Professional Documents

Culture Documents

Alpa - Product Datasheet - 2019

Alpa - Product Datasheet - 2019

Uploaded by

RicardoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alpa - Product Datasheet - 2019

Alpa - Product Datasheet - 2019

Uploaded by

RicardoCopyright:

Available Formats

Alpa life time extension

Full range competence – increased operational lifetime

Control system upgrade Condition monitoring

• Complete control system upgrade • Safe and easy installations – No need to interact

• Can be retrofitted with existing control system

• Also available for active heave compensation systems • Installation on all brands available

• Customer specific solution • Real time monitoring anytime anywhere

• Condition monitoring • Lifetime recording of all loads on all critical

• Online tool available at all times components

• Remote access • Optimized class – Maintenance when it is

necessary

• Control of all lifting operations, load

distribution and machinery true out lifetime

• Control and extension of the installation’s lifetime

Crane upgrades Radio remote installation / upgrade

• Control cabin replacement • Installed on existing system

• Inventory replacement (Chair, Operators panel, etc) • Customer defined functionality

• HPU upgrades • Ex or non-Ex

• Boom rest structures • Cranes, winches and skidding systems

• Access platforms

• Pipe or hose replacements

Maintenance and modifications Preservation and storage

• Experience from most crane vendors • Preservation planning

• Preventive maintenance • Dismount of fragile equipment

• Condition based maintenance • Efficient operations by use of rope access engineers

• 4- and 5-years maintenance and safe lifting

• Modifications for increased life time • Inspection and maintenance

• Modifications for increased lifting capacity • Storage procedure, including maintenance plan

• Modifications to correspond to rules and • Preservation

regulations • De-preservation

• Drivability improvement – hoist, luffing, slewing • Installation

• Active damping of crane oscillation • Start up

Special projects Turn key solutions by Alpa and Axess

• Pre projects to define clients requirements Alpa delivers projects ranging from pre-surveys by the Axess

• Crane studies group to product installation and commissioning by Alpa.

• EPCIC • Alpa system delivery, installation and commissioning

• Cost and benefit studies • Axess system verification and certification

• Installation planning • 24/7 service support through the systems life time.

• FMECA

• Engineering – tailor made solutions

• Analysis (structural, fatigue, life time estimates)

Inspection & Engineering Material handling

Findings Solutions

integrity solutions technology

management

Read more at alpahandling.com

Follow us on LinkedIn

Alpa AS Oscar Hanssens vei 7 6415 MOLDE NORWAY post@alpahandling.com alpahandling.com

Alpa product overview

Full range competence – increased operational lifetime

Please see product specific datasheet for additional technical information

Gripper yoke with quick connector Gantry crane

• Increased safety – easy automated shift between yoke • Specially designed to suit individual applications

and hook, no manual work • Non Ex and Ex available

• No oil spill • Electro or hydraulic operated

• Unlimited slewing function • Class approved

• Fail safe lock

• Proven solution

Spooling winch Manipulator crane

• Safe – No manual handling of wire drums • Multi purpose

• Flexible – No overhead lifting needed during • Can be equipped with quick connector for oil and

operation electro

• Efficient – One operation • Telescope with slewing function

• Back tension – No need for breaking in wire • Winch

Hose reel stations Access basket

• Electro or hydraulic operated • Maximum accessibility

• Non Ex and Ex available • Easy installation and maintenance

• Single and multi reels • 360˚ basket slewing

• Standard foundation for easy installation • Basket tilt

• Boom slewing

• Telescope

• Class approval

Winches Knuckle boom crane

• Electro or hydraulic operated • Special designed for marine operations

• Non Ex and Ex available • Various designs

• 2 – 25 t lifting capacity • Emergency operation system

• Customer specific functionality • Non Ex and Ex available

• Optional spooling device • Optional NORSOK

• Optional NORSOK R-002 • Radio remote

• Class approved • Class approval

Read more at alpahandling.com

Follow us on LinkedIn

Alpa AS Oscar Hanssens vei 7 6415 MOLDE NORWAY post@alpahandling.com alpahandling.com

SERVICE AND MAINTENANCE

Condition based maintenance – substantial cost reductions

Alpa service and maintenance

Your service and maintenance costs will be significantly reduced by use

of an objective third party.

Alpa offers continuously, yearly, four-yearly and five-yearly service and

maintenance on all your lifting equipment. The service and maintenance

are based on the OEM’s recommendations in combination with a close

dialogue with you as an owner and the certifying body / EoC (depending

on vessel / rig –class).

A critical evaluation of the recommended spare parts list has also proven

to be cost effective without increasing the clients risks.

• Condition based maintenance based on OEM’s recommendations

• Reduced spare parts requirements

• Synergy by use of Alpa and Axess

Read more at alpahandling.com

Follow us on LinkedIn

Alpa AS Oscar Hanssens vei 7 6415 MOLDE NORWAY post@alpahandling.com alpahandling.com

SERVICE AND MAINTENANCE

Condition based maintenance – substantial cost reductions

Recommended service and maintenance

OEM • The OEM’s recommendation for service and

maintenance are used as input for defining final

service and maintenance plan.

• Class will define the degree of involvement by

certifying body (e.g. DnV Drill)

Alpa evaluation of SoW

• Qualified evaluation of the OEM’s service and

maintenance recommendations.

• Critical evaluation of the OEM’s spare part

recommendations. Critical OEM specific task

and deliveries (e.g. software updates, spare

parts) can still be supplied by OEM.

Certifying body / Approval of maintenance plan by

EoC certifying body / EoC

• Evaluation and approval of Alpa’s inspection,

Client service and maintenance plan.

• Evaluation and approval of Alpa’s spare parts list.

• The Client, Alpa and the certifying body agrees

upon a final service and maintenance plan

including spare parts.

Service and maintenance by Alpa

• Service are carried out as agreed between the

parties.

• Service reports are established to verify the SoW.

Recertification by certifying body / EoC

• Service reports are evaluated and approved by

certifying body (Complete maintenance history is

used as a basis in the evaluation).

• Required tests are carried out according to class

(e.g. overload test)

Please contact Alpa AS for additional info

Read more at alpahandling.com

Follow us on LinkedIn

Alpa AS Oscar Hanssens vei 7 6415 MOLDE NORWAY post@alpahandling.com alpahandling.com

KNUCKE BOOM CRANE

SWL 3 mT – 11.2 m / 2.0 mT – 15 m

Offshore & Marine design

for safe and efficient material handling

Alpa Knuckle Boom Crane is designed for the special conditions

of offshore & marine application; harsh environment, dynamic

load conditions, excessive side loads and stresses exposed to

the crane during operation.

The Alpa knuckle Boom Crane is available for rental or purchase.

Several other models available upon request.

Read more at alpahandling.com

Follow us on LinkedIn

Alpa AS Oscar Hanssens vei 7 6415 MOLDE NORWAY post@alpahandling.com alpahandling.com

KNUCKE BOOM CRANE

Certified according to NORSOK R-002

ADVANTAGES

The design is based on the use of mainly high tensile steel

material. The design is focused on protecting the crane

against overloads by absorbing any additional forces through Compact Design

its special boom construction.

The design offers extremely high resistance against

overloads and combines perfectly high elasticity with rigidity

and thereby reducing the risk of accidents.

The crane is equipped with an Ex HPU. The HPU is container

mounted and designed for on-deck installation. The HPU can

optionally be installed on-door if requested. Standard supply

440V - 60Hz, other specifications available upon request.

Stowed Position

15 meter outreach

FUNCTIONS

• SWL 3.0 mT 11 m / 2.0 mT 15 m

• Ex – Zone 2

• Radio Remote Control with rated capacity

• Emergency lowering system

• Hydraulic & electric overload device installed

• 360⁰ slew with Limit switches

• Rated Capacity indicator in radio remote Radio Remote Control – With Load monitoring

• Standard documentation for CE-marking

• Dedicated containerized Ex HPU available

• Connection to existing HPU / Ring Line possible

CODES AND STANDARDS

• 2006/42/EC Machinery Directive Load Chart

• 97/23/EC Pressure Equipment Directive

• 94/9/EC ATEX Directive

• 2006/95/EC Low Voltage Directive

• 2004/108/EC EMC Directive

• DNV Rules for certification of lifting appliances No 2.22

• NORSOK R-002 • NORSOK S-002

• NORSOK Z-015 • NORSOK S-005

• NORSOK R-003 • NORSOK M-501

Several other models available upon request.

Read more at alpahandling.com

Follow us on LinkedIn

Alpa AS Oscar Hanssens vei 7 6415 MOLDE NORWAY post@alpahandling.com alpahandling.com

SPOOLING WINCH

Wire Replacement

ALPA

SPW 4.5

Through wire replacements, Alpa

has tried and experienced

different wire spooling systems,

with various functionality and

efficiency, without finding the

optimal solution in regards to

Safety, Functionality and

Efficiency.

ADVANTAGES

Safe

No manual handling of wire drums

Flexible

No overhead lifting needed during operation

Efficient

One operation. No need for reaking in wire.

Correct Backtension Contact for the product:

A must on multilayer wire spooling

post@alpahandling.com

Read more at alpahandling.com

Follow us on LinkedIn

Alpa AS Oscar Hanssens vei 7 6415 MOLDE NORWAY post@alpahandling.com alpahandling.com

SPOOLING WINCH

ALPA SPW 4.5

WHY?

Wire replacement on offshore deck cranes are high-risk operations, with

potential of serious injury and damage to personnel, equipment and

reputation, and has caused several incidents through the years.

By applying the correct backtension on winches, correct spooling is ensured

and wire life span may be prolonged due to less wear on wire strands.

Wire replacement is not a routine job for offshore personnel/crane operators.

HOW?

Remotely operated spooling winch. No manual

interference needed during operation.

Constant backtension applied by the hydraulic system.

Provides correct and measurable backtension through

the spooling process.

Hydraulically driven system for material handling. No

need for additional lifting applications during wire drum

replacement, for situations when crane coverage is

limited or absent.

Through the wire replacements, Axess has tried and

experienced different wire spooling systems, with various

functionality and efficiency, without finding the optimal

solution in regards to Safety, Functionality and Efficiency.

360 degree operation

FLEXIBLE SOLUTION

Pneumatic hydraulic system

ATEX approved

NORSOK Z-015

Cable remote control

360⁰ Rotation

Handles different wire drums

For onboard lift

Integrated fork lift pockets

Read more at alpahandling.com

Follow us on LinkedIn

Alpa AS Oscar Hanssens vei 7 6415 MOLDE NORWAY post@alpahandling.com alpahandling.com

WINCH

Designed for harsh environments

• Designed to suit individual applications

and installations worldwide

• NORSOK R-002

ALPA Winch 10T Winch

Green solution

Alpa Winches - an environmental friendly

solution as it is can run electrically.

By using modern electro frequency drive

technology and hydraulic, oil spill is not an issue. Contact for the product:

post@alpahandling.com

Read more at alpahandling.com

Follow us on LinkedIn

Alpa AS Oscar Hanssens vei 7 6415 MOLDE NORWAY post@alpahandling.com alpahandling.com

WINCH

Designed for harsh environments

ADVANTAGES

ALPA Winches provides safe and efficient winch operation,

low maintenance and high performance.

Designed to suit individual applications and installations worldwide.

PERFORMANCE

• Standard SWL: 2 - 6 - 10 – 25 TON

• Additional variations available upon request

TECHNICAL

• Electro drive solution

• Ex solutions / None Ex

OPTIONS

• All Electric Spooling Variations

• Electro-hydraulic

• Hydraulic ring line powered

CERTIFICATION

Available with:

• NORSOK R-002

• DNV SfC 2.22

• DNV-OS-E101

ADDITIONAL FUNCTIONALITY

• Emergency Lowering

• Secondary Brake

• Load Indication ALPA winch

• Wire Tensioning System

• EOS – Emergency Operation System

• CT – Constant Tension

• AHC – Active Heave Compensation

SWL 2 T SWL 10 T SWL 25 T

Read more at alpahandling.com

Follow us on LinkedIn

Alpa AS Oscar Hanssens vei 7 6415 MOLDE NORWAY post@alpahandling.com alpahandling.com

ACCESS BASKET

Designed for maximum accessibility

Alpa Access Basket provides

safe, flexible and efficient access

to remote equipment. With the

possibility of having three slew

functions the Alpa Basket gives the

operator maximum accessibility

and reduces occupied space

during parking.

Read more at alpahandling.com

Follow us on LinkedIn

Alpa AS Oscar Hanssens vei 7 6415 MOLDE NORWAY post@alpahandling.com alpahandling.com

Access Basket

Designed for maximum accessibility

ADVANTAGES

Alpa Access Basket provides safe, flexible and efficient access to

remote equipment. With the possibility of having 3 slew functions the

Alpa Basket gives the operator maximum accessibility and

reduces occupied space during parking.

It is operated locally from the basket or from a remote control panel

located at desired location.

The machine fulfils all relevant safety requirements put forward by Alpa Access Basket for

the certifying authority. The Access Basket can be equipped with maximum accessability

accumulator battery system for emergency evacuation of personnel.

The standard control mode is remote pilot oil controlled from the

basket and from a remote control stand. The basket control panel

govern the control, i.e. the operator will from this panel override the

functions of the remote panel.

FUNCTIONS STANDARD SOLUTION

• Basket tilt and slewing • Hydraulic

• Telescope extend/retract • Pilot oil remote control

• Telescope boom tilt • Standard documentation for CE-marking

• Boom slewing

OPTIONAL

• Accumulator battery for emergency evacuation of personnel

• Both None Ex and Ex solutions are available

• Radio remote control

• Parking cradle

• Prepared for high pressure washer system

• Plant air connection in basket

PERFORMANCE DATA

Safe working load 300 kg

Upper working position / parking 55 / 75

Basket tilt and slew for Lower working position / entering 55

maximum accessability

Main boom swing motion 90 (or up main structure limitation)

Access basket swing motion 90

Tilt motion 55

Max outreach 14 m

Boom Telescope Stroke 7m

Swing Speed 0-2,5 degree/sec, stepless

Boom Tilt Speed 0-2,0 degree/sec, stepless

Basket Tilt Speed 0-2,0 degree/sec, stepless

Boom Telescope Speed 0-0,15 m/sec, stepless

Read more at alpahandling.com

Follow us on LinkedIn

Alpa AS Oscar Hanssens vei 7 6415 MOLDE NORWAY post@alpahandling.com alpahandling.com

HOSE REEL STATION

Designed for harsh environments

• Safety and efficiency

• Designed to suit individual applications

and installations worldwide

ALPA Hose Reel Station

Green solution

Alpa Hose Reel Station an environmental

friendly solution as it is run electrically.

By using modern electro frequency drive

technology and hydraulic, oil spill is not an issue. Contact for the product:

post@alpahandling.com

Read more at alpahandling.com

Follow us on LinkedIn

Alpa AS Oscar Hanssens vei 7 6415 MOLDE NORWAY post@alpahandling.com alpahandling.com

HOSE REEL STATION

Designed for harsh environments

ADVANTAGES

Alpa Hose Reel Stations provides safe and efficient operation and

storage of bulk loading hoses, used for fluid or powder transfer

operations. Single, double or multireel stations are available,

specifically configured and designed to suit individual applications

and installations worldwide.

Hose assemblies, connectors and reel pipe work materials are

selected for compatibility with operation in a harsh offshore

environments.

STANDARD SOLUTION

• Electro drive solution

• Both None Ex and Ex solutions are available

• Cable remote control

• Variable speed with frequency converter

• Fail safe brake system

• Prepared for Emergency shut down from CCR

• 440V or 690V / 50Hz or 60Hz

ALPA Hose Reel Station

• Up to 60m 4” hose on each reel

• Standard foundation for on-deck installation

OPTIONAL

• Electro-hydraulic or hydraulic ring line solution is available

• Radio Remote Control

• Larger reels for more capacity than 60m 4” hose

• Installation specific designed foundation for installation

• Foundation and deck loading analysis

ALPA Hose Reel Station

Multi Reel Setup

ALPA Hose Reel Station

Read more at alpahandling.com

Follow us on LinkedIn

Alpa AS Oscar Hanssens vei 7 6415 MOLDE NORWAY post@alpahandling.com alpahandling.com

GRIPPER YOKE

Designed for safe and efficient

pipe and material handling

Alpa Gripper Yoke is designed for

safe, flexible and efficient pipe and material handling.

With the possibility for automatic connection system for

change between yoke and hook, Alpa Gripper Yoke gives

the operator and deck maximum functionality and

minimal physical interference.

Read more at alpahandling.com

Follow us on LinkedIn

Alpa AS Oscar Hanssens vei 7 6415 MOLDE NORWAY post@alpahandling.com alpahandling.com

Gripper Yoke

Designed for safe and efficient pipe and material handling

ADVANTAGES

Alpa Gripper Yoke is designed for

safe, flexible and efficient pipe and material handling. With the

possibility for automatic change between yoke and hook Alpa

Gripper Yoke gives the operator and deck maximum functionality

and minimal physical interference.

The machine fulfils all relevant safety requirements put forward by

the certifying authority.

Alpa provides complete control systems for maximum integration

and functionality, as well as integration in various 3rd party crane

systems.

FUNCTIONS

• 360⁰ slew with encoder

ALPA Gripper Yoke

• Yoke travel for balancing of load

• Fail safe functions

• Standard documentation for CE-marking

OPTIONAL

• Quick coupling hook

• Fully automated hydraulic connection from crane to yoke

• Cylinder position feedback

• Auto rotation of yoke

• Complete control system for maximum integration of

functionalities and possibilities.

EKSAMPLE OF PERFORMANCE DATA

SWL Gripper 4,5T

SWL centre lifting lug 10T

SWL end lifting lugs 5T

Pipe dimensions 2 7/8” to 20”

Distance between grippers 1250 mm

Distance between pipe supports 2450 mm

Easy switch between

Distance between lifting lugs 3050 mm

Yoke and Hook Slewing sector Unlimited

Yoke tilting angle 15 ⁰

Yoke travel length 1000 mm

Performance adjustments available upon request

Read more at alpahandling.com

Follow us on LinkedIn

Alpa AS Oscar Hanssens vei 7 6415 MOLDE NORWAY post@alpahandling.com alpahandling.com

Gantry Cranes

Designed for harsh environments

• Pipe and Riser handling

• Designed to suit individual applications

and installations worldwide

ALPA Gantry Crane

Green solution

Alpa Gantry Cranes an environmental friendly

solution as it is can run electrically.

By using modern electro frequency drive

technology and hydraulic, oil spill is not an issue. Contact for the product:

post@alpahandling.com

Read more at alpahandling.com

Follow us on LinkedIn

Alpa AS Oscar Hanssens vei 7 6415 MOLDE NORWAY post@alpahandling.com alpahandling.com

GANTRY CRANES

Designed for harsh environments

ADVANTAGES

ALPA Gantry Cranes provides safe and efficient handling of pipe

and risers. Specifically configured and designed to suit individual

applications and installations worldwide.

STANDARD SOLUTION

• SWL 2 x 7,5 T to 2 x 15 T

• 16 m rail span

• 10 m lifting height

(customer adaptation available upon request)

CERTIFICATION

Available with:

• NORSOK R-002

• DNV SfC 2.22

• DNV-OS-E101

TECHNICAL

• Electro drive solution

With Magnetic Yoke

• Both None Ex and Ex solutions are available

• Synchronized or individual operation of winches and trolleys

• Emergency lowering

OPTIONS

• All Electric

• Electro-hydraulic or hydraulic ring line powered

• Magnetic Yoke

• Mechanical Yoke

• Alpa Load Recorder with Maintenance Calendar and Component

Monitoring

General Arrangement

Read more at alpahandling.com

Follow us on LinkedIn

Alpa AS Oscar Hanssens vei 7 6415 MOLDE NORWAY post@alpahandling.com alpahandling.com

MANIPULATOR CRANE

Designed for Riser Tension Ring Handling

Alpa Manipulator Crane is designed for

safe, efficient and controlled handling of

Riser Tension Ring and DAT-cylinder assembly

Advantages

Reduces exposed personnel during tension ring preparation.

• No manual interference needed

• No need for man riding during operation

• No Work over sea

• Automatic mechanical connection

• Automatic hydraulic connection for locking riser ring mechanism

Read more at alpahandling.com

Follow us on LinkedIn

Alpa AS Oscar Hanssens vei 7 6415 MOLDE NORWAY post@alpahandling.com alpahandling.com

MANIPULATOR CRANE

Designed for Riser Tension Ring Handling

ADVANTAGES

Alpa Manipulator Crane is designed for safe, efficient and controlled handling of Riser Tension Ring and

DAT-cylinder assembly. The system is fitted with quick connection for mechanical interlock between Riser

Tension Ring and Manipulator Crane, and with an option for integrated hydraulic connections. Combined

these functionalities remove all need for personnel working over sea or use of man-rider during riser

tension ring preparation. With complete control and total functionality in one operation, the user can handle

the riser tension ring is safer and more efficient

FUNCTIONALITY

• The system is designed with winch, slew bearing, main

boom, and a telescopic knuckle boom with capacity to

handle the forces applied from the weight of risers and BOP.

System in Parked / Retracted position • The crane geometry is optimized for installation on small

spaces (e.g. cellar deck). Taking a bare minimum of space in

parked position.

• The system can be powered by existing ring line hydraulic

system or from separate HPU.

• The boom tip is designed for switching between different

tools, e.g. gripper manipulator or hook assembly.

Skidding Tension Ring to well center

OPTIONAL

• Gripper for manipulator operations

• Certified as material handling crane (lifting mode)

• Automatic Quick connection for hydraulic connections

Tension Ring and Cylinders in well center

PERFORMANCE DATA

Safe working load Pulling: 35 ton

Pushing: 8 ton

Lifting mode (optional) 5 ton

Swing motion 90

Max outreach 7.8 m

Boom Telescope Stroke 1.9 m

Swing Speed 0-2,5degree/sec, step less

Rigged as Crane

Boom Tilt Speed 0-2,0 degree/sec, step less Manipulator Crane (lifting mode)

Riser Tension With Gripper

Boom Telescope Speed 0-0,15 m/s

Ring Handling

Environmental loads Heel/trim 3⁰

Read more at alpahandling.com

Follow us on LinkedIn

Alpa AS Oscar Hanssens vei 7 6415 MOLDE NORWAY post@alpahandling.com alpahandling.com

CONDITION MONITORING

Lifetime diagnosis for structure and machinery

Continuous monitoring of loads and components

The Alpa condition monitoring system is designed to be installed both as a stand

alone monitoring system or as a integrated control system software. This multi use

gives the operators the possibility to utilize new technology on existing cranes without

high risk- and cost impact.

• Stand alone or integrated system

• Safe and easy installation – no need to interact with existing

control system

• Saved costs due to condition based maintenance

• Remote access – Real time monitoring anytime anywhere

• Optimized class - Plan and prove maintenance activities

• Lifetime recording of all loads on all critical components

• Control and extension of the installation’s lifetime

Contact for the product:

post@alpahandling.com

Read more at alpahandling.com

Follow us on LinkedIn

Alpa AS Oscar Hanssens vei 7 6415 MOLDE NORWAY post@alpahandling.com alpahandling.com

CONDITION MONITORING

Lifetime diagnosis for structure and machinery

Continuous monitoring of loads and components

ADVANTAGES

• Safe and easy installations – No need to interact with

existing control system

• Installation on all brands available

• Real time monitoring anytime anywhere

• Lifetime recording of all loads on all critical components

• Optimized class – Maintenance when it is necessary

• Control of all lifting operations, load distribution and

machinery true out lifetime

• Extension of the installation’s lifetime

SPECIFICATIONS

• Load monitoring on critical components

• Evaluates remaining lifetime on components

• Track changes to indicate potential failure

• Maintenance calendar

DELIVERY OPTIONS

• Stand alone or integrated system

• Alpa or client based monitoring

• Installation on new or existing lifting appliances

Online load recorder

ALPA COMPETENCE IN ALL AREAS:

• Long experience

• Familiar to all types and vendors of offshore cranes

WHY?

Increased safety and reduced

operational and maintenance costs.

• Lifetime condition monitoring and

analysis for structure and

machinery.

• Lift- and overload tables available

real time on screen. All lifts and

overloads is stored on file.

• Easy accessible activity recorder for

reconstruction of crane operation for

the last 24 hours.

Read more at alpahandling.com

Follow us on LinkedIn

Alpa AS Oscar Hanssens vei 7 6415 MOLDE NORWAY post@alpahandling.com alpahandling.com

SAFE LOAD INDICATOR

Alpa Safe Load Indicator

Our Safe Load Indicator fits both simple or more complex

installations - with your input we design the right solution either you

need a small system in addition to an existing system or a complete

stand alone system.

Alpa Safe Load Indicator is based on standard commercial products

which gives a flexible solution with easily accessible spares. The

system can be delivered for installation in Ex classified areas.

Alpas competence on cranes span from design, calculations and

analysis together with mechanics, hydraulics and electronics

ADVANTAGES

• Stand alone or combined solution

WE STRIVE FOR SIMPLICITY AS A

• Integrated recording system

SOLUTION TO EVERY COMPLEX

• Flexibility with modular design

CHALLENGE.

• Build upon standard industrial

IT'S EASY TO MAKE THINGS

components

BIGGER AND MORE COMPLEX.

• EN 13852-1, DNV 2.22 or API 2C

• Ex version available

IT TAKES INSIGHT AND COURAGE

TO MOVE IN THE OPPOSITE

DIRECTION.

Contact for the product:

post@alpahandling.com

ALPA Safe Load Indicator

Read more at alpahandling.com

Follow us on LinkedIn

Alpa AS Oscar Hanssens vei 7 6415 MOLDE NORWAY post@alpahandling.com alpahandling.com

SAFE WORK LOAD INDICATOR

FUNCTIONS

1. By means of load, overturning moment (option)

and angle measurements the system calculates

the crane utilization for all operating conditions.

The system will provide the operator with needed

information for safe crane operation, and the

system conforms to world wide prevailing

standards. Analog outputs and/or potential free

contacts for interfacing with other systems are

available.

2. Based on the lifting appliance’s design

parameters, the system will activate alarms and

output signals to initiate actions in the lifting

appliance’s control system. All calibrations are

performed from the operators display.

Configuration and calibration data is stored on CF

memory card, which will make reconfiguration of

the system easy.

3. Overload handling in accordance with EN 13852-1 or other specification. AOPS / GOPS

output signals are available. We do also calculation of AOPS safety function settings.

4. Load recorder integrated in load indicator system is available. Structure and machinery

components life time monitoring. Reports for lifts- and overload table and consumed life

time status available on operators display. No downloading of data is necessary for basic

report formats.

5. Separate black box recorder unit with separate memory for crane operation

reconstruction available. Spreadsheet readable files for easy reporting. PLC based solution

for high robustness and reliability during the lifting appliance's life time. Option for remote

downloading of data via TCP/IP.

6. Maintenance module option for scheduling and monitoring of important maintenance

activities. Reminder of upcoming tasks on operator’s display will ease the planning of

condition based maintenance.

7. Hoist counter option with position, direction, speed indications and overspeed outputs.

8. Slewing counter option with position and speed indication. Max. slew angle and user

defined forbidden sector functionality is available.

9. Miscellaneous measurement indicators are available as option (wind speed, pressure

measurement, temperatures etc.)

Read more at alpahandling.com

Follow us on LinkedIn

Alpa AS Oscar Hanssens vei 7 6415 MOLDE NORWAY post@alpahandling.com alpahandling.com

PRESERVATION AND STORAGE

Full range competence

Preservation and storage

Correct preservation and storage is important to obtain optimal life time of

equipment when not in use. We offer complete services to ensure that the

equipment is stored in a safe and protected state when stored on or off-

shore.

• Preservation planning

• Dismount of fragile equipment

• Efficient operations by use of rope access engineers and safe lifting

• Inspection and maintenance

• Preservation

• Storage procedure, including maintenance plan

• De-preservation

• Installation

Read more at alpahandling.com

Follow us on LinkedIn

Alpa AS Oscar Hanssens vei 7 6415 MOLDE NORWAY post@alpahandling.com alpahandling.com

PRESERVATION AND STORAGE

Full range competence

PRESERVATION AND STORAGE

The full range competence from Axess and Alpa gives an

unique combination of inspection and maintenance

knowledge. This knowledge ensures that the equipment is

inspected, maintained and preserved in a safe and protected

way.

The multi discipline capacities enables us to offer a turn key

solution ranging from pre-planning to complete preservation

and inspection routine. The safe lifting combined with the

rope access engineers gives a very efficient performance of

the job.

MECHANICAL PRESERVATION

• Cleaning

• Inspection

• Touch up paint

• Greasing

• Securing of fragile equipment

HYDRAULIC PRESERVATION

• Cleaning

• Inspection

• Maintenance / repair

• System (Hoses, piping, valves, tank)

• Motor

• Pump

• Cylinder

• Fittings

• Mechanical interface

ELECTRIC PRESERVATION

• Cleaning

• Inspection

• Maintenance / repair

• Cabling

• Motor

• Junction box

• Connectors

• Mechanical interface

STORAGE

• Marking - TAG

• Maintenance plan

• Recommendations Please contact Alpa AS for additional info

Read more at alpahandling.com

Follow us on LinkedIn

Alpa AS Oscar Hanssens vei 7 6415 MOLDE NORWAY post@alpahandling.com alpahandling.com

ALPA – a part of the Axess group

• The Material Handling Technology segment in Axess AS is from

01.01.2015 separated out as an independent legal entity. The new

company is named Alpa AS.

• Alpa AS is owned by Axess AS.

• Alpa has today 26 skilled and experienced employees.

• Alpa is challenging the lifting and handling market, with cost-effective

and simplified solutions that will make the clients day to day business

easier and safer.

Our objective is to make a clear and visible split between our services

related to

inspection, certification and verification

versus

service, modifications and new design

Read more at alpahandling.com

Follow us on LinkedIn

Alpa AS Oscar Hanssens vei 7 6415 MOLDE NORWAY post@alpahandling.com alpahandling.com

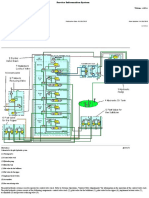

ALPA – a part of the Axess group

Maintenance

Management

Integrity Management

RBI / RCM /RAM analysis

Inspection & Integrity

Lifting and Drilling

Management Equipment Certification

DROPS Management

Findings

In-service Inspection

Electrical Inspection

QC-services

Mechanical Engineering

Electrical Engineering

• 3.rd part Verifications

Engineering Safe Lifting Operations

Solutions Material Handling compliance

consultancy

NORSOK R-002

NORSOK R-003

Solutions

Products

Service

Material Handling Maintenance

Technology Study and analysis

(ALPA)

Read more at alpahandling.com

Follow us on LinkedIn

Alpa AS Oscar Hanssens vei 7 6415 MOLDE NORWAY post@alpahandling.com alpahandling.com

You might also like

- Tandem Mooring & OffloadingDocument12 pagesTandem Mooring & OffloadingJim StrakerNo ratings yet

- W6F Towing Winch PDFDocument422 pagesW6F Towing Winch PDFAbdulRasheed100% (1)

- HMF Nacelle Service Crane 2530T VWP V02Document14 pagesHMF Nacelle Service Crane 2530T VWP V02Lisa Todd50% (2)

- 16.5.user Manual - Davit HMD A15 MacGregorDocument110 pages16.5.user Manual - Davit HMD A15 MacGregorGabriel Nogueira100% (1)

- Manual Grúa N65aDocument8 pagesManual Grúa N65aSaúlBorlandGalindoNo ratings yet

- Tirfor WrenchDocument18 pagesTirfor WrenchJOKO LELURNo ratings yet

- Specialty ConnectorsDocument62 pagesSpecialty ConnectorsLuis David Concha CastilloNo ratings yet

- TR 350M 3 - C1 1eDocument14 pagesTR 350M 3 - C1 1eFayez Alnamarneh86% (7)

- Basic Launch and Recovery System For Work-Class RovsDocument2 pagesBasic Launch and Recovery System For Work-Class RovsLorena NascimentoNo ratings yet

- 4 Lifts in ConveyorDocument8 pages4 Lifts in ConveyorAhmed LaoudiNo ratings yet

- Wheel Loader PDFDocument28 pagesWheel Loader PDFacarisimovic100% (2)

- Wheel Loader 950HDocument28 pagesWheel Loader 950Hacarisimovic100% (3)

- Pipe Racking: "Helping Our Customers Achieve Superior Results"Document6 pagesPipe Racking: "Helping Our Customers Achieve Superior Results"KACEM100% (1)

- Hose Loading StationsDocument16 pagesHose Loading StationsJim StrakerNo ratings yet

- Off The Truck and Ready For Work! Transports in One Load With CounterweightsDocument2 pagesOff The Truck and Ready For Work! Transports in One Load With CounterweightsJose Leonel Alvarez CamposNo ratings yet

- Loading/unloading Lines - Key Standard Features: Standard Feature Benefit Customer ValueDocument10 pagesLoading/unloading Lines - Key Standard Features: Standard Feature Benefit Customer Valueakmalul adabiNo ratings yet

- Productbrochure MT2000 22A1005389 2009-01Document12 pagesProductbrochure MT2000 22A1005389 2009-01son daNo ratings yet

- VACON 100 Product PresentationDocument100 pagesVACON 100 Product PresentationJuan Paulo Fernandez VallejosNo ratings yet

- Missile Actuation Systems Data SheetDocument2 pagesMissile Actuation Systems Data Sheetمحمد رزقNo ratings yet

- Rough Terrain Crane 30-Ton (30.0 MT)Document2 pagesRough Terrain Crane 30-Ton (30.0 MT)Juan Manuel Vázquez LeguizamónNo ratings yet

- Catalogo Grua Link Belt 8065Document2 pagesCatalogo Grua Link Belt 8065Raul LalindeNo ratings yet

- Etm V 2 Factsheet en Au 2021 11 PDF DataDocument4 pagesEtm V 2 Factsheet en Au 2021 11 PDF DataNobita RaguwanshiNo ratings yet

- Specialty ConnectorsDocument24 pagesSpecialty ConnectorsAndres SanchezNo ratings yet

- Catalogo Grua Link Belt RTC 8050Document2 pagesCatalogo Grua Link Belt RTC 8050Raul LalindeNo ratings yet

- Series A: Product GuideDocument8 pagesSeries A: Product GuideFrank Felipe Cruz ChavezNo ratings yet

- INTCV385 - HV and MV Switchgear (CB, CT, CVT, DC and SA) Operaion, Maintenance - L2 - v1Document3 pagesINTCV385 - HV and MV Switchgear (CB, CT, CVT, DC and SA) Operaion, Maintenance - L2 - v1PMG Bhuswal ProjectNo ratings yet

- The Experts: ComfortDocument20 pagesThe Experts: ComfortFabio DuarteNo ratings yet

- Specialty ConnectorsDocument62 pagesSpecialty ConnectorsjdmacbookNo ratings yet

- Pages From ProcessandPipelineServicesDocument1 pagePages From ProcessandPipelineServicesZulhilmi ZalizanNo ratings yet

- 21381844-0718 DEMAG LDC-Q EN ScreenDocument4 pages21381844-0718 DEMAG LDC-Q EN ScreenDante WilliamsNo ratings yet

- K-Winch FlylineDocument1 pageK-Winch Flylinejuliandomingo888No ratings yet

- CSU 160 UnitDocument4 pagesCSU 160 Unitgustavo rivasNo ratings yet

- Divisora de MasaDocument4 pagesDivisora de MasaNicolas Astudillo MaldonadoNo ratings yet

- 2dxl Super Loader Backhoe LoaderDocument8 pages2dxl Super Loader Backhoe LoaderNiranjan TailorNo ratings yet

- Presentation On RIG and CRANESDocument58 pagesPresentation On RIG and CRANESSathya NarayanaNo ratings yet

- CranesDocument4 pagesCranesZulhilmi ZalizanNo ratings yet

- Electric Reach Truck 48 Volt 1400 / 1600 KG 2800 / 3200 LbsDocument8 pagesElectric Reach Truck 48 Volt 1400 / 1600 KG 2800 / 3200 LbsThanh Ngoc0% (1)

- Mechanical Drives/Power Transmission: Course AgendaDocument2 pagesMechanical Drives/Power Transmission: Course Agendah2jfg4ihjbhjdbcqNo ratings yet

- Control Valve Sizing - Selection and MaintenanceDocument2 pagesControl Valve Sizing - Selection and Maintenanceemadsafy20002239No ratings yet

- Demag PDFDocument40 pagesDemag PDFclaudinei alves fonsecaNo ratings yet

- BR0GN01-09.22 Dodge General Overview (W)Document8 pagesBR0GN01-09.22 Dodge General Overview (W)William VillamizarNo ratings yet

- TMEIC Container Crane ModernizationDocument8 pagesTMEIC Container Crane ModernizationBoy AlfredoNo ratings yet

- Piping Vibration Screening - WoodDocument2 pagesPiping Vibration Screening - WoodAbbas Al MisbahNo ratings yet

- Atlas MilitaryDocument12 pagesAtlas MilitaryRasoolKhadibiNo ratings yet

- Catalogo RTC-8050 IIDocument2 pagesCatalogo RTC-8050 IISara Sarmiento EcheverryNo ratings yet

- The Solution To Meet Special Requirements: Demag DH Hoist UnitsDocument12 pagesThe Solution To Meet Special Requirements: Demag DH Hoist UnitsSajeev JacobNo ratings yet

- Container Crane Mod - I-3002-Feb2019-webDocument8 pagesContainer Crane Mod - I-3002-Feb2019-webstoneminerNo ratings yet

- Enhanced Quikrig Coiled Tubing SystemDocument4 pagesEnhanced Quikrig Coiled Tubing SystemMohamed KamalNo ratings yet

- Wood - Veridian - Piping Vibration Screening (A4)Document2 pagesWood - Veridian - Piping Vibration Screening (A4)rangga gumilang wiganjarNo ratings yet

- Push Pull and Pull Only Custom AssembliesDocument2 pagesPush Pull and Pull Only Custom AssembliesDhiven RamsayNo ratings yet

- National Series 1800 Product GuideDocument8 pagesNational Series 1800 Product GuideJuan PabloNo ratings yet

- Advanced Well Completion DesignDocument6 pagesAdvanced Well Completion DesignM.No ratings yet

- Conveyors and ChutesDocument2 pagesConveyors and ChutesGanesan Balraj50% (2)

- Range: Keeping The World FlowingDocument8 pagesRange: Keeping The World FlowingPiermarco ContrerasNo ratings yet

- Marine Product Guide: Twin Disc Family of ProductsDocument57 pagesMarine Product Guide: Twin Disc Family of ProductsAnonymous hlPPOmxXB7No ratings yet

- Build Beyond Imagination: Eik Engineering SDN BHDDocument20 pagesBuild Beyond Imagination: Eik Engineering SDN BHDdanangNo ratings yet

- Tubing Conveyed Perforating Systems PDFDocument8 pagesTubing Conveyed Perforating Systems PDFVishwanath BanerjieNo ratings yet

- Circuit Breakers and Switch GearDocument2 pagesCircuit Breakers and Switch GearMilind DombaleNo ratings yet

- Hydraulics and Conveyor Systems: TrainingDocument3 pagesHydraulics and Conveyor Systems: TrainingAbdalla Mohamed AbdallaNo ratings yet

- RackerDocument1 pageRackerDavid MayNo ratings yet

- Audel Guide to the 2005 National Electrical CodeFrom EverandAudel Guide to the 2005 National Electrical CodeRating: 4 out of 5 stars4/5 (1)

- Technology of Semiactive Devices and Applications in Vibration MitigationFrom EverandTechnology of Semiactive Devices and Applications in Vibration MitigationNo ratings yet

- IT Success!: Towards a New Model for Information TechnologyFrom EverandIT Success!: Towards a New Model for Information TechnologyRating: 3 out of 5 stars3/5 (1)

- P11099-HT ProcedureDocument7 pagesP11099-HT ProcedureRicardoNo ratings yet

- BRAZILIAN - RecipesDocument19 pagesBRAZILIAN - RecipesRicardoNo ratings yet

- 8215-367S D55 48barg NameplateDocument1 page8215-367S D55 48barg NameplateRicardoNo ratings yet

- 316L Angle and Channel Steel 3Document1 page316L Angle and Channel Steel 3RicardoNo ratings yet

- Base Painting Inspection RecordDocument8 pagesBase Painting Inspection RecordRicardoNo ratings yet

- World Class Solutions: Ricardo Calvet Freire Operations Manager APACDocument11 pagesWorld Class Solutions: Ricardo Calvet Freire Operations Manager APACRicardoNo ratings yet

- Annex B-1: Enhanced Jobs Support Scheme: Ministry of Finance 1Document5 pagesAnnex B-1: Enhanced Jobs Support Scheme: Ministry of Finance 1RicardoNo ratings yet

- Axess - Global Reference List - 2021Document8 pagesAxess - Global Reference List - 2021RicardoNo ratings yet

- Lyft - Pulsed Eddy CurrentDocument8 pagesLyft - Pulsed Eddy CurrentRicardoNo ratings yet

- Axess Group - Brazilian ComplianceDocument1 pageAxess Group - Brazilian ComplianceRicardoNo ratings yet

- Product Sheet - DROPS TrainingDocument2 pagesProduct Sheet - DROPS TrainingRicardoNo ratings yet

- 700169-04-271 - Motor Megger TestDocument3 pages700169-04-271 - Motor Megger TestRicardoNo ratings yet

- Conama 436Document34 pagesConama 436RicardoNo ratings yet

- RBI Assessment Recommended Work-Ing ProcessDocument1 pageRBI Assessment Recommended Work-Ing ProcessRicardoNo ratings yet

- Crane 1 2 HH400-1518-4Document244 pagesCrane 1 2 HH400-1518-4cengiz kutukcu100% (1)

- Product Sheet Asd Tug 2813Document2 pagesProduct Sheet Asd Tug 2813Roda NiagaNo ratings yet

- BGL - Pms Crane LibherrDocument6 pagesBGL - Pms Crane LibherrAbdul BasitNo ratings yet

- Haul Cables and Care For InfrastructureDocument11 pagesHaul Cables and Care For InfrastructureSathiyaseelan VelayuthamNo ratings yet

- Appleton Marine BrochureDocument12 pagesAppleton Marine Brochureseckin80No ratings yet

- Deck Machineries - 0817 - Rev5 PDFDocument44 pagesDeck Machineries - 0817 - Rev5 PDFShayn Rhyx TegioNo ratings yet

- PDS ExampleDocument9 pagesPDS ExampleAlex WilsonNo ratings yet

- Operation Manual - 18 Meter EMM (HCRR) ADTL - F 20-6-2020Document78 pagesOperation Manual - 18 Meter EMM (HCRR) ADTL - F 20-6-2020Mechanical DesignNo ratings yet

- Oshe Honmi Main Installation Vessel - SpecificationDocument6 pagesOshe Honmi Main Installation Vessel - SpecificationjohnhdatuNo ratings yet

- Combifloat C-7: Self Elevating PlatformDocument3 pagesCombifloat C-7: Self Elevating PlatformVetriselvan ArumugamNo ratings yet

- AP8950SDB-AL-250/200/150/100/50: Model Aircraft Towing VehicleDocument2 pagesAP8950SDB-AL-250/200/150/100/50: Model Aircraft Towing VehicleRadu50% (2)

- AP8950SDB-AL-200: Mod El Aircraft Towing VehicleDocument2 pagesAP8950SDB-AL-200: Mod El Aircraft Towing VehicleRaduNo ratings yet

- Ingersoll Rand FA10 Popeye Winch Air Tugger ManualDocument85 pagesIngersoll Rand FA10 Popeye Winch Air Tugger ManualAleksei ChernozhukovNo ratings yet

- 4.1 Mooring: Naftomar Shipping and Trading Co - LTDDocument7 pages4.1 Mooring: Naftomar Shipping and Trading Co - LTDVlad Harchenko100% (1)

- Smatco Cat 6-07Document12 pagesSmatco Cat 6-07Eleazar Maldonado RiveraNo ratings yet

- Rendering TestDocument7 pagesRendering TestDwiky syamcahyadi rahman100% (1)

- Sistema Hidraulico PilotoDocument6 pagesSistema Hidraulico PilotoRafael RodriguezNo ratings yet

- EFFER TELESCOPIC CRANE Use and Maintenance Manual AKC 115 LHE4 Aukra 250592Document102 pagesEFFER TELESCOPIC CRANE Use and Maintenance Manual AKC 115 LHE4 Aukra 250592Vladyslav BibkoNo ratings yet

- Kenr5711kenr5711-04 SisDocument32 pagesKenr5711kenr5711-04 SisEVCY100% (1)

- Fushun Yongmao Construction Machinery Co - LTDDocument157 pagesFushun Yongmao Construction Machinery Co - LTDOleksandr YakubetsNo ratings yet

- Planned Maintenance System Manual: Integrated Management System (Ims)Document63 pagesPlanned Maintenance System Manual: Integrated Management System (Ims)Jym GensonNo ratings yet

- TG043 Figure8 Install GuideDocument14 pagesTG043 Figure8 Install Guidemazen zaloudNo ratings yet

- ROC124 WinchesProductCatalogueWGD ProofDocument8 pagesROC124 WinchesProductCatalogueWGD ProofKc TanNo ratings yet

- Trident CraneDocument2 pagesTrident CranePavan RayNo ratings yet

- 2015 Specialized Force Electrical Catalogue FullDocument428 pages2015 Specialized Force Electrical Catalogue FullRizwan Ahmed RafiqNo ratings yet

- Poultry Growing Drinking Systems Big Dutchman enDocument8 pagesPoultry Growing Drinking Systems Big Dutchman enHeshamKotb0% (1)