Professional Documents

Culture Documents

Connection No - C08-C5: Loads: T-Loading

Connection No - C08-C5: Loads: T-Loading

Uploaded by

Krish ChandOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Connection No - C08-C5: Loads: T-Loading

Connection No - C08-C5: Loads: T-Loading

Uploaded by

Krish ChandCopyright:

Available Formats

Client : Date : DEC-05

Project : Calc'd by : KP

Estimate no : Checked by : SM

Contract no :

Sheet no :C08-C5/ 1

CONNECTION NO - C08-C5

LOADS: T-LOADING

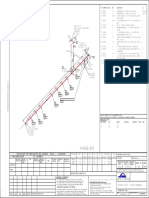

HE 300A

Vertical shear Fv := 150kN

Axial Force F := 310kN

Horizontal shear Fh := 44kN

170 Full prep., PPBW

90

8

8

70

20 THK WEB PLATE

70

HE300A HE300A

160X20 THK TEE FLANGE PLATE 160X25 THK END PLATE

BOLTS @ 90 X/CRS BOLTS @ 90 X/CRS

OL T S

B @ 90 X

/ C

RS

1 60 X

2 5 T

HKN EDPA

B LO T S @ 9 0X R

/C S

L E

T

OL T

B S @ 90 X

/C R S

NOTES:-

All bolts are M20, Grade 8.8

All welds are 6mm CFW U.N.O

All main steel & fittings are S275.

Variation no: Rev date Description

Client : Date : DEC-05

Project : Calc'd by : KP

Estimate no : Checked by : SM

Contract no :

Sheet no :C08-C5/ 2

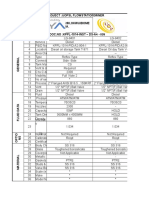

Sectional properties

Supporting beam HE300A Db1 := 290 ⋅ mm Wb1 := 300 ⋅ mm Tb1 := 14 ⋅ mm tb1 := 8.5 ⋅ mm rb1 := 27 ⋅ mm

Incoming beam HE300A Db2 := 290 ⋅ mm Wb2 := 300 ⋅ mm Tb2 := 14 ⋅ mm tb2 := 8.5 ⋅ mm rb2 := 27 ⋅ mm

2

Ab2 := 11300mm

Material Properties

N

Design strength of S275 material py275 := 275 ⋅

up to & including 16 thk 2

mm

N

Design strength of S275 material py265 := 265 ⋅

beyond 16thk and up to & including 2

mm

40mm thk

N

Bearing Strength of S275 material pbs275 := 460

2

mm

N

Design Strength of Weld pw := 220

2

mm

Shear capacity of M20 bolts Ps := 91.9kN

Tension capacity of M20 bolts Pnom := 110kN

Check for bolts

Taking rotation about centre of R := ( 83 153 223 )mm

beam top flange

⎡ 2 ⎤

⎢2 ⋅ ( 0 , n) 2⎥

⎢ ∑ R

⎥

⎣ n = 0 ⎦

Section modulus of bolt group Zp := Zp = 717.73 mm

R0 , 2

Eccentricity of shear from beam web e := 170mm

Moment induced due to eccentric shear M := Fv ⋅ e M = 25.5 kN ⋅ m

M

Max.Tensile Force on Single Ft1 := Ft1 = 35.5 kN

bolt due to induced moment Zp

Total number of bolts n := 6

F

Tension per bolt due to axial force & Ft := + Ft1 Ft = 87.2 kN

moment n

Fv

Vertical shear per bolt Fsv := Fsv = 25 kN

n

Fh

Horizontal shear per bolt Fsh := Fsh = 11 kN

4

Variation no: Rev date Description

Client : Date : DEC-05

Project : Calc'd by : KP

Estimate no : Checked by : SM

Contract no :

Sheet no :C08-C5/ 3

2 2

Resultant shear per bolt Fs := Fsv + Fsh Fs = 27.31 kN

⎛⎜ Fs Ft ⎞

Combined shear and tension Ratio := + Ratio = 1.09

⎜⎝ Ps Pnom ⎠

Ratio ( 1.09 ) < 1.4 : Therefore O.K.

Check for weld between beam web and end plate

F Ft1

Tension in second row of bolt Ft2 := + ⋅ R0 , 1 Ft2 = 76.04 kN

n R0 , 2

Bolt pitch p := 70mm

Bolt gauge g := 90mm

Dispersion length on weld Ld := p Ld = 70 mm

Length of weld Lweld := Ld

Ft2 kN

Tension per mm on weld FT := FT = 1.086

Lweld mm

Fv kN

Vertical shear per mm FL := FL = 0.361

2 ⋅ 208mm mm

2

⎛ FT ⎞ kN

Resultant force per mm R1 := ⎜ + FL

2

R1 = 0.941

⎝ 1.25 ⎠ mm

R1

Size of fillet weld required s req := s req = 6.11 mm

0.7 ⋅ pw

Adopt 8mm CFW

Check for end plate (Worst case)

Bolt tension Ft2 = 76.04 kN

Web thickness of HE 300A beam tb2 = 8.5 mm

Ft2 ⎛g tb2 ⎞

Moment due to bolt force M := ⋅⎜ − − 0.8 ⋅ 8mm M = 1.306 kN ⋅ m

2 ⎝2 2 ⎠

Dispersion length ld := p

M ⋅6

Thickness of plate required treqd := treqd = 20.55 mm

py265 ⋅ ld

Adopt 25mm thk end plate

Variation no: Rev date Description

Client : Date : DEC-05

Project : Calc'd by : KP

Estimate no : Checked by : SM

Contract no :

Sheet no :C08-C5/ 4

Check for tee flange plate (Worst case)

Thickness of Tee web plate ts := 20mm

Ft2 ⎛g ts ⎞

Moment due to bolt force M := ⋅⎜ − − 0.8 ⋅ 8mm M = 1.087 kN ⋅ m

2 ⎝2 2 ⎠

Dispersion length ld := p

M ⋅6

Thickness of plate required treqd := treqd = 18.75 mm

py265 ⋅ ld

Adopt 20mm thk tee flange plate

Check for tension capacity of incoming beam web

Tension capacity of beam web/ bolt tension PT := py275 ⋅ p ⋅ tb2 PT = 163.63 kN

Tension in web Ftw := 2 ⋅ Ft2 Ftw = 152.09 kN

PT (163.62 kN) > Ftw (152.09 kN): Therefore O.K.

Check for tee plate welds

Weld between tee flange/ end plate and HE300A top flange

⎡ 2 ⎤ b1

⎢ (R0 , n)⎥

⎢ ∑ ⎥

⎣n = 0 ⎦

Max. compression in top flange Fc := 2 ⋅ Ft ⋅ Fc = 358.95 kN

of beam due to moment R0 , 2

Width of end plate/tee flange plate wp := 160mm

Effective width of beam flange b1 := wp b1 = 160 mm

Effective C/S area of beam

⎣ (

Abeff := Ab2 − 2 ⋅ ⎡ Wb2 − b1 ⋅ Tb2⎤

⎦ ) Abeff = 7380 mm

2

b1 ⋅ Tb1

Compressive force on beam top flange Fca := ⋅F Fca = 94.09 kN

due to axial in beam Abeff

Total compression in top flange C := Fc + Fca C = 453.04 kN

Fh

Horizontal shear per flange Ff := Ff = 22 kN

2

Length of weld available Lweld := b1 Lweld = 160 mm

C kN

Compression per mm FT1 := FT1 = 2.83

Lweld mm

Variation no: Rev date Description

Client : Date : DEC-05

Project : Calc'd by : KP

Estimate no : Checked by : SM

Contract no :

Sheet no :C08-C5/ 5

Ff kN

Shear per mm FL1 := FL1 = 0.137

Lweld mm

2

⎛ FL1 ⎞ kN

FT1 + ⎜

2

Resultant force R2 := R2 = 2.841

⎝ 0.6 ⎠ mm

⎡ ⎛ R2 ⎞⎤

Size of PPBW required (

s := max ⎢ 2 ⋅ 14 + 3 mm , ⎜ ) + 3mm ⎥ s = 13.33 mm

⎢⎣ ⎜⎝ py275 ⎠⎥⎦

Adopt Full prep. PPBW.

Weld between tee flange/ end plate and HE300A bottom flange

Tension dispersed on beam ⎛ F + F ⎞ ⋅ 48.75

Ftf := ⎜ t1 48.75 + 54 Ftf = 41.37 kN

bottom flange ⎝n ⎠

54

Ftf 48.75

kN

Tension per mm on beam FT2 := FT2 = 0.849

bottom flange 48.75mm mm

Length of weld available Lweld1 := 2 ⋅ Wb2 − tb2 − 2 ⋅ rb2 Lweld1 = 537.5 mm

Ff kN

Horizontal shear per mm on beam FL2 := FL2 = 0.041

bottom flange Lweld1 mm

2

Resultant shear per mm on ⎛ FT2 ⎞ kN

R3 := ⎜ + FL2

2

R3 = 0.680

beam bottom flange ⎝ 1.25 ⎠ mm

R3

Size of fillet weld required s req := s req = 4.42 mm

0.7 ⋅ pw

Adopt 6mm CFW

Weld between tee web and HE300A flange

120.8

F Ft1 191.64 kN

Tension in first row of bolt Ft0 := + ⋅ R0 , 0 Ft0 = 64.89 kN

76

n R0 , 2

2 x 65.28 kN

70

F Ft1

Tension in second row of bolt Ft2 := + ⋅ R0 , 1 Ft2 = 76.04 kN 2 x 76.76 kN

46 70

n R0 , 2

2 x 88.24 kN

F

Tension in third row of bolt Ft := + Ft1 Ft = 87.2 kN 268.9 kN

n

(

2 Ft0 ⋅ 76 mm + Ft2 ⋅ 146mm + Ft ⋅ 216mm )

Max shear on the weld/side Fmax := Fmax = 266.17 kN

( 46 + 70 + 70 + 76 )mm

Variation no: Rev date Description

Client : Date : DEC-05

Project : Calc'd by : KP

Estimate no : Checked by : SM

Contract no :

Sheet no :C08-C5/ 6

Length available for weld/side Lweld2 := 145.8mm − 25mm Lweld2 = 120.8 mm

Fmax kN

Shear per mm FL3 := FL3 = 1.102

2Lweld2 mm

FL3

Size of fillet weld required s req := s req = 7.15 mm

0.7 ⋅ pw

Adopt 8mm CFW

Weld between HE300A supporting beam web and tee web

FL

Size of fillet weld required s req := s req = 2.34 mm

0.7 ⋅ pw

Adopt 6mm CFW

Check for tee web plate

Width of web plate w := 120.8mm

Fmax

Thickness of plate required in shear treq := treq = 15.4 mm

0.6 ⋅ 0.9 ⋅ w ⋅ py265

Adopt 20 thk plate as Tee web

Variation no: Rev date Description

You might also like

- Activa 4G CATULOGUEDocument59 pagesActiva 4G CATULOGUEPrashanth Narayan Swamy100% (7)

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Activa 125 Fi Engine Parts BookDocument17 pagesActiva 125 Fi Engine Parts BookJoeNo ratings yet

- Baseplate (Fixed Type 6 Bolts) 123Document15 pagesBaseplate (Fixed Type 6 Bolts) 123vijay10484No ratings yet

- 05a - HORIZONTAL BRACEDocument10 pages05a - HORIZONTAL BRACEShyamontika Choudhury ChakrabartiNo ratings yet

- ACI Code 315-14Document22 pagesACI Code 315-14murad_ce0% (3)

- Mathcad - C06-C8 PDFDocument7 pagesMathcad - C06-C8 PDFKrish ChandNo ratings yet

- Client: Project: Estimate No: Contract No: Sheet No: C06-C6/1Document7 pagesClient: Project: Estimate No: Contract No: Sheet No: C06-C6/1Krish ChandNo ratings yet

- Client: Project: Estimate No: Contract No: Sheet No: C06-C4/1Document7 pagesClient: Project: Estimate No: Contract No: Sheet No: C06-C4/1Krish ChandNo ratings yet

- Client: Project: Estimate No: Contract No: Sheet No: C06/C5/1Document8 pagesClient: Project: Estimate No: Contract No: Sheet No: C06/C5/1Krish ChandNo ratings yet

- Mathcad - C02-C1Document5 pagesMathcad - C02-C1Krish ChandNo ratings yet

- Mathcad - C06-C9 PDFDocument7 pagesMathcad - C06-C9 PDFKrish ChandNo ratings yet

- Mathcad - C05-C2Document6 pagesMathcad - C05-C2Krish ChandNo ratings yet

- Mathcad - C02-C2Document5 pagesMathcad - C02-C2Krish ChandNo ratings yet

- Client: Project: Estimate No: Contract No: Sheet No: C06-C2/1Document5 pagesClient: Project: Estimate No: Contract No: Sheet No: C06-C2/1Krish ChandNo ratings yet

- Mathcad - C05-C1 PDFDocument4 pagesMathcad - C05-C1 PDFKrish ChandNo ratings yet

- Mathcad - C06-C10 PDFDocument7 pagesMathcad - C06-C10 PDFKrish ChandNo ratings yet

- Connection No - C08-C6: Vertical Shear Tying Force FV 705 KN : Fa 705 KNDocument6 pagesConnection No - C08-C6: Vertical Shear Tying Force FV 705 KN : Fa 705 KNKrish ChandNo ratings yet

- Mathcad - C06-C3Document5 pagesMathcad - C06-C3Krish ChandNo ratings yet

- Connection - C02-C3: (UC Bracing Bar, Flanges Stripped and Lapped On)Document5 pagesConnection - C02-C3: (UC Bracing Bar, Flanges Stripped and Lapped On)Krish ChandNo ratings yet

- Connection No - C04-C1: Loads: 305X305X118 UCDocument5 pagesConnection No - C04-C1: Loads: 305X305X118 UCKrish ChandNo ratings yet

- Connection No-C08-C4: Vertical Shear Tie Force APG750X300X314 FV 1100kN: Fa 1100kNDocument5 pagesConnection No-C08-C4: Vertical Shear Tie Force APG750X300X314 FV 1100kN: Fa 1100kNKrish ChandNo ratings yet

- Aislador 69 KV Ta-Sb-047-127-XxDocument1 pageAislador 69 KV Ta-Sb-047-127-XxSalvador De La ReeNo ratings yet

- Lube Oil Cooler of Hydraulic Coupling GADocument2 pagesLube Oil Cooler of Hydraulic Coupling GAarunrajmech09No ratings yet

- Connection - C02-C5: (Combined Beam & Vertical Bracing Connection)Document7 pagesConnection - C02-C5: (Combined Beam & Vertical Bracing Connection)Krish ChandNo ratings yet

- Mathcad - C08-C3Document6 pagesMathcad - C08-C3Krish ChandNo ratings yet

- HBM RTN Datasheet UsaDocument4 pagesHBM RTN Datasheet UsaAntony Stip Flores TorresNo ratings yet

- Level Switch NS 10/NS 25 ..-AM: FluidcontrolDocument7 pagesLevel Switch NS 10/NS 25 ..-AM: FluidcontrolNguyễn Kim HùngNo ratings yet

- Tba810s SGSDocument6 pagesTba810s SGSjosue sotoNo ratings yet

- Loadcell RTN 100tDocument4 pagesLoadcell RTN 100tVũ Văn Thành100% (1)

- Célula de Carga - Download-Hbm-Rtnc3-A5d7a2ff56Document4 pagesCélula de Carga - Download-Hbm-Rtnc3-A5d7a2ff56Gabriel WeissNo ratings yet

- Punch Typ C4Document10 pagesPunch Typ C4Suhail AhamedNo ratings yet

- Fairchild Fasteners Europe: Saint Cosme OperationsDocument1 pageFairchild Fasteners Europe: Saint Cosme OperationsstaedtlerpNo ratings yet

- My PDMSDocument4 pagesMy PDMSNavaneeth PurushothamanNo ratings yet

- Pile Cap ChecksDocument6 pagesPile Cap ChecksNikhilNo ratings yet

- 1000 Hrs Survival Test (ASTM D 1598, ISO 14692-2) : Specimens DataDocument24 pages1000 Hrs Survival Test (ASTM D 1598, ISO 14692-2) : Specimens DataNADEEM AHMEDNo ratings yet

- Intake Kyn Toyota 1zrDocument2 pagesIntake Kyn Toyota 1zrALiito KNo ratings yet

- 0W430191-STR-051 - Squadcheck PipingDocument1 page0W430191-STR-051 - Squadcheck PipingNew BossNo ratings yet

- DE200012 - NS - 25 15 AM Atex - 25 25 AM AtexDocument3 pagesDE200012 - NS - 25 15 AM Atex - 25 25 AM AtexVincenzo CrippaNo ratings yet

- Schematic DiagramDocument1 pageSchematic DiagramNoufal OthupurayilNo ratings yet

- Contractor: Project:Uopsl Flowstation Owner Block:Opl 280, Okwuibome Field, Nigeria. Title:Data Sheet For Level Gauge (Reflex Type)Document4 pagesContractor: Project:Uopsl Flowstation Owner Block:Opl 280, Okwuibome Field, Nigeria. Title:Data Sheet For Level Gauge (Reflex Type)BABILIN VNo ratings yet

- Bolts Connection Design Based On AISC Manual 13th Edition: Input Data & Design SummaryDocument2 pagesBolts Connection Design Based On AISC Manual 13th Edition: Input Data & Design SummaryRayodcNo ratings yet

- Licad86061000009 F46Document1 pageLicad86061000009 F46Sakeel WagirkhanNo ratings yet

- (09-2) - L-ZL (26) 26RG01B.001 PDFDocument1 page(09-2) - L-ZL (26) 26RG01B.001 PDFRaznan RamliNo ratings yet

- Drawing 6x130 - CORIGY ENERGYDocument1 pageDrawing 6x130 - CORIGY ENERGYSTEFNo ratings yet

- Sub PLC Panel Wiring DiagramDocument9 pagesSub PLC Panel Wiring DiagramIyapparaj PazhaniNo ratings yet

- An1376 25w Quasiresonant Flyback Converter For Settop Box Application Using The l6565 StmicroelectronicsDocument35 pagesAn1376 25w Quasiresonant Flyback Converter For Settop Box Application Using The l6565 StmicroelectronicsElyes MbarekNo ratings yet

- Drawing 6x150 - CORIGY ENERGYDocument1 pageDrawing 6x150 - CORIGY ENERGYSTEFNo ratings yet

- Licad86061000010 F06Document1 pageLicad86061000010 F06Sakeel WagirkhanNo ratings yet

- 3 - Dimension For Cond Unit - 010Document4 pages3 - Dimension For Cond Unit - 010rendiirawan19No ratings yet

- Hot Tap Daily Welding Report 1Document1 pageHot Tap Daily Welding Report 1Jamal BakhtNo ratings yet

- Column at C-2: Reinforced Concrete CouncilDocument11 pagesColumn at C-2: Reinforced Concrete CouncilSuhail AhamedNo ratings yet

- Wind CoefficientDocument2 pagesWind Coefficientvisva scgNo ratings yet

- Drawing 6x100 - CORIGY ENERGYDocument1 pageDrawing 6x100 - CORIGY ENERGYSTEFNo ratings yet

- SIEMENS Rly PNL Drgs-1Document12 pagesSIEMENS Rly PNL Drgs-1Amit Kundu DVCNo ratings yet

- Spreadsheets To BS 8110: Advisory Group Ground Floor Columns at B1, B2 Etc 91Document12 pagesSpreadsheets To BS 8110: Advisory Group Ground Floor Columns at B1, B2 Etc 91SimaoNo ratings yet

- Crank DeflektionDocument1 pageCrank DeflektionObed S. PrabowoNo ratings yet

- CRA NK Web Deflection: Piston Stroke in (MM)Document1 pageCRA NK Web Deflection: Piston Stroke in (MM)Obed S. PrabowoNo ratings yet

- 4.3.7.1 - DWG TR Cab 01 00 02-ADocument1 page4.3.7.1 - DWG TR Cab 01 00 02-ASabit HasanNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Module 6 Bridge Engineering BatchDocument120 pagesModule 6 Bridge Engineering BatchKrish Chand100% (3)

- Slab Design Span 7mDocument12 pagesSlab Design Span 7mKrish ChandNo ratings yet

- Calculation Sheet: From Table 4.1 For Floor-Others (Distributed Imposed Action, Q)Document6 pagesCalculation Sheet: From Table 4.1 For Floor-Others (Distributed Imposed Action, Q)Krish ChandNo ratings yet

- Connection - C03-C2: Client: Project: Estimate No: Contract No: Sheet No: C03-C2 / 1Document7 pagesConnection - C03-C2: Client: Project: Estimate No: Contract No: Sheet No: C03-C2 / 1Krish ChandNo ratings yet

- Tech Notes On Bolts PDFDocument41 pagesTech Notes On Bolts PDFKrish ChandNo ratings yet

- Bridge Design Very Useful PDFDocument326 pagesBridge Design Very Useful PDFKrish ChandNo ratings yet

- Mathcad - C05-C2Document6 pagesMathcad - C05-C2Krish ChandNo ratings yet

- Single Span Beam: Untitled: Input TablesDocument1 pageSingle Span Beam: Untitled: Input TablesKrish ChandNo ratings yet

- Prokon - C08-C4Document2 pagesProkon - C08-C4Krish ChandNo ratings yet

- Ub DesignDocument8 pagesUb DesignKrish ChandNo ratings yet

- EarthfillingDocument6 pagesEarthfillingKrish ChandNo ratings yet

- Column Design: Information SheetDocument2 pagesColumn Design: Information SheetKrish ChandNo ratings yet

- Mathcad - Template IndexDocument6 pagesMathcad - Template IndexKrish ChandNo ratings yet

- Mathcad - C05-C2Document6 pagesMathcad - C05-C2Krish ChandNo ratings yet

- Client: Project: Estimate No: Contract No: Sheet No: C06-C2/1Document5 pagesClient: Project: Estimate No: Contract No: Sheet No: C06-C2/1Krish ChandNo ratings yet

- Connection No - C04-C1: Loads: 305X305X118 UCDocument5 pagesConnection No - C04-C1: Loads: 305X305X118 UCKrish ChandNo ratings yet

- Check For Compression Welds Between Beam Flanges and End PlateDocument3 pagesCheck For Compression Welds Between Beam Flanges and End PlateKrish ChandNo ratings yet

- Piping CodesDocument47 pagesPiping CodesSankar MukaNo ratings yet

- An Improved Design Approach For Mat Foundation With Variable Thickness PDFDocument261 pagesAn Improved Design Approach For Mat Foundation With Variable Thickness PDFdxzaberNo ratings yet

- Steam Jet Refrigeration SystemDocument6 pagesSteam Jet Refrigeration Systembbaytl100% (1)

- Lecture Presentation: Remembering General ChemistryDocument73 pagesLecture Presentation: Remembering General ChemistryshahjafferNo ratings yet

- Approaches To The Tight Reservoir Laboratory CharacterisationDocument6 pagesApproaches To The Tight Reservoir Laboratory Characterisationismail.shNo ratings yet

- 4.project ReportDocument38 pages4.project ReportJagadeeshan SivanNo ratings yet

- 21 - Electric Charge and Electric Field - R K ParidaDocument8 pages21 - Electric Charge and Electric Field - R K ParidaMonicaNo ratings yet

- SC RE Chap11-Drive MechanismsDocument45 pagesSC RE Chap11-Drive Mechanismsweldsv100% (1)

- Finite Element Analysis For The Design Validation of Mounded LPG BulletsDocument8 pagesFinite Element Analysis For The Design Validation of Mounded LPG BulletsMuhammed NoufalNo ratings yet

- Majorana Fermions in Condensed Matter Physics: The 1D Nanowire CaseDocument6 pagesMajorana Fermions in Condensed Matter Physics: The 1D Nanowire CaseOscar BohórquezNo ratings yet

- Double Shear Single ShearDocument3 pagesDouble Shear Single ShearJoyce ChepkiruiNo ratings yet

- Plate 1Document3 pagesPlate 1Mary Jane SañoNo ratings yet

- H32 1015Document2 pagesH32 1015JvNo ratings yet

- Blade-St: The Complete Steam Turbine Blade Analysis ToolDocument8 pagesBlade-St: The Complete Steam Turbine Blade Analysis Toolramnadh803181No ratings yet

- T13151-176 Api 614 PDFDocument26 pagesT13151-176 Api 614 PDFpietroNo ratings yet

- Turolla Catalog Group 3 Gear PumpsDocument36 pagesTurolla Catalog Group 3 Gear Pumpsdwilson fppNo ratings yet

- Folio Sains Ting.3 (Chap 9 & 10 + Questions)Document24 pagesFolio Sains Ting.3 (Chap 9 & 10 + Questions)Mr.D-SIM100% (18)

- SAP Shutdown Equipment CheckingDocument5 pagesSAP Shutdown Equipment CheckingjunaidiNo ratings yet

- Shayma Chem II Lab Manual.... Petrochemical Engineering DepartmentDocument55 pagesShayma Chem II Lab Manual.... Petrochemical Engineering DepartmentMUHAMMAD AKRAM100% (1)

- Types of Bridge BearingsDocument6 pagesTypes of Bridge BearingsVISHAL SHARMANo ratings yet

- Pre-Calculus: Quarter 2 - Module 5Document17 pagesPre-Calculus: Quarter 2 - Module 5Mark Allen LabasanNo ratings yet

- Pharmasutic (Physical Pharmacy) Assignment 01Document14 pagesPharmasutic (Physical Pharmacy) Assignment 01AAMIR NAWAZNo ratings yet

- Acoustics-4 (Sound Absorption Within A Space)Document16 pagesAcoustics-4 (Sound Absorption Within A Space)dishaNo ratings yet

- Preparation and Tack UpDocument5 pagesPreparation and Tack UpCarmelo AlejandrinoNo ratings yet

- The StratosphereDocument3 pagesThe StratosphereSuman JyotiNo ratings yet

- Calculation of Pipe Reinforcement ASME B31.3Document9 pagesCalculation of Pipe Reinforcement ASME B31.3yhnsharma80% (5)

- Development in Dye Sensitized Solar CellsDocument15 pagesDevelopment in Dye Sensitized Solar CellsJyoti Ranjan Nanda100% (1)

- Using Geophysics To Characterize The Subsurface: The PrinciplesDocument152 pagesUsing Geophysics To Characterize The Subsurface: The PrinciplesMasahiro Galang SusantoNo ratings yet

- Mitf600 Aisi 301 Full HardDocument4 pagesMitf600 Aisi 301 Full HardChemograf Ltd. MarketingNo ratings yet