Professional Documents

Culture Documents

Six Sigma - Lean Manufacturing and Six Sigma Definitions PDF

Six Sigma - Lean Manufacturing and Six Sigma Definitions PDF

Uploaded by

sanjaig0 ratings0% found this document useful (0 votes)

85 views3 pagesSix Sigma is a data-driven methodology used to improve processes by eliminating defects. It was developed by Motorola and Bill Smith in the 1980s and later adopted by General Electric. The goal of Six Sigma is to have a process mean that is six standard deviations from the nearest specification limit, allowing for minimal defects. Practitioners can be certified at various belt levels - White, Yellow, Green, Black, and Master Black - by completing training, experience requirements, and projects. Six Sigma aims to continually improve processes from 3 sigma to 4 sigma and beyond to reduce costs and increase customer satisfaction.

Original Description:

Original Title

Six Sigma – Lean Manufacturing and Six Sigma Definitions.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSix Sigma is a data-driven methodology used to improve processes by eliminating defects. It was developed by Motorola and Bill Smith in the 1980s and later adopted by General Electric. The goal of Six Sigma is to have a process mean that is six standard deviations from the nearest specification limit, allowing for minimal defects. Practitioners can be certified at various belt levels - White, Yellow, Green, Black, and Master Black - by completing training, experience requirements, and projects. Six Sigma aims to continually improve processes from 3 sigma to 4 sigma and beyond to reduce costs and increase customer satisfaction.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

85 views3 pagesSix Sigma - Lean Manufacturing and Six Sigma Definitions PDF

Six Sigma - Lean Manufacturing and Six Sigma Definitions PDF

Uploaded by

sanjaigSix Sigma is a data-driven methodology used to improve processes by eliminating defects. It was developed by Motorola and Bill Smith in the 1980s and later adopted by General Electric. The goal of Six Sigma is to have a process mean that is six standard deviations from the nearest specification limit, allowing for minimal defects. Practitioners can be certified at various belt levels - White, Yellow, Green, Black, and Master Black - by completing training, experience requirements, and projects. Six Sigma aims to continually improve processes from 3 sigma to 4 sigma and beyond to reduce costs and increase customer satisfaction.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

Six Sigma

Six Sigma is a disciplined, statistical-based, data-driven approach and

continuous improvement methodology for eliminating defects in a

product, process or service. It was developed by Motorola and Bill Smith

in the early 1980ʼs based on quality management fundamentals, then

became a popular management approach at General Electric (GE) with

Jack Welch in the early 1990ʼs. The approach was based on the methods

taught by W. Edwards Deming, Walter Shewhart and Ronald Fisher

among many others. Hundreds of companies around the world have

adopted Six Sigma as a way of doing business.

Sigma represents the population standard deviation, which is a measure

of the variation in a data set collected about the process. If a defect is

defined by specification limits separating good from bad outcomes of a

process, then a six sigma process has a process mean (average) that is

six standard deviations from the nearest specification limit. This provides

enough buffer between the process natural variation and the

specification limits.

For example, if a product must have a thickness between 10.32 and

10.38 inches to meet customer requirements, then the process mean

should be around 10.35, with a standard deviation less than 0.005 (10.38

would be 6 standard deviations away from 10.35), assuming a normal

distribution.

Six Sigma can also be thought of as a measure of process performance,

with Six Sigma being the goal, based on the defects per million. Once the

current performance of the process is measured, the goal is to

continually improve the sigma level striving towards 6 sigma. Even if the

improvements do not reach 6 sigma, the improvements made from 3

sigma to 4 sigma to 5 sigma will still reduce costs and increase customer

satisfaction.

Here are some examples of processes from different industries and their

actual sigma levels.

The video below provides a simple explanation of the different sigma

levels, and how they relate to golfing.

The martial arts belt structure is used to recognize proficiency in training

and application in Six Sigma, using the following colors:

White Belt – Overview, DMAIC, Define Phase

Yellow Belt – White Belt + process mapping, data collection and

charting, assisting with a project

Green Belt – Yellow Belt + Project leader, core Six Sigma tools (Gage

R&R, SPC, Capability, ANOVA, Regression), change management,

hypothesis tests and more

Black Belt – Green Belt + advanced statistical analysis and

experiments, change management, nonnormal distributions

Master Black Belt – Black Belt + Design for Six Sigma, more

advanced statistical analysis, unique tools for specific industries and

processes, working with leadership, implementing successful

improvement programs

However, not all levels are consistent and equal to each other, so it is

important to ask questions about the topics covered and requirements

needed to complete each belt level.

Formal certification is recognized at the Green Belt, Black Belt and

Master Black Belt level based on one or more of the following criteria:

Completion of training covering the body of knowledge

Years of work experience with the body of knowledge

Passing an exam covering the body of knowledge

Completion of one or more Six Sigma projects

Certification is typically authorized by consulting firms or industry

organizations and membership groups.

A combined Lean Six Sigma belt typically is an expanded or modified

version of Six Sigma training with the addition of Lean principles and

tools.

Want some ideas for Six Sigma projects you can run within your industry?

Check out this list of Six Sigma project ideas to help get you started…

Download the Lean Six Sigma Powerpoint course >>>

« Back to Glossary Index

You might also like

- Ch19 Bradford ManufacturingDocument6 pagesCh19 Bradford Manufacturingnurul_azizah0120% (5)

- Problem 1 (15 Marks) Select Only ONE of The Answers. Each Correct Answer Has 1 Mark. Write Your Answer On The Exam BookletDocument7 pagesProblem 1 (15 Marks) Select Only ONE of The Answers. Each Correct Answer Has 1 Mark. Write Your Answer On The Exam BookletKeyvan HajjarizadehNo ratings yet

- BS 6391 2009 HosesDocument32 pagesBS 6391 2009 HosessanjaigNo ratings yet

- CSSBB Cert Project AffidavitDocument2 pagesCSSBB Cert Project AffidavitJOSE LUISNo ratings yet

- Work Measurement and TimestudyDocument33 pagesWork Measurement and TimestudyAnshu RoyNo ratings yet

- Lean IT Foundation Publication v1.0 PDFDocument14 pagesLean IT Foundation Publication v1.0 PDFracringandhiNo ratings yet

- Lean Six Sigma Green Belt Body of KnowledgeDocument5 pagesLean Six Sigma Green Belt Body of KnowledgeShijuNo ratings yet

- Black Belt Certification Exam Faq: DescriptionDocument1 pageBlack Belt Certification Exam Faq: DescriptionKefin Tajeb0% (1)

- Chapter 4 - State-of-the-Art Process-Centric Models (Multi-Method Approach)Document2 pagesChapter 4 - State-of-the-Art Process-Centric Models (Multi-Method Approach)DeuterioTritioNo ratings yet

- Lean Six Sigma CrosswordDocument1 pageLean Six Sigma CrosswordexamplecgNo ratings yet

- Simulation-based Lean Six-Sigma and Design for Six-SigmaFrom EverandSimulation-based Lean Six-Sigma and Design for Six-SigmaRating: 3 out of 5 stars3/5 (2)

- Six SigmaDocument13 pagesSix Sigmashafvan_786No ratings yet

- ASQ - Course Outline Lean Six SIgma Black Belt Minitab - ASQ - LSSBBM01MS PDFDocument5 pagesASQ - Course Outline Lean Six SIgma Black Belt Minitab - ASQ - LSSBBM01MS PDFSalas J AlbertoNo ratings yet

- The Asq Certified Six Sigma Green BeltDocument12 pagesThe Asq Certified Six Sigma Green Beltم.رأفت الرباطيNo ratings yet

- ICGB - Exam.80q: Number: ICGB Passing Score: 800 Time Limit: 120 MinDocument36 pagesICGB - Exam.80q: Number: ICGB Passing Score: 800 Time Limit: 120 MinabdelaadimNo ratings yet

- Operational Excellence FAQsDocument3 pagesOperational Excellence FAQsNaresh DeshpandeNo ratings yet

- 8a Quiz QC Tool 2 Check SheetDocument2 pages8a Quiz QC Tool 2 Check SheetJose Ortega0% (1)

- Construction of A Pasig Riverside Green Building Condominium in Downtown ManilaDocument38 pagesConstruction of A Pasig Riverside Green Building Condominium in Downtown ManilaMehrad SarabandiNo ratings yet

- DMAIC - MethodologyDocument21 pagesDMAIC - MethodologySkirmisher PBNo ratings yet

- Acronyms - Six Sigma - LeanDocument3 pagesAcronyms - Six Sigma - LeantorrespacNo ratings yet

- Six Sigma Is A Business Management Strategy Originally Developed byDocument11 pagesSix Sigma Is A Business Management Strategy Originally Developed byharshil_shah007No ratings yet

- FEIGENBAUM + Ishikawa + TaguchiDocument7 pagesFEIGENBAUM + Ishikawa + Taguchiaulia rakhmawatiNo ratings yet

- Libro Lean Six SigmaDocument268 pagesLibro Lean Six SigmaRobert CamposNo ratings yet

- GE Six SigmaDocument6 pagesGE Six Sigmaimran27pk100% (2)

- Six Sigma Case Studies - Vytra Call Center PDFDocument2 pagesSix Sigma Case Studies - Vytra Call Center PDFVbaluyoNo ratings yet

- GB MockexamDocument24 pagesGB MockexamAnonymous 7K9pzvziNo ratings yet

- Kaizen Case StudyDocument44 pagesKaizen Case StudyTanmoy ChakrabortyNo ratings yet

- Six Sigma Black Belt CourseDocument4 pagesSix Sigma Black Belt CourseKhalńaayak Ji100% (1)

- Applied Statistics For The Six Sigma Green Belt (PDFDrive)Document425 pagesApplied Statistics For The Six Sigma Green Belt (PDFDrive)chinotov4No ratings yet

- Benchmark Six Sigma Green BeltDocument18 pagesBenchmark Six Sigma Green BeltANKITH BEERA MBA 2019-21 (Delhi)No ratings yet

- Multi Vari ChartsDocument9 pagesMulti Vari ChartsDearRed FrankNo ratings yet

- Lean Six Sigma White Belt Autor University of California San DiegoDocument31 pagesLean Six Sigma White Belt Autor University of California San DiegoGoran SpasićNo ratings yet

- IATF 16949 Webinar Slides 3.7.17 Final PDFDocument47 pagesIATF 16949 Webinar Slides 3.7.17 Final PDFmilou88No ratings yet

- Cusum Ewma TemplateDocument11 pagesCusum Ewma TemplateDavid ArechagaNo ratings yet

- The Asq Certified Six Sigma Black BeltDocument16 pagesThe Asq Certified Six Sigma Black BeltJohn Jerome ThompsonNo ratings yet

- Value Stream Mapping: Dr. Syed Amir IqbalDocument41 pagesValue Stream Mapping: Dr. Syed Amir IqbalNOSHEEN MEHFOOZ100% (1)

- Basics of Six SigmaDocument117 pagesBasics of Six SigmaMauricio AmayaNo ratings yet

- Lean Six Sigma Asq Road MapDocument2 pagesLean Six Sigma Asq Road Maphj100% (4)

- ICGB Study Guide and How To Crack Exam o PDFDocument4 pagesICGB Study Guide and How To Crack Exam o PDFAttef BedawyNo ratings yet

- SSBB Fact SheetDocument2 pagesSSBB Fact SheetNJOY81No ratings yet

- Project Report On Maynard Operation Sequence TechniqueDocument9 pagesProject Report On Maynard Operation Sequence TechniqueEditor IJTSRDNo ratings yet

- Enterprise Dynamics TutorialDocument66 pagesEnterprise Dynamics TutorialBaracNo ratings yet

- Lean Six Sigma in The Service Industry by Alessandro Laureani PDFDocument14 pagesLean Six Sigma in The Service Industry by Alessandro Laureani PDFnaacha457No ratings yet

- Ref Phase2 Lean Six Sigma Green Beltv11institute 07072023191233 2Document221 pagesRef Phase2 Lean Six Sigma Green Beltv11institute 07072023191233 2Vinayak ChaturvediNo ratings yet

- 1 Introduction To Statistical Quality Control, 7th Edition by Douglas C. MontgomeryDocument78 pages1 Introduction To Statistical Quality Control, 7th Edition by Douglas C. MontgomeryNejra Trle0% (1)

- TQM Versus Six SigmaDocument16 pagesTQM Versus Six Sigmaapi-3751356No ratings yet

- Six Sigma Black Belt CertificationDocument1 pageSix Sigma Black Belt CertificationHARI HARA RAO GUJJARNo ratings yet

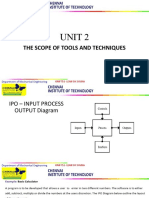

- Unit 2: The Scope of Tools and TechniquesDocument64 pagesUnit 2: The Scope of Tools and TechniquesKamal KannanNo ratings yet

- Application of MCDM Model For Assessing Suitability of JIT ManufacturingDocument6 pagesApplication of MCDM Model For Assessing Suitability of JIT ManufacturingJournal of ComputingNo ratings yet

- 1.0 LSS Quality Files Define OpportunitiesDocument113 pages1.0 LSS Quality Files Define OpportunitiesMurrell J RizonNo ratings yet

- 03 - BB Manual - Measure - v12 - 4 PDFDocument154 pages03 - BB Manual - Measure - v12 - 4 PDFRicardo BravoNo ratings yet

- GB 6 Sigma Productivity Solutions PDFDocument2 pagesGB 6 Sigma Productivity Solutions PDFJHCPNo ratings yet

- Just in Time System (2) 10000Document24 pagesJust in Time System (2) 10000John GriffiesNo ratings yet

- Project Charter ExampleDocument2 pagesProject Charter ExampleJohnNo ratings yet

- Instructions: 'No' Answers Are To Be Resolved Immediately and DocumentedDocument1 pageInstructions: 'No' Answers Are To Be Resolved Immediately and Documentedrgrao85No ratings yet

- Lean Playbook Series - The TPM Playbook - A Step-By-step Guideline For The Lean PractitionerDocument37 pagesLean Playbook Series - The TPM Playbook - A Step-By-step Guideline For The Lean PractitionerMatheus NascimentoNo ratings yet

- Sepuran® N Selective System 6": in NM /H at 9 Barg 25°CDocument2 pagesSepuran® N Selective System 6": in NM /H at 9 Barg 25°CsanjaigNo ratings yet

- Sepuran® N Module 4": in NM /H at 7 Barg 25°CDocument2 pagesSepuran® N Module 4": in NM /H at 7 Barg 25°CsanjaigNo ratings yet

- Is.884.1985 - First Aid Hose ReelDocument17 pagesIs.884.1985 - First Aid Hose ReelsanjaigNo ratings yet

- Disclosure To Promote The Right To InformationDocument14 pagesDisclosure To Promote The Right To InformationsanjaigNo ratings yet

- BS En-11Document24 pagesBS En-11sanjaigNo ratings yet

- Health Technical Memorandum 01-04:: Decontamination of Linen For Health and Social CareDocument16 pagesHealth Technical Memorandum 01-04:: Decontamination of Linen For Health and Social CaresanjaigNo ratings yet

- NiCo Supercoat 500Document2 pagesNiCo Supercoat 500sanjaigNo ratings yet

- British Standard British Standard Bs en Bs en 733:1995 733:1995Document12 pagesBritish Standard British Standard Bs en Bs en 733:1995 733:1995sanjaigNo ratings yet

- EMC Management and Related Technical Aspects in Railway SystemsDocument30 pagesEMC Management and Related Technical Aspects in Railway SystemssanjaigNo ratings yet

- IEE Current Ratings Regulations Table 4E1ADocument3 pagesIEE Current Ratings Regulations Table 4E1AsanjaigNo ratings yet

- Is 904-Specification For 2-Way and 3-Way Suction Collecting Heads For Fire Fighting PurposDocument11 pagesIs 904-Specification For 2-Way and 3-Way Suction Collecting Heads For Fire Fighting PurpossanjaigNo ratings yet

- Premium Liab&WarrantyDocument25 pagesPremium Liab&WarrantyPipz G. CastroNo ratings yet

- Chapter 03 TestbankDocument108 pagesChapter 03 TestbankanukshaNo ratings yet

- Layers of Fear: Horror House F-9Document4 pagesLayers of Fear: Horror House F-9Sardar EhtashamNo ratings yet

- All Contributions Noon 23Document23 pagesAll Contributions Noon 23Alexandria ShahabianNo ratings yet

- Iso Terms of Reference For Iso9001.2015 All Departments MindoroDocument10 pagesIso Terms of Reference For Iso9001.2015 All Departments MindoroZyreen Kate BCNo ratings yet

- 4 - Effective Resource Management PlanningDocument21 pages4 - Effective Resource Management PlanningGökrem TekirNo ratings yet

- Full Download PDF of Modern Competitive Strategy 4th Edition All ChapterDocument43 pagesFull Download PDF of Modern Competitive Strategy 4th Edition All Chaptermaljictahor100% (14)

- PTW & SWC TrainingDocument26 pagesPTW & SWC Trainingعبدالحميد عبدالغفار الدرديريNo ratings yet

- Profile Summary: Ca Vaibhav KumarDocument3 pagesProfile Summary: Ca Vaibhav KumarThe Cultural CommitteeNo ratings yet

- Aud Prob SolutionsDocument10 pagesAud Prob SolutionsAngel AguinaldoNo ratings yet

- Material MasterDocument127 pagesMaterial Mastersridharcvlr100% (4)

- Question AirsDocument4 pagesQuestion Airsabraham admassieNo ratings yet

- Chapter Three: Developing Marketing Strategies and PlansDocument40 pagesChapter Three: Developing Marketing Strategies and PlansSuLeng LokeNo ratings yet

- How To Approach The Advanced Performance Management (APM) ExamDocument1 pageHow To Approach The Advanced Performance Management (APM) ExamНаиль Ризванов0% (1)

- Surat Lamaran Kerja - PT. Kao Indonesia ChemicalsDocument2 pagesSurat Lamaran Kerja - PT. Kao Indonesia Chemicalshanif nur fahriNo ratings yet

- Subject Matter of CopyrightDocument2 pagesSubject Matter of CopyrightSahil GuptaNo ratings yet

- CH 21 SMDocument45 pagesCH 21 SMNafisah Mambuay100% (1)

- Personal Portfolio: Here Is Where Your Presentation BeginsDocument21 pagesPersonal Portfolio: Here Is Where Your Presentation BeginsANH TRẦN VÂNNo ratings yet

- Warehouse InductionDocument11 pagesWarehouse InductionElandre BurgerNo ratings yet

- SBM Dimension1 LEADERSHIPDocument32 pagesSBM Dimension1 LEADERSHIPFe ApolonioNo ratings yet

- Packfinder™ - Francis Alvin PepitoDocument5 pagesPackfinder™ - Francis Alvin PepitoFrancis PepitoNo ratings yet

- FInal Script.Document7 pagesFInal Script.PRINCE SINGH RAJPUT Student, Jaipuria IndoreNo ratings yet

- Project ManagementDocument37 pagesProject ManagementNahom Asegid TeressaNo ratings yet

- Programme Support Manager - MedairDocument7 pagesProgramme Support Manager - MedairModong DangasukNo ratings yet

- Human Resource Management For Small Businesses PDFDocument6 pagesHuman Resource Management For Small Businesses PDFAnastasia GoularaNo ratings yet

- MCQ 6Document5 pagesMCQ 6Eng-Ahmed Baasaay0% (1)

- "Marketing Strategy of Air India": A Project Report OnDocument17 pages"Marketing Strategy of Air India": A Project Report OnShreyas ParabNo ratings yet

- Lesson 1: Introduction To Operations ManagementDocument6 pagesLesson 1: Introduction To Operations ManagementVanesa Calimag ClementeNo ratings yet

- Advances in Accounting, Incorporating Advances in International AccountingDocument7 pagesAdvances in Accounting, Incorporating Advances in International Accountingbusyaib syamsul sirotNo ratings yet