Professional Documents

Culture Documents

Helifix Retrotie Product Infosheet

Helifix Retrotie Product Infosheet

Uploaded by

Rahul AgarwalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Helifix Retrotie Product Infosheet

Helifix Retrotie Product Infosheet

Uploaded by

Rahul AgarwalCopyright:

Available Formats

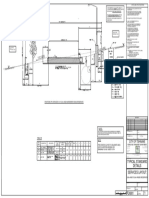

PRODUCT SHEET – PS/RT01

RetroTie

A remedial wall tie

with a dry / resin fix

Applications

• Versatile replacement wall tie

• Use where there is hard external

brick material

• Use where random testing is

required of the security of fixing in

the inner leaf

Features

• Quick, easy, non-disruptive installation

• Effective in all common building materials

• Far leaf security of fixing easily proof tested

Remedial wall tie –

brick to brick and brick to block

Over 100 standard repair specifications

are available online, covering all common

structural faults.

Relevant Repair Details: RDs WT02,WT06,

WT08,WT20,WT22,WT25,WT28,WT31

For full Product Information,

Case Studies and downloadable

Repair Details go to:

www.helifix.co.uk/products/remedial-products/retrotie/

Injecting resin to complete the RetroTie installation

PRODUCT SHEET – PS/RT01

Installation Procedures

1. Mark the points for RetroTie insertion on 2. Widen the hole, through the near leaf only, to 3. Load the RetroTie into the support tool,

the face of the near leaf brickwork. Drill an 12 mm diameter. Clean the hole in both the insert through the near leaf and drive home

appropriate diameter pilot hole through the near and far leaves into the far leaf. The ‘O’ ring marker allows

near leaf brick and to the required depth into the cavity width to be measured and avoids

the far leaf. The hole should be drilled about over-driving

half way up the brick and around 15mm from

the end to avoid frogs and core holes

4. Position the plastic sleeve over the outer end 5. Security of fixing in the far leaf can be tested 6. Inject PolyPlus resin until the hole is filled and

of the RetroTie and slide it down the tie with with a Helifix Load Test Unit then make good

the support tool until the mark on the tool

stem is flush with the outer face. The sleeve

centres the tie and seals the hole adjacent to

the cavity

Technical Specifications

Material: Austenitic stainless steel Grade 304 (1.4301) or 316 (1.4401)

Diameter: 8mm (6mm available – suitable for timber far leaf)

Length: 3/4 of near leaf thickness + cavity width + far leaf penetration depending

on material, typically 70mm

Standard lengths: 170mm, 195mm, 220mm, 245mm, 270mm and 295mm – in packs of 100

Depth of pilot hole: Near leaf thickness + cavity width + far leaf penetration + 10mm

Near Leaf Material Far Leaf Material Near Leaf Pilot/ Far Leaf Pilot/ Penetration Pull Out

Clearance Hole Clearance Hole into far leaf

Clay Brick Aircrete 12mm None 75-90mm 1.0kN

Clay Brick Timber Stud 12mm (10mm if 6mm tie) None 55mm 1.0kN

Clay Brick Clay Brick 12mm 5-6mm 70mm 2.0kN

Clay Brick Concrete Block 12mm 6mm 70mm 2.0kN

Clay Brick Concrete 12mm 6-6.5mm 35mm 2.0kN

NOTE: All figures quoted are indicative dependent on the exact nature of the substrate.Testing should always be undertaken on site using the Helifix Load Test Unit.

Compression Resistance should be checked with the Helifix Technical Department. Fixing Density should be calculated by the Helifix Technical Department

Minimum fixing density: Ties should be at 900mm centres horizontally by 450mm vertically,

in a staggered pattern, or as specified

Bonding agent (near leaf only): PolyPlus resin (or HeliBond if required)

ReCOMMenDeD TOOLIng

For drilling pilot hole: Rotary percussion 3-jaw-chuck drill

For drilling clearance hole: SDS hammer drill or rotary percussion drill

For installing RetroTie: Power driver or hand held Support Tool

The Mille, 1000 Great West Road, Brentford, London TW8 9DW

Tel: 020 8735 5200 • Fax: 020 8735 5201 • email: info@helifix.co.uk

www.helifix.co.uk April 2014

You might also like

- Risk Management AssignmentDocument15 pagesRisk Management AssignmentYee KangNo ratings yet

- BituTape HD - Application ProcedureDocument14 pagesBituTape HD - Application ProcedureArbaz KhanNo ratings yet

- Helifix Crack StitchingDocument2 pagesHelifix Crack Stitchingneel12321No ratings yet

- Instalacion PolicarbonatoDocument4 pagesInstalacion Policarbonatobproano3992No ratings yet

- PVC and Polycarbonate RoofingDocument2 pagesPVC and Polycarbonate RoofingApollyonNo ratings yet

- PVC and Polycarbonate RoofingDocument2 pagesPVC and Polycarbonate RoofingMerényi OszkárNo ratings yet

- Dr. Fixit Bathseal Range 169 1 PDFDocument3 pagesDr. Fixit Bathseal Range 169 1 PDF41464147No ratings yet

- Firestop Wrap Strip CFS-W EL: Technical Data ApplicationsDocument5 pagesFirestop Wrap Strip CFS-W EL: Technical Data ApplicationsValentin A.No ratings yet

- Denso SeaShield Series 2000HDDocument4 pagesDenso SeaShield Series 2000HDAnonymous wKvJXBJ2iNo ratings yet

- Casting Procedure and Casting DefectsDocument85 pagesCasting Procedure and Casting DefectsChaithraNo ratings yet

- Polycarb Diy Tech ManualDocument5 pagesPolycarb Diy Tech ManualScottDT1No ratings yet

- Basf Masterseal NP 474 TdsDocument3 pagesBasf Masterseal NP 474 TdsAdnan ČehajićNo ratings yet

- Backer RodDocument2 pagesBacker RodasdasNo ratings yet

- Rotary Shaft Seals: Common Rotary Seal ProfilesDocument2 pagesRotary Shaft Seals: Common Rotary Seal ProfilesEarl HarbertNo ratings yet

- UGC Multirib8 05082023Document2 pagesUGC Multirib8 05082023Mary Elizabeth AltaNo ratings yet

- Pipewrap BT: DescriptionDocument2 pagesPipewrap BT: DescriptionVineet KhanduriNo ratings yet

- Comparison of Polycarbonate Sheets With Conventional MaterialsDocument6 pagesComparison of Polycarbonate Sheets With Conventional Materialssatheesh velNo ratings yet

- Anchor Bolt MTCDocument6 pagesAnchor Bolt MTCshamshadkadavath1998No ratings yet

- FRP Louver Catalogue 1Document9 pagesFRP Louver Catalogue 1sidsaleemNo ratings yet

- Qui Cutter - Brochure 2022Document11 pagesQui Cutter - Brochure 2022William LauNo ratings yet

- New Duraroof 2021 0Document2 pagesNew Duraroof 2021 0Bryan AmernaNo ratings yet

- GXF147-FDT2103D V100R002C01 Quick Installation Guide 05Document20 pagesGXF147-FDT2103D V100R002C01 Quick Installation Guide 05Chua DavidNo ratings yet

- Effast Solvent Jointing Guide 0 0Document6 pagesEffast Solvent Jointing Guide 0 0MeNo ratings yet

- InnoVantennas 6-Duo-5070 6el 50-70MHz Dual Band YagiDocument6 pagesInnoVantennas 6-Duo-5070 6el 50-70MHz Dual Band Yagisboonuy331No ratings yet

- Basf Masterseal NP 474 TdsDocument3 pagesBasf Masterseal NP 474 Tdstally3tallyNo ratings yet

- Automotive Test Probe ConstructionDocument4 pagesAutomotive Test Probe ConstructionLy Fotoestudio DigitalcaNo ratings yet

- Multi-Wall Polycarbonate Installation Instructions: Bending/Burying Bending/Burying Bending/Burying Bending/BuryingDocument5 pagesMulti-Wall Polycarbonate Installation Instructions: Bending/Burying Bending/Burying Bending/Burying Bending/BuryingreyromanyNo ratings yet

- UGC Durarib 08232022Document2 pagesUGC Durarib 08232022Ram CaceresNo ratings yet

- Haglöf Increment Borers Product Sheet ENUDocument2 pagesHaglöf Increment Borers Product Sheet ENULeo LeoNo ratings yet

- Brett FillersDocument2 pagesBrett Fillerslokomoko1No ratings yet

- Appendix G - Manufacturer Catalogue - Pit MaintenanceDocument7 pagesAppendix G - Manufacturer Catalogue - Pit MaintenancehardikNo ratings yet

- Specification & Product Safety Guide 45mm Supadek H416: Maximum Span and LoadDocument3 pagesSpecification & Product Safety Guide 45mm Supadek H416: Maximum Span and LoadWalid DuscaffNo ratings yet

- Raci Brochure 2019 03 Single PagesDocument16 pagesRaci Brochure 2019 03 Single PagesIrina CretuNo ratings yet

- JCP Resin Data SheetDocument2 pagesJCP Resin Data SheetgijimmyyoNo ratings yet

- Parches Handy Cap IPDocument2 pagesParches Handy Cap IPalvaro_sqsNo ratings yet

- Installation StandardDocument6 pagesInstallation StandardDinanath SharmaNo ratings yet

- Installing Gyprock Plasterboard: How To Install Gyprock Plasterboard Walls and CeilingsDocument4 pagesInstalling Gyprock Plasterboard: How To Install Gyprock Plasterboard Walls and CeilingsAjay DattNo ratings yet

- SMSGutter System Installation SpecificationDocument13 pagesSMSGutter System Installation SpecificationChristan Daniel RestorNo ratings yet

- Koldlok Surface Mount Grommets: Applications BenefitsDocument2 pagesKoldlok Surface Mount Grommets: Applications BenefitsDenan SaherNo ratings yet

- BCP Technical ConstructionDocument22 pagesBCP Technical ConstructionKarthik KarthikNo ratings yet

- Membrana FIRESTONEDocument12 pagesMembrana FIRESTONERaúl PérezNo ratings yet

- T102-1 Monofilm TapeDocument1 pageT102-1 Monofilm Tapetesting eiplNo ratings yet

- Rainwater Diffuser Brochure v2Document8 pagesRainwater Diffuser Brochure v2Jake BarlowNo ratings yet

- BitucellDocument2 pagesBitucellMuhammad ShoaibNo ratings yet

- 6035 L2u204 PPT Outcome6Document17 pages6035 L2u204 PPT Outcome6shahin.noktehdan4102No ratings yet

- Basic Info TK-U.B.I Sleeves3Document17 pagesBasic Info TK-U.B.I Sleeves3Saradhi MedapureddyNo ratings yet

- FEROOF ROOF Tile Installation (Veneto2, Rio, Rio EZ, Wood, Diva, Zissen, Slate) - Rev.3Document18 pagesFEROOF ROOF Tile Installation (Veneto2, Rio, Rio EZ, Wood, Diva, Zissen, Slate) - Rev.3TgNo ratings yet

- DONIT IG Brosura NOVO PDFDocument36 pagesDONIT IG Brosura NOVO PDFMohamed RizkNo ratings yet

- 6035 L2u204 PPT Outcome6Document17 pages6035 L2u204 PPT Outcome6Adrian JugariuNo ratings yet

- TDS - Premcote 101 TropicalDocument1 pageTDS - Premcote 101 TropicalThomas C. LaneNo ratings yet

- Adh Transfer Tapes Prod InfoDocument3 pagesAdh Transfer Tapes Prod InfohshchandraNo ratings yet

- Inclinometer Casing: HighlightsDocument2 pagesInclinometer Casing: Highlightsvelmurug_balaNo ratings yet

- DEKSTRIP Expandable Edged Flashing Product Data 661408Document2 pagesDEKSTRIP Expandable Edged Flashing Product Data 661408luisNo ratings yet

- Leviat Isedio ShieldJoint Arris Repair Datasheet AustraliaDocument2 pagesLeviat Isedio ShieldJoint Arris Repair Datasheet Australiam_mahfuz118187No ratings yet

- 20009E Trenton Corp Guard-Wrap Rev1Document2 pages20009E Trenton Corp Guard-Wrap Rev1Fernando CamargoNo ratings yet

- Fire Crunch. 07 01 Internal Walls Installation ManualDocument5 pagesFire Crunch. 07 01 Internal Walls Installation ManualTimaiagNo ratings yet

- 20030e Trenton Corp Patchpad Rev7Document2 pages20030e Trenton Corp Patchpad Rev7Rohammed CastilloNo ratings yet

- Thermal Pipe Sleeve InstallDocument5 pagesThermal Pipe Sleeve InstallDominic V. PantigNo ratings yet

- Door Frame MethodologyDocument8 pagesDoor Frame Methodologychhaya BhardwajNo ratings yet

- Family Handyman Do-It-Yourself Basics Volume 2From EverandFamily Handyman Do-It-Yourself Basics Volume 2Family HandymanRating: 5 out of 5 stars5/5 (2)

- Duct Tape Engineer: The Book of Big, Bigger, and Epic Duct Tape ProjectsFrom EverandDuct Tape Engineer: The Book of Big, Bigger, and Epic Duct Tape ProjectsRating: 5 out of 5 stars5/5 (1)

- Sample Report For Rebar ScanningDocument1 pageSample Report For Rebar ScanningRahul AgarwalNo ratings yet

- In Situ Measurements For The Structural Assessment of Existing Tall Industrial ChimneysDocument10 pagesIn Situ Measurements For The Structural Assessment of Existing Tall Industrial ChimneysRahul AgarwalNo ratings yet

- Focus: Ultrasonic Testing of Bolts and Pins: Longitudinal Beam ReviewDocument16 pagesFocus: Ultrasonic Testing of Bolts and Pins: Longitudinal Beam ReviewRahul AgarwalNo ratings yet

- SR - DEN Co NGP Acting For and On Behalf of The President of India Invites E-Tenders Against Tender No DRMWNGP-21-2019 ClosingDocument5 pagesSR - DEN Co NGP Acting For and On Behalf of The President of India Invites E-Tenders Against Tender No DRMWNGP-21-2019 ClosingRahul AgarwalNo ratings yet

- Please Calculate With FX or Fy For Lateral Load & FZ For FDN LoadsDocument1 pagePlease Calculate With FX or Fy For Lateral Load & FZ For FDN LoadsRahul AgarwalNo ratings yet

- Deterioration of Concrete Due To Laumontite and Its MechanismDocument8 pagesDeterioration of Concrete Due To Laumontite and Its MechanismRahul AgarwalNo ratings yet

- DR Fixit Micro Concrete 69 1Document3 pagesDR Fixit Micro Concrete 69 1Rahul AgarwalNo ratings yet

- BS+812 105 2 1990 Testing+aggregates MethodsDocument10 pagesBS+812 105 2 1990 Testing+aggregates MethodsRahul Agarwal100% (1)

- List of Holidays For Year 2012Document1 pageList of Holidays For Year 2012Rahul AgarwalNo ratings yet

- Mathcad Prime Alpha3 GuideDocument35 pagesMathcad Prime Alpha3 GuideRahul AgarwalNo ratings yet

- 2002 08 FosrocDocument1 page2002 08 FosrocRahul AgarwalNo ratings yet

- Ussor 2012 Ecr CS-1 (BMK)Document291 pagesUssor 2012 Ecr CS-1 (BMK)prasagnihotri100% (3)

- Torts Digests 2Document30 pagesTorts Digests 2D De LeonNo ratings yet

- No Fees Required For The Filing, Evaluation and Approval of CSHPDocument3 pagesNo Fees Required For The Filing, Evaluation and Approval of CSHPJai C. SantosNo ratings yet

- Catalog Precomprimare TENSACCIAIDocument40 pagesCatalog Precomprimare TENSACCIAITamaduianu IoanNo ratings yet

- MRT JAKARTA Annual Report 2013 PDFDocument100 pagesMRT JAKARTA Annual Report 2013 PDFDanu RangkutiNo ratings yet

- GGP Concept Paper FormatDocument2 pagesGGP Concept Paper FormatHernan PinedaNo ratings yet

- Senior Living Market Remains Strong Into 2014: Assisted Living Expected To Continue Its Senior Housing Reign in 2014Document1 pageSenior Living Market Remains Strong Into 2014: Assisted Living Expected To Continue Its Senior Housing Reign in 2014charlestaylor3804No ratings yet

- NHAI Quality Assurance Manual PDFDocument308 pagesNHAI Quality Assurance Manual PDFkom1984No ratings yet

- Facade FabricsDocument66 pagesFacade FabricsAiswarya SreekumarNo ratings yet

- For Rooms Below 32F Site Conditions 3x5x3.5: Load Calculation FormDocument4 pagesFor Rooms Below 32F Site Conditions 3x5x3.5: Load Calculation FormKarthik HegdeNo ratings yet

- Repair Starter Rebar Wall On Column CH DW2 1-3Document5 pagesRepair Starter Rebar Wall On Column CH DW2 1-3Muhammad YudaNo ratings yet

- SACS Modelling EseminarDocument3 pagesSACS Modelling EseminarBolarinwaNo ratings yet

- Design Brief - Old Age HomeDocument3 pagesDesign Brief - Old Age HomeChaitrali PatilNo ratings yet

- 104 Pre-Qualification For Provision of Water WorksDocument36 pages104 Pre-Qualification For Provision of Water Worksapi-257725116No ratings yet

- Gypsum False CeilingDocument6 pagesGypsum False Ceilingkalpesh86patel9246No ratings yet

- Module 2 Present Economy PPT - 1146613701Document19 pagesModule 2 Present Economy PPT - 1146613701MIKE ARTHUR DAVIDNo ratings yet

- SewerageDocument13 pagesSeweragerafidah mazlanNo ratings yet

- Road Map For Digital Design and ConstructionDocument20 pagesRoad Map For Digital Design and ConstructionSyl Vain RissNo ratings yet

- Steel FlatDocument5 pagesSteel Flatચેતન સુથારNo ratings yet

- A10 A Pid Va 718577 203Document1 pageA10 A Pid Va 718577 203zhangNo ratings yet

- Lithonia Fluorescent Lighting Catalog 1971Document68 pagesLithonia Fluorescent Lighting Catalog 1971Alan MastersNo ratings yet

- National GYP Construction GuideDocument166 pagesNational GYP Construction GuideDarcy BudworthNo ratings yet

- Alarm Valve: Model: Sdh-AvaDocument14 pagesAlarm Valve: Model: Sdh-AvaRolandNo ratings yet

- BR So Aps enDocument4 pagesBR So Aps enAlejandro HernandezNo ratings yet

- Whitepaper - State of Construction TechnologyDocument16 pagesWhitepaper - State of Construction TechnologyRicardo FigueiraNo ratings yet

- Typical Standard Details: City of TshwaneDocument1 pageTypical Standard Details: City of TshwaneRenier JoubertNo ratings yet

- Design of Combined FootingsDocument7 pagesDesign of Combined FootingsFrank StephensNo ratings yet

- Dxe PrtlistDocument31 pagesDxe PrtlistdevilsharmaNo ratings yet

- TCA Permissions ProcessDocument13 pagesTCA Permissions ProcessDavidNo ratings yet