Professional Documents

Culture Documents

Certificate Drywall Building Material

Certificate Drywall Building Material

Uploaded by

steauandrei0 ratings0% found this document useful (0 votes)

8 views6 pagesCertificate

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCertificate

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

8 views6 pagesCertificate Drywall Building Material

Certificate Drywall Building Material

Uploaded by

steauandreiCertificate

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 6

CER FOR Shave

Col(tedy -hAcToR PRIWOLL Riazéera,

: TE 00973 OZ 783940

| i rs 2017

| AL HORS} DRYWALL BUILDING MATERIAL ee

| puuirtsdssieringe er | PBT, a Town, Kingdom of Bahai =

TEST REPORT ON TENSILE STRENGTH REQNO:STO-17040115 |

| | ‘OF HOT DIPPED GALVANIZED STEEL eee

SAWELE No:STS-170401")

\ | METHOD : ASTM A370 / AB53 |___REPORT No: sTR7001724

| PROJECT GENERAL PURPOSES

| SAMPLE DESCRIPTION HOT DIPPED GALVANIZED STEEL - FURRING CHANNEL

DATE SUBMITTED 30.032017

DATE TESTED 01.06.2017

REMARKS, The sample lested pass tho above requirements,

NITIL.K. SH vA

| Material Laboratory Manager

| peecme—

Rov ‘i

Renae ares SAMPLE ID | ASTM A683 Gr.CS Type @

RESULTS eae Specification Mechanical

__EURRING CHANNEL, Reauiremenis

Condition othe Sample upon Receipt | Satisfactory

rat tom) | we

Thickness (mm)

| a) 5625

| ee

| Yield Load a) 1.85

Yield Stress: (Nem?) 319.513, | 205-380

222 | |

| - ~ |

Bente |

Elongatio om | 27.60 | 20% Min. |

check:

c 2017

AL HOTY DRYWALL BUILDING MATERIAL ae Se

auspices wile 08013278 Town, Kingdom of aan ==

TEST REPORT ON TENSILE STRENGTH REQNO-STOTOAOTISS

(OF HOT DIPPED GALVANIZED STEEL wales ld

JP arr 000

METHOD : ASTM A370 / A652 REPORT No: STR 1704012)

PROJECT GENERAL PURPOSES

SAMPLE DESCRIPTION HOT DIPPED GALVANIZED STEEL ~MAIN CHANNEL

DATE SUBMITTED 30.09.2017

DATE TESTED 01.04.2017

| peers SAMPLEID | ASTM A653 Gr8 Type

| RESULTS - | "Specification Mechanical

| MAIN CHANNEL Requiroments

i Condon of Sample upen Recent Satisfactory

| 1253

| =

| 0.502

6.290

178

| | 205-380

| Tensts Looe ie)

Tensi Stoss (enn?) 356.121

Elongation oo 2704 20% Min

REMARKS: The sample tested pass the above requirements,

NITIL.K. SHRIVASTAVA

Material Laboratory Manager

For No. ARS--OSRE-MET A008

Revd

(Chackod by:

ALHOTY |

ANALYTICAL SERVICES WL

DRYWALL BUILDING MATERIAL

.0.ox S278, a Town, Kingdom ef ahaa

DATE: 03042017

eee

REF.

‘TEST REPORT ON TENSILE STRENGTH

OF HOT DIPPED GALVANIZED STEEL

REGNO.STO-170401/195-6

METHOD : ASTM A370/ A653

SAMPLE No‘STS-170401/135

REPORT No: STR-170401/214

PROJECT

‘SAMPLE DESCRIPTION

DATE SUBMITTED.

DATE TESTED

GENERAL PURPOSES

HOT DIPPED GALVANIZED STEEL - WALL ANGLE

30.03.2017

01.04.2017

‘SAMPLE ID ‘ASTI A 653 G-OS Type B

RESULTS "Specification Mechanical

_WALLANGLE Requirements

Salistactory

Condition of the Sample upon Receipt

with =) |

[Thickness (on) |

‘Area : . 5770 a

“ets Lows ny) 17 iz ee

| Vill Stross (nim) mers | 205.300

Tensile Load

Tonsile Stress 419.401 eS

Elongation om) 2430 [20% mn

REMARKS: The sampl

NITIL K. SHRIVASTAVA

Material Laboratory Manager

le tested pass the above requirements,

(Checked by: a

| Stren aor dora

Form No,“ AAS-8-O8RF-ME

DRYWALL BUILDING MATERIAL

0.84 5270 a Tow, Kingdom of Gaal

ALHOTY |

ANALYTICAL SERVICES W.LL.)

03.04.2017

DATE:

‘TEST REPORT ON TENSILE STRENGTH

(OF HOT DIPPED GALVANIZED STEEL.

=

METHOD : ASTM A370 / A853

| Reano-sta-ros01135-

‘SAMPLE No:STS-170405/1

[REPORT No: STR-7040"

| provect GENERAL PURPOSES

| SAWPLEDESCRIPTION ‘HOT DIPPED GALVANIZED STEEL ~ STUD acm

| DATE SUBMITTED 300032017

| DATE TESTED 0.062017

|

| :

| | ‘SAMPLE ID AST A683 6585 Type 8 |

RESULTS 1 SAMPLED __| "Specfcation Mechanical |

STUD 78mm Rewurerens. |

Concition of the Sample upon Racoipt

Satisfactory

wth (rm 1270

Thickness alee cane

[Area 2 _

iy ield Load a (kN)

Yield Stress (Nimm")

Tern Lose ww

Tensile Str (Winn)

ongavon %

REMARKS. The sample tested ass the above requirements.

Matorial Laboratory Manager

|

|

|

|

|

| IL K. SHRIVASTAVA,

|

|

| Lets eerie eae ee age

=

form ANS 6G MET 1A

re

Checked by:

Page 11

| ANALYTICAL SERVICES WL.

| TEST REPORT ON TENSILE STRENGTH

|

\

|

|B

|

|

|

ALHOTY | DRYWALL BUILDING MATERIAL, Das

7.08 27%, Ton igo of evan

| ‘OF HOT DIPPED GALVANIZED STEEL,

METHOD : ASTM A370 / AB5S

= | .

REPORT No; STR-A7040112

PROJECT (GENERAL PURPOSES

‘SAMPLE DESCRIPTION HOT DIPPED GALVANIZED STEEL —RUNNER 75mm

DATE SUBMITTED. 30.03.2017

DATE TESTED 1.042017

‘SAMPLE ID | ASTM A652 GrCS Type |

a

Sori bo age RE sate

with = ped (mm) 12.75 . %

he ers |

Yield Load z KN) 1.80 } = a

Yield Stress (wine) | «908.880 | 205-380

Tensile Load (kN) 2.30 |

Tod ah ‘ann |

Elongation ) | 25.84 . a 20% Min.

REMARKS: The sample tested pass the above requirements.

NTL, VA

Material Laboratory Managor Cchocken by

Sea ae ta nara rhea vcaarn a

FamNe. AABOROSRF MET 018 Paget

ec

PROJECT

‘SAMPLE DESCRIPTION

DRYWALL BUILDING MATERIAL, ae

086x327 a Town, Kingdom of Bahrain Fane

TEST REPORT ON : |__ Rea.no:sra.1oso1952

WEIGHT OF ZINC COATING t =o

ee SAMPLE NosSTS-170401/195

METHOD : ASTM Ag9-13

GENERAL PURPOSES

GALVANIZED STEEL THIN SHEET

REPORT No. STR. A7OHO1242

DATE sueMiTTeD 20032017

DATE TESTED 1042017

| weisir or znc.coarne |

8.No, | sampLevescriprion | “INCLUDING BOTH ONES

(oi) |

1

| ace eens |

3 | Furring Channel |

4 “Stud 73mm i ae

5 Runner 75mm

NITIL K. SHRIVAS:

Material Laboratory Manager

Checkeat ty

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

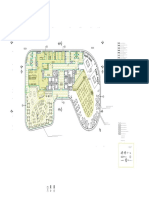

- I-3.0 FINISH PLAN GROUND FLOOR LEVEL-I 3.0 Finish Plan Ground FloorDocument1 pageI-3.0 FINISH PLAN GROUND FLOOR LEVEL-I 3.0 Finish Plan Ground FloorsteauandreiNo ratings yet

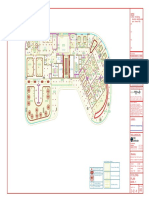

- 2017 03 07-I-3.5 FINISH PLAN LEVEL 5-ModelDocument1 page2017 03 07-I-3.5 FINISH PLAN LEVEL 5-ModelsteauandreiNo ratings yet

- 2017 03 07-I-3.4 FINISH PLAN LEVEL 4-ModelDocument1 page2017 03 07-I-3.4 FINISH PLAN LEVEL 4-ModelsteauandreiNo ratings yet

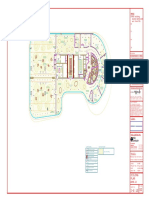

- Ceiling Plan: 1. Notes All Ceiling Levels Mentioned Are From FFLDocument1 pageCeiling Plan: 1. Notes All Ceiling Levels Mentioned Are From FFLsteauandreiNo ratings yet

- 2017 03 04 I-3.4 FINISH PLAN LEVEL 4-ModelDocument1 page2017 03 04 I-3.4 FINISH PLAN LEVEL 4-ModelsteauandreiNo ratings yet

- Ceiling Plan: 1. Notes All Ceiling Levels Mentioned Are From FFLDocument1 pageCeiling Plan: 1. Notes All Ceiling Levels Mentioned Are From FFLsteauandreiNo ratings yet

- Ceiling Plan: 1. Notes All Ceiling Levels Mentioned Are From FFLDocument1 pageCeiling Plan: 1. Notes All Ceiling Levels Mentioned Are From FFLsteauandreiNo ratings yet

- Ceiling Plan: 1. Notes All Ceiling Levels Mentioned Are From FFLDocument1 pageCeiling Plan: 1. Notes All Ceiling Levels Mentioned Are From FFLsteauandreiNo ratings yet

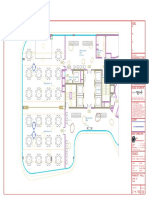

- 334-I4.9A-4.9D-DD-LEVEL 13-Banquet Hall 20160520-I4.9ADocument1 page334-I4.9A-4.9D-DD-LEVEL 13-Banquet Hall 20160520-I4.9AsteauandreiNo ratings yet

- What Is The Tool Bar?: CMPIC: System Orientation, User ManualDocument3 pagesWhat Is The Tool Bar?: CMPIC: System Orientation, User ManualsteauandreiNo ratings yet

- Ceiling Plan: Notes All Ceiling Levels Mentioned Are From FFLDocument1 pageCeiling Plan: Notes All Ceiling Levels Mentioned Are From FFLsteauandreiNo ratings yet

- Company: Alyusuf Building Materials W.L.LDocument2 pagesCompany: Alyusuf Building Materials W.L.LsteauandreiNo ratings yet

- Ceiling Plan: Notes All Ceiling Levels Mentioned Are From FFLDocument1 pageCeiling Plan: Notes All Ceiling Levels Mentioned Are From FFLsteauandreiNo ratings yet

- Drywall Building MaterialDocument1 pageDrywall Building MaterialsteauandreiNo ratings yet

- Sikacrete®-215 F: SheetDocument4 pagesSikacrete®-215 F: SheetsteauandreiNo ratings yet

- Cementitious FireproofingDocument5 pagesCementitious FireproofingsteauandreiNo ratings yet

- Altawasel Gate Building MaterialsDocument1 pageAltawasel Gate Building MaterialssteauandreiNo ratings yet