Professional Documents

Culture Documents

2 Introduction To Silo Forming Machines

2 Introduction To Silo Forming Machines

Uploaded by

red patriotCopyright:

Available Formats

You might also like

- Sumitomo LinepipeDocument46 pagesSumitomo LinepipeDekky Mulyadi100% (1)

- Ebook - Industrial Hammer MillDocument17 pagesEbook - Industrial Hammer MillNayankumar Patel100% (1)

- Faccin Eng Web PDFDocument40 pagesFaccin Eng Web PDFIstván SzékelyNo ratings yet

- Introduction To Bhilai Steel PlantDocument6 pagesIntroduction To Bhilai Steel PlantSunny BhartiNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Valency Table PDFDocument1 pageValency Table PDFrkrishna4470% (20)

- Training Report On BSPDocument14 pagesTraining Report On BSPsanchay3090No ratings yet

- Wheel Crack TrurningDocument27 pagesWheel Crack TrurningdevendraNo ratings yet

- High-Quality Wire Rod and Bar Production at YongXing Special Stainless SteelDocument12 pagesHigh-Quality Wire Rod and Bar Production at YongXing Special Stainless SteelJJNo ratings yet

- All New Brochure 2Document12 pagesAll New Brochure 2Dawood NalbandNo ratings yet

- SAPH 440 MaterialDocument16 pagesSAPH 440 MaterialDinesh SharmaNo ratings yet

- 47 NCPMillsDocument5 pages47 NCPMillsraosp66No ratings yet

- 5 Integrated Steel PlantsDocument4 pages5 Integrated Steel PlantsSanjna KaulNo ratings yet

- Vocational Training ReportDocument34 pagesVocational Training ReportRavi kumarNo ratings yet

- Final ProjectDocument54 pagesFinal ProjectShakti NaiduNo ratings yet

- A Project Report On Summer Vocational Training in Bhilai Steel PlantDocument24 pagesA Project Report On Summer Vocational Training in Bhilai Steel PlantRahul PandeyNo ratings yet

- Sepor CatalogDocument18 pagesSepor Catalogjaelani sidikNo ratings yet

- Proman - IntroductionDocument9 pagesProman - IntroductionHarshala ChoudharyNo ratings yet

- Sumitomo LinepipeDocument46 pagesSumitomo LinepipeMaqsoodAnwarNo ratings yet

- Foil FormulaDocument22 pagesFoil FormulaMoontasirNasimNo ratings yet

- An 15 Days Training in Casting IndustrialDocument27 pagesAn 15 Days Training in Casting IndustrialAmar Shete100% (1)

- E-catalog-Aluminum Extrusion Equipmet-Nenghong MachineryDocument11 pagesE-catalog-Aluminum Extrusion Equipmet-Nenghong MachineryJigar GalaNo ratings yet

- Proman Infrastructure Services Pvt. LTDDocument9 pagesProman Infrastructure Services Pvt. LTDsatgNo ratings yet

- Bhilai Steel PlantDocument37 pagesBhilai Steel PlantPratyush MishraNo ratings yet

- Training Report PRASADDocument32 pagesTraining Report PRASADshekharazad_suman85% (13)

- Multi SlittingDocument6 pagesMulti Slittingeng_ahmedkassemNo ratings yet

- TND - 081639 - 162600 BokaroDocument52 pagesTND - 081639 - 162600 BokaroBhavya MakhaniaNo ratings yet

- Samiya Wire Nail All Data Project ReportDocument23 pagesSamiya Wire Nail All Data Project ReportferishsuratiNo ratings yet

- Faccin CatalogoDocument40 pagesFaccin CatalogoBunnyNo ratings yet

- Training Report On BSPDocument14 pagesTraining Report On BSPnitinrnnnNo ratings yet

- Scan 12 Aug 23 22 45 54Document34 pagesScan 12 Aug 23 22 45 54Ashu PatelNo ratings yet

- Bokaro Steel Plant An OverviewDocument20 pagesBokaro Steel Plant An OverviewAðitya SínghNo ratings yet

- Brochure PSMDocument19 pagesBrochure PSMsirajuddin khowajaNo ratings yet

- Machinery DetailsDocument7 pagesMachinery DetailsDOTDNo ratings yet

- Steel Rebar Industry ProfileDocument34 pagesSteel Rebar Industry ProfileOvidiu TomaNo ratings yet

- BR MiningDocument12 pagesBR MiningSteven TremolNo ratings yet

- Marketing PDFDocument61 pagesMarketing PDFMithun Konjath0% (1)

- J28475 Galnorth Presentation Royal BafokengDocument17 pagesJ28475 Galnorth Presentation Royal BafokengLeeLowersNo ratings yet

- Bhilai Steel PlantDocument12 pagesBhilai Steel PlantGanta AnuNo ratings yet

- Ball MillDocument11 pagesBall MillAkhil Bhadouria0% (1)

- AM Katalog Ploche EngDocument28 pagesAM Katalog Ploche EngDejanNo ratings yet

- Functions of Various Departments of Rinl/VspDocument16 pagesFunctions of Various Departments of Rinl/VspdhruNo ratings yet

- Functions of Various Departments of Rinl/VspDocument16 pagesFunctions of Various Departments of Rinl/VspGoogle AccountNo ratings yet

- Himal Iron and Steel QuestionareDocument9 pagesHimal Iron and Steel QuestionareAdarsha Man TamrakarNo ratings yet

- ProjectDocument61 pagesProjectPritam Ghosh100% (1)

- Internship Report: Heavy Industries TaxilaDocument49 pagesInternship Report: Heavy Industries TaxilaSyed Waqas HussainNo ratings yet

- Important Aspects of Rolling of Hot Rolled Coil in Hot Strip Mill - IspatGuruDocument7 pagesImportant Aspects of Rolling of Hot Rolled Coil in Hot Strip Mill - IspatGuruBoban RajkovicNo ratings yet

- Internship Report of Poeples Steel MillsDocument88 pagesInternship Report of Poeples Steel MillsShahid Ali LeghariNo ratings yet

- Super-Orion®Ball Mill: Types S.O., S.O.-Cl Compact Line, S.O.-Sf Super FineDocument6 pagesSuper-Orion®Ball Mill: Types S.O., S.O.-Cl Compact Line, S.O.-Sf Super FineKrmača RužaNo ratings yet

- THERMIT-Presentasi Lengkap Thermit-Oxy LanceDocument14 pagesTHERMIT-Presentasi Lengkap Thermit-Oxy LanceFirdaus AdenNo ratings yet

- Index: SL - No. Topic P NODocument24 pagesIndex: SL - No. Topic P NOShahbaz AlamNo ratings yet

- Mathan Kumar - Salem Steel Plant SSPDocument33 pagesMathan Kumar - Salem Steel Plant SSPDhanish KumarNo ratings yet

- Steel Slag RecyclingDocument2 pagesSteel Slag RecyclingNickRuiNo ratings yet

- A Project Report OnDocument45 pagesA Project Report Onamruta_warwatkarNo ratings yet

- Wire Rod Mailable PDFDocument11 pagesWire Rod Mailable PDFVenu PrasadNo ratings yet

- Crushing and GrindingDocument13 pagesCrushing and GrindingKumar NathanNo ratings yet

- Bolt-Nut BrochureDocument13 pagesBolt-Nut BrochureLong Beautéophile100% (1)

- Descriptive Pamphlet of the Richmond Mill Furnishing WorksFrom EverandDescriptive Pamphlet of the Richmond Mill Furnishing WorksNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- CO Pipelines Material and Safety ConsiderationsDocument7 pagesCO Pipelines Material and Safety Considerationsred patriotNo ratings yet

- 7 Common Problems Found in Pumps On Board ShipsDocument7 pages7 Common Problems Found in Pumps On Board Shipsred patriot100% (1)

- Girth Gear Failures - LinkedInDocument7 pagesGirth Gear Failures - LinkedInred patriotNo ratings yet

- Verification - Hevii Technologie GMBHDocument2 pagesVerification - Hevii Technologie GMBHred patriotNo ratings yet

- HR Recruitment and SelectionDocument29 pagesHR Recruitment and Selectionred patriotNo ratings yet

- Liebherr RTG Cranes BrochureDocument7 pagesLiebherr RTG Cranes Brochurered patriotNo ratings yet

- 3 Common Mistakes Made When Handling Stainless SteelDocument13 pages3 Common Mistakes Made When Handling Stainless Steelred patriotNo ratings yet

- Hot Insulation ProcedureDocument8 pagesHot Insulation Procedurered patriotNo ratings yet

- The Magic of Bolting For A Grinding Mill Assembly - MetsoDocument3 pagesThe Magic of Bolting For A Grinding Mill Assembly - Metsored patriotNo ratings yet

- Air Hose Connections Double Seat Valve d624 en deDocument1 pageAir Hose Connections Double Seat Valve d624 en dered patriotNo ratings yet

- Method Statement For Insulation Works and JacketingDocument8 pagesMethod Statement For Insulation Works and Jacketingred patriotNo ratings yet

- Managing Your Emotions at Work - Career Development FromDocument6 pagesManaging Your Emotions at Work - Career Development Fromred patriotNo ratings yet

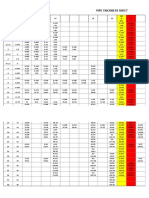

- Pipe Thickness ChartDocument4 pagesPipe Thickness Chartred patriotNo ratings yet

- Installation and Operating Instructions: Ventilated Silos D5.3 AND D7.5Document28 pagesInstallation and Operating Instructions: Ventilated Silos D5.3 AND D7.5red patriotNo ratings yet

- Process Plant Insulation & Fuel Efficiency: Pdhonline Course M156 (4 PDH)Document76 pagesProcess Plant Insulation & Fuel Efficiency: Pdhonline Course M156 (4 PDH)red patriotNo ratings yet

- Lipp Silo Building System: Product OverviewDocument10 pagesLipp Silo Building System: Product Overviewred patriotNo ratings yet

- Cadmium Sulfide Thin Films Prepared by Chemical Bath Deposition MethodDocument7 pagesCadmium Sulfide Thin Films Prepared by Chemical Bath Deposition Methodbib123456789huNo ratings yet

- Table of K ValuesDocument7 pagesTable of K ValuesdasoodaseeNo ratings yet

- VLÄTKRIG InstructionsDocument2 pagesVLÄTKRIG InstructionsEscargotNo ratings yet

- Dims Pipe and TubeDocument32 pagesDims Pipe and Tuberach4harvNo ratings yet

- Vacuum Distillation DillaDocument3 pagesVacuum Distillation DillaRifqi Dwi RamadhaniNo ratings yet

- Damage and Plasticity For Concrete BehaviorDocument16 pagesDamage and Plasticity For Concrete BehaviorJosé Antonio Cornetero UrpequeNo ratings yet

- Land or No Land?: Tablet Compression ToolingDocument2 pagesLand or No Land?: Tablet Compression Toolingrohan satwaraNo ratings yet

- Grade12 Rigel Group4 Assesing The Solid Waste Management Off Small Foos Store in Gingoog CityDocument31 pagesGrade12 Rigel Group4 Assesing The Solid Waste Management Off Small Foos Store in Gingoog CityMa. Joan ApolinarNo ratings yet

- The Difference Between BS5308 Cable PAS 5308 Cable and en 50288 Cable - What Are en 50288-7 CablesDocument3 pagesThe Difference Between BS5308 Cable PAS 5308 Cable and en 50288 Cable - What Are en 50288-7 CablesveerendraNo ratings yet

- For Exer 3Document16 pagesFor Exer 3Louiegi AlvarezNo ratings yet

- Paint-Off Remover 2016 SDSDocument2 pagesPaint-Off Remover 2016 SDSdina auliaNo ratings yet

- Ex Pan Proof 100Document3 pagesEx Pan Proof 100Amar WadoodNo ratings yet

- Solution and Scheme CIV 212 (Test 2)Document8 pagesSolution and Scheme CIV 212 (Test 2)SanthoshMBSanthuNo ratings yet

- I. Read The Dialogue and Answer The Questions BelowDocument3 pagesI. Read The Dialogue and Answer The Questions BelowM.alwaly syariefNo ratings yet

- Assignment 2Document2 pagesAssignment 2Ryan S. BudionganNo ratings yet

- LAB VIVA QuestionsDocument4 pagesLAB VIVA QuestionsKh Bappi ShahriarNo ratings yet

- 32 Samss 005 PDFDocument33 pages32 Samss 005 PDFRajan SteeveNo ratings yet

- JP 34 5 434Document4 pagesJP 34 5 434Fajar Sri Lestari PangukirNo ratings yet

- BET Chem Soc Reviews 2017Document26 pagesBET Chem Soc Reviews 2017SivasankarVenkatramanNo ratings yet

- Annexure 16 - Structural SteelDocument12 pagesAnnexure 16 - Structural SteelmasoodNo ratings yet

- Caltherm Pharmaceutical Processing SolutionsDocument4 pagesCaltherm Pharmaceutical Processing SolutionsBusiness DevelopmentNo ratings yet

- Effects of Dust Suppression On Conveyor Belting: TechtipsDocument3 pagesEffects of Dust Suppression On Conveyor Belting: TechtipsAlbar BudimanNo ratings yet

- Low-Voltage Hydrogen Peroxide Electrolyzer For Highly Efficient - Power-To-Hydrogen ConversionDocument8 pagesLow-Voltage Hydrogen Peroxide Electrolyzer For Highly Efficient - Power-To-Hydrogen ConversionShangli HuangNo ratings yet

- Product Data Sheet: K-Sperse 152MSDocument2 pagesProduct Data Sheet: K-Sperse 152MSManoj Lalita GoswamiNo ratings yet

- Centrifugal Monoblock Pumpset: MDH SeriesDocument2 pagesCentrifugal Monoblock Pumpset: MDH Seriesakshay upadhyayNo ratings yet

- Chicken Processing PlantDocument8 pagesChicken Processing PlantRoem EsmernaNo ratings yet

- Example of Stress Absorbing Membrane InterlayerDocument7 pagesExample of Stress Absorbing Membrane Interlayershanil3001No ratings yet

- Related Literature of The StudyDocument3 pagesRelated Literature of The StudySam Christian DucoNo ratings yet

- SOP Trial StretchDocument4 pagesSOP Trial StretchashutoshpathakcivilNo ratings yet

2 Introduction To Silo Forming Machines

2 Introduction To Silo Forming Machines

Uploaded by

red patriotOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2 Introduction To Silo Forming Machines

2 Introduction To Silo Forming Machines

Uploaded by

red patriotCopyright:

Available Formats

Grain Storage Silos

Cement Storage Silos

Steel Silo Making Equipments

Home | Products | News | About us | Projects | Application | Services | Contacts us

1 2 3

BAIRONG Bolt bulk storage silo system - Best solution of the bulk grain storage, bulk cement storage system

HOME >> NEWS >>Introduction of Lipp Silo Forming Machine

FULL STEEL SILO SOLUTION As following is the introduction of our SM 40 lipp silo forming machine.

Lipp Steel Silo Uncoiler uses and works: The 2-4mm thick, 495mm wide after Rx4.0m / m steel molding seams, stitching unit five and five bending molding process,

Bolted Steel Silo seams process will strip forming a circle I forced seams and after spiral stitched into 4-50m round cylinder diameter ranging from specifications (the

wall).

Welded Steel Silo

These steel cylinder (wall) is widely used in:

Application Fields

1, from the material shape points: Storage granular material, powdered materials, liquid materials.

Agricultural and Grain

2, from the industry point: use in food, feed, brewing, petroleum, pharmaceutical, food, cement, water, and other collar.

Construction Industry

3, specific varieties such as: wheat, soybeans, corn, sorghum, wheat flour, bulk cement, fly ash, sewage, water, medicine and other chemical storage.

Chemicals & Plastics

These metal containers in our space is large, it may replace past traditional welding metal containers. So Rx4.0m / m steel molding machine stitched

Energy and Bioenergy seams, superior construction speed, reliable operational performance and quality assurance become the first choice of investment insight.

Conditioning, sludges and wastes Steel silo equipment - uncoiling machine features:

Spiral Steel Silos Making Equipments 1, Rx4.0m / m steel molding seams, stitching unit, is the company's latest round silo (pool) of the construction unit, which is based on foreign SM40-

type units, innovation revised national standard product, with the same function, easy operation and maintenance, reducing the diameter tooling

different specifications, saving installation time machine in place, greatly reducing the cost of construction, so the introduction of Rx4.0m / m steel

molding seams, stitching machine and abroad SM40-type construction of the unit more competitive compared.

Tel: 86-18610 0838 68 2, the company launched Rx4.0m / m steel molding machine stitched seams on the machine selection are used high-strength alloy steel, greatly

improving the life of the machine. (Rx 4.0m / m steel molding seams, stitching unit, is the company's latest round silo (pool) construction unit, which is

Fax: 86-371-6871 6761

based in Germany LIPP-SM40-type units, the innovative design of the market the latest products, and LIPP-SM40-type unit has the same function,

Email:tanjie@spiral-silo.com

more competitive market. its advantage is easy operation and maintenance, reducing the diameter tooling different specifications, saving installation

kingreal2004@gmail.com time machine in place, reducing the cost of construction works in the selection the use of high-strength alloy steel, longer machine life.

Address: NO1, Renmin Road,

Anyang City 455000, Henan

Province, China PR

Copyright © 2010-2015 Zhengzhou Bairong Machinery CO., Ltd All rights reserved.

Address: NO1, Renmin Road, Anyang City 455000, Henan Province, China PR

Email: tanjie@spiral-silo.com kingreal2004@gmail.com

Tel:86-1861 0083 868

You might also like

- Sumitomo LinepipeDocument46 pagesSumitomo LinepipeDekky Mulyadi100% (1)

- Ebook - Industrial Hammer MillDocument17 pagesEbook - Industrial Hammer MillNayankumar Patel100% (1)

- Faccin Eng Web PDFDocument40 pagesFaccin Eng Web PDFIstván SzékelyNo ratings yet

- Introduction To Bhilai Steel PlantDocument6 pagesIntroduction To Bhilai Steel PlantSunny BhartiNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Valency Table PDFDocument1 pageValency Table PDFrkrishna4470% (20)

- Training Report On BSPDocument14 pagesTraining Report On BSPsanchay3090No ratings yet

- Wheel Crack TrurningDocument27 pagesWheel Crack TrurningdevendraNo ratings yet

- High-Quality Wire Rod and Bar Production at YongXing Special Stainless SteelDocument12 pagesHigh-Quality Wire Rod and Bar Production at YongXing Special Stainless SteelJJNo ratings yet

- All New Brochure 2Document12 pagesAll New Brochure 2Dawood NalbandNo ratings yet

- SAPH 440 MaterialDocument16 pagesSAPH 440 MaterialDinesh SharmaNo ratings yet

- 47 NCPMillsDocument5 pages47 NCPMillsraosp66No ratings yet

- 5 Integrated Steel PlantsDocument4 pages5 Integrated Steel PlantsSanjna KaulNo ratings yet

- Vocational Training ReportDocument34 pagesVocational Training ReportRavi kumarNo ratings yet

- Final ProjectDocument54 pagesFinal ProjectShakti NaiduNo ratings yet

- A Project Report On Summer Vocational Training in Bhilai Steel PlantDocument24 pagesA Project Report On Summer Vocational Training in Bhilai Steel PlantRahul PandeyNo ratings yet

- Sepor CatalogDocument18 pagesSepor Catalogjaelani sidikNo ratings yet

- Proman - IntroductionDocument9 pagesProman - IntroductionHarshala ChoudharyNo ratings yet

- Sumitomo LinepipeDocument46 pagesSumitomo LinepipeMaqsoodAnwarNo ratings yet

- Foil FormulaDocument22 pagesFoil FormulaMoontasirNasimNo ratings yet

- An 15 Days Training in Casting IndustrialDocument27 pagesAn 15 Days Training in Casting IndustrialAmar Shete100% (1)

- E-catalog-Aluminum Extrusion Equipmet-Nenghong MachineryDocument11 pagesE-catalog-Aluminum Extrusion Equipmet-Nenghong MachineryJigar GalaNo ratings yet

- Proman Infrastructure Services Pvt. LTDDocument9 pagesProman Infrastructure Services Pvt. LTDsatgNo ratings yet

- Bhilai Steel PlantDocument37 pagesBhilai Steel PlantPratyush MishraNo ratings yet

- Training Report PRASADDocument32 pagesTraining Report PRASADshekharazad_suman85% (13)

- Multi SlittingDocument6 pagesMulti Slittingeng_ahmedkassemNo ratings yet

- TND - 081639 - 162600 BokaroDocument52 pagesTND - 081639 - 162600 BokaroBhavya MakhaniaNo ratings yet

- Samiya Wire Nail All Data Project ReportDocument23 pagesSamiya Wire Nail All Data Project ReportferishsuratiNo ratings yet

- Faccin CatalogoDocument40 pagesFaccin CatalogoBunnyNo ratings yet

- Training Report On BSPDocument14 pagesTraining Report On BSPnitinrnnnNo ratings yet

- Scan 12 Aug 23 22 45 54Document34 pagesScan 12 Aug 23 22 45 54Ashu PatelNo ratings yet

- Bokaro Steel Plant An OverviewDocument20 pagesBokaro Steel Plant An OverviewAðitya SínghNo ratings yet

- Brochure PSMDocument19 pagesBrochure PSMsirajuddin khowajaNo ratings yet

- Machinery DetailsDocument7 pagesMachinery DetailsDOTDNo ratings yet

- Steel Rebar Industry ProfileDocument34 pagesSteel Rebar Industry ProfileOvidiu TomaNo ratings yet

- BR MiningDocument12 pagesBR MiningSteven TremolNo ratings yet

- Marketing PDFDocument61 pagesMarketing PDFMithun Konjath0% (1)

- J28475 Galnorth Presentation Royal BafokengDocument17 pagesJ28475 Galnorth Presentation Royal BafokengLeeLowersNo ratings yet

- Bhilai Steel PlantDocument12 pagesBhilai Steel PlantGanta AnuNo ratings yet

- Ball MillDocument11 pagesBall MillAkhil Bhadouria0% (1)

- AM Katalog Ploche EngDocument28 pagesAM Katalog Ploche EngDejanNo ratings yet

- Functions of Various Departments of Rinl/VspDocument16 pagesFunctions of Various Departments of Rinl/VspdhruNo ratings yet

- Functions of Various Departments of Rinl/VspDocument16 pagesFunctions of Various Departments of Rinl/VspGoogle AccountNo ratings yet

- Himal Iron and Steel QuestionareDocument9 pagesHimal Iron and Steel QuestionareAdarsha Man TamrakarNo ratings yet

- ProjectDocument61 pagesProjectPritam Ghosh100% (1)

- Internship Report: Heavy Industries TaxilaDocument49 pagesInternship Report: Heavy Industries TaxilaSyed Waqas HussainNo ratings yet

- Important Aspects of Rolling of Hot Rolled Coil in Hot Strip Mill - IspatGuruDocument7 pagesImportant Aspects of Rolling of Hot Rolled Coil in Hot Strip Mill - IspatGuruBoban RajkovicNo ratings yet

- Internship Report of Poeples Steel MillsDocument88 pagesInternship Report of Poeples Steel MillsShahid Ali LeghariNo ratings yet

- Super-Orion®Ball Mill: Types S.O., S.O.-Cl Compact Line, S.O.-Sf Super FineDocument6 pagesSuper-Orion®Ball Mill: Types S.O., S.O.-Cl Compact Line, S.O.-Sf Super FineKrmača RužaNo ratings yet

- THERMIT-Presentasi Lengkap Thermit-Oxy LanceDocument14 pagesTHERMIT-Presentasi Lengkap Thermit-Oxy LanceFirdaus AdenNo ratings yet

- Index: SL - No. Topic P NODocument24 pagesIndex: SL - No. Topic P NOShahbaz AlamNo ratings yet

- Mathan Kumar - Salem Steel Plant SSPDocument33 pagesMathan Kumar - Salem Steel Plant SSPDhanish KumarNo ratings yet

- Steel Slag RecyclingDocument2 pagesSteel Slag RecyclingNickRuiNo ratings yet

- A Project Report OnDocument45 pagesA Project Report Onamruta_warwatkarNo ratings yet

- Wire Rod Mailable PDFDocument11 pagesWire Rod Mailable PDFVenu PrasadNo ratings yet

- Crushing and GrindingDocument13 pagesCrushing and GrindingKumar NathanNo ratings yet

- Bolt-Nut BrochureDocument13 pagesBolt-Nut BrochureLong Beautéophile100% (1)

- Descriptive Pamphlet of the Richmond Mill Furnishing WorksFrom EverandDescriptive Pamphlet of the Richmond Mill Furnishing WorksNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- CO Pipelines Material and Safety ConsiderationsDocument7 pagesCO Pipelines Material and Safety Considerationsred patriotNo ratings yet

- 7 Common Problems Found in Pumps On Board ShipsDocument7 pages7 Common Problems Found in Pumps On Board Shipsred patriot100% (1)

- Girth Gear Failures - LinkedInDocument7 pagesGirth Gear Failures - LinkedInred patriotNo ratings yet

- Verification - Hevii Technologie GMBHDocument2 pagesVerification - Hevii Technologie GMBHred patriotNo ratings yet

- HR Recruitment and SelectionDocument29 pagesHR Recruitment and Selectionred patriotNo ratings yet

- Liebherr RTG Cranes BrochureDocument7 pagesLiebherr RTG Cranes Brochurered patriotNo ratings yet

- 3 Common Mistakes Made When Handling Stainless SteelDocument13 pages3 Common Mistakes Made When Handling Stainless Steelred patriotNo ratings yet

- Hot Insulation ProcedureDocument8 pagesHot Insulation Procedurered patriotNo ratings yet

- The Magic of Bolting For A Grinding Mill Assembly - MetsoDocument3 pagesThe Magic of Bolting For A Grinding Mill Assembly - Metsored patriotNo ratings yet

- Air Hose Connections Double Seat Valve d624 en deDocument1 pageAir Hose Connections Double Seat Valve d624 en dered patriotNo ratings yet

- Method Statement For Insulation Works and JacketingDocument8 pagesMethod Statement For Insulation Works and Jacketingred patriotNo ratings yet

- Managing Your Emotions at Work - Career Development FromDocument6 pagesManaging Your Emotions at Work - Career Development Fromred patriotNo ratings yet

- Pipe Thickness ChartDocument4 pagesPipe Thickness Chartred patriotNo ratings yet

- Installation and Operating Instructions: Ventilated Silos D5.3 AND D7.5Document28 pagesInstallation and Operating Instructions: Ventilated Silos D5.3 AND D7.5red patriotNo ratings yet

- Process Plant Insulation & Fuel Efficiency: Pdhonline Course M156 (4 PDH)Document76 pagesProcess Plant Insulation & Fuel Efficiency: Pdhonline Course M156 (4 PDH)red patriotNo ratings yet

- Lipp Silo Building System: Product OverviewDocument10 pagesLipp Silo Building System: Product Overviewred patriotNo ratings yet

- Cadmium Sulfide Thin Films Prepared by Chemical Bath Deposition MethodDocument7 pagesCadmium Sulfide Thin Films Prepared by Chemical Bath Deposition Methodbib123456789huNo ratings yet

- Table of K ValuesDocument7 pagesTable of K ValuesdasoodaseeNo ratings yet

- VLÄTKRIG InstructionsDocument2 pagesVLÄTKRIG InstructionsEscargotNo ratings yet

- Dims Pipe and TubeDocument32 pagesDims Pipe and Tuberach4harvNo ratings yet

- Vacuum Distillation DillaDocument3 pagesVacuum Distillation DillaRifqi Dwi RamadhaniNo ratings yet

- Damage and Plasticity For Concrete BehaviorDocument16 pagesDamage and Plasticity For Concrete BehaviorJosé Antonio Cornetero UrpequeNo ratings yet

- Land or No Land?: Tablet Compression ToolingDocument2 pagesLand or No Land?: Tablet Compression Toolingrohan satwaraNo ratings yet

- Grade12 Rigel Group4 Assesing The Solid Waste Management Off Small Foos Store in Gingoog CityDocument31 pagesGrade12 Rigel Group4 Assesing The Solid Waste Management Off Small Foos Store in Gingoog CityMa. Joan ApolinarNo ratings yet

- The Difference Between BS5308 Cable PAS 5308 Cable and en 50288 Cable - What Are en 50288-7 CablesDocument3 pagesThe Difference Between BS5308 Cable PAS 5308 Cable and en 50288 Cable - What Are en 50288-7 CablesveerendraNo ratings yet

- For Exer 3Document16 pagesFor Exer 3Louiegi AlvarezNo ratings yet

- Paint-Off Remover 2016 SDSDocument2 pagesPaint-Off Remover 2016 SDSdina auliaNo ratings yet

- Ex Pan Proof 100Document3 pagesEx Pan Proof 100Amar WadoodNo ratings yet

- Solution and Scheme CIV 212 (Test 2)Document8 pagesSolution and Scheme CIV 212 (Test 2)SanthoshMBSanthuNo ratings yet

- I. Read The Dialogue and Answer The Questions BelowDocument3 pagesI. Read The Dialogue and Answer The Questions BelowM.alwaly syariefNo ratings yet

- Assignment 2Document2 pagesAssignment 2Ryan S. BudionganNo ratings yet

- LAB VIVA QuestionsDocument4 pagesLAB VIVA QuestionsKh Bappi ShahriarNo ratings yet

- 32 Samss 005 PDFDocument33 pages32 Samss 005 PDFRajan SteeveNo ratings yet

- JP 34 5 434Document4 pagesJP 34 5 434Fajar Sri Lestari PangukirNo ratings yet

- BET Chem Soc Reviews 2017Document26 pagesBET Chem Soc Reviews 2017SivasankarVenkatramanNo ratings yet

- Annexure 16 - Structural SteelDocument12 pagesAnnexure 16 - Structural SteelmasoodNo ratings yet

- Caltherm Pharmaceutical Processing SolutionsDocument4 pagesCaltherm Pharmaceutical Processing SolutionsBusiness DevelopmentNo ratings yet

- Effects of Dust Suppression On Conveyor Belting: TechtipsDocument3 pagesEffects of Dust Suppression On Conveyor Belting: TechtipsAlbar BudimanNo ratings yet

- Low-Voltage Hydrogen Peroxide Electrolyzer For Highly Efficient - Power-To-Hydrogen ConversionDocument8 pagesLow-Voltage Hydrogen Peroxide Electrolyzer For Highly Efficient - Power-To-Hydrogen ConversionShangli HuangNo ratings yet

- Product Data Sheet: K-Sperse 152MSDocument2 pagesProduct Data Sheet: K-Sperse 152MSManoj Lalita GoswamiNo ratings yet

- Centrifugal Monoblock Pumpset: MDH SeriesDocument2 pagesCentrifugal Monoblock Pumpset: MDH Seriesakshay upadhyayNo ratings yet

- Chicken Processing PlantDocument8 pagesChicken Processing PlantRoem EsmernaNo ratings yet

- Example of Stress Absorbing Membrane InterlayerDocument7 pagesExample of Stress Absorbing Membrane Interlayershanil3001No ratings yet

- Related Literature of The StudyDocument3 pagesRelated Literature of The StudySam Christian DucoNo ratings yet

- SOP Trial StretchDocument4 pagesSOP Trial StretchashutoshpathakcivilNo ratings yet