Professional Documents

Culture Documents

Isr 12v 10k - Dat PDF

Isr 12v 10k - Dat PDF

Uploaded by

mahumboOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Isr 12v 10k - Dat PDF

Isr 12v 10k - Dat PDF

Uploaded by

mahumboCopyright:

Available Formats

Two Channel Relay with

Intrinsically Safe Outputs ISR

Specifications

Electrical Physical

Supply Voltage: 12 or 24 AC/DC ±10% Mounting: Din Rail mount

Power: 1.5 watts Termination: Touch safe screw terminals,

Inputs: Switch Closure or Probe with lift mechanism, #12 AWG max.

Input Sensitivity: 10k - 100k Ω Weight: 10 Oz.

Pick-up & Drop-out Delays: 0.5 second

Max. Open Circuit Voltage: 5.9 volts DC Ambient Temperatures

Max. Source Current: 0.1 milliamps Operating: 0°C to 55°C

Output Rating @ 25°C: Storage: -40°C to 85°C

5 Amps @ 125VAC

5 Amps @ 30VDC or 250VAC

20,000,000 Mechanical Cycles

UL-913

Class 1, Division 1 • 2 Independent Relays

Groups A, B, C, and D

Hazardous Locations • Compact Design

• Contact or Probe Input

Ordering Information

• Built-in De-bounce

Delays

ISR - 24V - 10K

• Power and Output

R-K Model Sensitivity status LEDs

10K - 10k Ω

• Low Voltage Design for

(Consult factory for

other sensitivity options.)

12 or 24VAC/DC

Operating Voltage • Din Mounting

12V - 12VAC/DC

24V - 24VAC/DC • 12 or 24VDC Battery

Back-Up

E199046

Connections Dimensions

Low Standard UL 913

COMMON Voltage

Supply 1.42" 2.8" Operation

(LVS)

1 2 Two Channel Relay

A B Input The ISR has two independent outputs

Commons

GND Power “G” and

3.55" to the hazardous area and two inde-

Ground

“IS GND” pendent (dry contact) relay outputs.

are internally 3.7"

A B The outputs to the hazardous area

IS GND

IS GND

joined

IN IN together. can be switches or, when used with a

A GGB

conductive liquid, electrodes. When

output “A” is completed (contact closed

or low resistance), 0.5 second later the

dry output contact “A” is closed and

Ground 0.5 sec. the “A” LED turns On. When output

A “A” is opened (contact opened or high

0.5 sec. resistance), 0.5 second later the dry

See control drawing A6757-4 output contact “A” opens and the “A”

ANO

for other input examples. LED turns Off. “B” operates the same

0.5 sec. way, but is independent of “A.” There is

If Low Voltage Supply is B also a supply power LED indicator. The

grounded, the ground must 0.5 sec. ISR must be located and grounded in a

be connected to terminal 2. BNO non-hazardous location.

513.204.6060 or 800.543.4936 • www.rke.com 8/1/06 P3

Installation of Relays with

Intrinsically Safe Outputs

Installation of these relays should only be performed by personnel experienced with intrinsically safe devices.

Proper wiring practices must be strictly adhered to in order to prevent injury to personnel and property damage due

to explosion or fire.

IMPORTANT: BEFORE PROCEEDING TO INSTALL AND WIRE THE RELAY, READ AND THOROUGHLY UNDER-

STAND THESE INSTRUCTIONS.

When installed according to the following instructions and Control Drawing A-6757-4 these Relays are for use in

Class I, Division 1, Groups A, B, C, and D. The relay must be mounted in a suitable enclosure which is tool acces-

sible and is situated in a non hazardous area where an explosive atmosphere will not exist at any time.

Wiring:

1. All intrinsically safe wiring should 6. Maximum distance between the 7. This device may be used in a

be installed in accordance with input of the relay and the switch is Division 2. Location if so

NEC NFPA 70 Article 504 and 1000 feet. Cable capacitance approved.

ISA RP 12.6 plus intrinsically safe equipment

capacitance must be less than the 8. Selected barriers must have

2. Electrical equipment connected marked capacitance (Ca) Voc not exceeding Vmax and

to the non intrinsically safe side shown on any barrier used. The Isc not exceeding Imax as

should not use or be capable of same applies for inductance. We shown below. All barriers

generating more than 250 volts recommend the use of 14 AWG must be of the same polarity.

with respect to earth. type THHN wire without splices.

In no case should the capacitance Entity parameters:

3. Intrinsically safe wiring connecting Voc = 5.89 Volts

or inductance exceed the

to the relay must be kept separate Isc = 0.132 mA

specified limits. If the characteris-

from non-intrinsically safe wiring Ca = 0.45 µf

tics of your wire are unknown the

by means of physical barriers and La=500mH

following values may be used.

wiring tie down devices to insure Voc ≤ Vmax

no contact. CAPACITANCE: 60 pf / ft Isc ≤ Imax

INDUCTANCE: 0.20 µh / ft Ca ≥ CI + Ccable

4. The cabinet must have a proper La ≥ Li + Lcable

earth ground and the relay must

be grounded. At least one ground CONTROL DRAWING A6757-4

from the intrinsically safe side and LATCHING RELAY

the non intrinsically safe side of NON-HAZARDOUS LOCATION

HAZARDOUS LOCATION

CLASS I, GROUPS A,B,C,D

relay must be made using #12 SEE NOTE 2

NO IS GND

AWG insulated conductors. The 250V MAX

C IN B

units redundant earth ground NC G

LOW SWITCH

wires must be individually PUMP DOWN

OPERATION

SHOWN WITH N.O.

connected with metal screws and

G

FLOAT SWITCHES

HI SWITCH

COMMON LVS

lockwashers to the cabinets earth GND IN A

LVS

ground. Resistance between GND IS GND SWITCH CONTACT SEE NOTE 5

INTRINSICALLY SAFE WIRING SEE NOTE

the relay ground to the grounding LOW VOLTAGE

ISOLATED

POWER NOTE 4

electrode shall be less than one

ohm. 2 CHANNEL RELAY

HAZARDOUS LOCATION

NON-HAZARDOUS LOCATION CLASS I, GROUPS A,B,C,D

SEE NOTE 2

5. Intrinsically safe connections must 250V MAX B

NO IS GND

not be made to any energy gener- C IN B

B SWITCH

ating device or device mounted NO G

250V MAX A

inside a tank subjected to pres- C G

sures greater than 15 psi without COMMON LVS

GND IN A

A SWITCH

specific approval. LVS

GND IS GND SWITCH CONTACT SEE NOTE 5

INTRINSICALLY SAFE WIRING SEE NOTE

LOW VOLTAGE

ISOLATED

POWER NOTE 4

P5 1/1/03 513.204.6060 or 800.543.4936 • www.rke.com

You might also like

- Features Applications: MicroDocument14 pagesFeatures Applications: Microjorgeortiz1982No ratings yet

- Ina122 PDFDocument11 pagesIna122 PDFFer Martinez de la RivaNo ratings yet

- Ina122 PDFDocument14 pagesIna122 PDFCDDSANo ratings yet

- INA122Document14 pagesINA122runar libraryNo ratings yet

- Datasheet KDN-relays V1.3pdfDocument12 pagesDatasheet KDN-relays V1.3pdfAhmedKhaledSalahNo ratings yet

- Datasheet PDFDocument9 pagesDatasheet PDFFelix Gutierrez VdglNo ratings yet

- At Series: AC Current TransducersDocument2 pagesAt Series: AC Current TransducersSaurabh BhosaleNo ratings yet

- SIL3 230 Vac Relay Out Module For 10 A NE Loads: Features Technical DataDocument1 pageSIL3 230 Vac Relay Out Module For 10 A NE Loads: Features Technical DataSamim KhosraviNo ratings yet

- Ob 2223 HCDocument11 pagesOb 2223 HCRivaldyNo ratings yet

- APTGL120TDU120TPG: Triple Dual Common Source Trench + Field Stop IGBT4 Power ModuleDocument6 pagesAPTGL120TDU120TPG: Triple Dual Common Source Trench + Field Stop IGBT4 Power ModuleRadu CrisanNo ratings yet

- Notifier FCM 1 Supervised Control ModuleDocument2 pagesNotifier FCM 1 Supervised Control ModuleAhmedNo ratings yet

- Solenoid Driver KCD0-SD-Ex1.1245: FunctionDocument4 pagesSolenoid Driver KCD0-SD-Ex1.1245: FunctionRohan NadkarNo ratings yet

- General Purpose Relay - G2RS: Slim and Space-Saving Power Plug-In RelayDocument10 pagesGeneral Purpose Relay - G2RS: Slim and Space-Saving Power Plug-In Relaydiarjohn9979No ratings yet

- Edb - 7580022 - GBR - en Isolating Switching Amplifier 2-Channel IMX12-DI01-2S-2T-0 24VDC CC TurckDocument3 pagesEdb - 7580022 - GBR - en Isolating Switching Amplifier 2-Channel IMX12-DI01-2S-2T-0 24VDC CC Turckzeropoint_romeoNo ratings yet

- 65N06 Series: N-Channel Power MOSFET (63A, 55volts) DescriptionDocument8 pages65N06 Series: N-Channel Power MOSFET (63A, 55volts) DescriptionRamon Cuba LopezNo ratings yet

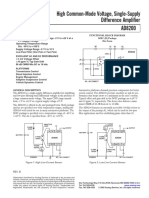

- High Common-Mode Voltage, Difference Amplifier AD629: Features Functional Block DiagramDocument16 pagesHigh Common-Mode Voltage, Difference Amplifier AD629: Features Functional Block DiagramMARIANONo ratings yet

- Detailed Characteristics For Each FunctionDocument1 pageDetailed Characteristics For Each FunctionRana Umar FarooqNo ratings yet

- AS 603PC Photoelectric Smoke Detector User ManualDocument1 pageAS 603PC Photoelectric Smoke Detector User ManualDonald OUedraogoNo ratings yet

- MGDD 21Document18 pagesMGDD 21baldiwala aliabbasNo ratings yet

- Electrical Position Feedback: Type 1062Document4 pagesElectrical Position Feedback: Type 1062Francisco Mones RuizNo ratings yet

- Duelco nst-3.2 8-36vdc Conpart2Document2 pagesDuelco nst-3.2 8-36vdc Conpart2majidtaherkazemyNo ratings yet

- Datasheet PDFDocument23 pagesDatasheet PDFshamim ahmedNo ratings yet

- Lm2825n Datasheet PDF AipcbaDocument21 pagesLm2825n Datasheet PDF AipcbaBarth XaosNo ratings yet

- Data Sheet: ACPL-331JDocument23 pagesData Sheet: ACPL-331JPiman MiriNo ratings yet

- Bic 2200 eDocument24 pagesBic 2200 eHassan NaveedNo ratings yet

- AD8232Document28 pagesAD8232محمد نNo ratings yet

- Single-Lead, Heart Rate Monitor Front End: Data SheetDocument29 pagesSingle-Lead, Heart Rate Monitor Front End: Data SheetasfafqwfwqNo ratings yet

- Single-Lead, Heart Rate Monitor Front End: Data SheetDocument28 pagesSingle-Lead, Heart Rate Monitor Front End: Data SheetMax Gutierrez FloresNo ratings yet

- AD8200 AnalogDevices Elenota - PLDocument12 pagesAD8200 AnalogDevices Elenota - PLpiotreNo ratings yet

- Quad SPDT Wide-Bandwidth Video Switch With Low On-State ResistanceDocument30 pagesQuad SPDT Wide-Bandwidth Video Switch With Low On-State ResistancefabiobonadiaNo ratings yet

- Sihfd 902Document9 pagesSihfd 902amenoeraNo ratings yet

- LEV200Document2 pagesLEV200clipclapNo ratings yet

- DCD Disconnector - Catalogue - EN - 1YHA000349 - REV D 09-2021Document8 pagesDCD Disconnector - Catalogue - EN - 1YHA000349 - REV D 09-2021FreyNo ratings yet

- Pulsar TDocument46 pagesPulsar TGuillaume DentrelleNo ratings yet

- OVR LeafletDocument2 pagesOVR Leafletbatzorig valyaNo ratings yet

- SR33 ManualDocument4 pagesSR33 ManualВалентин МазаевNo ratings yet

- NCP431A, SC431A, NCP431B, NCP432B Series Programmable Precision ReferencesDocument17 pagesNCP431A, SC431A, NCP431B, NCP432B Series Programmable Precision ReferencesPedro OrtegaNo ratings yet

- C Ais e 1901 PDFDocument44 pagesC Ais e 1901 PDFTuan DuongNo ratings yet

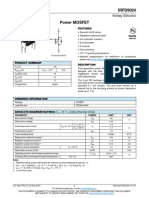

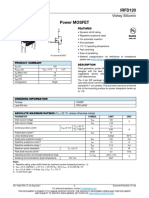

- IRFD120 HVMDIPcaseDocument9 pagesIRFD120 HVMDIPcaseRuslanNo ratings yet

- Littelfuse Power Semiconductor Ignition IGBT Devic-1224117Document10 pagesLittelfuse Power Semiconductor Ignition IGBT Devic-1224117ProbadorAutomotrizNo ratings yet

- SAP4825DDocument4 pagesSAP4825DbhizartNo ratings yet

- JF5055-00Rev3 PrivateLabel R1Document2 pagesJF5055-00Rev3 PrivateLabel R1Nguyễn Anh DanhNo ratings yet

- Vacuum Circuit Breakers: Small Without CompromiseDocument2 pagesVacuum Circuit Breakers: Small Without CompromiseRafaelDeSouzaDeckerNo ratings yet

- 2.5 V To 5.5 V, 120 Μa, 2-Wire Interface, Voltage-Output 8-/10-/12-Bit Dacs / /Document24 pages2.5 V To 5.5 V, 120 Μa, 2-Wire Interface, Voltage-Output 8-/10-/12-Bit Dacs / /fahmi1987No ratings yet

- Dsa00534608 PDFDocument8 pagesDsa00534608 PDFHugo AponteNo ratings yet

- Add A Composite Video Input To A TVDocument6 pagesAdd A Composite Video Input To A TVEnya Andrea Ribba HernandezNo ratings yet

- Safelink CB: Gas Insulated Ring Main UnitDocument2 pagesSafelink CB: Gas Insulated Ring Main UnitABCDNo ratings yet

- EngDocument3 pagesEngmojinjoNo ratings yet

- IDEC RU - ExtractsDocument7 pagesIDEC RU - ExtractsTaQuangDucNo ratings yet

- MU320 Merging Unit: Analog and Digital, Fast and Accurate: Fully-Integrated Merging Unit For Process Bus ApplicationsDocument2 pagesMU320 Merging Unit: Analog and Digital, Fast and Accurate: Fully-Integrated Merging Unit For Process Bus ApplicationsMohamedNo ratings yet

- Assembly Features: Removable Terminal BlueDocument3 pagesAssembly Features: Removable Terminal BlueismuNo ratings yet

- Can Driver Ram 2005 Ecus Marco EsteliDocument27 pagesCan Driver Ram 2005 Ecus Marco EsteliautocomputerNo ratings yet

- AL624 Power Supply/Charger: OverviewDocument1 pageAL624 Power Supply/Charger: OverviewLiver Haro OrellanesNo ratings yet

- Datasheet PDFDocument16 pagesDatasheet PDFMarco Pilaguano LogañaNo ratings yet

- D5098 DTS0675 enDocument2 pagesD5098 DTS0675 enmbidNo ratings yet

- QPL1002 Data SheetDocument14 pagesQPL1002 Data SheetRaziel EsauNo ratings yet

- Rmia 45Document3 pagesRmia 45oscaremfzqwxxwxxNo ratings yet

- 2.5 RGB Series - EN Ed1 03-16Document4 pages2.5 RGB Series - EN Ed1 03-16metrofireNo ratings yet

- CapacitorsDocument35 pagesCapacitorsSatrianiRahmayantiNo ratings yet

- Termomagneticos SiemensDocument24 pagesTermomagneticos SiemensluisNo ratings yet

- Step by Step Guide Book On Home Wiring PDFDocument50 pagesStep by Step Guide Book On Home Wiring PDFAliyu Mohammed InuwaNo ratings yet

- PDF 256372311 Pec QC With Answerpdf DDDocument6 pagesPDF 256372311 Pec QC With Answerpdf DDLee Robert OlivarNo ratings yet

- Microspeed 12Document44 pagesMicrospeed 12rrebollarNo ratings yet

- Infineon SPP04N80C3 DS v02 91 enDocument10 pagesInfineon SPP04N80C3 DS v02 91 entombeanNo ratings yet

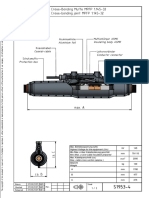

- Crossbonding Joint S1953-4 MPFP1.145-32Document2 pagesCrossbonding Joint S1953-4 MPFP1.145-32olgi cheifNo ratings yet

- Brushless DC MotorsDocument7 pagesBrushless DC MotorsRonald LugwireNo ratings yet

- MS-ST09432 Technical Standard - Electrical Safety RulesDocument16 pagesMS-ST09432 Technical Standard - Electrical Safety RulesJansenNo ratings yet

- Interpretation of Gas-In-Oil Analysis Using New IEC Publication 60599 and IEC TC 10 DatabasesDocument11 pagesInterpretation of Gas-In-Oil Analysis Using New IEC Publication 60599 and IEC TC 10 DatabasesSergio OrtegaNo ratings yet

- 2014 IC Sec 13 Limit SwitchesDocument113 pages2014 IC Sec 13 Limit SwitchesmealysrNo ratings yet

- Electrical Isolator or Electrical Isolation SwitchDocument3 pagesElectrical Isolator or Electrical Isolation Switchfathonix100% (1)

- Is 1180Document4 pagesIs 1180prajwal shivaiahNo ratings yet

- 3408C & 3412C Electrical System Marine Auxillary Generator SetDocument2 pages3408C & 3412C Electrical System Marine Auxillary Generator SetHamid Essarbouti100% (1)

- Tugas Jawab TN-F 1-100 Hal 1225-1249Document25 pagesTugas Jawab TN-F 1-100 Hal 1225-1249Anonymous jyWpsYNo ratings yet

- FCE20 CompletoDocument6 pagesFCE20 CompletoRig 25 Sr. ElectricianNo ratings yet

- Features: Power Isolation TransformersDocument8 pagesFeatures: Power Isolation TransformersLKGNo ratings yet

- Panasonic NN-SD377SDocument16 pagesPanasonic NN-SD377SJerry LeeNo ratings yet

- Scope Meter: User's ManualDocument40 pagesScope Meter: User's ManualJohn WalesNo ratings yet

- Hager Price ListDocument8 pagesHager Price ListSuvashis SahooNo ratings yet

- Electric Generator Class 12 ProjectDocument24 pagesElectric Generator Class 12 ProjectDeepanshu VermaNo ratings yet

- Motors - Generators and Transformers PDFDocument46 pagesMotors - Generators and Transformers PDFYashodhaNo ratings yet

- Supplementary Sheet 97 0 080 - enDocument2 pagesSupplementary Sheet 97 0 080 - enOlivier ORMANNo ratings yet

- Armature ReactionDocument19 pagesArmature ReactionAyush SrivastavaNo ratings yet

- Panasonic CA Dm4290 CA Dm4291 CA Dm4292 CA Dm4293 CA Dm4294 Mazda.Document11 pagesPanasonic CA Dm4290 CA Dm4291 CA Dm4292 CA Dm4293 CA Dm4294 Mazda.Anonymous C6Vaod9No ratings yet

- Sig H-1-1Document4 pagesSig H-1-1Muhammad RidwanNo ratings yet

- SHIFT SPARES UPDATAD AT (17/04/2019) : S.No Equipment Type Description Material Code QuantityDocument6 pagesSHIFT SPARES UPDATAD AT (17/04/2019) : S.No Equipment Type Description Material Code QuantityTiyyagura RoofusreddyNo ratings yet

- Gozouta Kit: Assembly InstructionsDocument17 pagesGozouta Kit: Assembly InstructionsJuahanNo ratings yet

- Over Voltage, Over Current, Transient Voltage & Reverse Polarity Protection Circuit Using RT1720 Hot Swap Controller With Fault TimerDocument10 pagesOver Voltage, Over Current, Transient Voltage & Reverse Polarity Protection Circuit Using RT1720 Hot Swap Controller With Fault TimerKoushik MaityNo ratings yet

- TWG 5B DraftDocument87 pagesTWG 5B DraftMoe ThidarNo ratings yet