Professional Documents

Culture Documents

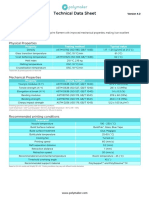

A PDF

A PDF

Uploaded by

Verenice CentenoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A PDF

A PDF

Uploaded by

Verenice CentenoCopyright:

Available Formats

SUPPLEMENTAL SPECIFICATIONS

August 20, 1997

ELASTOMERIC BEARINGS

GENERAL

Elastomeric bearings may be either “plain” (consisting of elastomer only) or “laminated” (consisting of

alternating individual layers of elastomer and internal steel laminates) as shown on plans.

The Contractor may select any manufacturer of bearing pads who is able to comply with the specification

requirements. Pre-qualification test samples, certifications, and elastomer formulation shall be submitted to

the Research and Materials Engineer for approval prior to its first use on Department projects. The materials

shall be submitted well in advance of anticipated use and contain certified test results showing the actual test

values obtained when the physical properties of the elastomer to be furnished were tested for compliance

with the pertinent specification requirement. Pre-qualification test samples shall consist of at least two

bearings typical of the formulations and workmanship intended for use on Department projects. Sample size

should be no larger than 11 inches x 17 inches (280 mm x 430 mm).

The Department’s inspection and acceptance of bearing pads will be in accordance with the “Policy for

Inspection and Acceptance of Elastomeric Bearing Pads” latest edition. A list of previously qualified

manufacturers may be obtained from the Research and Materials Engineer.

FABRICATION

The bearing pads shall be constructed in conformance with the American Association of State Highway and

Transportation Officials (AASHTO) Specification M 251 (latest edition) and in conformance with details shown

in the plans, or the AASHTO Specification for Highway Bridges where referenced.

Pin grooves in laminated bearings shall be filled with a vulcanized neoprene or a silicone material capable of

bonding and maintaining integrity with the pad.

Materials shall consist of Polychloroprene (Neoprene) Grade 2 elastomer as shown in AASHTO Bridge

Specification, Div. I, Table 14.3.2, Temperature Zone B and for Low Temperature Brittleness. In accordance

with the Bridge Specification Division II, Section 18 Grade 2 material does not rerquire a brittleness test. The

physical properties of the cured elastomer shall comply with the requirements shown in Table I of AASHTO M

251. Reinforced pads shall be 50 or 60 DUROMETER HARDNESS as specifically designated on the plans.

Table I in M 251-92 is shown below for ready information.

S. C. File No. Page 1

SUPPLEMENTAL SPECIFICATIONS

TABLE 1 Elastomer Properties

Polychloroprene Polychloroprene

Material ASTM Test 50 60

Property Standard Requirements Durometer Durometer

Physical D 2240 Hardness, Shore Points 50 + 5 60 + 5

Properties D 412 Min tensile strength PSI 2250 2250

(MPa) (15.5) (15.5)

Min Ultimate elongation % 400 350

Heat Resistance D 573 at Specified Temperature of

Specified the test 0F 212 212

Temp (0C) (100) (100)

Aging Time, Hours 70 70

Max change in durometer

Hardness, Shore Points +15 +15

Max change in tensile

Strength % -15 -15

Max change in ultimate

Elongation % -40 -40

Compression D 395 Specified Temp., 0F 212 212

Set (0C) (100) (100)

Method B at Max permissible set

Specif. Temp After 22 hrs. % 35 35

Tear D 624 Min pounds per inch 180 180

Resistance Die C (kN per meter) (31.5) (31.5)

Brittleness D 2137 Low temp. brittleness Pass Pass

At –400F (-400C) Method A

Ozone Resistance D 1149 Partial pressure of ozone

During test (MPa) (100) (100)

Duration of test, Hours 100 100

Tested at 20% strain

1000F + 20F

(37.70C + 10C)mounting

procedure No No

D 518, procedure A Cracks Cracks

Other M 251-92 One pad per lot.

Requirement Section Steel reinforced

Bond 8.2.4 & lb/in 40 40

Strength Section kN per meter 7.0 7.0

9.2 Fabric Reinf.

lb/in 30 30

kN per meter 5.2 5.2

S. C. File No. Page 2

SUPPLEMENTAL SPECIFICATIONS

In addition to the Table 1 requirements, one pad per lot shall be tested for Peel Strength. Peel Strength shall

be a minimum of 40 pounds per inch (6.9 kN per meter) as specified in AASHTO M 251-90 (9.3).

The equivalent ASTM D-2000 line call out number would be M2BC515.5A14B14F17G21 plus ozone and peel

strength.

Tolerance in dimensions of completed pads shall be as listed in Table 2 of AASHTO M 251 as shown below

for information:

TABLE 2 Tolerances

Inches: (mm)

1. Overall vertical dimensions:

Design thickness 1 ¼ in. (32mm) or less -0, +1/8 (- 0,+3)

Design thickness over 1 ¼ in. (32 mm) -0, +1/4 (- 0,+6)

2 Overall horizontal dimensions:

36 in. (914mm) and less -0, +1/4 (-0,+6)

Over 36 in. (914mm) -0, +1/2 (-0, +12)

3 Thickness of individual layers of elastomer

(Laminated bearings only) at any point + 20% of design

within the bearing value but no more

than + 1/8” (3)

4 Variation from a plane parallel to the theoretical surface:

(as determined by measurements at the

edge of the bearings):

Top Slope relative to

the bottom of no

more than 0.005

radians

Sides ¼ (6)

5 Position of exposed connection members 1/8 (3)

6 Edge cover of embedded laminates of -0, +1/8 (-0, +3)

Connection members

7 Size of holes, slots, or inserts + 1/8 (+ 3)

8 Position of holes, slots, or inserts + 1/8 (+ 3)

ACCEPTANCE TESTING

Acceptance shall be based on either Level I or Level II testing. Level I testing is applied to all bearings and

Level II shall, at the discretion of the Engineer, be applied to the more critical or unusual bearings. It shall

also be used to resolve differences over acceptance of bearings under Level I.

Level I testing shall be performed as stated in Section 8.2 of AASHTO M 251 except that only 10% of the

bearings are required to undergo the compressive test. Results of the compressive stress-strain curve shall

be submitted for record.

Level II certification requires that all Level I conditions are satisfied, except that individual conditions may be

waived by the Engineer if Level II certification is used as an arbitration of disputes. As a minimum, shear

modulus and compressive stiffness shall be determined in accordance with ASTM D4014. The shear

modulus may be determined by testing a piece of the finished bearing as specified on D 4014, or at the

discretion of the Engineer, a comparable non-destructive test may be performed on the complete bearing.

Compressive stiffness tests shall be performed on the complete bearing. The shear modulus shall fall within

+ 15 percent of the value specified in the design document or within the limits of the shear modulus table

contained in AASHTO M 251 if no value for shear stiffness is specified. The compressive stiffness shall vary

by no more than + 10 percent from the median value of all bearings, nor + 20 percent from the design value, if

specified. However, a compressive stiffness and a shear stiffness shall not both be specified for the same

bearing.

S. C. File No. Page 3

SUPPLEMENTAL SPECIFICATIONS

CERTIFICATIONS

The bearing manufacturer shall certify that all of the prequalification samples submitted are of the same

elastomer formulation and of equivalent cure to that used in the finished products to be furnished on

Department projects.

The producer may be required to perform the complete prequalification testing procedure again during later

production should the Research and Materials Engineer feel such action appropriate based on performance

of the pad in service.

After prequalification approval, the inspection, sampling, and testing of actual bearing production will be

performed by the manufacturer with certified laboratory test results of the following:

1. Elastomer properties on each batch or lot of elastomer used in the manufacture of the bearings,

as contained in Table 1

2. One peel test per lot of reinforced bearings.

3. Compressive load results required by Level I testing which requires each bearing to be load

tested at 150% of maximum design load.

INSTALLATION

All bearing surfaces under elastomer must be plane to within 1.5 mm and horizontal to within 0.01 radians in

accordance with Project plans. Elastomeric bearings shall bear directly on the concrete surface.

Nuts for anchor bolts shall be tightened finger tight then back off 1/16 inch (2 mm). The threads shall then be

burred with a sharp pointed tool or peened.

When sole plates are attached to the beam flange they are to be placed so as to be aligned with the anchor

bolts after the dead load deflection has occurred if the dead load deflection and slope produce a change in

length of more than ¼ inch (6 mm).

Caution shall be exercised where a field weld or shop weld will be made while elastomeric bearing pad is in

contact with metal. In no case shall the elastomer or elastomer bond be exposed to instantaneous

temperatures greater than 400°F (204°C). Any damage to elastomeric bearing due to welding will be cause

for rejection. Temperature shall be controlled by use of heat crayons furnished by the Contractor.

METHOD OF MEASUREMENT

Elastomeric bearing shall be measured by each bearing pad which conforms to the size and dimensions

specified on the plans.

METHOD OF PAYMENT

All cost for furnishing and placing elastomeric bearings shall be included in the unit price bid for that item.

Payment for the steel sole plate shall be included in the unit price bid for structural steel if structural steel

beams are used or in the price bid for prestressed concrete beams if prestressed beams are used.

Item No. Pay Item Pay Unit

7093100 Elastomeric Bearing Each

S. C. File No. Page 4

You might also like

- Reed Prentice ManualDocument25 pagesReed Prentice ManualMikelyn Anderson100% (2)

- Asme Ii A Sa-276Document10 pagesAsme Ii A Sa-276Ruth Montoya100% (1)

- Laminated CompressDocument42 pagesLaminated CompressMACHINE-30 ISTENNo ratings yet

- Steel Castings, Welding, Qualifications of Procedures and PersonnelDocument19 pagesSteel Castings, Welding, Qualifications of Procedures and PersonnelDavidNo ratings yet

- Pneumatic Sheet Metal Cutting MachineDocument24 pagesPneumatic Sheet Metal Cutting MachineMyneni Sriram70% (10)

- Chapter 3 Miscellaneous Items: Quality Control Manual On Concrete and Steel Bridge StructuresDocument33 pagesChapter 3 Miscellaneous Items: Quality Control Manual On Concrete and Steel Bridge StructuresMae Ann GonzalesNo ratings yet

- Elastomeric Materials m17Document5 pagesElastomeric Materials m17Mad WonderNo ratings yet

- GRI-GM30 Specification Coated Tape Polymeric BarriersDocument28 pagesGRI-GM30 Specification Coated Tape Polymeric BarriersГригорий ЛевашовNo ratings yet

- Storage Tank Design CalculationDocument32 pagesStorage Tank Design CalculationE Santosh Kumar100% (1)

- API Engine Oil Classifications Infineum 2017Document12 pagesAPI Engine Oil Classifications Infineum 2017iosalcido100% (1)

- Assignment 3Document34 pagesAssignment 3YAHAMPATH ARACHCHIGE PASAN MADURA YahampathNo ratings yet

- HD Smooth Geomembrane MetricDocument1 pageHD Smooth Geomembrane MetricAndreas Erdian WijayaNo ratings yet

- Reinforcing SteelDocument39 pagesReinforcing SteelGage Floyd Bitayo100% (1)

- Polygomma EPDM Roofing Membrane CatalogueDocument4 pagesPolygomma EPDM Roofing Membrane Cataloguepolygomma Industries Pvt. LtdNo ratings yet

- Strip Seal Expansion JointDocument13 pagesStrip Seal Expansion JointsmithNo ratings yet

- Design Computations: Exhaust Tailpipe Extension Material Selection and Material Endurance StrengthDocument9 pagesDesign Computations: Exhaust Tailpipe Extension Material Selection and Material Endurance StrengthMarc Joshua MACATANGAYNo ratings yet

- PolyMax PLA TDS V4Document2 pagesPolyMax PLA TDS V4fNo ratings yet

- Polymax PC Tds v4Document2 pagesPolymax PC Tds v4Hector GarciaNo ratings yet

- Tension Properties For Materials Used in ShipbuildingDocument10 pagesTension Properties For Materials Used in ShipbuildingKarla JuárezNo ratings yet

- Calculation Sheet SubmittingDocument2 pagesCalculation Sheet SubmittingPloy Phoott NitthaNo ratings yet

- DIMO 30M - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsDocument4 pagesDIMO 30M - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsFernando LaraNo ratings yet

- HDPE All ThicnkenssDocument2 pagesHDPE All ThicnkenssmikeNo ratings yet

- Attn.: Mr. Jamal Diab Managing Director: M/s. Survey & Test Consult International KuwaitDocument3 pagesAttn.: Mr. Jamal Diab Managing Director: M/s. Survey & Test Consult International Kuwaitraja qammarNo ratings yet

- Progen: Pipe Thickness Calculation As Per IBR 350 Eqn.Document4 pagesProgen: Pipe Thickness Calculation As Per IBR 350 Eqn.P s JagatheesanNo ratings yet

- IRS Specification For Composite GRSP (6.2mm Thick) With Amendment 2 of 2017Document27 pagesIRS Specification For Composite GRSP (6.2mm Thick) With Amendment 2 of 2017RAJKUMARINo ratings yet

- Method Statement FX-E400 TDS 170714Document4 pagesMethod Statement FX-E400 TDS 170714Ranmal AbhaNo ratings yet

- 3 A6 Concrete MixDocument33 pages3 A6 Concrete MixBabu SundararamanNo ratings yet

- CC - GCCM Data SheetDocument2 pagesCC - GCCM Data SheetLarizza TesicoNo ratings yet

- PolyCast TDS V3Document2 pagesPolyCast TDS V3jerome.luganNo ratings yet

- Pipeline Wall Thickness Calculation DNV OS 101Document5 pagesPipeline Wall Thickness Calculation DNV OS 101abdul holil100% (1)

- MIRAFI G100N Drainage CompositeDocument1 pageMIRAFI G100N Drainage CompositeHardeo Dennis ChattergoonNo ratings yet

- Fire Piping Astm A135Document2 pagesFire Piping Astm A135sinahimsNo ratings yet

- AASHTODocument1 pageAASHTOZax SantanaNo ratings yet

- Note de Calcul Ancrage Rev3Document3 pagesNote de Calcul Ancrage Rev3Bilel MahjoubNo ratings yet

- Construction & Quality Control of Flexible Pavement: Dr. N.K.S. Pundhir Senior Principal Scientist E-MailDocument84 pagesConstruction & Quality Control of Flexible Pavement: Dr. N.K.S. Pundhir Senior Principal Scientist E-MailMohd Ali100% (1)

- Bergquist Gap Pad Comparison TableDocument1 pageBergquist Gap Pad Comparison TableMaike SongNo ratings yet

- Technical Data Sheet Polyfoam Normal: Extruded Polystyrene Insulation (Non Fire R Etardant)Document1 pageTechnical Data Sheet Polyfoam Normal: Extruded Polystyrene Insulation (Non Fire R Etardant)Raha Trading and ContactingNo ratings yet

- Kapton HN Data SheetDocument5 pagesKapton HN Data Sheet谢朋亨No ratings yet

- Datasheet: Delastic Preformed Compression SealsDocument2 pagesDatasheet: Delastic Preformed Compression SealsSaroj BhattaraiNo ratings yet

- AAC LeichtBric 2020Document10 pagesAAC LeichtBric 2020Jared Josef GomezNo ratings yet

- PV 1390 Cal R1Document44 pagesPV 1390 Cal R1namasralNo ratings yet

- PORON 4701-50 Firm - Supported MaterialsDocument2 pagesPORON 4701-50 Firm - Supported MaterialsLayeeq AhmedNo ratings yet

- MIRATAKDocument1 pageMIRATAKmiroslava mondragonNo ratings yet

- Corys Geosynthetics Data Sheet HDPE Smooth Geomembrane: Metric UnitsDocument1 pageCorys Geosynthetics Data Sheet HDPE Smooth Geomembrane: Metric UnitsVenkadesh PeriathambiNo ratings yet

- Storage Tank Design Calculation - Api 650: Close Cone-RoofDocument14 pagesStorage Tank Design Calculation - Api 650: Close Cone-RoofSalah JallaliNo ratings yet

- DIMO 2311 - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsDocument5 pagesDIMO 2311 - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsFernando LaraNo ratings yet

- Preliminary Design Report: Arcelormittal Composite Bridge Predesign Preliminary Design Software For Composite BridgesDocument4 pagesPreliminary Design Report: Arcelormittal Composite Bridge Predesign Preliminary Design Software For Composite BridgesIoana Codrea OrtelecanNo ratings yet

- Bagian C - Spesifikasi Pengadaan Pipa Dan AcessoriesDocument15 pagesBagian C - Spesifikasi Pengadaan Pipa Dan AcessoriesSoleh SulaemanNo ratings yet

- TDS ASIA MACMAT R Polymeric - Rev14 20161129Document1 pageTDS ASIA MACMAT R Polymeric - Rev14 20161129Andrew Zapanta Jr.No ratings yet

- Tech Data - PF Alidrain AD230 - 250Document1 pageTech Data - PF Alidrain AD230 - 250BinSayeed100% (1)

- General PropertiesDocument2 pagesGeneral PropertiesIsrael ExporterNo ratings yet

- Rubber Elements PropertiesDocument1 pageRubber Elements PropertiesMa ProvoloneNo ratings yet

- Nyco Grease GN 22 Air4222Document1 pageNyco Grease GN 22 Air4222muhammad_andinovaNo ratings yet

- Resumen SuperpaveDocument60 pagesResumen SuperpaveFranklinNo ratings yet

- 310 Data SheetDocument10 pages310 Data SheetAbdullrahman AlzahraniNo ratings yet

- Astm D4462-90Document2 pagesAstm D4462-90Priyadarshini KrishnaswamyNo ratings yet

- Caracteristicas API 2HGr50 PDFDocument3 pagesCaracteristicas API 2HGr50 PDFFernandoBarreraDominguezNo ratings yet

- Cold Rolled CoilDocument23 pagesCold Rolled Coilmametcool100% (1)

- Example 4: Diesel Hammer Input: GRLWEAP Standard ExamplesDocument3 pagesExample 4: Diesel Hammer Input: GRLWEAP Standard ExamplesbozarromegustaNo ratings yet

- Thermalbond v2200 Foam Tape Tds 1067 PDFDocument2 pagesThermalbond v2200 Foam Tape Tds 1067 PDFDario DiazNo ratings yet

- Mechanical Behavior of Organic Matrix Composites: Effect of Thermo-oxidative AgeingFrom EverandMechanical Behavior of Organic Matrix Composites: Effect of Thermo-oxidative AgeingNo ratings yet

- Send Us An Email: Elastomeric Bridge Bearing DesignDocument2 pagesSend Us An Email: Elastomeric Bridge Bearing DesignVerenice CentenoNo ratings yet

- Deluxe Integrated: FeaturingDocument1 pageDeluxe Integrated: FeaturingVerenice CentenoNo ratings yet

- Cost Effective For Soil Nail Wall Designs - Fast Installation and Immediate Loading - Predictable Capacity - Limited Access Areas - Pre-Engineered SystemDocument4 pagesCost Effective For Soil Nail Wall Designs - Fast Installation and Immediate Loading - Predictable Capacity - Limited Access Areas - Pre-Engineered SystemVerenice CentenoNo ratings yet

- A Case History: Project: Contractor: Structural EngineeringDocument2 pagesA Case History: Project: Contractor: Structural EngineeringVerenice CentenoNo ratings yet

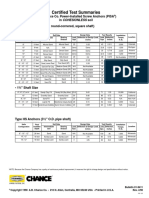

- Certified Test SummariesDocument1 pageCertified Test SummariesVerenice CentenoNo ratings yet

- Jack PostsDocument21 pagesJack PoststyannottiNo ratings yet

- ASTM A 437 A 437 M - Alloy-Steel PDFDocument3 pagesASTM A 437 A 437 M - Alloy-Steel PDFLugard WoduNo ratings yet

- 44 - Adam C Hawkins - The Cheese Thugs - v3Document1 page44 - Adam C Hawkins - The Cheese Thugs - v3Олег КацыNo ratings yet

- Electrochemical Deburring Principle and EquipmentsDocument30 pagesElectrochemical Deburring Principle and EquipmentsBARANINo ratings yet

- A516 MaterialDocument3 pagesA516 MaterialductaiutcNo ratings yet

- Programme AFC 13 The 13th Asian Foundry Congress Hanoi PDFDocument9 pagesProgramme AFC 13 The 13th Asian Foundry Congress Hanoi PDFPhung Tuan AnhNo ratings yet

- PATTA Blind Rivets Cat2018Document44 pagesPATTA Blind Rivets Cat2018Environ SupportNo ratings yet

- Sand Bucket SpecsDocument2 pagesSand Bucket SpecsAntonio Pedro Varela TavaresNo ratings yet

- Butt Weld Cap Dimension - Penn MachineDocument1 pageButt Weld Cap Dimension - Penn MachineEHT pipeNo ratings yet

- How To Select ElectrodeDocument2 pagesHow To Select Electrodesbmmla100% (1)

- Innotool Cat 2015Document336 pagesInnotool Cat 2015Info 5S Supply LtdNo ratings yet

- Module 06 - Materials & HardwareDocument1,090 pagesModule 06 - Materials & HardwaresreeramNo ratings yet

- Keeping Your Food Processing Plant Sanitary and SafeDocument34 pagesKeeping Your Food Processing Plant Sanitary and SafeThẩm NguyễnNo ratings yet

- Wet Film Thickness Gages: Comb Type GageDocument1 pageWet Film Thickness Gages: Comb Type GageNelson BarriosNo ratings yet

- ScienceQuestion - 3 7thDocument8 pagesScienceQuestion - 3 7thAmrita SenNo ratings yet

- Chain Block - Tiger LiftingDocument7 pagesChain Block - Tiger LiftingYADAGIRI REDDYNo ratings yet

- Steel Fence Posts and Assemblies, Hot-Wrought: Standard Specification ForDocument3 pagesSteel Fence Posts and Assemblies, Hot-Wrought: Standard Specification ForFRANZ RICHARD SARDINAS MALLCONo ratings yet

- Chromium Metal: Standard Specification ForDocument2 pagesChromium Metal: Standard Specification ForJerry Bean100% (1)

- Suncor Catalog PDFDocument166 pagesSuncor Catalog PDFLC ChongNo ratings yet

- Manual de Fundicion - StandardsDocument1 pageManual de Fundicion - StandardsFederico MoranNo ratings yet

- Dr. Vika Rizkia, S.T., M.T Mechanical Engineering State Polytechnic of JakartaDocument31 pagesDr. Vika Rizkia, S.T., M.T Mechanical Engineering State Polytechnic of JakartaCANDRA ANDREAN Mahasiswa PNJNo ratings yet

- List of New Projects Received During The Year 2018-19 (II)Document23 pagesList of New Projects Received During The Year 2018-19 (II)SurajPandeyNo ratings yet

- Iso 209-1:1989Document9 pagesIso 209-1:1989davezakNo ratings yet

- Grade 12: Shielded Metal Arc WeldingDocument10 pagesGrade 12: Shielded Metal Arc WeldingDarry BlanciaNo ratings yet

- Emissivity Manuscript Revision (Final)Document28 pagesEmissivity Manuscript Revision (Final)Praful PatilNo ratings yet

- Juntas Antisismicas U - AyvazDocument4 pagesJuntas Antisismicas U - AyvazAnonymous ZBdivmRoNo ratings yet