Professional Documents

Culture Documents

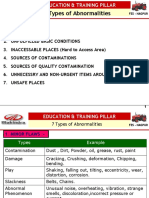

Table 4.6 Sample Manual On Exposing 7 Type of Abnormality

Table 4.6 Sample Manual On Exposing 7 Type of Abnormality

Uploaded by

Mohit Bansal0 ratings0% found this document useful (0 votes)

27 views3 pagesThis document outlines 7 types of abnormalities that can occur: 1) Minor flaws such as contamination, damage, play, slackness, and abnormal phenomena. 2) Unfulfilled basic conditions like insufficient lubrication. 3) Inaccessible places that are difficult to clean, check, lubricate, tighten, operate, or adjust. 4) Contamination sources from products, raw materials, lubricants, gases, liquids, scraps, and other sources. 5) Quality defect sources including foreign matter, shock, moisture, grain size, and concentration issues. 6) Unnecessary and non-urgent items left in places like machinery, piping, measuring instruments, and electrical equipment. 7) Unsafe places

Original Description:

Original Title

Table 4.6 sampl-WPS Office

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines 7 types of abnormalities that can occur: 1) Minor flaws such as contamination, damage, play, slackness, and abnormal phenomena. 2) Unfulfilled basic conditions like insufficient lubrication. 3) Inaccessible places that are difficult to clean, check, lubricate, tighten, operate, or adjust. 4) Contamination sources from products, raw materials, lubricants, gases, liquids, scraps, and other sources. 5) Quality defect sources including foreign matter, shock, moisture, grain size, and concentration issues. 6) Unnecessary and non-urgent items left in places like machinery, piping, measuring instruments, and electrical equipment. 7) Unsafe places

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

0 ratings0% found this document useful (0 votes)

27 views3 pagesTable 4.6 Sample Manual On Exposing 7 Type of Abnormality

Table 4.6 Sample Manual On Exposing 7 Type of Abnormality

Uploaded by

Mohit BansalThis document outlines 7 types of abnormalities that can occur: 1) Minor flaws such as contamination, damage, play, slackness, and abnormal phenomena. 2) Unfulfilled basic conditions like insufficient lubrication. 3) Inaccessible places that are difficult to clean, check, lubricate, tighten, operate, or adjust. 4) Contamination sources from products, raw materials, lubricants, gases, liquids, scraps, and other sources. 5) Quality defect sources including foreign matter, shock, moisture, grain size, and concentration issues. 6) Unnecessary and non-urgent items left in places like machinery, piping, measuring instruments, and electrical equipment. 7) Unsafe places

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 3

Table 4.

6 sample manual on exposing 7 type of abnormality

Abnormality Examples

Minor flaws

Contamination Dust, dirt, powder, oil, grease, rust, paint

Damage Cracking, crushing, deformation, chipping, bending

Play Shaking, falling out, tilting, corrosion, eccentricity

Slackness Belt & chain

Abnormal phenomena Unusual noise, overheating vibration, strange

smell, discoloration, improper pressure or current

Adhesion Blocking hardening, accumulation of debris,

peeling, malfunction

Unfulfilled basic conditions

Lubrication Insufficient dirty and identified unsuitable or

leaking lubricant

Lubricant supply Dirty, damage or deformed lubricant inlet, faulty

lubricant pipes

Oil level gauge Dirty, damage, leakage, no indication of correct

level

Tightening Nuts and bolts, slackness, missing , cross threads,

too long, crushed, corroded, washer unsuitable l,

wing nuts on backward

Inaccessible place

Cleaning Machine construction, cover, layout, footholds and

space

Checking Covers, construction, layout, inspection position

and orientation, operating range display

Lubricating Position of lubricant inlet, construction, height,

foothold, lubricant outlet and space

Tightening Cover, construction, layout, size, foothold and

space

Operation Machine layout, position of valve, switches, levers

and foothold

Adjustment Position of pressure gauge, thermometer, flow

metre, moisture gauge, vacuum gauge etc

Contamination sources

Product Leaks, spills, spurts, scatter, overflow

Raw materials Leaks, spills, spurts, scatter, overflow

Lubricant Leakage, split, seeping of lubricant oils and other

oils

Gases Leakage of compressed air, gases, steam , vapor,

exhaust fumes, etc.

Liquid Leakage, split and spiriting cold water, hot water,

half finished product, cooling water, waste water

etc.

Scrape Flashes, cutting, packing material, and

nonconforming product

Others Contaminants brought in by people, fork lift trucks,

etc. and infiltrating through cracks in building

5. Quality Defect Sources

Foreign Matter Inclusion, infiltration, and entrainment of rust, chips,

wire scrape, insects, Etc

Shock Dropping, Jolting, collision, vibration

Moisture Too much, Too little, infiltration, defective elimination

Grain Size Abnormalities in screens, Centrifugal separator,

Compressed – Air separator, etc.

Concentration Inadequate warming, heating, Compounding, mixing,

evaporation, Stirring, Etc.

Viscosity Inadequate warming, heating, Compounding, mixing,

evaporation, Stirring, Etc.

6. Unnecessary and Non-urgent items

Machinery Pumps, Fans, Compressors, Columns, tanks, etc.

Piping Equipment Pipes, hoses, duct, valves, dampers, etc.

Measuring Instrument Temperature, Pressure Gauges, Vacuum gauges,

ammeters, etc.

Electrical Equipment Wiring, piping, Power leads, Switches, Plugs, Etc.

Jigs and Tools General tools, Cutting tools, jigs, molds, dies, frames,

etc.

Spare Parts Standby Equipment, Spares, permanent stocks, Auxiliary

material, Etc.

Makeshift Repair Tape, string, wire, metal plates, etc.

7. Unsafe Places

Floors Unevenness, ramps, projections, cracking, peeling, wear

(Steel Deck plates)

Steps Too Step, Irregular, peeling anti-slip covering, corrosion,

missing handrails

Lights Dim, out of position, Dirty or broken cover, not properly

explosion – proofed

Rotating Machinery Displaced, fallen off or broken covers, no safety or

emergency stop devices

Lifting Gear Wire, hooks, brakes, and other part of cranes and hoists

Other Special substance, solvent, toxic gases, insulating

material, danger signs, protective clothing etc.

You might also like

- ZW310 Workshop ManualDocument572 pagesZW310 Workshop ManualMihaelaGabriela79% (14)

- Safety & Maintenance Checklist Skid-Steer Loaders and Multi-Terrain LoadersDocument1 pageSafety & Maintenance Checklist Skid-Steer Loaders and Multi-Terrain Loaderskkmech50% (2)

- PARACHUTE-MC1-1C User Manual-Packing and Maintenance GuidelinesDocument30 pagesPARACHUTE-MC1-1C User Manual-Packing and Maintenance Guidelinesaba distributor100% (3)

- Safety & Maintenance Checklist - Landfill Compactors V0611.2Document1 pageSafety & Maintenance Checklist - Landfill Compactors V0611.2cherifNo ratings yet

- Cat 312Document30 pagesCat 312MANUTENÇÃO CAVA ENGENHARIANo ratings yet

- Safety & Maintenance Checklist - Demolition Hydraulic Excavators V0611.2Document1 pageSafety & Maintenance Checklist - Demolition Hydraulic Excavators V0611.2cherif100% (3)

- Safety+&+Maintenance+Checklist+-+Motor+Graders+V0810 1Document1 pageSafety+&+Maintenance+Checklist+-+Motor+Graders+V0810 1Carlos E. Delius SciaroniNo ratings yet

- ASTM D3700-14 MuestreoDocument11 pagesASTM D3700-14 MuestreomarcosNo ratings yet

- 7 Types of AbnormalitiesDocument34 pages7 Types of AbnormalitiesYoga Adi100% (1)

- OSH Safety Harness Inspection ChecklistDocument1 pageOSH Safety Harness Inspection ChecklistXozan100% (1)

- Safety & Maintenance Checklist - D7E Track-Type Tractors V0611.2 PDFDocument1 pageSafety & Maintenance Checklist - D7E Track-Type Tractors V0611.2 PDFcherifNo ratings yet

- Safety & Maintenance Checklist - D7E Track-Type Tractors V0611.2Document1 pageSafety & Maintenance Checklist - D7E Track-Type Tractors V0611.2cherifNo ratings yet

- IDES Troubleshooting FlipchartDocument2 pagesIDES Troubleshooting FlipchartAnonymous fCp1HRwp100% (1)

- 7 Types of Abnormalities: Fes - NagpurDocument9 pages7 Types of Abnormalities: Fes - NagpurUtkarsh TalmaleNo ratings yet

- 18 Points Preparation Sheet of Step 0Document4 pages18 Points Preparation Sheet of Step 0Pradeep AdhikariNo ratings yet

- 5S & TPM Training Module Step ShiftDocument29 pages5S & TPM Training Module Step ShiftnitenmaruNo ratings yet

- 7 Steps For Evolving Autonomous Maintenance: Step Name Description 1 Initial Clean-UpDocument24 pages7 Steps For Evolving Autonomous Maintenance: Step Name Description 1 Initial Clean-UpPanch BNo ratings yet

- 7 Type AbnormalitiesDocument24 pages7 Type AbnormalitiesShantanu Shukla100% (2)

- Jishu HozenDocument65 pagesJishu HozenAnkit RanjanNo ratings yet

- Safety & Maintenance Checklist - TelehandlersDocument1 pageSafety & Maintenance Checklist - Telehandlersbob thompsoniNo ratings yet

- Excavadoras Hidráulicas DemoliciónDocument1 pageExcavadoras Hidráulicas DemoliciónJoel RodríguezNo ratings yet

- Backhoe English PDFDocument1 pageBackhoe English PDFGino AndersonNo ratings yet

- C10836834 PDFDocument1 pageC10836834 PDFFabian LopezNo ratings yet

- Track-Type TractorsDocument1 pageTrack-Type TractorsMOHAMMED THOUFIQNo ratings yet

- Fault CategoryDocument15 pagesFault CategoryShubham BhagwatNo ratings yet

- Failure Analysis ExaminationDocument3 pagesFailure Analysis ExaminationNelbert SumalpongNo ratings yet

- Tappi Press: Document Name: 0101r234 Section: TAPPI PRESS Title: Roll and Web Defect TerminologyDocument4 pagesTappi Press: Document Name: 0101r234 Section: TAPPI PRESS Title: Roll and Web Defect TerminologykeyurNo ratings yet

- Do Bearings Fail Us, or Do We Fail ThemDocument13 pagesDo Bearings Fail Us, or Do We Fail ThemRichieNo ratings yet

- 84.B 7 Types of AbnormalitiesDocument7 pages84.B 7 Types of AbnormalitiesVũ QuangNo ratings yet

- Daily Pre-Operationla Check List (Wheel Loader)Document1 pageDaily Pre-Operationla Check List (Wheel Loader)Soufian BahmadNo ratings yet

- Safety & Maintenance Checklist - Backhoe Loaders V0611 - 2E2Document1 pageSafety & Maintenance Checklist - Backhoe Loaders V0611 - 2E2Abdellatef HossamNo ratings yet

- AT - Safety & Maint. InspectionDocument2 pagesAT - Safety & Maint. Inspectionliva rakotondrasoaNo ratings yet

- Bearing PresentationDocument22 pagesBearing PresentationMunam AhmedNo ratings yet

- Edgetech SuperSpacer Systems Insulating Glass Manufacturing ManualDocument51 pagesEdgetech SuperSpacer Systems Insulating Glass Manufacturing ManualJelena ĆukNo ratings yet

- Chapter2 Damage PartsDocument16 pagesChapter2 Damage Partsmolla biyadgieNo ratings yet

- HC - TTT - Safety & Maint. InspectionDocument2 pagesHC - TTT - Safety & Maint. InspectionE & A Outlet100% (3)

- MH - Wheel - Safety & Maint. InspectionDocument2 pagesMH - Wheel - Safety & Maint. InspectionElisette RahantamalalaNo ratings yet

- Damage Analysis Chart 2Document1 pageDamage Analysis Chart 2NuM NaNo ratings yet

- Telehandler Daily Inspection ChecklistDocument2 pagesTelehandler Daily Inspection ChecklisthoverNo ratings yet

- I & M P S H: Nspection Aintenance Rocedure For Afety ArnessesDocument4 pagesI & M P S H: Nspection Aintenance Rocedure For Afety ArnessesUlviyye ElesgerovaNo ratings yet

- GC - TTT - Safety & Maint. InspectionDocument2 pagesGC - TTT - Safety & Maint. InspectionE & A OutletNo ratings yet

- 7 Types of AbnormalitiesDocument23 pages7 Types of AbnormalitiesBalachandar SathananthanNo ratings yet

- Examples of Autonomous Maintenance Review Sheets LeanManufacturing - OnlineDocument15 pagesExamples of Autonomous Maintenance Review Sheets LeanManufacturing - Onlinesuzhou cNo ratings yet

- Tarea deDocument3 pagesTarea deDavid UrbinaNo ratings yet

- 794 AC Safety and Maint. Inspection ChecklistDocument3 pages794 AC Safety and Maint. Inspection Checklistliva rakotondrasoaNo ratings yet

- CV2 TRB B Earing DamageDocument4 pagesCV2 TRB B Earing DamageAlvaroNo ratings yet

- Full Body Harness Equipment Inspection Checklist: Date InspectedDocument3 pagesFull Body Harness Equipment Inspection Checklist: Date InspectedChristian AndalNo ratings yet

- Form Inspeksi PMDocument4 pagesForm Inspeksi PMArnold LapianNo ratings yet

- Symptoms Causes Remedies: Rolling Bearing DamageDocument1 pageSymptoms Causes Remedies: Rolling Bearing Damageemad sabriNo ratings yet

- Webbing Anchor Strap-Inspection SheetsDocument1 pageWebbing Anchor Strap-Inspection SheetsRasLDKNo ratings yet

- Front Shovel ExcavatorsDocument1 pageFront Shovel ExcavatorsMOHAMMED THOUFIQNo ratings yet

- Timken MDV2 Tapered Roller Bearing Damage - 10826Document4 pagesTimken MDV2 Tapered Roller Bearing Damage - 10826mariamalloney1730No ratings yet

- Maintenance of Gears and Gear DrivesDocument44 pagesMaintenance of Gears and Gear Driveskapun kumar nayak100% (2)

- MH - Tracked - Safety & Maint. InspectionDocument2 pagesMH - Tracked - Safety & Maint. InspectionElisette RahantamalalaNo ratings yet

- FallProtectionEquipmentChecklist v2.0 20230116 PDFDocument3 pagesFallProtectionEquipmentChecklist v2.0 20230116 PDFHadi LaffafchiNo ratings yet

- Safety & Maintenance Inspection Checklist - Cold PlanersDocument1 pageSafety & Maintenance Inspection Checklist - Cold PlanersPedro BarriosNo ratings yet

- Bearings FailDocument15 pagesBearings FailHamza BounezraNo ratings yet

- Commissioning Inspection Checklist BEHDocument8 pagesCommissioning Inspection Checklist BEHDeny SaputraNo ratings yet

- C10836843 PDFDocument1 pageC10836843 PDFsandrobhaNo ratings yet

- Daily Pre-Operationla Check List (Excavator)Document1 pageDaily Pre-Operationla Check List (Excavator)Soufian BahmadNo ratings yet

- Checklist - Wheel Loaders V0611 2Document2 pagesChecklist - Wheel Loaders V0611 2Noxolo BhenguNo ratings yet

- Improvment Schadule Control ChartDocument2 pagesImprovment Schadule Control ChartMohit BansalNo ratings yet

- TPM (Red Tag)Document1 pageTPM (Red Tag)Mohit BansalNo ratings yet

- One - Point Lesson Sheet Device Name No. Date Prepared Prepared by Topic Approved byDocument1 pageOne - Point Lesson Sheet Device Name No. Date Prepared Prepared by Topic Approved byMohit BansalNo ratings yet

- 01 Purchase - DDocument3 pages01 Purchase - DMohit BansalNo ratings yet

- TurbinesDocument52 pagesTurbinesAnuragMaheshwariNo ratings yet

- Boiler Mountings and Accessories1Document31 pagesBoiler Mountings and Accessories1anuranjanshardaNo ratings yet

- Guideline For Flow and Pressure Testing of Hydrants: The Joiff StandardDocument8 pagesGuideline For Flow and Pressure Testing of Hydrants: The Joiff StandardALAA EWAIDANo ratings yet

- Concept Plus LRDocument2 pagesConcept Plus LRAnonymous jW9BkgbQmENo ratings yet

- Katalog Aksesoris HydrantDocument21 pagesKatalog Aksesoris HydrantPratikno SajaNo ratings yet

- Sullair Corporation: A Subsidiary of Sundstrand CorporationDocument165 pagesSullair Corporation: A Subsidiary of Sundstrand Corporationcarlos100% (2)

- Catalogo Rotametros Aalborg Linha CompletaDocument74 pagesCatalogo Rotametros Aalborg Linha CompletaAntonio MartelliNo ratings yet

- Catalogo BC35Document16 pagesCatalogo BC35tecnicomanelNo ratings yet

- SQ FLOW CONTROL LIMITED-Final EditionDocument33 pagesSQ FLOW CONTROL LIMITED-Final EditionSIMON S. FLORES G.No ratings yet

- Bobcat 530, 533 Hydrostatic Pump Component Service Repair Manual SN All PDFDocument10 pagesBobcat 530, 533 Hydrostatic Pump Component Service Repair Manual SN All PDFfkskefmmse0% (1)

- Fuel System Cessna 150Document21 pagesFuel System Cessna 150BookMaggotNo ratings yet

- A Project Report On Causes For Absenteeism in B.D.K. Engineering Industry Ltd. HubliDocument80 pagesA Project Report On Causes For Absenteeism in B.D.K. Engineering Industry Ltd. HubliBabasab Patil (Karrisatte)No ratings yet

- Ata 49 ApuDocument77 pagesAta 49 ApuSohaib Aslam Chaudhary100% (1)

- CASE 7 Case Study On Process Safety - Ammonia Plant (CDLT)Document6 pagesCASE 7 Case Study On Process Safety - Ammonia Plant (CDLT)Stephanie JainarNo ratings yet

- Front Attachment: Section 4Document40 pagesFront Attachment: Section 4suriantoNo ratings yet

- Test Pump WindlassDocument40 pagesTest Pump WindlassMd.farman Ali AhmedNo ratings yet

- Pressure Relief Valve, Direct Operated: RE 25402, Edition: 2016-07, Bosch Rexroth AGDocument20 pagesPressure Relief Valve, Direct Operated: RE 25402, Edition: 2016-07, Bosch Rexroth AGRafael Pérez PupoNo ratings yet

- Flo Tech™ ITB: ApplicationsDocument4 pagesFlo Tech™ ITB: ApplicationsMartha LimbergerNo ratings yet

- Baldwin-Filters Dahl Diesel Fuel Filter - Water Separators PDFDocument20 pagesBaldwin-Filters Dahl Diesel Fuel Filter - Water Separators PDFMihai PopaNo ratings yet

- Operation and Maintenance Manual Motor GraderDocument47 pagesOperation and Maintenance Manual Motor GraderAntonio MendezNo ratings yet

- (Technical) Pipo130 37 enDocument8 pages(Technical) Pipo130 37 enEslam MansourNo ratings yet

- Instrument Valves - PGI-IV PDFDocument32 pagesInstrument Valves - PGI-IV PDFRahmat RiskiNo ratings yet

- MXG 30 50 Manual Usa Etl 09-07Document77 pagesMXG 30 50 Manual Usa Etl 09-07Sanu PhilipNo ratings yet

- 2a29477 Clapper Check Valve Ops ManualDocument28 pages2a29477 Clapper Check Valve Ops ManualIFI ARGENTINA S.A.No ratings yet

- Esb 135 1Document0 pagesEsb 135 1edwinramonNo ratings yet

- Specifications, Scope of Work, Bid Rejection/Evaluation CriteriaDocument59 pagesSpecifications, Scope of Work, Bid Rejection/Evaluation CriteriaSOPANNo ratings yet

- Manual Trabajo JAC 5Document374 pagesManual Trabajo JAC 5david.vaquerahotmail.comNo ratings yet