conference PapersDocument0 pagesG E A P S: Research & Development - Conference PapersMai Lan NguyenNo ratings yet

- Jsvi 1999 2542Document18 pagesJsvi 1999 2542Pungky Rachma DewiNo ratings yet

- Kavvadas Monitoring and PDFDocument19 pagesKavvadas Monitoring and PDFAndyara DuarteNo ratings yet

- Ultra-Thin Whitetopping (UTW) Project: UTW Thickness (MM) Joint Spacing (M) Fiber Concrete Plain ConcreteDocument3 pagesUltra-Thin Whitetopping (UTW) Project: UTW Thickness (MM) Joint Spacing (M) Fiber Concrete Plain ConcreteEric GironNo ratings yet

- 12 Tunnels and GeologyDocument7 pages12 Tunnels and Geology22100204No ratings yet

- Driven Ductile Iron PilesDocument61 pagesDriven Ductile Iron PilesFrans van der MerweNo ratings yet

- CICE 2021 Quadrino Et Al PREPRINTDocument18 pagesCICE 2021 Quadrino Et Al PREPRINTxstaNo ratings yet

- Gupta 2010 Soil Dynamics and Earthquake EngineeringDocument16 pagesGupta 2010 Soil Dynamics and Earthquake EngineeringquentindelvigneNo ratings yet

- Tunnelling and Underground Space Technology: Yong Fang, Jianguo Fan, Bernadette Kenneally, Michael MooneyDocument10 pagesTunnelling and Underground Space Technology: Yong Fang, Jianguo Fan, Bernadette Kenneally, Michael MooneyBrahayan Adrian Gómez SilvaNo ratings yet

- Keller 39 03E Vibration Mitigation RailwayDocument4 pagesKeller 39 03E Vibration Mitigation RailwayDanielSierraNo ratings yet

- Experimental Research On The Corrosion of X Series Pipel - 2017 - Engineering Fa PDFDocument12 pagesExperimental Research On The Corrosion of X Series Pipel - 2017 - Engineering Fa PDFXONΔΡΑΚΗΣ ΓΙΩΡΓΟΣNo ratings yet

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- Tuttle Stark Axtell Soil Inclusions DFI 09Document13 pagesTuttle Stark Axtell Soil Inclusions DFI 09diana cristina arias aldanaNo ratings yet

- 1010 Auxiliary Lanes: 1010.01 General 1010.03 DefinitionsDocument14 pages1010 Auxiliary Lanes: 1010.01 General 1010.03 Definitionsdiana cristina arias aldanaNo ratings yet

- Muir Wood 2015-BD PDFDocument56 pagesMuir Wood 2015-BD PDFdiana cristina arias aldanaNo ratings yet

- The Groundbreaking Tunnel: Allplan Engineering in PracticeDocument5 pagesThe Groundbreaking Tunnel: Allplan Engineering in Practicediana cristina arias aldanaNo ratings yet

- Simplified Mining Sequence ExampleDocument9 pagesSimplified Mining Sequence Examplediana cristina arias aldanaNo ratings yet

- Calculo Soil Nail FHWADocument91 pagesCalculo Soil Nail FHWAdiana cristina arias aldanaNo ratings yet

- Hydraulic Design of Road-Edge Surface Water Channels: StandardsDocument40 pagesHydraulic Design of Road-Edge Surface Water Channels: Standardsdiana cristina arias aldanaNo ratings yet

- Tutorial RocSupportDocument13 pagesTutorial RocSupportdiana cristina arias aldanaNo ratings yet

- 347 Foamjett GBDocument4 pages347 Foamjett GBdiana cristina arias aldanaNo ratings yet

- Aluvial: Determinación Del Coeficiente de Reacción Horizontal Formación Elemento Estr. Parámetros Del SueloDocument5 pagesAluvial: Determinación Del Coeficiente de Reacción Horizontal Formación Elemento Estr. Parámetros Del Suelodiana cristina arias aldanaNo ratings yet

- ScourAssessmentofUnlinedRockSpillways George UCBGT12 02Document75 pagesScourAssessmentofUnlinedRockSpillways George UCBGT12 02diana cristina arias aldanaNo ratings yet

- Slope Stabilization With High-Performance Steel Wire Meshes in Combination With Nails and Anchors PDFDocument36 pagesSlope Stabilization With High-Performance Steel Wire Meshes in Combination With Nails and Anchors PDFdiana cristina arias aldanaNo ratings yet

- Aua Guidelines For Backfilling and Contact Grouting of Tunnels A 2003 PDFDocument270 pagesAua Guidelines For Backfilling and Contact Grouting of Tunnels A 2003 PDFdiana cristina arias aldana100% (1)

- Case Studies in Construction Materials: A. Koutous, E. HilaliDocument16 pagesCase Studies in Construction Materials: A. Koutous, E. Hilalidiana cristina arias aldanaNo ratings yet

- Pore Water Pressure Manipulation in Computerised Slope Stability AnalysisDocument12 pagesPore Water Pressure Manipulation in Computerised Slope Stability Analysisdiana cristina arias aldanaNo ratings yet

- Rock Mechanics Advances of Underground Construction and MiningDocument15 pagesRock Mechanics Advances of Underground Construction and Miningdiana cristina arias aldanaNo ratings yet

- Energies 10 00563Document16 pagesEnergies 10 00563diana cristina arias aldanaNo ratings yet

- ROCKTOPPLE v1.0.3Document2,751 pagesROCKTOPPLE v1.0.3diana cristina arias aldanaNo ratings yet

- New Austrian Tunneling Method (NATM) in Himalayan Geology: Emphasis On Execution Cycle MethodologyDocument14 pagesNew Austrian Tunneling Method (NATM) in Himalayan Geology: Emphasis On Execution Cycle Methodologydiana cristina arias aldana100% (1)

- Fischer Tunnel ConstructionDocument20 pagesFischer Tunnel Constructiondiana cristina arias aldanaNo ratings yet

- Mechanistic-Empirical Pavement Design A Brief OverviewDocument8 pagesMechanistic-Empirical Pavement Design A Brief OverviewedgomurNo ratings yet

- DMDE Construction Supervision Manual (Draft) PDFDocument54 pagesDMDE Construction Supervision Manual (Draft) PDFKidanemariam67% (3)

- Chapter 2 - Footways and WalkwaysDocument35 pagesChapter 2 - Footways and WalkwaysDiyoke HenryNo ratings yet

- Example Project NarrativeDocument9 pagesExample Project Narrativeayu cahyaNo ratings yet

- RCD Bihar SOR 2021 Volume IDocument734 pagesRCD Bihar SOR 2021 Volume ILalitesh KumarNo ratings yet

- RoadsDocument35 pagesRoadssalahudinNo ratings yet

- Laboratory Evaluation of Lime Modified Asphalt Concrete Mixes With Respective To Moisture Susceptibility PDFDocument8 pagesLaboratory Evaluation of Lime Modified Asphalt Concrete Mixes With Respective To Moisture Susceptibility PDFbala subramanyamNo ratings yet

- AASHTO R 30-02 Standard PracticeDocument4 pagesAASHTO R 30-02 Standard PracticeAzlan AbdNo ratings yet

- Title DefenseDocument34 pagesTitle DefenseHerwinn Ruiz ReyesNo ratings yet

- Univ Jordan GradationDocument13 pagesUniv Jordan GradationHafiz IrzaNo ratings yet

- Seminar Topics Al Ameen CollegeDocument14 pagesSeminar Topics Al Ameen CollegejinshadNo ratings yet

- Item 200-201 & 310Document19 pagesItem 200-201 & 310KaJong JaclaNo ratings yet

- TCS (DRAIN) - Model PDFDocument1 pageTCS (DRAIN) - Model PDFYAZERNo ratings yet

- Transportation Engg: Compiled By: Engr Muhammad Abbas KhanDocument9 pagesTransportation Engg: Compiled By: Engr Muhammad Abbas KhanMuhammad Abbas KhanNo ratings yet

- Use of Plastic Waste in Construction of Flexible Pavement 8Document50 pagesUse of Plastic Waste in Construction of Flexible Pavement 8Ujwal Jaiswal100% (2)

- Schedule 2021Document213 pagesSchedule 2021shahpubg68No ratings yet

- Asphalt Base, Binder and Wearing Course - Adm Part SpecDocument9 pagesAsphalt Base, Binder and Wearing Course - Adm Part SpecRolando de GuzmanNo ratings yet

- Materials: Study On The Durability of Bamboo Fiber Asphalt MixtureDocument22 pagesMaterials: Study On The Durability of Bamboo Fiber Asphalt MixtureCesar Idrogo MontalvoNo ratings yet

- Ec 068Document113 pagesEc 068Gezim GezimNo ratings yet

- Chapter 1Document40 pagesChapter 1Wia AbdullahNo ratings yet

- BP Bitumen - Guide To Bituminous Binders in Asphalt and Sprayed Sealing Applications-2014Document32 pagesBP Bitumen - Guide To Bituminous Binders in Asphalt and Sprayed Sealing Applications-2014Jacques Van HeerdenNo ratings yet

- Irc Specifications, Standards, Design Codes - Help The EngineerDocument14 pagesIrc Specifications, Standards, Design Codes - Help The EngineerK SWETHANo ratings yet

- Gamma Construction BlogDocument4 pagesGamma Construction BlogQuality ControlNo ratings yet

- Fly Ash UtilizationDocument15 pagesFly Ash Utilizationsarkar82722No ratings yet

- Full ThesisDocument210 pagesFull ThesisMd. Shofiul IslamNo ratings yet

- Sor 01 04 2018 PDFDocument658 pagesSor 01 04 2018 PDFSushantKumarNo ratings yet

- Annex Road53 19Document294 pagesAnnex Road53 19AAeltayebNo ratings yet