Professional Documents

Culture Documents

Enzymaic Production of HFCS Containing 55% Fructose in Aqueous Ethanol

Enzymaic Production of HFCS Containing 55% Fructose in Aqueous Ethanol

Uploaded by

sinta putri karismaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Enzymaic Production of HFCS Containing 55% Fructose in Aqueous Ethanol

Enzymaic Production of HFCS Containing 55% Fructose in Aqueous Ethanol

Uploaded by

sinta putri karismaCopyright:

Available Formats

Enzymatic Production of High Fructose Corn

Syrup (HFCS) Containing 55% Fructose in

Aqueous Ethanol

Kalevi Visuri and Alexander M . Klibanov

Department of Applied Biological Sciences, Massachusetts Institute of

Technology, Cambridge, Massachusetts 02 139

Accepted for publication November 26, 1986

Production of high fructose corn syrup (HFCS) catalyzed HFCS containing 55% of fructose when the process is con-

by immobilized glucose isomerase is by far the greatest ducted in 85-90% ethanol.

industrial success of enzyme technology to date. I The gist of

this process is the enzymatic isomerization of glucose (usu-

EXPERIMENTAL

ally derived, also enzymatically, from corn starch) into a

mixture typically containing 42% fructose, 5 1% glucose,

Materials

and 7% oligosaccharides (remaining from incomplete

amylase-catalyzed hydrolysis of starch).*-' Although this Four different preparations of glucose isomerase

mixture is isosweet with sugar and suitable for some com- (D-xylose ketol isomerase, EC 5.3.1.5) were employed in

mercial applications, it is insufficiently sweet for HFCS's our work. Free glucose isomerase from mycelium of Strep-

major use -in more acidic soft drinks (such as Coca-Cola tomyces rubiqinosus" was a generous gift of Finnish Sugar

and Pepsi-Cola).' The latter market requires a fructose con- Co. (Kantvik, Finland). The enzyme was purified by them

tent of 55% of the total solids to give the same sweetness using lysozyme-assisted cell lysis, ammonium sulfate frac-

level as sucrose (at the same concentration of solids).' Con- tionation, and subsequent recrystallization with ammonium

sequently, glucose isomerase-catalyzed isomerization of sulfate eight times. The resultant preparation (wet crystals

glucose syrup in industry is usually followed by chro- containing 41% protein, 6% ammonium sulfate, and 53%

matographic enrichment of the HFCS formed.'-' water) was pure by SDS-polyacrylamidegel electrophoresis

Since the chromatographic step is a considerable expense, and FPLC and had a specific activity of 0.32 international

it would be highly desirable to omit it. Conceptually, one units (IU) per mg of protein (fructose was used as a substrate

way to accomplish this is to conduct the isomerization reac- in this and subsequent determinations). The following three

tion not at the currently employed temperature of immobilized glucose isomerases have been used: 1) The

60-65°C,3-5 but at 1oO-l10°C.6 Due to the fact that a tem- first was the described above Streptomyces rubiqinosus en-

perature increase favors fructose in its equilibrium with glu- zyme adsorbed on DEAE-cellulose. The sample, also ob-

cose, HFCS containing 55% fructose can be enzymatically tained from Finnish Sugar and called Spezyme IGI, had an

formed directly above 100°C.' Unfortunately, glucose activity of 11.8 IU/g dry wt. 2) The second was the enzyme

isomerases are far too labile to work at such high tem- from Bacillus coagulans immobilized by covalent cross-

peratures for even hours, let alone days and weeks required linking with gl~taraldehyde.~ This sample, obtained from

for a commercial operation.6 Furthermore, recently eluci- Novo Industri (Bagsvaerd, Denmark) and called Sweetzyme

dated mechanisms of irreversible thermoinactivation of S, had an activity of 2.9 IU/g dry wt. 3) Finally, the en-

enzymes',' strongly suggest that the upper limit of enzyme zyme from Actinoplanes missouriensis was immobilized by

thermostability is a half-life of several hours at loO°C, thus entrapment in a gelatin gel, followed by covalent cross-

making the foregoing stability levels unattainable. '

linking with glutaraldehyde. This sample, obtained from

In a search for an alternative approach, we turned to the Gist-Brocades (Delft, The Netherlands) and called Max-

emerging area of enzyme catalysis in nonaqueous media. lo azyme GI, had an activity of 3.0 IU/g dry wt.

It occurred to us that the equilibrium between glucose and Crystalline a-D( +)-glucose and P-D(-)-fructose were

fructose might be shifted towards the latter not only at high purchased from Sigma Chemical Co. (St. Louis, MO). High

temperatures but also in aqueous-organic mixtures even at fructose corn syrup, containing 71% (w/w) solids con-

the ambient temperature. For the reasons of safety for a food sisting of 42% fructose, 52% glucose, and 6% oli-

application, cost and reactant solubility, ethanol was the gosaccharides, was a kind gift from Cargill Co. (Dayton,

only choice for the organic solvent. In the present study, we OH); the sample (trade name Isoclear 42) was a viscous,

have discovered that glucose isomerase can directly produce clear aqueous solution. The enzymes used for assays, yeast

Biotechnology and Bioengineering, Vol. 30, Pp. 917-920 (1987)

0 1987 John Wiley & Sons, Inc. CCC 0006-3592/87/070917- 04$04.00

hexokinase and phosphoglucose isomerase and Leuconostoc Table I. Dependence of glucose isomerase activity on the concentration

mesenteroides glucose-6-phosphatedehydrogenase, as well of ethanol in the solvent."

as NAD' and ATP, were purchased from Sigma. All other Concentration of ethanol Enzymatic activity

chemicals and solvents used in this work were obtained 1% (w/w)l (nmoI/s mg enzymeb)

commercially and were of the highest purity availabIe.

0 2.80

40 2.65

Assays 80 2.51

90 0.68

Glucose isomerase (both free and immobilized) was as- 92 0.44

sayed as follows. An enzyme solution (1 mL) or 2 g 94 0.10

96 0.044

presoaked immobilized enzyme was added to 10 mL of 98 0.044

6% aqueous solution of fructose ( 0 . M Tris-HCl, pH 7.0,

containing 0.2mM CoC12) and shaken at 30°C. Periodi- a Glucose isomerase activity is expressed as the initial rate of enzymatic

cally, aliquots were withdrawn and assayed for glucose as isomerization of fructose to glucose in various mixtures of ethanol and

aqueous solution of sodium malate buffer (25mM, pH 7.0). The reaction

outlined below. mixture (which contained 7pM CoC12 and 1 3 0 a MgSO,), consisting of

Glucose was determined using the standard enzymatic 1.5% (w/w) fructose and 3.33 mg/mL Stregromyces rubiqinosus glucose

(hexokinase/glucose-6-phosphate dehydrogenase)method. l 3 isomerase, was stirred at 25°C; periodically, aliquots were withdrawn and

Fructose (in the presence of glucose) was determined by the analyzed for glucose as outlined in the Methods.

Wet enzyme crystals are as defined in the Materials section.

phosphoglucose isomerase method. l4 When glucose isomer-

ization was catalyzed by free glucose isomerase, the latter

was irreversibly inactivated by 0.1M sulfuric acid prior to

the glucose/fructose assay to avoid interferences. changed appreciably and were unaffected by addition of

more enzyme, thus indicating that the thermodynamic equi-

librium was approximately reached. At that point, the

RESULTS AND DISCUSSION

concentration of fructose in the two solutions originally

The initial goal of this study was to ascertain whether the containing only glucose or only fructose was 46.8% and

equilibrium between glucose and fructose can be shifted 45.6%, respectively, which is in a reasonable agreement

(hopefully in favor of fructose) when water is replaced with with the literature data.7 When the same experiments were

aqueous-organicmixtures. To avoid working with emulsions conducted in 80% (w/w) ethanol (with the other 20% being

and due to the insolubility of the sugars in water-immiscible the aqueous buffer), then the equilibrium concentrations of

solvents, we were limited to water-miscible organic sol- fructose obtained were 55.6 and 54.8%, respectively. That

vents. Since HFCS is a food ingredient, it was sensible to is, replacement of water with 80% aqueous ethanol as the

select a FDA-approved solvent. These restrictions narrowed reaction medium resulted in a 9% increase of the fructose

the choice of the organic solvent down to just one -ethanol. concentration in its equilibrium mixture with glucose.

Since the isomerization of glucose to fructose is to be The above results looked sufficiently promising to war-

enzymatically catalyzed, it was critical to establish whether rant a more detailed investigation. We decided to carry it out

glucose isomerase can act as a catalyst in aqueous ethanol. with immobilized glucose isomerase, for this form of the

Table I depicts the dependence of the catalytic activity of enzyme is currently used in i n d ~ s t r y . ~Initially,

-~ glucose

free Streptomyces rubiqinosus glucose isomerase on the isomerase from Streptomyces rubiqinosus adsorbed on

ethanol content of solution. One can see that in 80% (w/w) DEAE-cellulose was employed to determine the position of

ethanol the enzymatic activity is as high as 90% of that in the thermodynamic equilibrium between glucose and fruc-

pure water and even in 90% (w/w) ethanol the activity is tose as a function of ethanol content. At each ethanol con-

almost one-quarter of that exhibited in a purely aqueous centration, three independent experiments were run using

solution. (At higher ethanol contents, the glucose isomerase glucose, fructose or their equimolar mixture as substrates. In

activity drops precipitously.) Hence, the enzyme can be all cases, a suspension of the immobilized enzyme in a

readily used to catalyze the isomerization reaction at least up substrate solution was vigorously shaken at 30°C and the

to 90% (w/w) of ethanol in the medium. concentrations of fructose and glucose monitored until they

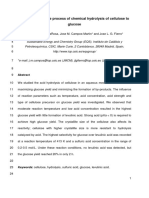

We then proceeded to determine whether the thermo- nearly leveled off. The time courses of the enzymatic

dynamic equilibrium between glucose and fructose is indeed isomerization in pure water and in 85% ethanol are depicted

different in aqueous ethanol from that in pure water. First, in Figures 1(A) and 1(B), respectively. Similar patterns

the equilibrium was measured in the latter. To 100 mL of were obtained at other ethanol concentrations, and the re-

aqueous buffer (50mM Tris-HC1, 1mM CoC12, 20mM sultant equilibrium fructose fractions are shown in Table 11.

MgS04, pH 7.0), containing 3 g of either glucose or fruc- It is seen that addition of ethanol to the reaction medium

tose, 1.33 g wet crystals of glucose isomerase was added, substantially favors fructose in its equilibrium with glucose.

and the solutions were stirred at 25°C. Periodically, the Also note that approximately the same equilibrium values

reaction mixtures were assayed for glucose and fructose. for fructose ensued regardless of whether the substrate was

After three days, the reactant concentrations no longer glucose, fructose, or an equimolar mixture of the two

918 BIOTECHNOLOGY AND BIOENGINEERING, VOL. 30, NOVEMBER 1987

by Novo and Gist-Brocades)-from Bacillus coagulans

'"OF- crosslinked with glutaraldehyde and from Actinoplanes mis-

souriensis entrapped in gelatin and crosslinked with

glutaraldehyde- to equilibrate glucose and fructose in 85%

aqueous ethanol. As one can see in Figures 1(B), 1(C), and

1(D), the positions of the equilibrium obtained are virtually

identical for all three immobilized glucose isomerases and

much more favorable towards fructose than in water.

Operational stability is a practically important character-

istic of a bio~ata1yst.l~ With that in mind, we examined the

remaining activity of the three immobilized glucose isomer-

ases as a function of time of the catalyzed reaction [30"C,

shaking at 250 rpm, 10% (w/w) substrate; for other condi-

tions see Figures 1(B), 1(C), and l(D)]. After three days,

the residual activity was ca. 25, 35, and 57% of the initial

level for the FinnSugar, Gist-Brocades, and Novo enzymes,

respectively. It is difficult to directly compare these numbers

with their counterparts in water, because in 10% aqueous

solutions of sugars at 30°C microbial growth begins in just

a few hours (which presumably does not happen in 85%

ethanol) and leads to enzyme inactivation. However, it is

3 6 known from the that at 60-65°C (where the

days days microbial growth is essentially suppressed), the half-life of

Figure 1. Time courses of glucose isomerase-catalyzed isomerization of immobilized glucose isomerase is of the order of a month.

(a) glucose, (b) fructose, or their (c) equimolar mixture in (A) water or (B, Hence, it appears that addition of ethanol significantly labil-

C, and D) 85% ethanol: (A and B) Streptomyces rubiqinosus glucose izes the biocatalyst. The operational stability of the enzymes

isomerase immobilized by adsorption on DEAE-cellulose; (C) Bacillus in aqueous ethanol mixtures will have to be enhanced to

coagulans glucose isomerase immobilized by crosslinking with glu-

taraldehyde; (D) Actinoplanes missouriensis glucose isomerase entrapped

make them feasible as industrial catalysts.

in gelatin and crosslinked with glutaraldehyde. General conditions are 10% The next step was to verify that our approach to enriching

(w/w) substrate, 3 0 T , and shaking at 250 rpm. Other conditions are glucoseifructose mixtures with the latter by adding ethanol

(A) 50mM Tris. HCl aqueous buffer (pH 8.2), 0.17 g/mL enzyme; (B, C, is directly applicable to commercial HFCS. To that end, we

and D) 85% aqueous ethanol (5OmM final Tris.HC1 concentration, pH obtained high fructose corn syrup from Cargill. The solu-

adjusted to 8.2 prior to mixing with ethanol), 0.25 g/mL enzyme.

tion, which according to the manufacturer contained 42%

fructose, 52% glucose (according to our analysis 41.5 and

(which is quite close to the ultimate equilibrium). This fur- 52.5%, respectively), and 6%oligosaccharides, was diluted

ther validates the reported results. with ethanol to bring its ratio with water to 85: 15 (the

We then employed two other, unrelated immobilized glu- overall solution composition (w/w) was 10% dry substrates,

cose isomerases (both commercial catalysts manufactured 76.5% ethanol, and 13.5% H,O), and the pH was adjusted

Table 11. Equilibrium fractions of fructose in its mixtures with glucose in different aqueous ethanol

solutions. a

Equilibrium fraction of fructose enzymatically

Concentration of formed when the substrateb was

ethanol in the

solvent 100% glucose 100% fructose 50% glucose + 50% fructose

(%) (%I (%) (%)

0 45.1 46.0 45.1

50 48.5 49.3 49.0

80 53.7 54.5 53.9

85 55.9 56.7 56.0

90 57.8 59.4 58.2

A substrate was dissolved in a reaction medium consisting of varying proportions of ethanol and

aqueous Tris . HCI buffer (25mM, pH 7.0, containing ImM CoCI2 and 20mM MgS04). Then

immobilized glucose isomerase was added (0.2 g/mL), and the suspension was shaken at 250 rpm

and 30°C for 2 days which is sufficient to reach the practical equilibrium between glucose and

fructose.

The substrate concentration was 1) 12% (w/w) in pure water, in 50% ethanol, and in 80% ethanol;

2) 6% (w/w) in 85% ethanol; and 3) 3% (w/w) in 90% ethanol. Lower concentrations of the sugars

at higher ethanol contents are due to a decreasing solubility upon addition of the organic solvent.

COMMUNICATIONS TO THE EDITOR 919

to 8.2 (where the enzyme is more stable than at pH 7.0) This work was supported, in part, by Miles Laboratories. Kalevi

-

following addition of Tris HC1 buffer (the final concen- Visuri is a Finnish Sugar Company visiting research fellow.

tration in the aqueous ethanol mixture of 50mM). A

2.5 x 106-cm column was packed with presoaked immo-

bilized glucose isomerase (Finnish Sugar, 200 g dry wt).

Then the above-mentioned substrate solution in aqueous

ethanol was passed through the column (ascending direc- References

tion, using a peristaltic pump) at 70 mL/h for 62 h. As a

1. A. M. Klibanov, Science, 219, 722 (1983).

result, 4.3 L of the product solution which contained 51.6% 2. C. Bucke, Topics in Enzyme and Fermentation Biotechnology. A.

fructose, 42.4% glucose, and 6% oligosaccharides was ac- Wiseman, Ed. (Ellis Horwood, Chichester, 1977), Vol. 1 ,

cumulated. pp. 147-171.

The foregoing data suggest the following straightforward 3. R. L. Antrim. W. Colilla, and B. J. Schnyder, Applied Biochemistry

prototype for an industrial setup. First, HFCS containing and Bioengineering, L. B. Wingard, E. Katchalski-Katzir, and L.

Goldstein, Eds. (Academic, New York, 1979), Vol. 2, pp. 97-155.

42% fructose is enzymatically produced the same way as at 4. S . H. Hemmingsen, Applied Biochemistry and Bioengineering, L. B.

present: in water at 60-65"C.3-s Then, instead of enriching Wingard, E. Katchalski-Katzir, and L. Goldstein, Eds. (Academic,

it by ion-exchange chromatography, the syrup is diluted New York, 1979), Vol. 2, pp. 157-183.

with ethanol (ideally, also produced from starch hydrolysate 5 . C. Bucke, Enzymes and Food Processing, G. G. Birch, N. Blake-

by fermentation at the same site) and passed through a brough, and K. J. Parker, Eds. (Applied Science Publishers, London,

1981), pp. 51-72.

smaller glucose isomerase column (or columns) to enhance 6. N. E. Lloyd, U.S. Patent No. 4,567,142 (January 28, 1986).

the fructose content to a desired level. Ethanol is then recov- 7. Y . B. Tewari and R. N. Goldberg, Appf. Biochem. Biotechnof., 11, 17

ered by distillation and reused. We have demonstrated that (1985).

this approach can be used for the production of the syrup 8. T. J. Ahern and A.M. Klibanov, Science, 228, 1280 (1985).

containing 55% fructose needed for acidic soft drinks (see 9. S . E. Zale and A. M. Klibanov, Biochemistry. 25, 5432 (1986).

10. A. M. Klibanov, CHEMTECH, 16, 354 (1986).

the Introduction). The effluent from the aforedescribed col- 11. N. E. Lloyd and K. Khaleeluddin, Cereal Chem., 53, 270 (1976).

umn was supplemented with more ethanol [to bring its ratio 12. J. V. Hupkes and R. Van Tilburg, Starke, 28, 356 (1976).

with water to 9: 1 (w/w)] and then passed through another 13. H. U. Bergmeyer, E. Berut, F. Schmidt, and H. Stork, in Methods of

column half the size of the first one. The effluent of the Enzymatic Analysis, H. U. Bergmeyer, Ed. (Academic, New York,

second column contained 55.3% fructose, 38.7% glucose, 1974), VoI. 3, pp. 1196-1201.

14. E. Berut and H. U. Bergmeyer, in Methods of Enzymatic Analysis,

and 6% oligosaccharides. It is hoped that the novel approach H . U . Bergmeyer, Ed. (Academic, New York, 1974), Vol. 3,

reported in this communication will be useful for the manu- pp. 1304-1307.

facturing of HFCS. 15. A.M. Klibanov, Anal. Biochem., 93, 1 (1979).

920 BIOTECHNOLOGY A N D BIOENGINEERING, VOL. 30, NOVEMBER 1987

You might also like

- Lab Report 8Document6 pagesLab Report 8Ng LeepingNo ratings yet

- Extraction of InvertaseDocument5 pagesExtraction of InvertaseDianne Joy Pascua100% (1)

- Extraction of Invertase by Heat Denaturation and Analysis of Invertase Activity by Dinitrosalicylic MethodDocument9 pagesExtraction of Invertase by Heat Denaturation and Analysis of Invertase Activity by Dinitrosalicylic MethodJohn Henrick G. UyNo ratings yet

- D & E Wedding and Events Inc.Document30 pagesD & E Wedding and Events Inc.Kenn Marvin Salcedo II100% (1)

- Hydrolysis of Lactose in Whey Permeate For Subsequent Fermentation To EthanolDocument13 pagesHydrolysis of Lactose in Whey Permeate For Subsequent Fermentation To EthanolkaltoumNo ratings yet

- Hydrolysis of Beet Pulp Polysaccharides Bu Extracts of Solid State Cultures of Penicillium CapsulatumDocument6 pagesHydrolysis of Beet Pulp Polysaccharides Bu Extracts of Solid State Cultures of Penicillium CapsulatumANTONIO CELSO R DE OLIVEIRANo ratings yet

- 3156 14676 1 PB PDFDocument10 pages3156 14676 1 PB PDFKatherine AlvarezNo ratings yet

- K Tsta 100a - DataDocument24 pagesK Tsta 100a - DataAyrtonNo ratings yet

- In This Phase, 2 ATP Are Used.: 1 Glucose Is Converted Into 2 Glyceraldehyde-3-PhosphateDocument8 pagesIn This Phase, 2 ATP Are Used.: 1 Glucose Is Converted Into 2 Glyceraldehyde-3-PhosphateGia HoàngNo ratings yet

- Influence of PHDocument7 pagesInfluence of PHamelieNo ratings yet

- Chem 2 (Repaired)Document9 pagesChem 2 (Repaired)Hemesh RNo ratings yet

- Modelling Ethanol Production From Cellulose: Separate Hydrolysis and Fermentation Versus Simultaneous Saccharification and FermentationDocument10 pagesModelling Ethanol Production From Cellulose: Separate Hydrolysis and Fermentation Versus Simultaneous Saccharification and FermentationlandolandazNo ratings yet

- Paper1 - Improved SSF-cellulosic Ethanol Production by The Cellobiose Fermenting Yeast Kluyveromyces Marxianus G2-16-1 - KridsanaDocument12 pagesPaper1 - Improved SSF-cellulosic Ethanol Production by The Cellobiose Fermenting Yeast Kluyveromyces Marxianus G2-16-1 - Kridsanakridsana.krisomdeeNo ratings yet

- Yulistiani 2019 J. Phys. Conf. Ser. 1295 012032Document9 pagesYulistiani 2019 J. Phys. Conf. Ser. 1295 012032Zanariah HashimNo ratings yet

- Kluyveromyces Fragilis: Mechanism of Ethyl Acetate Synthesis byDocument6 pagesKluyveromyces Fragilis: Mechanism of Ethyl Acetate Synthesis byMpilo ManyoniNo ratings yet

- Or-Amylase Production in Aqueous Two-Phase Systems With: Bacillus SubtilisDocument6 pagesOr-Amylase Production in Aqueous Two-Phase Systems With: Bacillus SubtilisHong HanhNo ratings yet

- Simulacao Da Prod de EtanolDocument4 pagesSimulacao Da Prod de EtanolLuann KarlosNo ratings yet

- Dahlqvist1968 - Alfa Glucosidase OkDocument9 pagesDahlqvist1968 - Alfa Glucosidase OkLeon NikolaiNo ratings yet

- Cellulose HydrolysisDocument28 pagesCellulose HydrolysisMohamedNo ratings yet

- Laboratory Analytical Procedure: Chemical Analysis and Testing TaskDocument8 pagesLaboratory Analytical Procedure: Chemical Analysis and Testing TaskJuan Alzate JaramilloNo ratings yet

- Starch Analysis MethodDocument25 pagesStarch Analysis Methodjohnnywilson87No ratings yet

- 4 - Enzymes in Starch ModificationDocument28 pages4 - Enzymes in Starch ModificationLoredana Dana100% (1)

- Sugar Respiration LabDocument6 pagesSugar Respiration Laboofnivlak5100% (1)

- Hydrolysis of Lactose in Milk by Kluyveromyces LactisDocument5 pagesHydrolysis of Lactose in Milk by Kluyveromyces Lactisonyu kimNo ratings yet

- Interconversion of Sugar From Aldose To KetoseDocument7 pagesInterconversion of Sugar From Aldose To Ketosebeia21No ratings yet

- The Fermentation of Sugars Using YeastDocument7 pagesThe Fermentation of Sugars Using YeastJames BelciñaNo ratings yet

- Starch Hydrolysis by AmylaseDocument9 pagesStarch Hydrolysis by Amylasegaurav saxenaNo ratings yet

- High-Fructose Corn Syrups (HFCS) : Table 4.3Document40 pagesHigh-Fructose Corn Syrups (HFCS) : Table 4.3Gabriel HerreraNo ratings yet

- Purification of Amylases and Other Enzymes by A Forced-Affinity Chromatography MethodDocument5 pagesPurification of Amylases and Other Enzymes by A Forced-Affinity Chromatography Methodnitn385No ratings yet

- Determination of Pentosan ContentDocument10 pagesDetermination of Pentosan ContentMelixaxNo ratings yet

- Artículo CatalisisDocument8 pagesArtículo CatalisisVivi AbelloNo ratings yet

- Sugar Utilization by Yeast During FermentationDocument10 pagesSugar Utilization by Yeast During FermentationLESHANTHIY A/P K SANTHI RASEGARAN -No ratings yet

- Sugar Utilization by Yeast During Fermentation PDFDocument9 pagesSugar Utilization by Yeast During Fermentation PDFAdrian WongNo ratings yet

- Biochemistry Review For Final Examination PDFDocument19 pagesBiochemistry Review For Final Examination PDFHà Anh Minh Lê100% (1)

- Yang Et Al. - 2009 - Characterization of A Novel Mesophilic Bacterial Amylase Secreted by ZW2531-1, A Strain Newly Isolated From SoilDocument5 pagesYang Et Al. - 2009 - Characterization of A Novel Mesophilic Bacterial Amylase Secreted by ZW2531-1, A Strain Newly Isolated From SoilEstudiante BioNo ratings yet

- Mansour2003 PDFDocument5 pagesMansour2003 PDFGissell VargasNo ratings yet

- K-Tsta DataDocument24 pagesK-Tsta DataLorena VillavicencioNo ratings yet

- Optimisation of Enzymatic Hydrolysis of Apple PomaceDocument13 pagesOptimisation of Enzymatic Hydrolysis of Apple PomaceDea Inthay WulanNo ratings yet

- A Kinetic Model Starch Hydrolysis by and 0-Amylase During MashingDocument16 pagesA Kinetic Model Starch Hydrolysis by and 0-Amylase During MashingJulio SantosNo ratings yet

- Elimination of Glucose in Egg WhiteDocument6 pagesElimination of Glucose in Egg WhiteRocio R. LamadridNo ratings yet

- Effect of PH On The Activity of Denatured and Non-Denatured Invertase From Baker's YeastDocument7 pagesEffect of PH On The Activity of Denatured and Non-Denatured Invertase From Baker's YeastEilleen SagunNo ratings yet

- RDD 750Document32 pagesRDD 750Sana NazNo ratings yet

- Biochemj00072 0026Document4 pagesBiochemj00072 0026ahmed.mo.22555417No ratings yet

- Patel2004 PDFDocument4 pagesPatel2004 PDFArrianne Jaye MataNo ratings yet

- Localization and Characterization of Ac-Glucosidase ActivityDocument7 pagesLocalization and Characterization of Ac-Glucosidase ActivityCauré Barbosa PortugalNo ratings yet

- Ethanol Corn Cob - Phế Phụ LiệuDocument6 pagesEthanol Corn Cob - Phế Phụ LiệuDuy Tân NguyễnNo ratings yet

- 2018 Megazyme Procedur K-TSTA AssayDocument24 pages2018 Megazyme Procedur K-TSTA Assayfitri electrikaNo ratings yet

- K Tsta 100a - DataDocument25 pagesK Tsta 100a - DataThanh HươngNo ratings yet

- Kinetic Study of The Thermal Hydrolysis of Agave Salmiana For Mezcal ProductionDocument8 pagesKinetic Study of The Thermal Hydrolysis of Agave Salmiana For Mezcal ProductionRené MartínezNo ratings yet

- The Pathway of The Adaptive Fermentation of Galactose by YeastDocument8 pagesThe Pathway of The Adaptive Fermentation of Galactose by YeastSimone Bassan Zuicker ElizeuNo ratings yet

- Linjianqiang 6Document8 pagesLinjianqiang 6Med Ramy Gaddem EssefiNo ratings yet

- Hernandez 1995Document6 pagesHernandez 1995Ifan Delapan TigaNo ratings yet

- Immobilization of A Thermostable Alpha-Amylase: Saiyavit Varavinit, Narisa Chaokasem and Sujin ShobsngobDocument5 pagesImmobilization of A Thermostable Alpha-Amylase: Saiyavit Varavinit, Narisa Chaokasem and Sujin ShobsngobxmlbioxNo ratings yet

- Food Chemistry: L. Amaya-Delgado, M.E. Hidalgo-Lara, M.C. Montes-HorcasitasDocument6 pagesFood Chemistry: L. Amaya-Delgado, M.E. Hidalgo-Lara, M.C. Montes-HorcasitasWindy NainggolanNo ratings yet

- Modelling of The Alcohol Dehydrogenase Production in Baker's YeastDocument10 pagesModelling of The Alcohol Dehydrogenase Production in Baker's Yeast321No ratings yet

- Large Scale Production of D-Allose From D-Psicose Using Continuous Bioreactor and Separation SystemDocument5 pagesLarge Scale Production of D-Allose From D-Psicose Using Continuous Bioreactor and Separation SystemFabián Camilo OtáloraNo ratings yet

- CARBOHYDRATES LabDocument42 pagesCARBOHYDRATES LabZiaNo ratings yet

- 1981 Hizukuri, Takjzda, Yasuda 1981Document9 pages1981 Hizukuri, Takjzda, Yasuda 1981Łukasz GraczykNo ratings yet

- Plant and Animal Bio-Chemistry - Including Information on Amino Acids, Proteins, Pigments and Other Chemical Constituents of Organic MatterFrom EverandPlant and Animal Bio-Chemistry - Including Information on Amino Acids, Proteins, Pigments and Other Chemical Constituents of Organic MatterNo ratings yet

- Biochemistry Applied to Beer Brewing - General Chemistry of the Raw Materials of Malting and BrewingFrom EverandBiochemistry Applied to Beer Brewing - General Chemistry of the Raw Materials of Malting and BrewingRating: 4 out of 5 stars4/5 (1)

- BD 2009-06-10 Bulk Density and Tapped Density of Powders Sign OffDocument8 pagesBD 2009-06-10 Bulk Density and Tapped Density of Powders Sign Offsinta putri karismaNo ratings yet

- VISC - Hossen2011 (Starch Damage Vs Viscosity) VISCDocument8 pagesVISC - Hossen2011 (Starch Damage Vs Viscosity) VISCsinta putri karismaNo ratings yet

- BD - MOIST Grinding-Parameters-And-Their-Effects-On-The-Quality-Of-Corn-For-Feed-Processing-2157-7110-1000482Document7 pagesBD - MOIST Grinding-Parameters-And-Their-Effects-On-The-Quality-Of-Corn-For-Feed-Processing-2157-7110-1000482sinta putri karismaNo ratings yet

- BD&VISC - Haros2004 (Effect of Steeping Corn With Lactic Acid On Starch Properties) VISCDocument5 pagesBD&VISC - Haros2004 (Effect of Steeping Corn With Lactic Acid On Starch Properties) VISCsinta putri karismaNo ratings yet

- BD - Dhanalakshmi2011 (Moisture Vs Particle Size) BDDocument11 pagesBD - Dhanalakshmi2011 (Moisture Vs Particle Size) BDsinta putri karismaNo ratings yet

- BD - Bulk Density of Corn StarchDocument6 pagesBD - Bulk Density of Corn Starchsinta putri karismaNo ratings yet

- Manufacturing, Composition, and Applications of Fructose1'2: L Mark Hanover and John S WhiteDocument9 pagesManufacturing, Composition, and Applications of Fructose1'2: L Mark Hanover and John S Whitesinta putri karisma100% (1)

- Yang 2013Document5 pagesYang 2013sinta putri karismaNo ratings yet

- Starbucks Case SolutionDocument5 pagesStarbucks Case SolutionAnsh LakhmaniNo ratings yet

- Analysis Consumer Values and Behaviour in The United Arab EmiratesDocument65 pagesAnalysis Consumer Values and Behaviour in The United Arab EmiratesRi LNo ratings yet

- Bisleri ProjectDocument8 pagesBisleri ProjectABBASNo ratings yet

- GPT Protocol - Trypcase Soy AgarDocument8 pagesGPT Protocol - Trypcase Soy AgarmailboxofmurliNo ratings yet

- Big 2Document8 pagesBig 2Viola Dwi KarolinNo ratings yet

- YD6 20 1985 New Year - Aetheria Sought Baroque Secretes Knotting StringsDocument7 pagesYD6 20 1985 New Year - Aetheria Sought Baroque Secretes Knotting StringsIvan BroesNo ratings yet

- Ibu Nelka: Salam Hangat Dari Aruna Senggigi Resort & ConventionDocument3 pagesIbu Nelka: Salam Hangat Dari Aruna Senggigi Resort & ConventionShimaoka SumikoNo ratings yet

- Proteinas en VegetarianosDocument19 pagesProteinas en VegetarianosAlejandro Estrada RiosNo ratings yet

- Mike Jones April 6 Lowell Closed CampusDocument1 pageMike Jones April 6 Lowell Closed CampusJoe EskenaziNo ratings yet

- An Evaluation of Oxalate Content in Cassava Roots and Sweet Potato Tubers in Areka, EthiopiaDocument6 pagesAn Evaluation of Oxalate Content in Cassava Roots and Sweet Potato Tubers in Areka, EthiopiaLeycoline AlmrenNo ratings yet

- Global EconomyDocument3 pagesGlobal EconomyAngielyn Montibon JesusNo ratings yet

- Put in The Correct Verb FormsDocument1 pagePut in The Correct Verb FormsGetaLefterNo ratings yet

- GO CheeseDocument1 pageGO CheesenevrekasNo ratings yet

- WorkbookDocument9 pagesWorkbookAstha SharmaNo ratings yet

- Worship Team Building: Times But Also When Troubles Comes With The Help and For The Glory and Kingdom of GodDocument7 pagesWorship Team Building: Times But Also When Troubles Comes With The Help and For The Glory and Kingdom of GodElay SarandiNo ratings yet

- Facultatea Management Marketing În Afaceri Economice Brăila: Sesiunea de Comunicari Stiintifice 25.05.2021Document24 pagesFacultatea Management Marketing În Afaceri Economice Brăila: Sesiunea de Comunicari Stiintifice 25.05.2021CostinaNo ratings yet

- ExerciseDocument8 pagesExerciseSudenaz YeginNo ratings yet

- A Bowl of Noodles From A StrangerDocument2 pagesA Bowl of Noodles From A StrangerAldrianne LiganNo ratings yet

- Internship SummaryDocument3 pagesInternship Summaryapi-494587938No ratings yet

- Company Overview: Unilever Global: Unilever Is An Anglo-Dutch Company, With A History of ColonialDocument4 pagesCompany Overview: Unilever Global: Unilever Is An Anglo-Dutch Company, With A History of ColonialJahidul AlamNo ratings yet

- Publix Strawberry Cake Filling - Google SearchDocument1 pagePublix Strawberry Cake Filling - Google SearchLawrence DixonNo ratings yet

- 74 - YOU - RE MY BEST FRIEND - Mary Beth Barone - Erin WoodsDocument109 pages74 - YOU - RE MY BEST FRIEND - Mary Beth Barone - Erin WoodsBebeNo ratings yet

- 1 Dipl. Brew. Module 1: Unit 1.8 - Mashing and Wort Separation - Section 1.8.2Document11 pages1 Dipl. Brew. Module 1: Unit 1.8 - Mashing and Wort Separation - Section 1.8.2RiyanNo ratings yet

- Sheep Unit Terms CrosswordDocument3 pagesSheep Unit Terms Crosswordapi-356744572No ratings yet

- Telc English b1 Hotel-Restaurant Uebungstest 1Document44 pagesTelc English b1 Hotel-Restaurant Uebungstest 1Mabrouk Hussein AL-habriNo ratings yet

- Nutrients: Factors That Influence The Perceived Healthiness of Food-ReviewDocument20 pagesNutrients: Factors That Influence The Perceived Healthiness of Food-ReviewYash KothariNo ratings yet

- Countable and Uncountable NousDocument22 pagesCountable and Uncountable NousMisael MorenoNo ratings yet

- Spanish Sentence Builders KFCs Per TopicDocument28 pagesSpanish Sentence Builders KFCs Per TopicarchiehankeyNo ratings yet

- 2nd PGCLDocument16 pages2nd PGCLGauravNo ratings yet